Hengstler signo 727 SSI User manual

Seite1/7Sach-Nr. 2 727 022 Version 1250899MW

operating instructions

signo 727 SSI

Position-Indicator with/without limit

values and SSI input from absolute

encoder

1. Safety instructions

This instrument has been built and tested in

accordance with EN 61010, part1 - Protection

Measures for Electronic Measuring Instruments -

and have left our works in safe and proper condition.

In order to maintain these conditions and to ensure

safe operation, the user must observe the

instructions and warnings provided in these

operating instructions.

•This units must only be operated if correctly

installed!

•The supply voltage must be derived from a SELF

SOURCE (12-24VDC versions) according to EN 60

950, since no galvanic separation is provided

between power-supply and electronic in-/outputs!

•When mounting and installing the units, the

instructions of the local suppliers of energy are to

be considered.

•The unit must only be opened for setting by trained

personnel.

•The plug-in terminals, at rear of the unit, must not

be accessed before first isolating the supply.

•The identification numbers of the plug-in terminals

and of the corresponding socket strip must be

observed.

•Unassigned terminals (NC) may not be connected!

•Connection terminals are to be protected by

installation!

Contents

1. Safety instructions 1

2. Mounting of the position indicator 2

2.1 Mounting and dimensional drawing 2

2.2.1 Connections 2

2.2 Terminal connections 2

2.2.2 Description of inputs and outputs 3

2.3 Description of function of position

indicator 3

3. Operation of the position indicator 3

3.1 Display and keyboard 3

3.2 Setting the reference value and resset

of the chain value 3

3.3 Changing limit value 1and 2 and set

value 4

4. Programming 4

4.1 Survey 4

4.2 Display of the absolute data of the

absolute shaft encoders 5

4.3 Changing system parameters 5

4.4 Survey on the system parameters

and alternatives 5

5. Locking of keyboard functions 6

6. Failures and error messages 6

7. Technical data 6

7.1 Ordering information 7

7.2 Accessories 7

7.3 Explanation of technical terms 7

•In order to ensure hand contact safety at the

connection terminals, live wires must be con-

nected properly to the connection terminals.

•If safe operation can no longer be ensured, the

position indicator must be disabled and secured

against accidential operation.

•Installation of electrical devices should only be

carried out by a qualified electrican.

•Panel mounting devices should only be operated

when proberly mounted in the panel

•Before switching on, make sure that the power and

control voltages do not exceed the values specified

in the technical data.

•In a situation where failure of the device could

cause harm to people, animals or property,

additional safety measures must be employed,

e.g. stop switches, protection devices etc.

•Hengstler counters are intended for industrial

applications.

•The mounting and environment and nearby cabling

have an important influence on the EMC (noise

radiation and noise immunity) of the counter.

When putting into operation, the EMC of the whole

installation (unit) has to been secured. In

particular, the relay outputs are to be protected

from high noise radiation by suitable wiring.

