Henny Penny 581 Programming manual

Other Henny Penny Fryer manuals

Henny Penny

Henny Penny 581 User manual

Henny Penny

Henny Penny OFE-322 User manual

Henny Penny

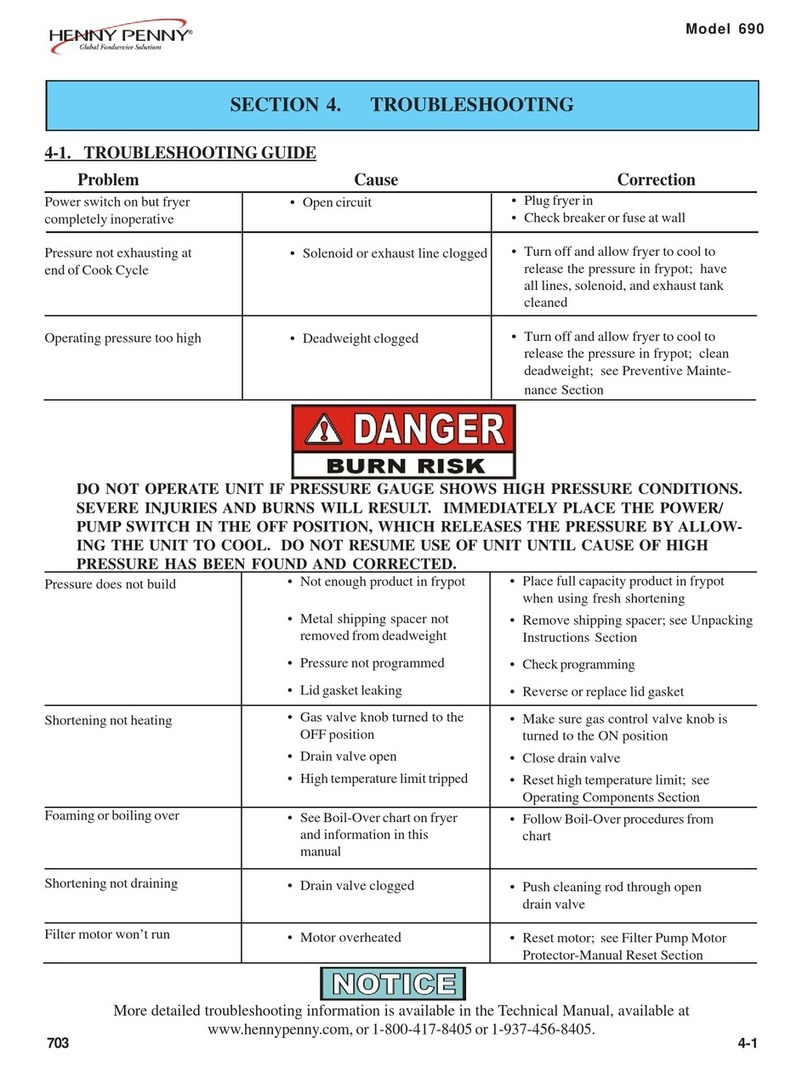

Henny Penny 690 Operating instructions

Henny Penny

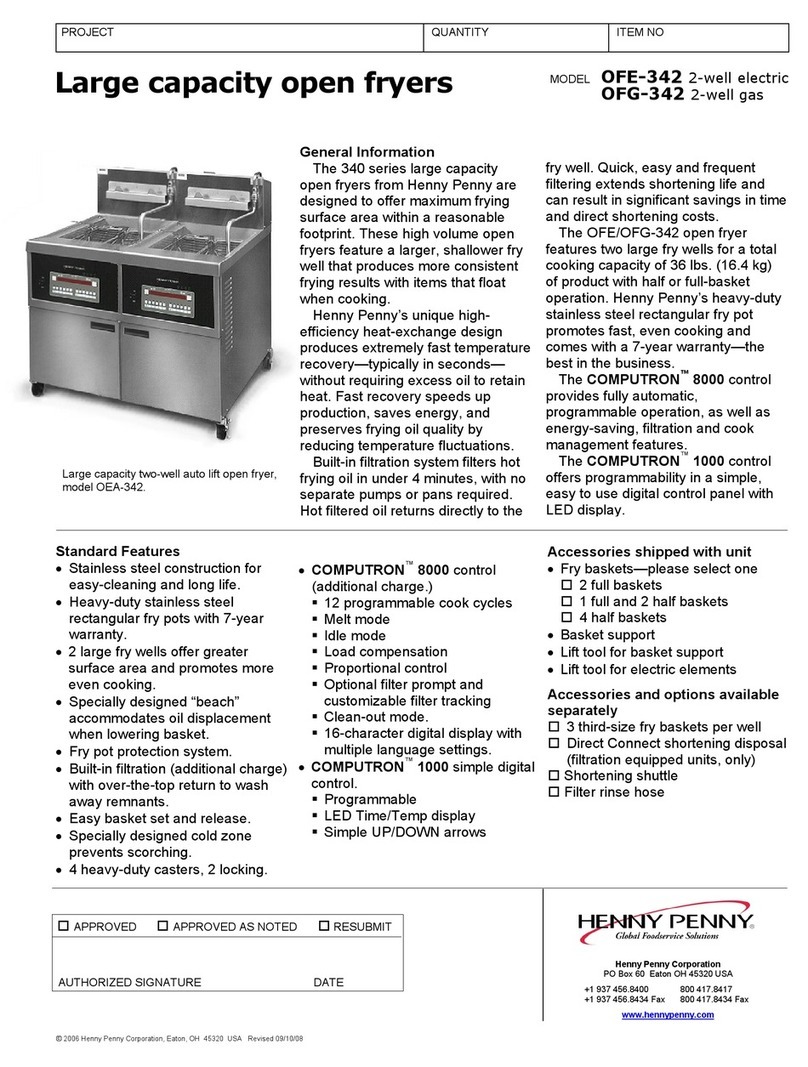

Henny Penny OFE-342 User manual

Henny Penny

Henny Penny OE 301 Operating instructions

Henny Penny

Henny Penny 500 User manual

Henny Penny

Henny Penny PFE-591 User manual

Henny Penny

Henny Penny KVE-071 User manual

Henny Penny

Henny Penny 590 Guide

