hergom Pas II User manual

1

Pas II Cooker

Owner’s Manual

INSTALLATION, USE AND MAINTENANCE INSTRUCTIONS.

Please read this manual thoroughly before installing and lighting your Fireplace.

Keep These Instructions for future reference.

(Glass Top Pas 1 Shown)

2

WELCOME to the HERGÓM family

We appreciate the consideration that you have shown us by choosing our stove, which

represents an important step forward in technique and style for coal and wood-burning stoves.

We are sure that your new Hergóm model will satisfy you in many ways, which is the greatest

incentive for our team. Owning a Hergóm model is a demonstration of an exceptional sense

of quality.

Please read the manual in its entirety. Its purpose is to familiarise you with your stove, showing

the guidelines for installing, operating and maintaining it, which should prove very useful.

Keep it and go to it when you need it.

If, after reading this manual, you need any further clarification, do not hesitate to consult your

usual supplier.

NDUSTRIAS HERGOM, S.A. is not liable for consequential damage arising from modifications to its

products that have not been authorised in writing, or from faulty installation.

Also, the right to modify its products without prior notice is reserved.

Industrias Hergóm, S.A., with head office in Soto de la Marina - Cantabria - Spain, offers a warranty

of TWO YEARS for its appliances.

The warranty in Australia only includes product purchased through the Australian distributor

network and installed correctly by a licensed installer.

The warranty will commence on the date of purchase of the appliance shown on the warranty

receipt and only covers any damage or breakage due to manufacturing faults or defects

IMPORTANT NOTE

If the device is not installed correctly, it will not provide the excellent service for which it has been

designed. Please, read these instructions in full and ensure the installation is carried out by a

certified installer.

Your appliance is protected with a special heat-resistant paint for high temperatures. During the first

few times that you start it up, it is normal for it to smoke slightly, as some of its components

evaporate, allowing the paint to cure. For this reason, we recommend ventilating the room until this

phenomenon dies down.

3

WARNING: THE APPLIANCE & FLUE SYSTEM SHALL BE INSTALLED IN

ACCORDANCE WITH AS/NZS 2918:2018 AND THE APPROPRIATE

REQUIREMENTS OF THE RELEVANT BUILDING CODE OR CODES.

CAUTION: MIXING OF APPLIANCE OR FLUE SYSTEM COMPONENTS FROM

DIFFERENT SOURCES OR MODIFYING THE DIMENSIONAL SPECIFICATION OF

COMPONENETS MAY RESULT IN HAZARDOUS CONDITIONS. WHERE SUCH

ACTION IS CONSIDERED, THE MANUFACTURER SHOULD BE CONSULTED IN

THE FIRST INSTANCE.

CAUTION: CRACKED AND BROKEN COMPONENTS, e.g., GLASS PANELS OR

CERAMIC TILES, MAY RENDER THE INSTALLATION UNSAFE.

1. WARNING: DO NOT US FLAMMABLE LIQUIDS OR AEROSOLS TO

START OR REKINDLE THE FIRE.

2. WARNING: DO NOT US FLAMMABLE LIQUIDS OR AEROSOLS IN THE

VICINITY OF THIS APPLICANCE WHEN IT IS OPERATING.

3. WARNING: DO NOT STORE FUEL WITHIN THE HEATER INSTALLATION

CLEARANCES.

4. WARNING: OPEN AIR CONTROL (AND DAMPER WHEN FITTED)

BEFORE OPENING FIRING DOOR.

5. CAUTION: THIS APPLIANCE SHOULD NOT BE OPERATED WITH A

CRACKED GLASS.

6. CAUTION: THIS APPLIANCE SHOULD BE MAINTAINED AND OPERATED

AT ALL TIMES IN ACCORDANCE WITH THESE INSTRUCTIONS.

7. CAUTION: THE USE OF SOME TYPES OF PRESERVATIVE-TREATED WOOD

AS A FUEL CAN BE HAZARDOUS.

