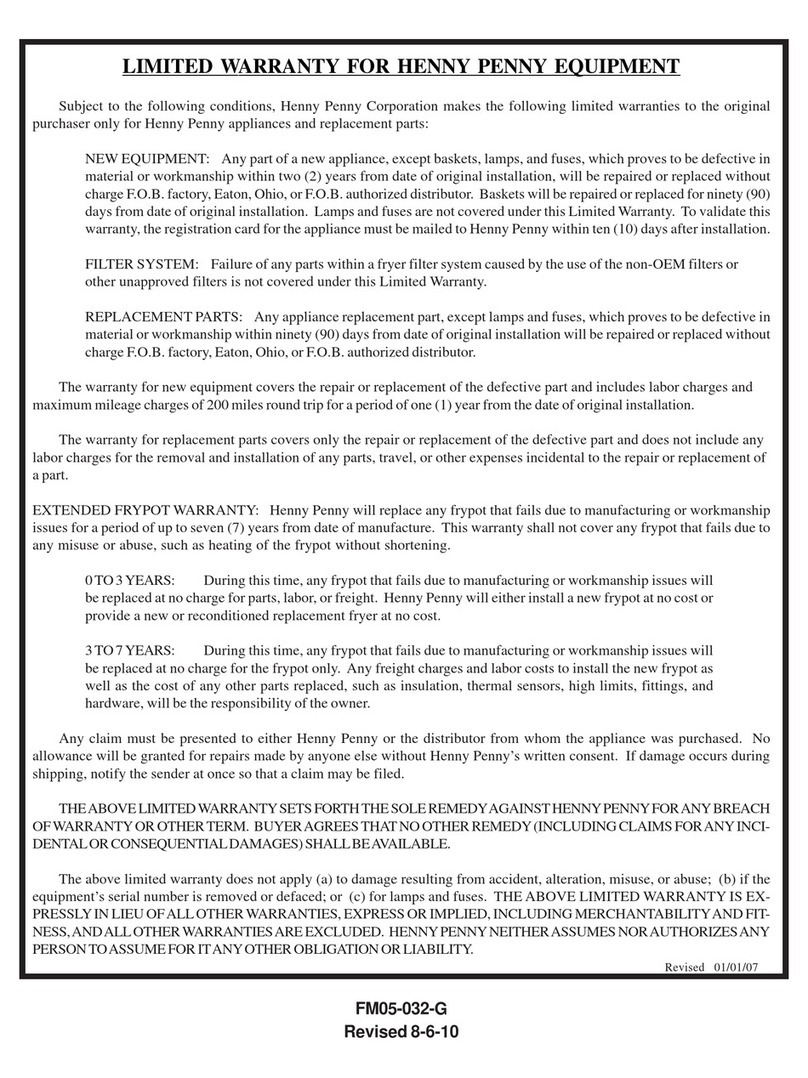

Henny Penny OE 301 Operating instructions

Other Henny Penny Fryer manuals

Henny Penny

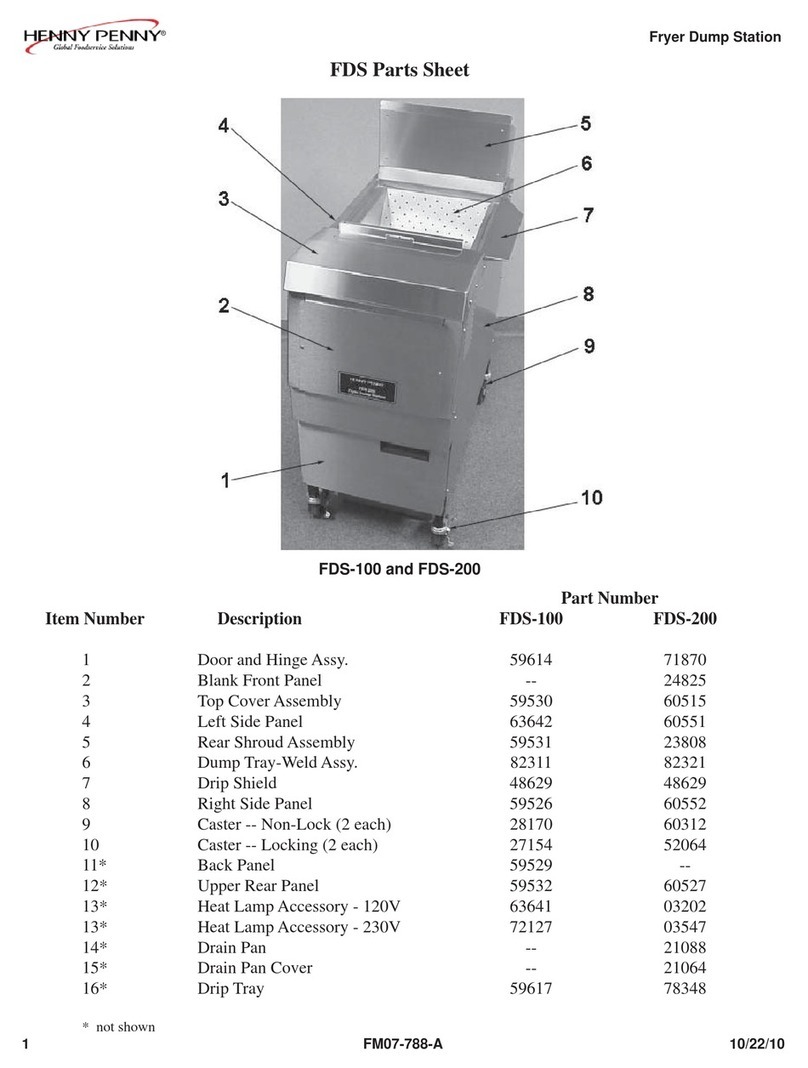

Henny Penny FDS-200 User manual

Henny Penny

Henny Penny EVOLUTION ELITE Series User manual

Henny Penny

