Content

6.2.1 Opening the terminal compartment on the device ........................... 35

6.2.2 Installing cables ............................................................................... 36

6.2.3 Preparing coaxial cables for pH/redox electrodes ........................... 38

6.2.4 Conductor cross-sections for base unit and power supply unit .......40

6.2.5 Conductor cross-sections for optional boards ................................. 41

6.3 Galvanic isolation ............................................................................. 42

6.4 Connection diagram ......................................................................... 43

6.4.1 Overview of connections .................................................................. 43

6.4.2 Analog inputs base unit ................................................................... 44

6.4.3 Analog inputs optional boards ......................................................... 45

6.4.4 Analog outputs ................................................................................. 54

6.4.5 Binary inputs .................................................................................... 55

6.4.6 Binary outputs, power supply unit board .......................................... 57

6.4.7 Binary outputs, optional boards ....................................................... 58

6.4.8 Mains power connection .................................................................. 59

6.4.9 Voltage supply outputs .................................................................... 59

6.4.10 Interfaces ......................................................................................... 61

7 Startup ..............................................................................67

7.1 Initial startup .................................................................................... 67

7.2 Basic setup ...................................................................................... 68

7.2.1 Date and time .................................................................................. 68

7.2.2 Basic settings ................................................................................... 69

7.3 Digital sensors ................................................................................. 70

7.3.1 Initial startup .................................................................................... 70

7.3.2 Restarting and replacing .................................................................. 74

7.4 Function test .................................................................................... 75

7.4.1 Checking the optional boards .......................................................... 75

7.4.2 Checking sensors and inputs/outputs .............................................. 75

8 Operation .........................................................................77

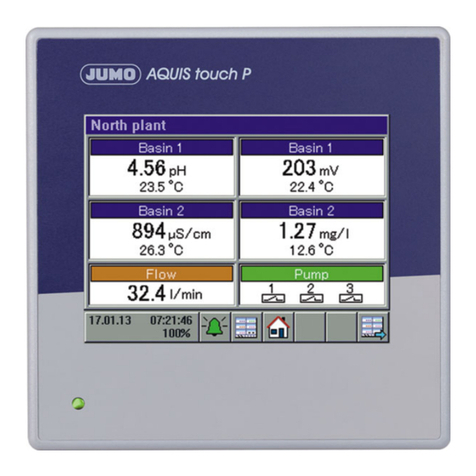

8.1 Operating concept ........................................................................... 77

8.1.1 Passwords and user rights .............................................................. 77