Seite2/7Sach-Nr. 2 727 022 Version 1250899MW

2. Mounting of the position indicator

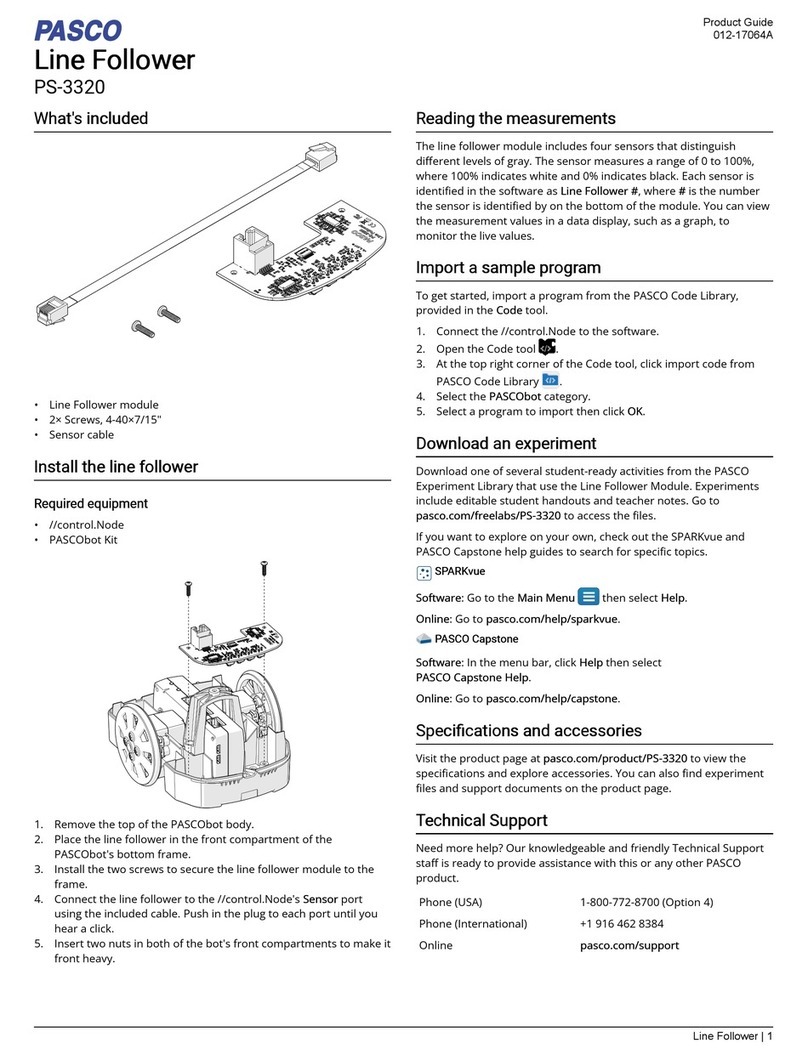

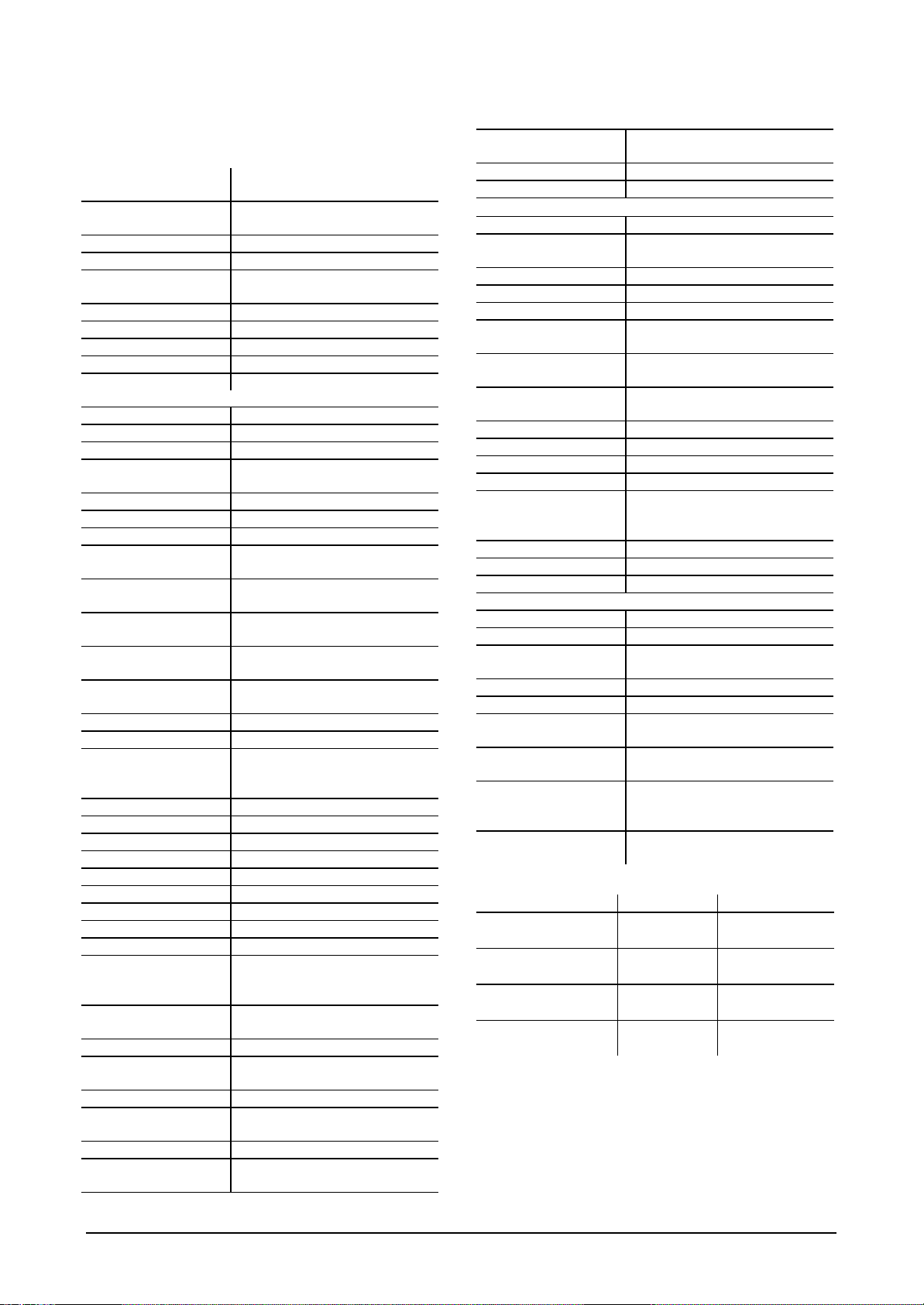

Mounting and dimensional drawing (dimensions in mm)

2.1 Mounting the position indicator into the panel.

1. Slide installation frame towards the rear and off the position indicator, lift the two self locking catch

springs.

2. Turn back the screws of the installation frame by approx. 5 mm.

3. Insert position indicator into the cut-out of panel and snap installation frame into place

4. Fix the position indicator with the screws against the panel.

2.2 Terminal connections

Attention:

Take care that all parts of system are deenergized during the installation of position indicator and that current is

not switched on during assembly!

Safety conditions are to be observed during installation, which shall be effected by trained personnel only.

Caution: The operation and/or switched voltages can reach 100...240 VAC!

To maintain interference grade 3, all count and control lines shall be shielded. The supply lines should be

routed in separate channels.