4

1 - Presentation

The Pas Cooker has an all cast iron front, with porcelain enamelled finish, and fittings with chrome-

plated cast brass.

The internal frame of the slow combustion cooker is made from galvanized steel. The hob outer

frame is made of plate steel with porcelain enamel finish. The worktop on the glass-ceramic top

version with folding splashback has a stainless-steel trim frame and beneath that the countertop hob

is brushed cast iron.

The oven is fully stainless steel lined, and includes a porcelain enamelled roasting tray, and chrome

plated oven rack.The Oven door includes a tempered glass viewing window with thermometer for

gauging the oven temperature.

The side rack supports are fixed to the oven walls and allow maximum extension of the oven tray

and Chrome grill, without the risk of spillage of the cooked foods.

The side racks are easily removable for easy cleaning (lift them up, freeing them slightly from the

bottom hole and then slide them out to release them from the upper hole).

The air supply for the cooker can be supplied into the rear through an outside air duct fixed to the

rear of the cooker.

Secondary air for combustion:

• Is supplied from the slot at the top of the door glass, which in turn acts as an air-wash for the glass.

The oxygen hitting the glass ensures any creosote deposits from a low burn are cleaned off. The

intake for this is next to the fire-door top hinge.

• Through the back of the refractory stove, which at the same time acts as a cooling effect to the

back of the cooker. The primary air supply can come through the holes at the bottom of the fire-

door if there is not outside air kit fitted. This air passes through the damper at the rear, controlled

by the lever at the front. This supplies primary and secondary air to the base of the firebox and up

the flutes behind the rear casting.

The hidden door below the oven hidden behind the oven door is access to cleaning of the soot build

up around the oven flue path. The flue paths must be kept clean - see section 2, Operating

Instructions.