Henny Penny 500 User manual

Henny Penny

Henny Penny CFE-410 User manual

Henny Penny

Henny Penny PFG-690 User manual

Henny Penny

Henny Penny WENDY'S EVOLUTION ELITE EEE-151 User manual

Henny Penny

Henny Penny Evolution Elite EEE-153 User manual

Henny Penny

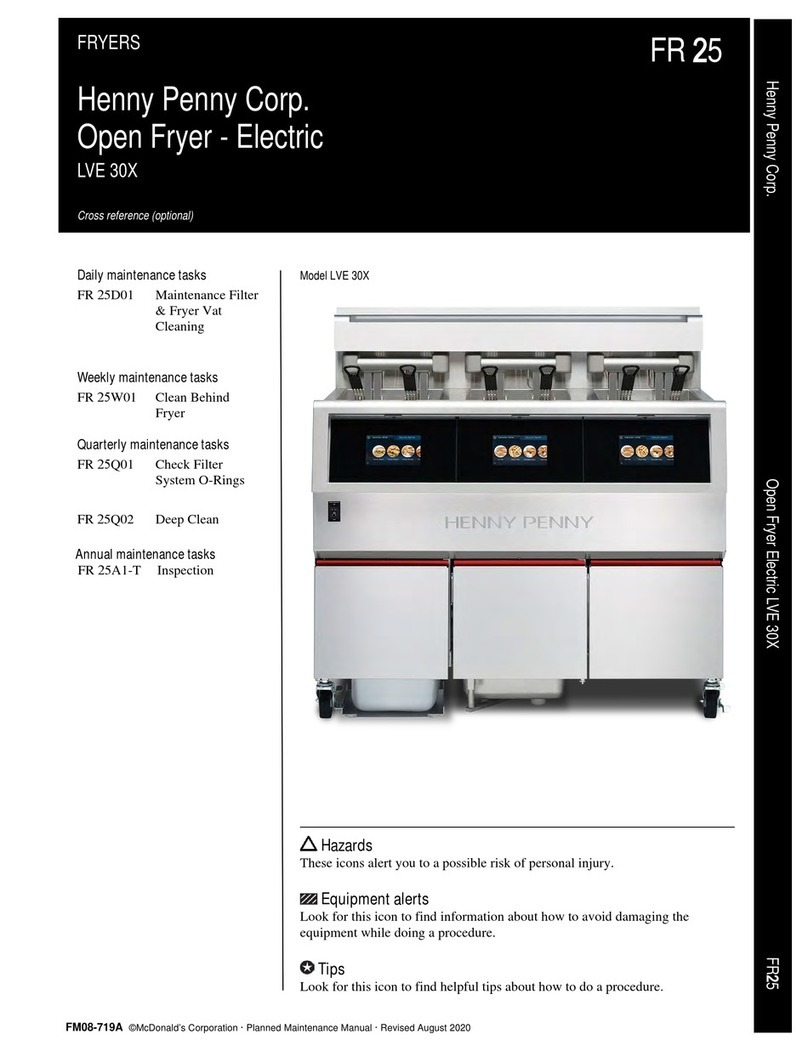

Henny Penny LVE 30 Series User manual

Henny Penny

Henny Penny OFG-392 User manual

Henny Penny

Henny Penny EVOLUTION ELITE EEG-241 User manual

Henny Penny

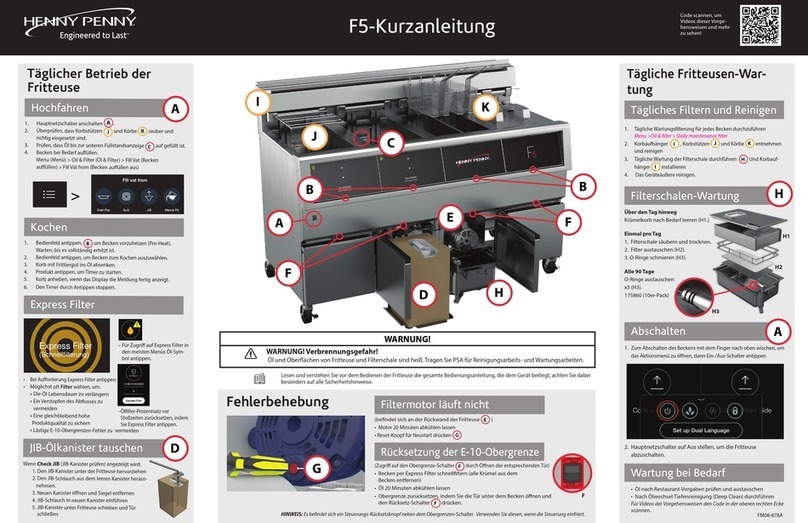

Henny Penny F5 User manual

Henny Penny