2.2.1 Connection

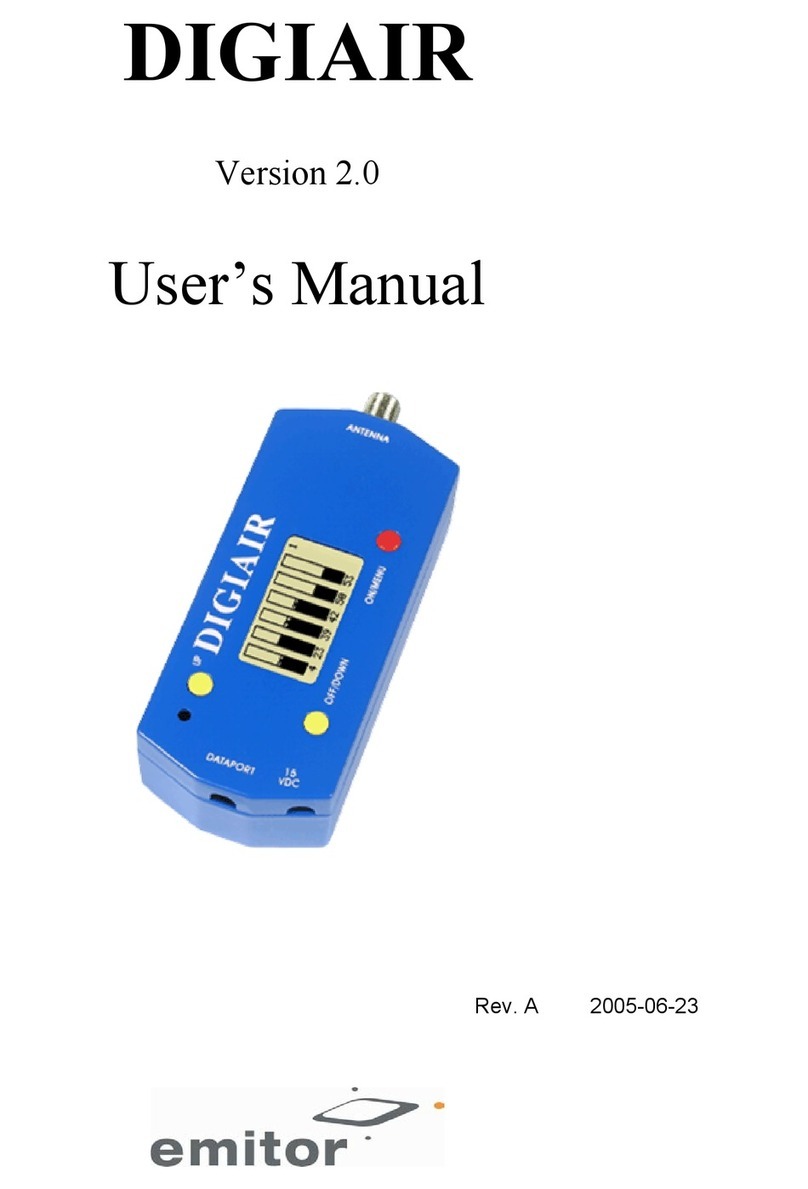

AC-Version: here with limit values DC-Version: here without limit values

Sach-Nr. 2 727 022 Version 1250899MW Seite3/7

2.2.2 Description of in- and outputs

Function Terminal Remarks:

Power supply of position

indicator AC: Terminal 1-4

DC: Terminal 1-2 at 230 VAC: bridge terminals 2-3;

at 115 VAC: bridge terminals 1-2 and 3-4;

at 12..24VDC:Terminals 3 and 4 are not connected

Relay output for limit

value 1 or limit value 2 Terminal 6-8

or 10-12 change over contact, Remark: these terminals are not

connected at position indicators without limit values

Transistor output for limit

value 1 or limit value 2 Terminal 14 or 15 PNP transistor output 10 mA, Remark: these terminals are

not connected at position indicators without limit values

Sensor power supply Terminal 32 and 31 Supply of sensor with 12...24 VDC / 60 mA (max)

DATA + Terminal 30 differential signal data + (data input from SSI - encoder)

DATA - Terminal 29 differential signal data - (data input from SSI - encoder)

CLOCK + Terminal 28 differential signal clock + (clock output for SSI - encoder)

CLOCK - Terminal 27 differential signal clock - (clock output for SSI - encoder)

Keylock Terminal 26 locking of operation levels can be programmed (see chapter

4.3)

Application input Terminal 25 set value, refernce point, display hold or chain reset, can be

programmed ( see chapter 4.3)

2.3 Description of function of position indicator

The position indicator is working in range mode, i.e. the output signals (Out 1 and Out 2) are set when reaching

the respective limit value. The bistable signal is active until the count value falls below the limit value or the

counter is reset to zero.

Reset to zero or to the set value is done manually from the keyboard or electrically from the reset input.

Example 1: (set value = 0)

limit value 2

limit value 1

Out1

Out2

t

count impulses

Example 2: (set value between limit value 1 and limit

value 2)