Cleaning access

door

5

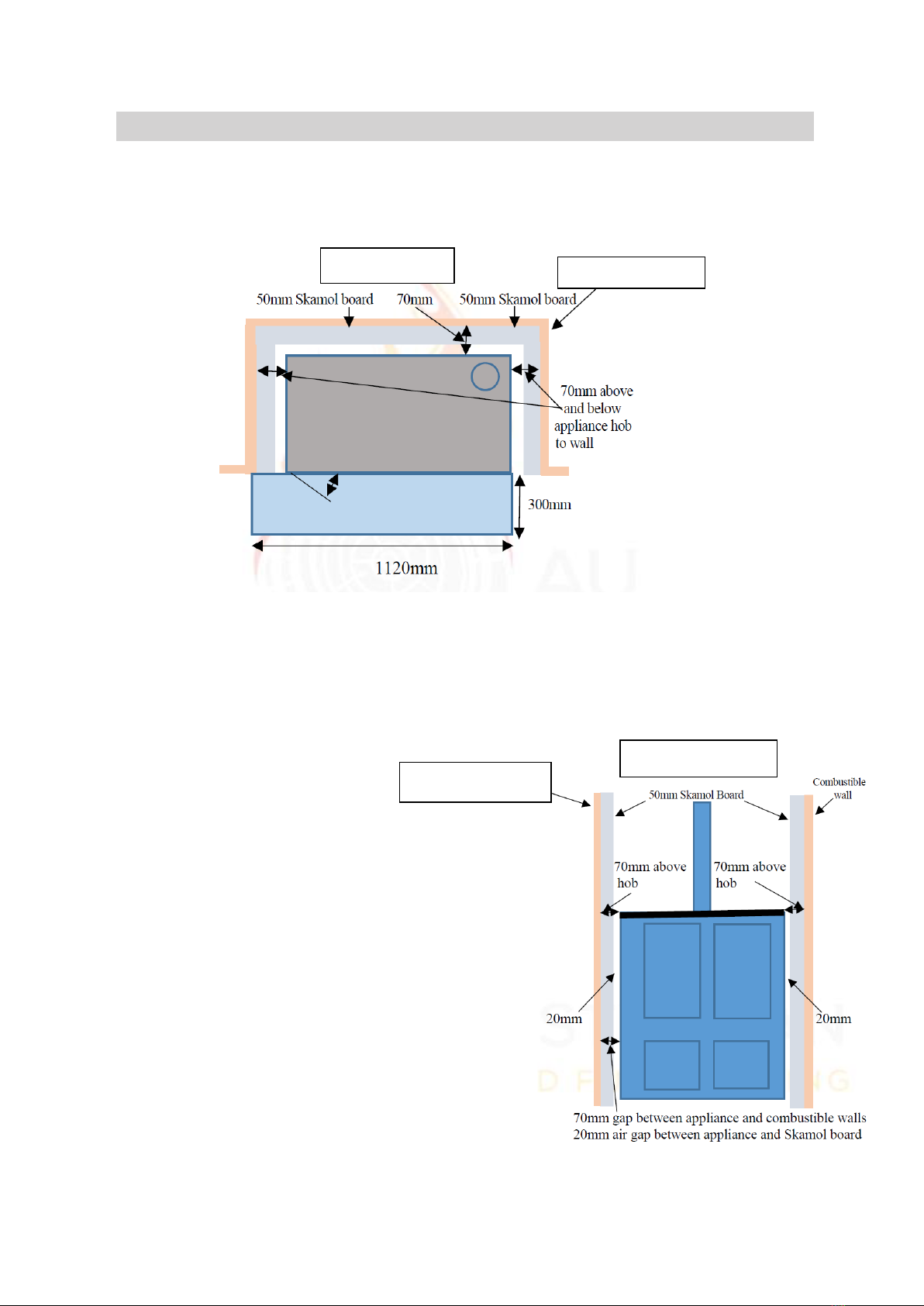

2 - Installation

The hearth must be a minimum of 12mm thick fibre cement sheeting, ie Bellis board or equivalent,

with Thermal resistivity of 0.1m2.K/W for 9mm thick sheets. The sheet must be underneath the

appliance and minimum requirement in front of the cooker is 1120mm wide and 300mm in front,

with 200mm included to the left of the firebox door opening.

The installation alcove must be lined with 50mm Skamol enclosure board for insulation, and a 20mm

air gap between the cooker and the Skamol board (or 70mm to the combustible wall). For building

out dimensions see the dimensions on page 12. The board must be on all combustible walls to the

sides and to the rear of the appliance to a minimum height of 2m from the floor.

Skamol must start from the floor and continue to a height

of 2m above the floor.

Installation into a double brick wall alcove would need to

be equivalent to an open brick fireplace – see the Building

Code of Australia - BCA or NCC for details.