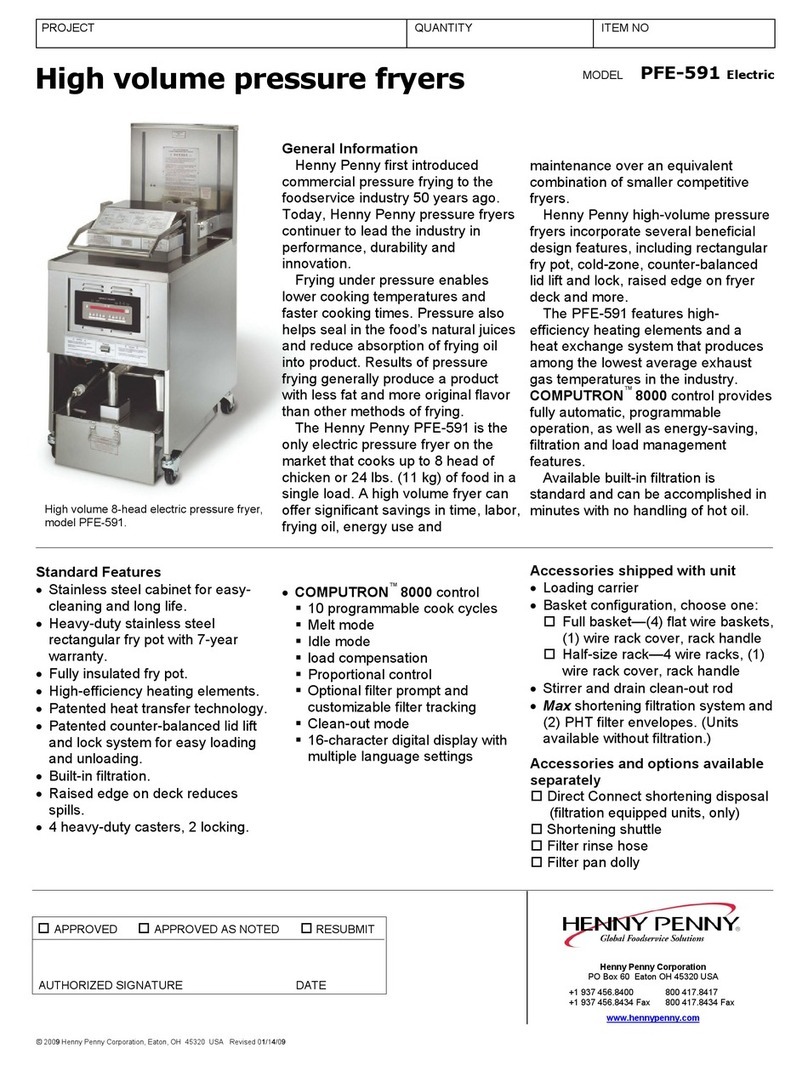

Henny Penny PFE-591 User manual

Henny Penny

Henny Penny F5 User manual

Henny Penny

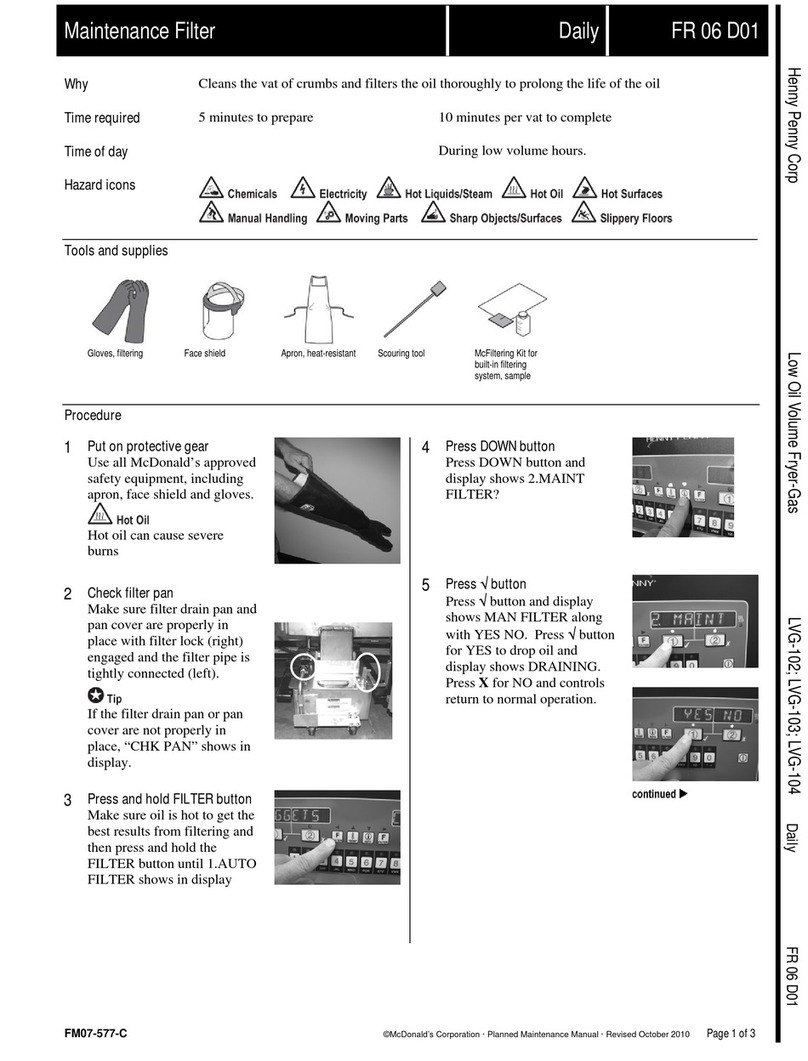

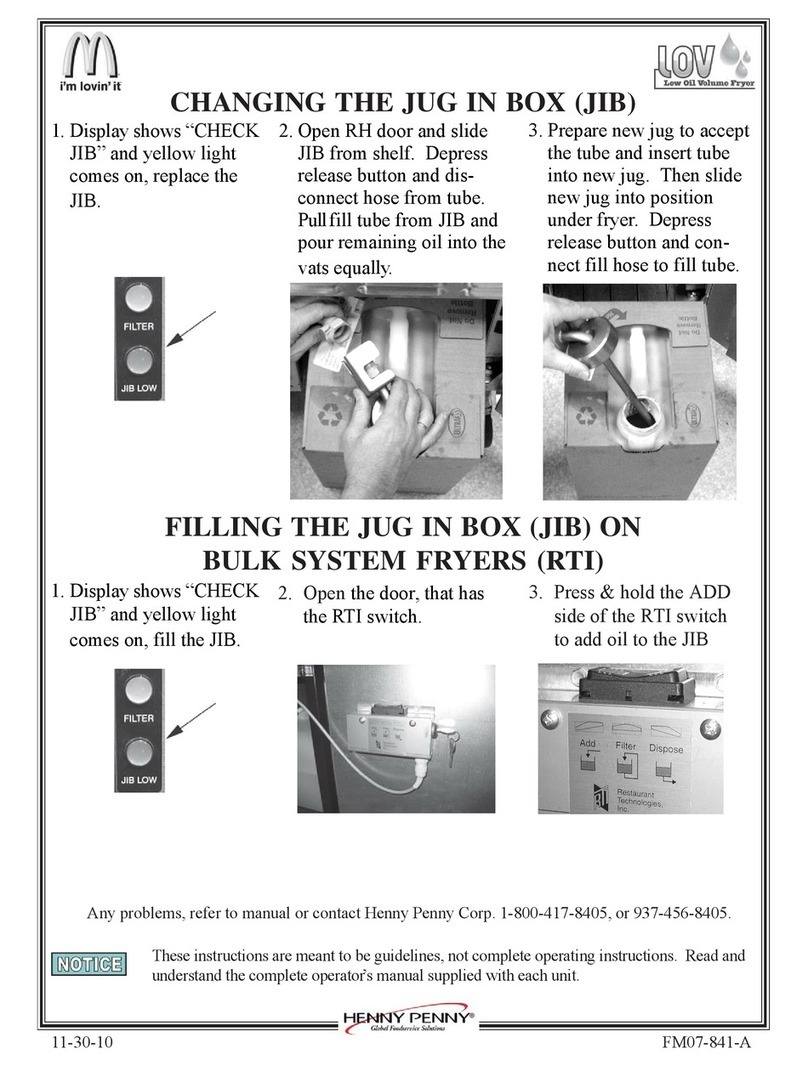

Henny Penny LOV LVG-100 Series Guide

Henny Penny

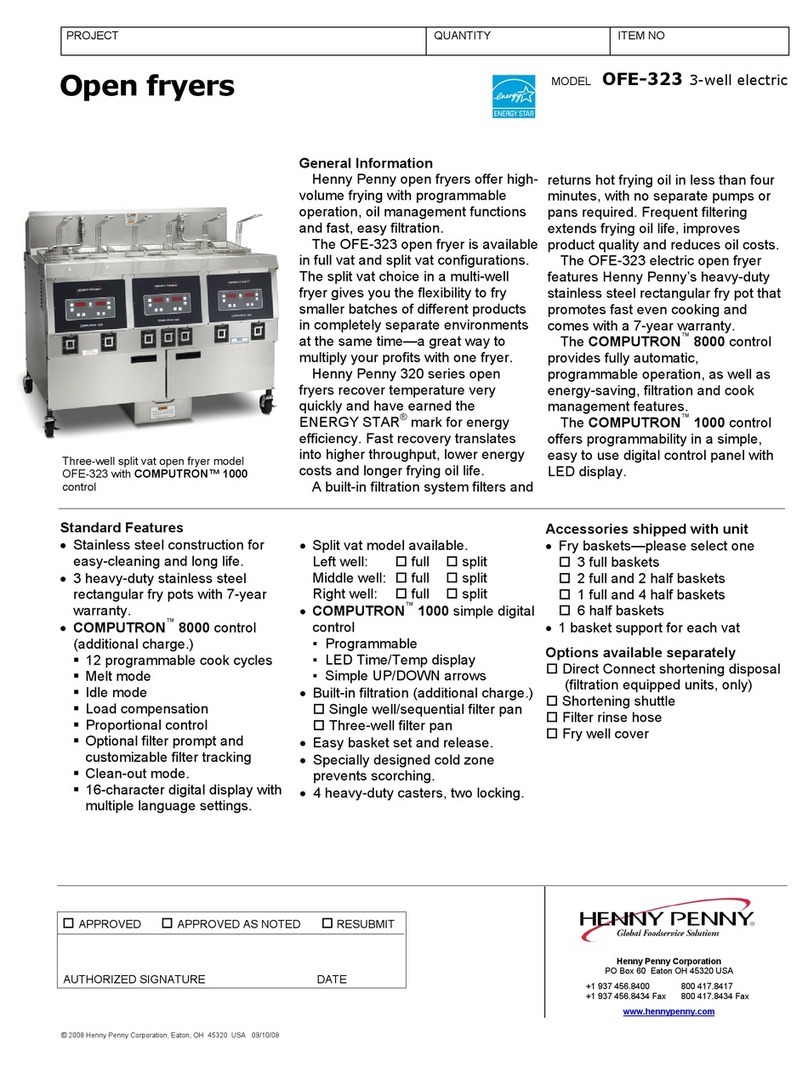

Henny Penny OFE-323 User manual

Henny Penny

Henny Penny 500 User manual

Henny Penny

Henny Penny 291 Instruction Manual

Henny Penny

Henny Penny OFG-390 User manual

Henny Penny

Henny Penny LVE-202 User manual

Henny Penny

Henny Penny LOV LVG-100 Series User manual