limit value 2

limit value 1

Out1

Out2

t

count impulses

set value

3. Operation of the position indicator

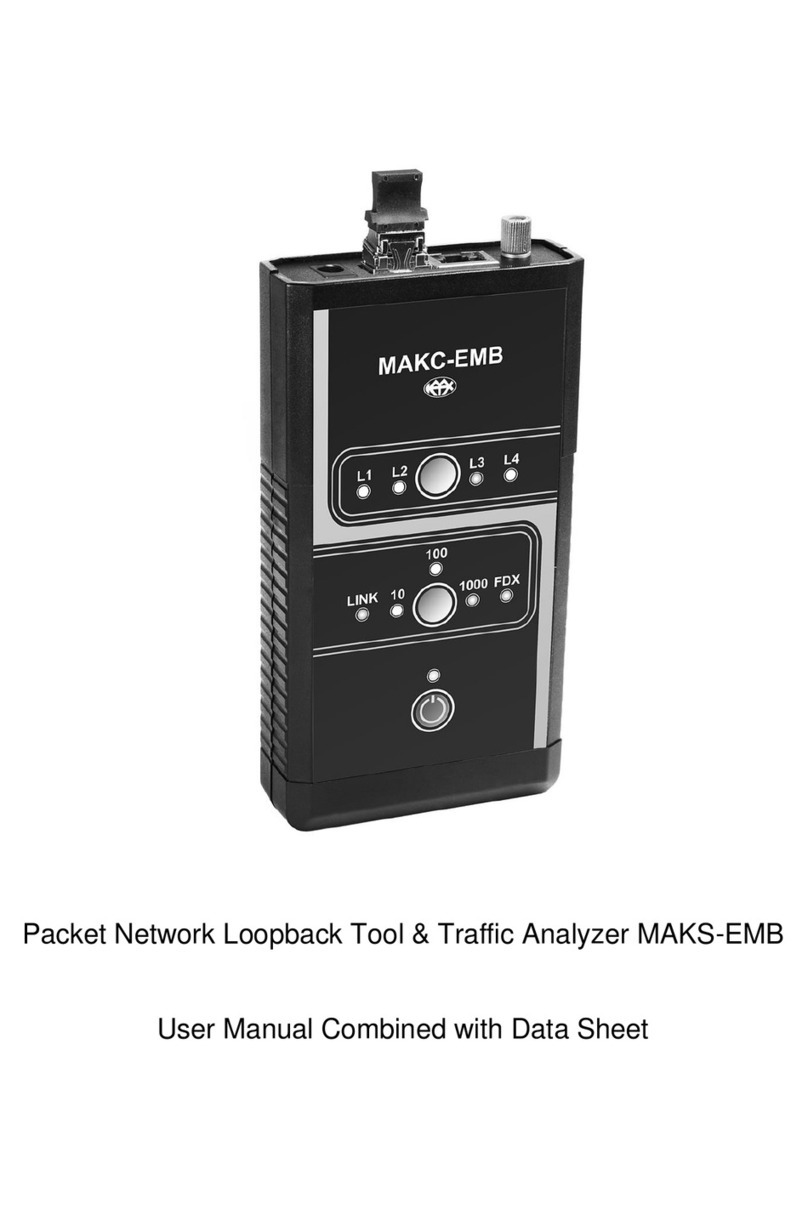

3.1 Display and keyboard

DATA

CHAIN

SET

P2

P1 SSI

Area A: Display, in counting mode showing the

actual or absolute position (chain value or absolute

value), and in programming mode the changeable

parameters.

Area B: LED indicators

LED Explanation

P1 OUTPUT1of limit value 1 is active

P2 OUTPUT1of limit value 2 is active

SET display shows set value

DATA display shows absolute value

CHAIN display shows chain value

Area C: Keyboard: The use of the different keys is

explained in chapter 3.2 .

1only position indicator with limit value

Seite4/7Sach-Nr. 2 727 022 Version 1250899MW

3.2. Setting the reference value or reset of the chain value

Function Procedure

•Setting the absolute value to a

reference value When absolute value is dis-played: Press simultaneously the buttons R

and -

•Zerosetting of the chain value

When chain value is dis-played (LED CHAIN illuminated): Press R-button.

•Cancelling reference value Press simultaneously the buttons R and

3.3 Changing of limitation value 1, limitation value 2 and set value

Function Procedure

•Selection of limitation value 1 Press key F1 (LED P1 is flashing)

•Selection of limitation value 2 Press key F2 (LED P2 is flashing)

•Selection of set value Press key E and F1 simultaneously (LED SET is flashing)

•Changing parameters Press -key (arrow up) to change the value of the blinking digit.

Press -Key (arrow left) to switch to the next digit. Change sign

with the +/- key. Press R-key to reset the value to zero

•Storage of parameters Press E key shortly to exit and return to display mode

•Exit without storage by time criterion: the return to the display mode is automatically