Combustible Wall

PLAN VIEW

FRONT ELEVATION

Combustible wall

6

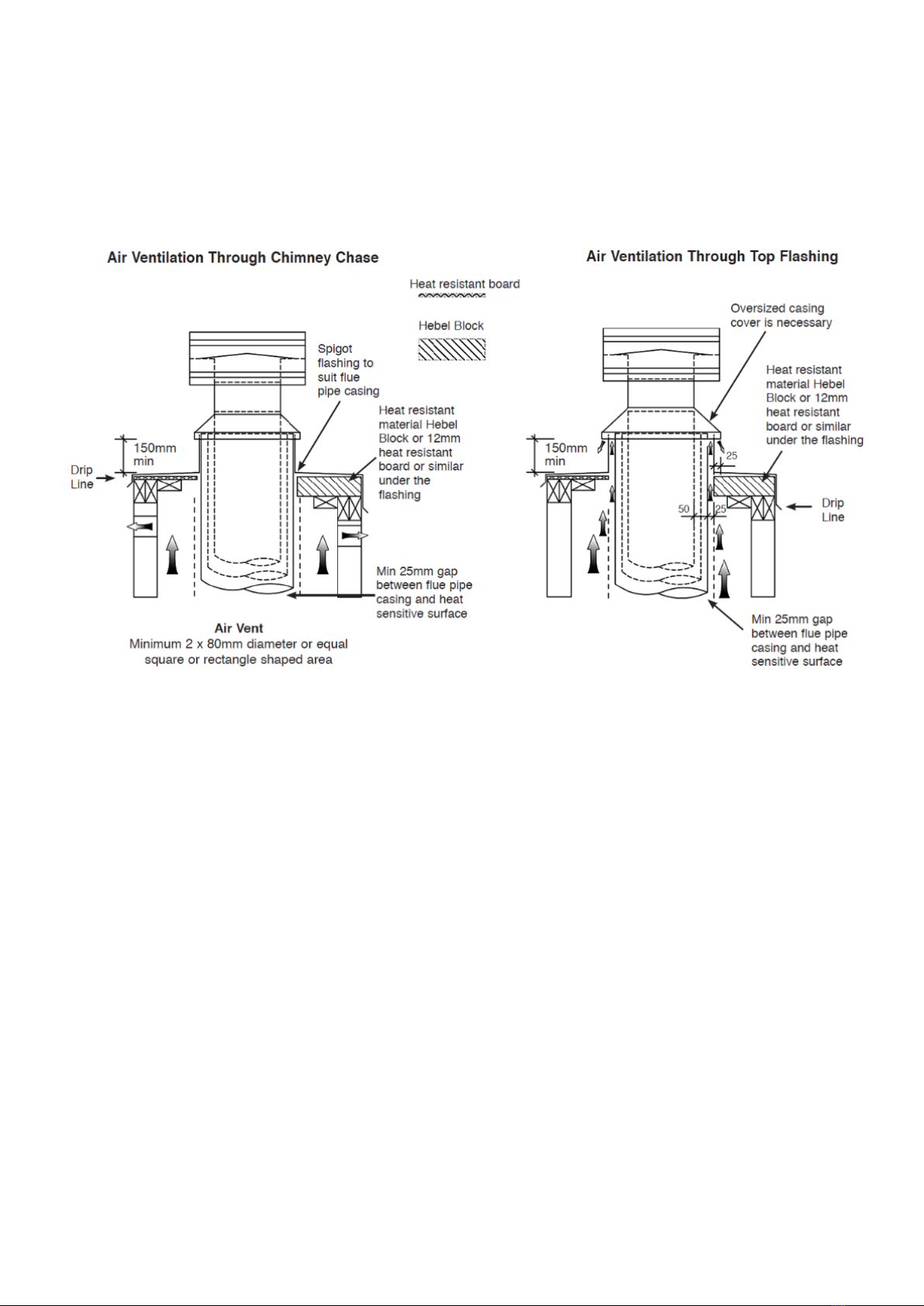

Flue Installation

The Flue type required: 152mm ( 6”) active flue and a solid 8” heat shield within the room, and air

cooled Double casing insulation (triple skin) from above the ceiling, as per AS2918:2018 default flue

kit. See diagrams below for flue requirements. The Active 152mm flue must be a tight fit into the

heater collar.

The heater must have its own dedicated flue. The active flue must be 6” for the entire length of

the flue, and always less than 45 degrees from the vertical.

Replacement room air from outside equivalent in open area to 91cm2 must be supplied into the

room.

Flue Outlet Positions

Minimum Flue Height as per AS/NZS 2918:2018

NOTE: Flue exit MUST also be as high as any nearby structure within a 6m Radius. ( AS

2918:2018 )

7

External Requirements

Refer to AS/NZS 2918:2018

Note: All external air vents & ceiling penetrations must be bird & rodent proofed with

permanently fixed screens

8

3 – Operating Instructions

Before you begin using your cooker, make sure you are fully aware of how the cooker functions, as

well as the maintenance requirements of the cooker you have purchased.

With each cooker a set of useful tools is included, including a hook to remove the hob rings, and to

use as a fire poker, and a scraper for cleaning out the Ashtray chamber, and for scraping the soot out

of the flue ways, particularly through the cleaning door, located just below the oven, behind the

oven door.

Before lighting the cooker, check that the flue way is perfectly clean, and free of packaging material.