Henny Penny

Henny Penny OFE-322 User manual

Henny Penny

Henny Penny Evolution Elite EEE-153 User manual

Henny Penny

Henny Penny LVE-102 User manual

Henny Penny

Henny Penny PFE-592 User manual

Henny Penny

Henny Penny Evolution Elite EEE-141 User manual

Henny Penny

Henny Penny 500 User manual

Henny Penny

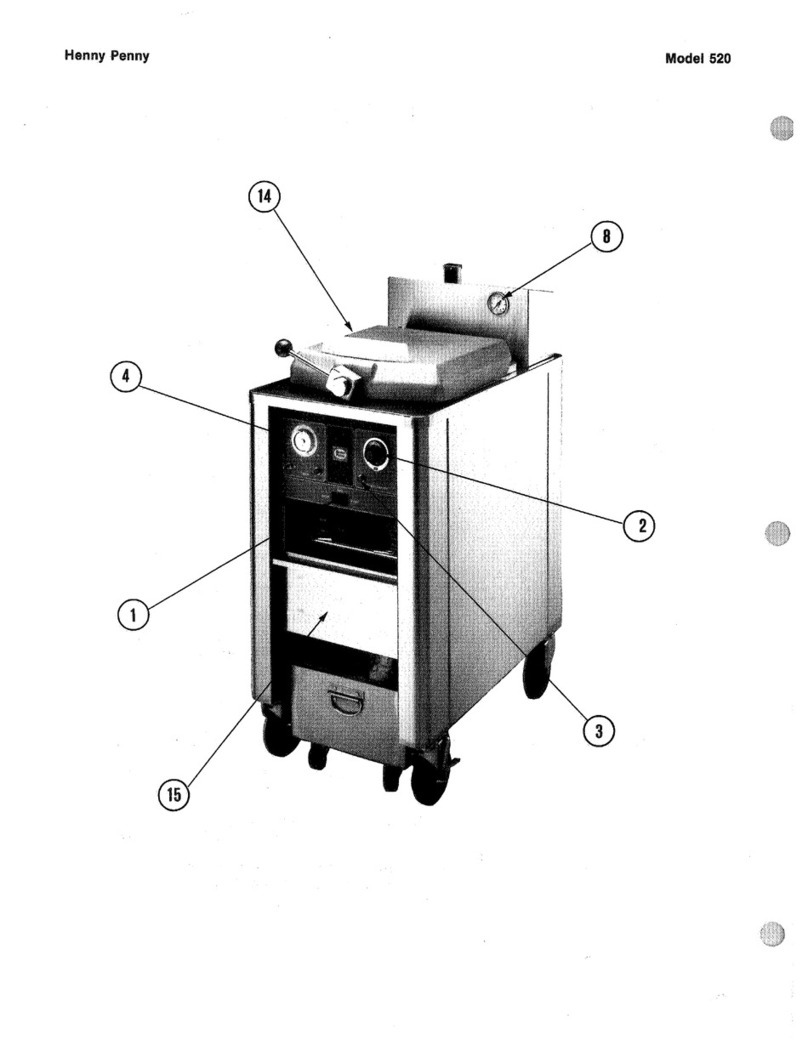

Henny Penny 520 User manual

Henny Penny

Henny Penny 803 User manual

Henny Penny

Henny Penny 342 Guide

Henny Penny

Henny Penny OFG-321 User manual

Henny Penny

Henny Penny OEA-342 User manual