Directory of contents

1Password overview ............................................................ 5

2Introduction......................................................................... 6

2.1About this manual ............................................................................ 6

2.2Warranty............................................................................................ 6

3Safety instructions ............................................................. 7

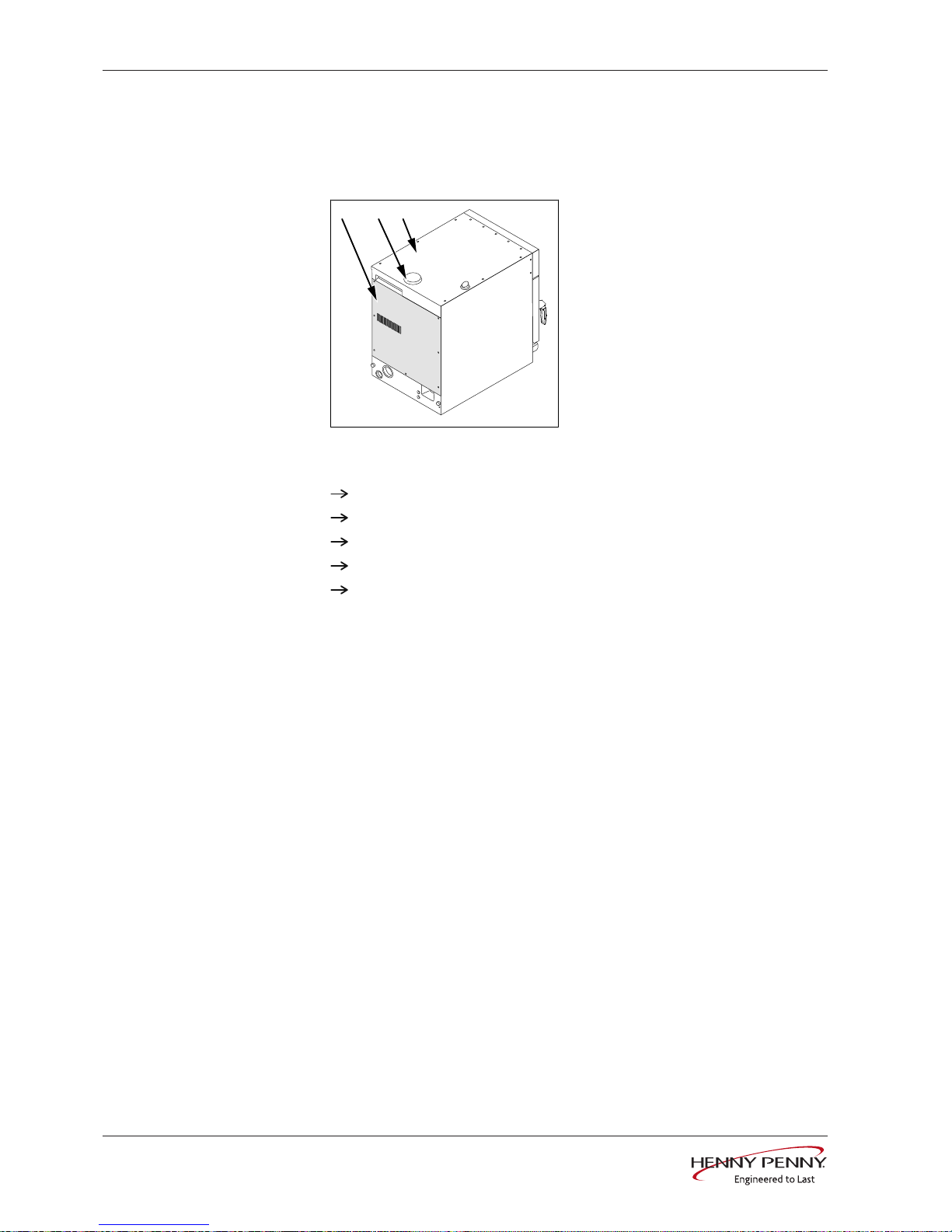

4Opening the appliance....................................................... 8

4.1Unit cover and rear wall................................................................... 8

5Service menu - appliance test........................................... 9

5.1Service menu .................................................................................... 9

5.1.1Calling up the service level........................................................................ 9

5.1.2Service menu overview ............................................................................. 9