When you are starting up the cooker, lighting

the cooker from cold, open the primary air

valve (below fire door) by pushing it fully

across to the right, and the direct-flue valve,

which is above the oven door, should be

pulled outwards all the way out.

Once the fire is burning well and you have a good bed of glowing coals (say 75 or 100mm if getting

the oven hot) and the new fuel is well lit, push the air control lever all the way to the left (see below)

and close the direct-flue damper valve (above the oven door) by pushing the handle fully back into

its normal position.

Closed –

Shut down

Open –

Heating up

9

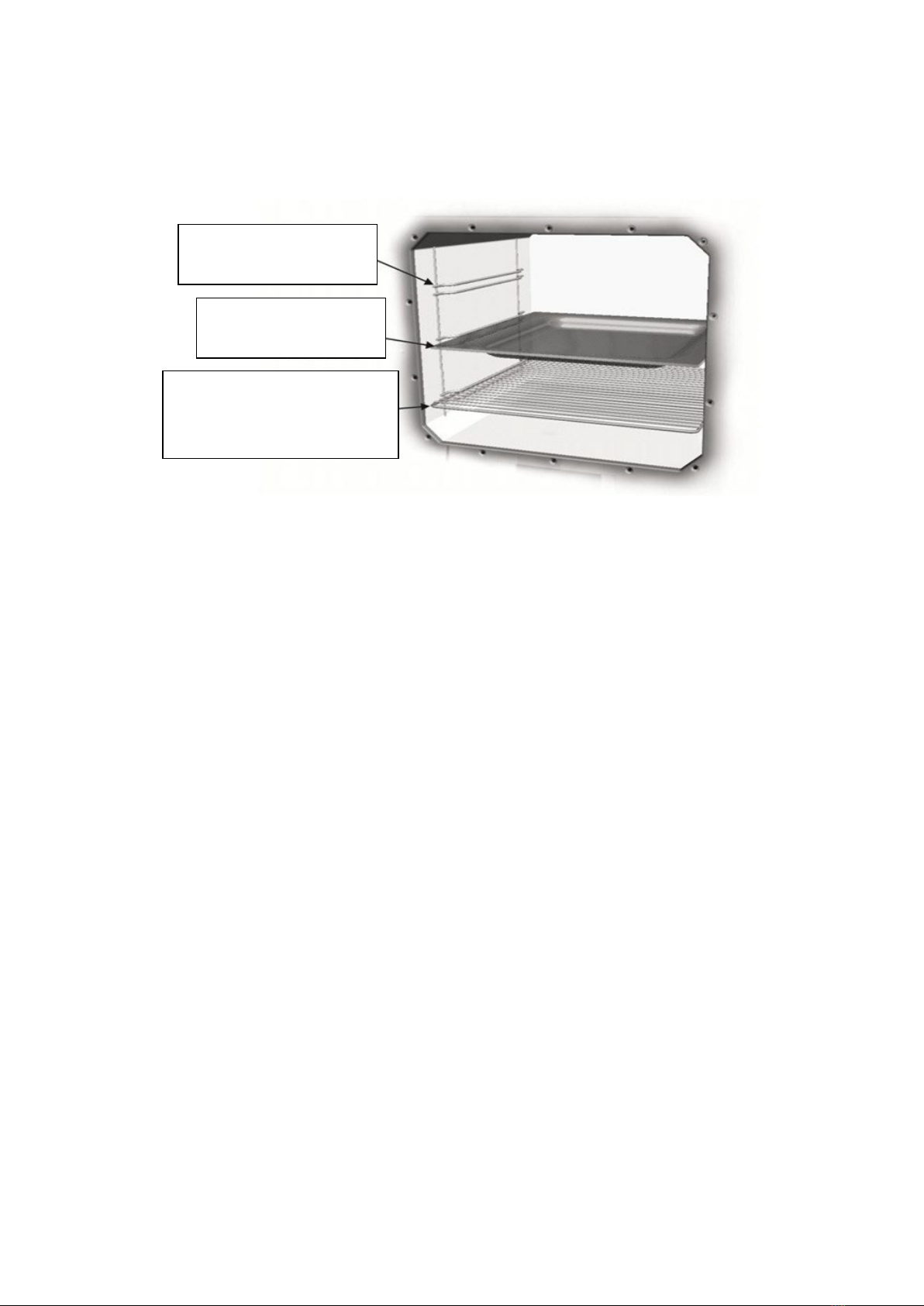

Insert the Chrome wire Rack and the Roasting tray into the side rails at the desired height.