done 15 sec after the last pressing of a key, without storing the

changed parameter

4. Programming

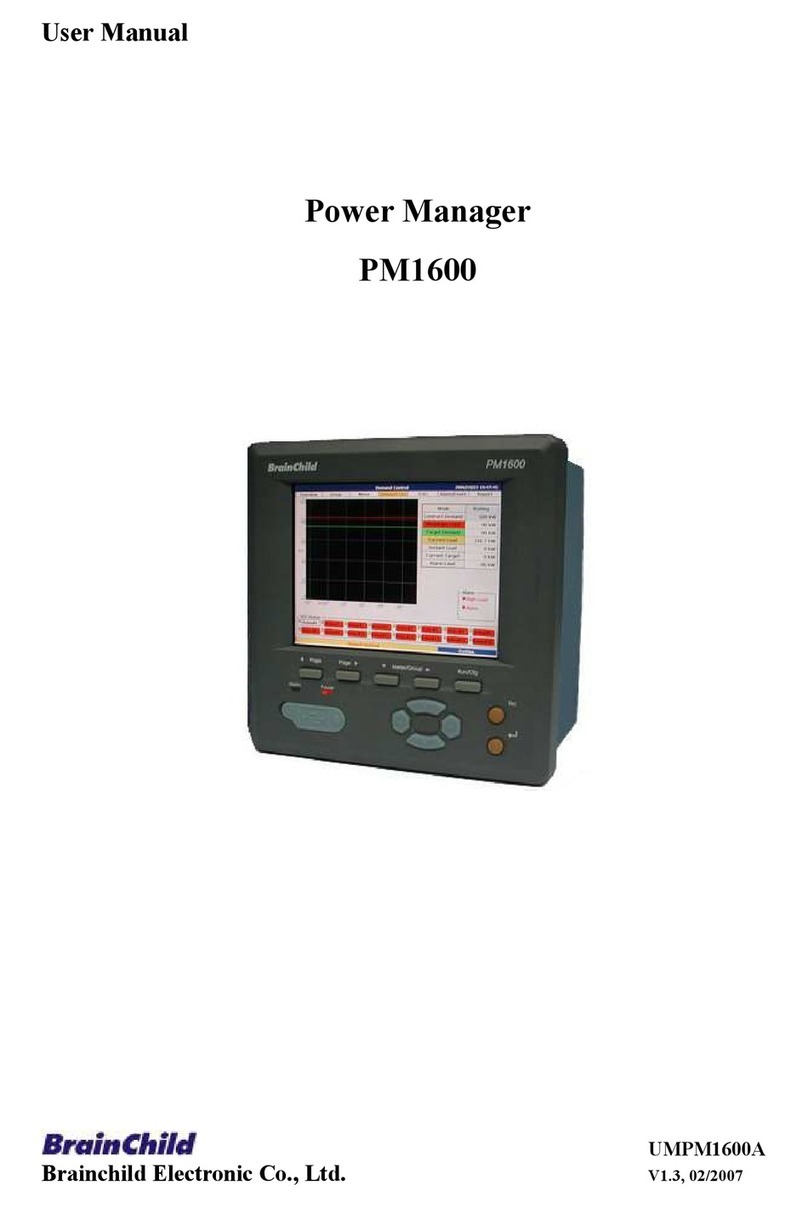

4.1 Survey

level 1

SET: Setvalue

long (>2s)

Power ON

and

simultaneous

P1: limit-value 1* P2: limit-value 2*

short

-key to switch to the

remarks:

next parameter

DISPLAYMODE (Normal Count Mode)

simultaneoussimultaneous

short

level 2

level 3

short

Absolute-Postion-Mode CHAIN-Mode

switch Mode

Reset absolute

Value

(CHAIN-LED illuminated)

reset Chain-

value to Zero

simultaneous

short

singleturn display

z.Bsp. _4321

multiturn display

z.Bsp. 8765_

System parameters:

'F1' = totalresolution in bit

'F2' = singleturn resolution in bit

'F3' = binary/gray code

'F4' = format

'F5 ' = output P1 locked / free

'F6' = output P2 locked / free

'F7' = special bits

'F8' = display per revolution

'F9' = display divisor

'F10' = drive direction

'F11' = multiple transmission

'F12' = decimal point

'F20' = funktion of first limit value

'F24' = switching pnp/npn

'F26' = locking set function

'F27' = locking level 1

'F28' = locking level 2

'F29' = locking buttons F1/F2

'F30' = basic settings

'F31' = function application input

'F35' = display of chain value

* only for position indicators with limitation values

Sach-Nr. 2 727 022 Version 1250899MW Seite5/7

4.2 Display of the absolute data of the absolute shaft encoders

Function Procedure

•Entering level 2 Press E and F2 simultaneously, light diode DATA is illuminated

•Select absolute data Press to switch either to single turn or to multi turn data.

Editing of the value is not possible.

For differentation of the data, the values are displayed:

Singleturn: f.e. _4321

Multiturn: f.e. 8765_

4.3 Changing system parameters

Function Procedure

•Entering level 3 Press keys E and -key (arrow up) key in de-energized state, then switch

on power

•Selection of changeable

parameter Press key E shortly, until the desired indication " " in display is flashing (see

table chapter 4.4)

•Changing parameter Selection of the various alternatives for each parameter by pressing -key

(arrow up) (see table chapter 4.4)

•Storage of parameter value Press key E shortly to switch to the next parameter or press Key E for at

least 2 sec to exit operation level and return to the display mode

•Exit level 3 without storage by the time criterion: the return to the display mode is done automatically 15

sec after a key has been pressed last, without the changed parameter being

stored

4.4 Survey on the system parameters and alternatives

Parameter Display Alternatives / Signification

total encoder

resolution / bit 'F1' '1' to

'24'* total encoder resolution in bits

encoder resolution single

turn / bit 'F2' '0' to

'12''*resolution of the singleturn part in bits

Data coding 'F3' 'bin':*

'Gray': binary code

gray code

Data transfer format 'F4' 'Std':*

'tan': standard format, MSB-flush

pine-tree format

Signal OUT 1 'F5' 'off':