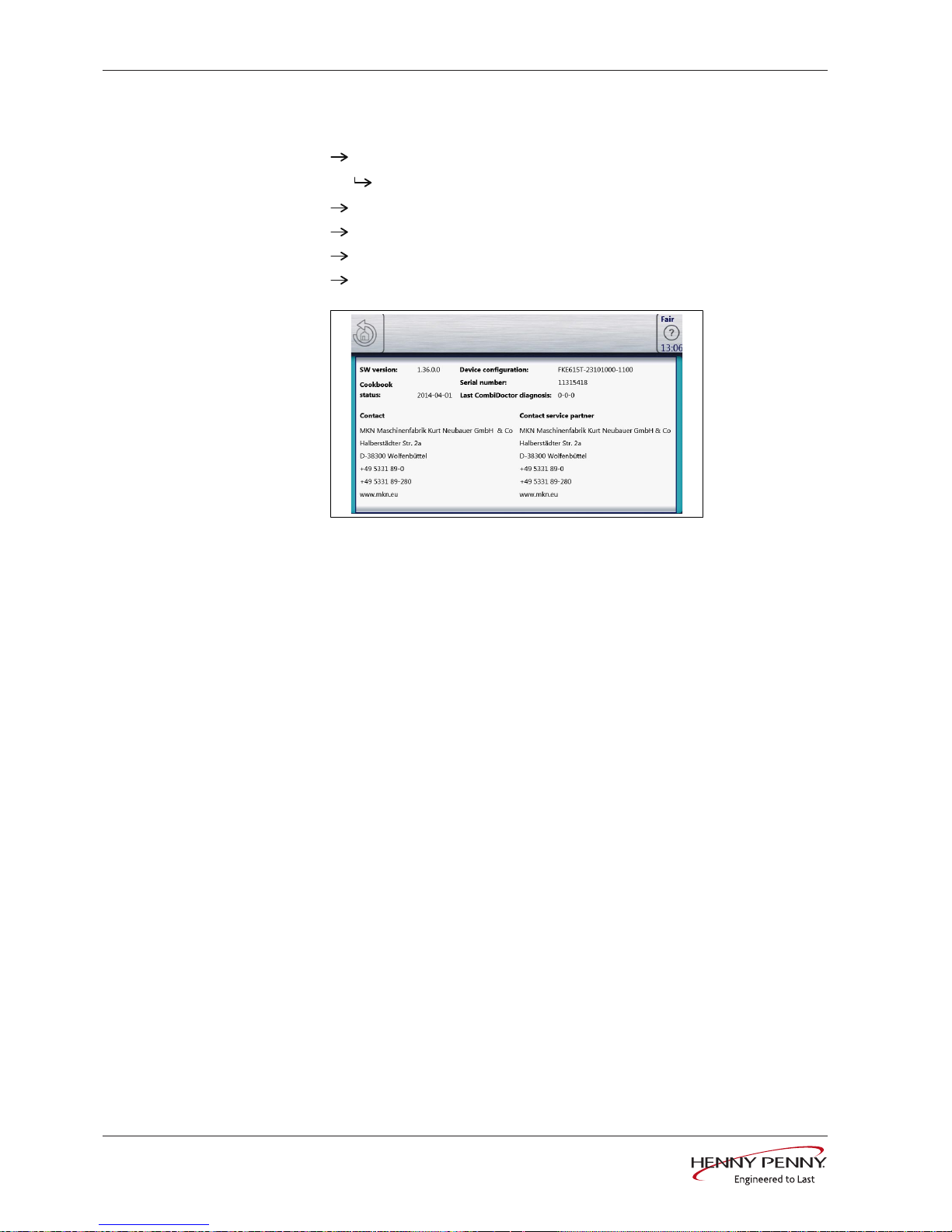

5.2Appliance information.................................................................... 10

5.3Status overview .............................................................................. 11

5.4CombiDoctor................................................................................... 12

5.5Relay test ........................................................................................ 14

5.6WaveClean test (option)................................................................. 16

5.7100°C + core temperature calibration........................................... 17

5.7.1Check calibration..................................................................................... 18

5.7.2Calibrate cooking chamber sensor.......................................................... 19

5.8DynaSteam test .............................................................................. 20

5.9Emptying the water ........................................................................ 21

5.10Setting the set-up height ............................................................. 21

5.11Audio settings .............................................................................. 22

5.12Select signal tones....................................................................... 23

5.13POS activation .............................................................................. 23

5.14Log data export ............................................................................ 23

5.15Software update ........................................................................... 25

5.16Importing additional content....................................................... 25

5.17Restoring data .............................................................................. 26

5.18Backing up data............................................................................ 26

5.19Water filter maintenance.............................................................. 27

5.20Importing contact data................................................................. 27

5.21Setting units.................................................................................. 28

5.22Backup relay ................................................................................. 28

5.23Status overview direct access .................................................... 29

6Software ............................................................................ 31

6.1Software update ............................................................................. 31

6.2Importing additional content......................................................... 33

6.3Importing the manufacturer's cookbook...................................... 35

10015160-0ASAE-A

3Service instructions