Regulate the heat of the cooker by means of the primary air valve, always be aware that overfiring

can occur if the valve is left constantly open, this will also consume a higher consumption of

firewood, making the hotplate reach an excessive temperature. Never fully fill the firebox or leave

the ashtray door open. Do not throw firewood through the loading door when refuelling.

When running the oven, to get it up to temperature use smaller split pieces – the greater the surface

area to volume of wood, the hotter the fire. Smaller pieces will create a hotter coal bed quicker, and

then adding the smaller pieces will regulate the heat better. Larger logs can’t be removed once

going, but also will give a lesser heat over a longer period of time.

Note: Cooking pots, pans with flat bottoms will be much quicker in getting up to temperature.

FIRST IGNITION

It is recommended that the first ignition when new is just a smaller fire for 3 or 4 hours to get the

parts stabilized. DON’T over fire the cooker when first used. This allows the parts to settle and

remove any moisture in the firebricks.

In the annual cleaning and maintenance, check the condition rope / glass tape below the hot plate,

and replace if necessary.

Side Rails

Roasting Tray

Chrome Wire

Rack

10

4 – CLEANING AND MAINTENANCE

Cleaning should only be done when the cooker is cold, using a slightly damp cloth with soapy water,

drying out below.

Avoid using strong detergents or caustic cleaning products or using abrasives that could scratch or

damage the enamel or glass.

THE CERAMIC GLASS TOP

(On the Eclecsys and Pas 1 Rear flue models only)

The ceramic glass top plate should never be cleaned on its underside.

Glass top on the Eclecsys model - when the plate has been tempered you can then use a special

cleaner for ceramic hobs, applying it with a paper towel.Then rinse with a damp cloth, and dry with

a clean cloth. The use of sponges should be used with cleaning products, ensure not to use a scourer

or steel wool that will scratch the surfaces.

When hot the outer surface should only be cleaned using a scraper appropriate for ceramic glass, for

sale in supermarkets, hardware stores, etc. Use the scraper to clean food remains, grease spatters,

etc. when still hot, to stop them from sticking more firmly to the surface when they cool down.

Always keep scraper within easy reach. If small pieces of aluminium foil, plastic, sugar or other

materials that melt quickly fall onto the surface of the worktop, they should be eliminated

immediately while the worktop is hot using the scraper, to prevent the surface from getting

damaged.

Cleaning products

When the plate has already cooled, always use a special cleaner for ceramic glass, applying it with

paper towels. Then wipe it clean with a damp cloth, and dry it with a clean cloth.

We do not recommend using sponges or other high-absorption kitchen cloths, as the liquid part of

the cleaning products is absorbed, leaving the harsher or highly concentrated components on their

surface, which could lead to scratching or abrasions. There are preservative products that produce a

shiny protective layer against dirt.

Some materials on the bottom of containers can leave marks with a metallic shine on ceramic glass.

There are products on the market that solve these problems.

Limescale marks on the surface can also be eliminated, but they are avoidable if the surfaces of the

containers are clean and dry.

If discolouration marks or damages appear on the glass plate, it is due to the fact that products not

specified for ceramic glass have been used.

Under no circumstances should metal scouring pads, steel wool, knives or any another utensil that is

liable to damage the ceramic glass surface be used for cleaning the worktop. Make sure that any

cooking pans are specially for ceramic glass or at least have bottoms that do not have any roughness

or defects that could scratch the surface.