'bi':* no output signal

output signal

Signal OUT 2 'F6' 'off':

'bi':* no output signal

output signal

Special bits 'F7' '0':*

'1':

'2':

no special bits

alarm

parity

Display per revolution 'F8' '0'-

'4096' *

-'9999'

value, added to or subtracted from the display per revolution

Display divisor 'F9' '1':*

'10':

'100':

'1000':

value by which the display is divided

(f.e. display per revolution = 35, display divisor = 10, display

per revolution = 3,5; i.e. first revolution = 3, second revolution

= 7).

Drive direction 'F10' '0':*

'1': adding in clockwise sense

adding in anti-clockwise sense

Multiple transfer 'F11' '0':*

'1': single transfer

double transfer in comparison

Decimal point 'F12' '0':*

'1':

'2':

'3':

no decimal point

-.- decimal point at first digit

-.-- decimal point at 2nd digit

-.--- decimal point at 3rd digit

Function of first limit

value 1 'F20' '0':*

'1': limit value 1 is absolute

limit value 1 is relative to limit value 2

Seite6/7Sach-Nr. 2 727 022 Version 1250899MW

Parameter Display Alternatives / Signification

NPN/PNP selection 'F24' '0':

'1':*KEYLOCK and APPL.are low active, npn switching

KEYLOCK and APPL.are high active, pnp switching

Set funktion key lock

(calibration) 'F26' '0':*

'1':

if key lock input is active, setting and canceling of calibration

value is not locked

is locked

Level 1 key lock 'F27' '0':*

'1': if key lock input is active, access to level 1 is not locked

access is locked

Level 2 key lock 'F28' '0':*

'1': if key lock input is active, access to level 2+3 is not locked

access is locked

F1 and F2 key lock 'F29' '0':*

'1':

'2':

'3':

if key lock input is active, keys F1 and F2 are not locked

F1 locked

F2 locked

F1 and F2 are locked

Basic setting 'F30' '0':*

'1': no function

all parameters are set to the * marked values

function of application input

'F31' '0':

'1':*

'2':

setting of reference point

display-hold

chain reset

chain mode 'F35' '0':

'1':*chain function locked

chain function unlocked

1 hint for funktion of limit value 1: if limit value is absolute, OUT 1 will be active as soon as counter position equals to

limit value 1. If limit value is in relative function, OUT 1 will be active as soon as the counter position equals to limit

value 2 plus limit value 1. Example: limit value 1 = -20, limit value 2 = 100

absolute OUT1 at -20 OUT2 at 100

relative OUT1 at 80 (=100-20) OUT2 at 100

5. Locking keyboard functions

In level 3, the following keyboard functions can be locked: Calibration function, entry to level 1, entry to level 2,

buttons F1 and F2. The setting of those keylocks is explained in chapter 4.3.

6. failures and error messages

failure diagnosis

no display •check if supply voltage is correctly connected/ switched on?

limit and set values

are not programmable •check if level 1 or F1/F2 buttons are locked?

•check if level 2 is locked?

Set function not

possible (calibration

function)

•keylock set function active?

position indicator

does not operate •check if counting input is correctly connected?

•check if display-hold is triggered?

•check if mass connection position indicator-encoder is correct?

•check if encoder is in good condition?

SSI error •data format incorrectly set

•wiring incorrect or connection defective

failure diagnosis

SSI error •no data compatibility at multiple reading

•parity check active and no parity output from encoder

-...... •range exceeded; tune back to the range or set display to defined value.

_...... •fallen below range; tune back to the range or set display to defined value

If any failure occurs, which is not mentioned above, our sales support for electronic counters will assist you.

(Tel. 07424/89-0).