11

THE ENAMELLED WORKTOP COMPONENTS

To keep the worktop looking good, we recommend cleaning it frequently using a damp cloth.

Do not use acidic or abrasive products to clean the worktops as these products can damage the

vitreous enamel. See the comments for Ceramic glass above.

STAINLESS STEEL FRAMEWORK

To take care of the stainless steel, use dedicated stainless steel cleaners available in the market.

Avoid any utensils that may scratch the stainless steel, it is important that the outer surface is not

damaged.

EMPTYING THE ASHES

The special design of the stove in heat-resistant material, which makes it possible to make maximum

use of the fuel, means that the volume of ashes produced is low.

This makes it possible to light the stove repeatedly without needing to remove them from the stove.

When it is necessary to carry out this operation, remove the grill from the stove and move the ashes

to the ashtray. Empty the ashtray into a metal container and take it out of the house immediately.

Leave a bed of Ash in the base on the grate to insulate the fire and keep it burning, but never leave

the ash tray full so the soot has filled up all the space at the bottom of the cast grate, this can

damage the grate casting from overheating

During the annual cleaning, or when necessary, check that the hob cooktop is in good condition and

sealing with the cooker. If necessary, change the glass tape liner or change the hotplate. This plate is

simply inserted in the frame, and its replacement is a very simple operation.

12

REMOVING THE SOOT AND CLEANING THE FLUE PATH

The door cover for cleaning soot out of the base, is hidden behind the bottom of the oven door.

This door is used for scraping out the soot that accumulates in the bottom of the cooker.

The cooker has access to the rear flue path, to clean out the soot and creosote from the flue path.

To access it should proceed as follows

1. Remove the hob/hotplate from the cooker hob.

2. The chimney access cover is removed next to the direct-flue damper valve (See below)

3. Clean out the flue path down the back, the right-hand side and below the oven. Drag the soot out

through the access door at the front below the oven, to remove all the soot.

4. For the RHS of the oven, using a thick steel chain with a knot in the end push this down the RHS of

the oven and drag up and down and left and right to loosen all the soot. This should be done

regularly so the soot and creosote doesn’t get a chance to crystallise up and become much harder to

clean.

13

5 – Safety

There are potential safety risks that must be taken into consideration when it comes to running your

solid fuel cooker, regardless of the brand. These risks can be minimized by following the instructions

given in this manual. Below are several points that must be followed, but above all, remember to

use your common sense (if available – not included).

1. Keep any flammable material (curtains, clothing, fuel storage) a minimum of 1m away.

2. Ensure the relevant clearances are kept to combustible materials, both above and below the

countertop height (as per installation instructions).

3. Leave a minimum of 30 – 40 mm gap around the unit on rear and sides to allow air to

circulate around the cooker.

4. When emptying the ashes, make sure to use a non-combustible metal container, and

remove immediately from the house (hot ashes in metal container could transfer heat

through the base).

5. Never use liquid fuels to light your cooker.

6. Keep flammable liquids away from your cooker (Lighter fluid, Petrol, alcohol, cooking oil).

7. Inspect the cooker regularly and clean the cooker and flue as soon as it is necessary.

Your retailer or local distributor can supply you with a range of products for the maintenance of

your cooker, including:

-Fire cement (black) for sealing between metal and cast joins, to keep the cooker tightly air

sealed as required

-An Anti-Soot catalyst such as Smart Burn or Soot-Loose to reduce creosote build-up within

the cooker.

-Air set cement (Grey) for keeping refractory bricks in position, as well as products for

repairing bricks.

-Glass cleaner, for removing creosote / soot from the fire door, and oven door clean.

6 – TECHNICAL DATA AND EXPLODED PARTS DIAGRAMS

Flue Diameter

150mm

Nominal Output

13.7kW

Efficiency

70.6%

Flue Temperature

256 °C

Minimum Draft requirement

12 Pa

Weight

265 kg

Clearance Test AS/NZS 2918:2018

ASFT18099

14

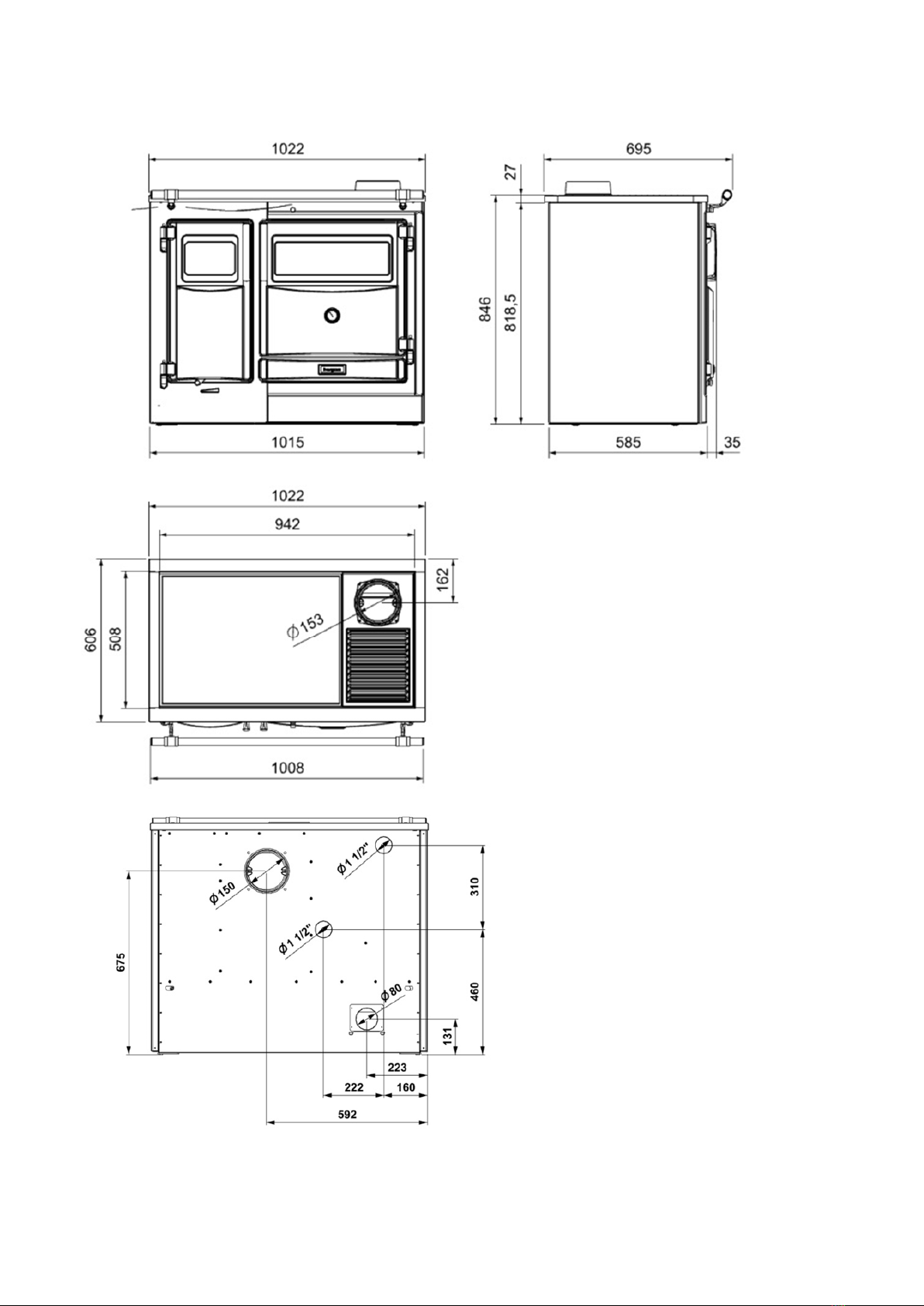

DIMENSIONS - Top Flue Exit Model; PAS II

15

EXPLODED DIAGRAM

Detail A:

Table of contents

Other hergom Cooker manuals