Sach-Nr. 2 727 022 Version 1250899MW Seite7/7

7. Technical data

Mechanical Specifications

Dimensions according to DIN 43700, 96 x 48 x

108 mm

Mounting with clamping frame in a panel cut-

out of 92x45 mm

Fixing screws M 3

Panel thickness up to 11 mm

Electrical connection three plug-in terminals, 10,8 or 6

poles,

5 mm pattern

Connection profile wire end ferrules 1...1,5mm2

Screw M 2,6

Weight DC version: approx. 200 g;

AC version: approx. 420 g

Electrical Specifications

Power Supply

DC Voltage Ub(Terminal 1-2) 12...24 VDC=

max. Tolerances + 10% / - 5%

Current Consumption max. 250 mA (including sensor

supply 60 mA)

Power Consumption max. 4,5 W

AC Voltage 115/230 VAC /50...60 Hz

max. Tolerances + 6% / - 10%

Overload Protection external Fuse:115V: 63mAT

230V: 32mAT

Current Consumption max. 50/25 mA (incl. sensor

supply)

Power failure one mains half wave according to

IEC 127-2

Inputs and out-puts

of encoder SSi konform

Data input (DATA+ and

DATA-) terminals 29,30 differential signal, RS 422, clock

rate approx. 100kHz

Input resistance approx. 470 Ohm

Amplitude max. -7....12V

Clock output

(CLOCK+,CLOCK-)

terminals 27,28

differential signal, RS 422, clock

rate approx. 100kHz

Output level high 3,5V typ., low 1,3V typ.

Output current +/- 8mA typ.,+/- 60mA max.

Wire length 400 m max.

Control Inputs

Switching level low < 2 V, high > 8 V

Amplitude max. 40 V

Active edge pnp/npn selectable

Input resistance approx. 5kOhm

Pulse shape any

Application Input

(Terminal 25) Setting reference point, display

hold, chain reset function see

chapter 4.3

Input mode static / dynamic; dependent on

function

PulseDuration Tmin min 3 ms

Keylock input (terminal

26) static

PulseDuration Tmin min 3 ms

Output Values Relay

Output (Terminals 6-8 and 10-12;

OUT 1, OUT 2)

Contact Type changeover relay

Contact Guard Circuit no; externally recommended for

capacitive and/or inductive loads

Switching Voltage max 30 VDC/250 VAC; min. 5 V

AC/DC

Switching Current max 1 A; min 10 mA

Relay Response Delay 15 ms

Transistor-Output (terminals 14, 15)

Switching voltage PNP, 24VDC at AC supply, VDC-2V

at DC supply

Switching current 10 mA max.

Response delay 10 ms max.

Sensor Supply

(Terminal 31/32) AC operation: 12-24 VDC, Imax =

60 mA

DC operation: Ub -2V, Imax = 60

mA

Data Retention Data are retained in a non-volatile

memory

Write Cycles >100000

Read Cycles Unlimited

Data Retention >10 years

Display

Type 7-segment LED, 6 digits,

suppression of leading zeros,

programmable decimal point

Display Colour red

Digit Height 14 mm

Indicator LED`s 5

Ambient Conditions / Safety Regulations

Operating Temperature 0°C ... 50°C

Storage Temperature -20°C ... +70°C

Protection Class (IEC

144) front side IP 54,

terminals IP 20

Noise immunity EMC according to EN 50082-2

Noise emittance EMC according to EN 50081-2

Vibrostability 10 m/s2(10...150 Hz) according to

IEC 68-part 2-6

Shock stability 100 m/s2(18 ms) according to IEC

68- part 2-27

General Rating DIN EN 61010-T1,protection class

II, contamination level 2, over-

voltage category III

Climatic Standards (DIN

40 040) 40/92 °C/% relative air humidity

7.1 Ordering information

Type Supply Ordering code

signo727 without

limit values 12...24VDC 0 727 111

signo727 without

limit values 115/230VAC 0 727 112

signo727 with limit

values 12...24VDC 0 727 131

signo727 with limit

values 115/230VAC 0 727 132

7.2. Accessories

Adapter frame for panel mounting, cut-out

106 x 55 for panel frame size 4,

ordering code 1 405 679

7.3 Explanation of technical terms

You will find a detailled explanation in the glossary of

our counter catalogue.

Table of contents

Other Hengstler Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Spectrum

Spectrum SP-UV 200 Series operating manual

Heyuan Intelligence

Heyuan Intelligence DZ81-MS3UI7E3 user manual

JUMO

JUMO AQUIS touch S 202581 installation instructions

ABB

ABB SPEF 3A2 C User manual and technical description

TSI Instruments

TSI Instruments 4040 Operation and service manual

Unipulse

Unipulse F370 Operation manual