H.E.R.O. INDUSTRIES LTD. 1000MD OWNERS MANUAL -“B” VERSION

6

SETTING UP TO SPRAY

1. Remove unit from shipping carton.

2. Remove shipping seal from under hydraulic tank cap.

3. Re-position paint tank lid knob from the shipping position, on the underside

of lid, and place on the lid top.

4. Attach paint hose to outgo tee (ref# 43) and gun to paint hose.

NOTE; Spray tip and tip guard should be attached to gun prior to attaching

to hose.

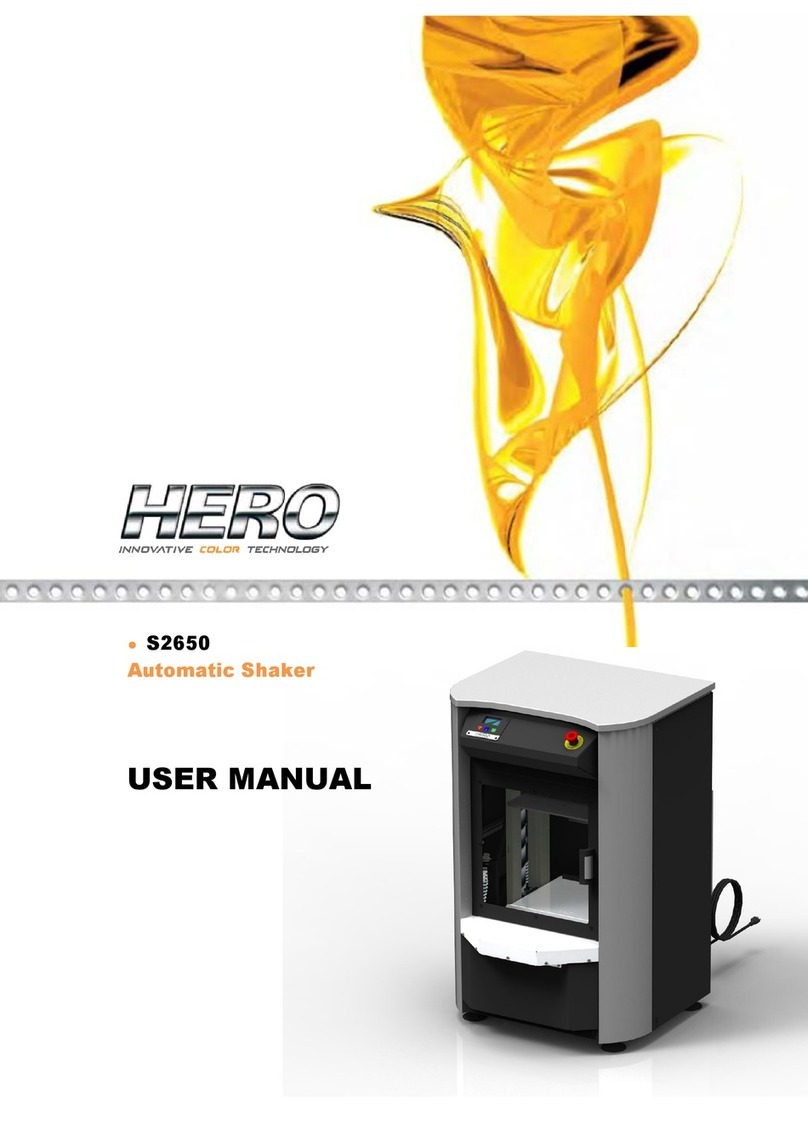

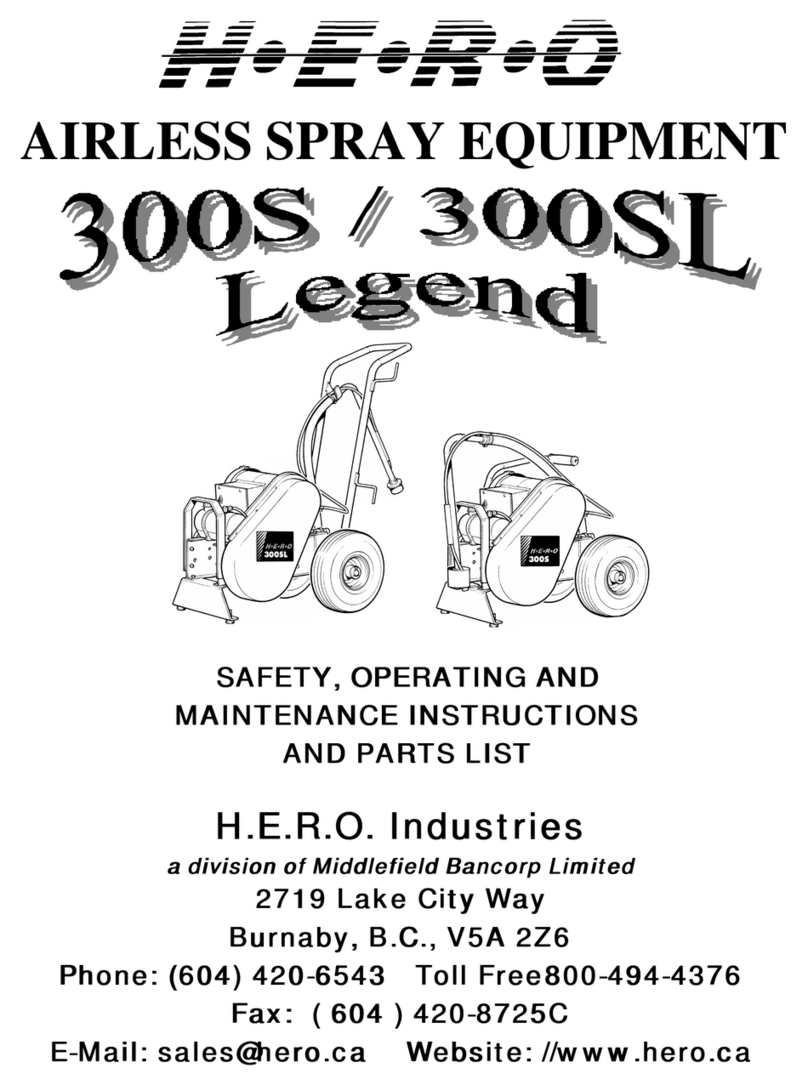

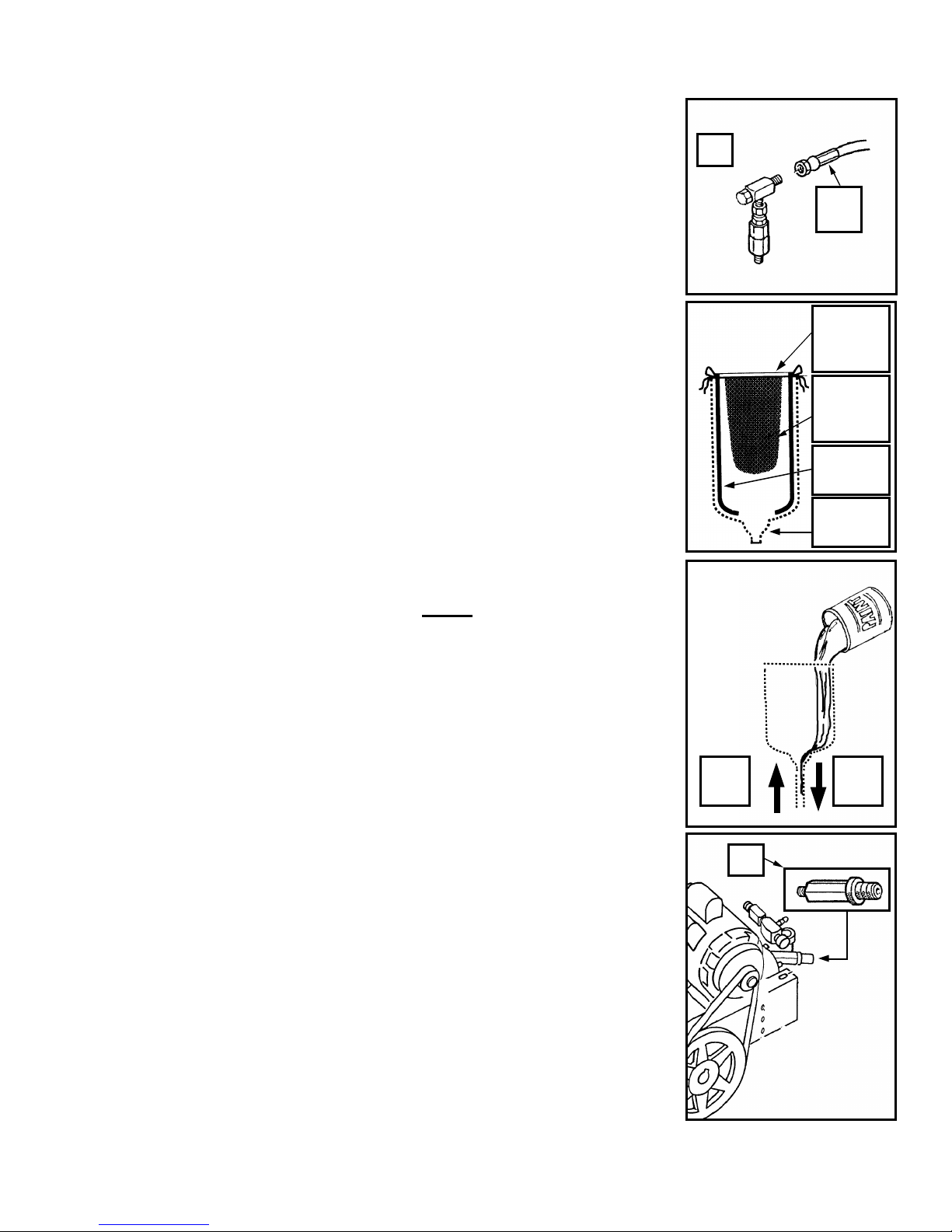

5. To assist in clean up, use and install paint tank plastic liners ( accessory item

3 GAL PL ). Line the inner sides of tank, ensuring that the liner does not

block the tank screen in the bottom of the tank. Fold excess over the outside

of tank.

6. Install strainer bag (accessory item 3GAL SB) in tank and secure with large

rubber band ( accessory item 106 ).

NOTE; Strainer bag must remain 4 inches from the bottom of tank.

7. Trigger gun to release any pressure in the unit. Use extreme caution to ensure

that the gun is not directed towards anyone or any object which may be

damaged.

NOTE; Unit may contain storage solution.

8. To remove storage solution, add one gallon of thinner, compatible with the

type of paint to be used, to the paint tank.

9. Turn pressure control knob (ref# 71) to lowest pressure setting.

10. Be sure motor switch is in "OFF" position. Plug unit into 115V, 15 amp.,

grounded circuit.

NOTE; If using an extension cord, you MUST use a #12/3 wire grounded

cord, up to50feet or #10/3 wire grounded cord, up to 100 feet. DO NOT

EXCEED 100 FEET OF EXTENSION CORD. If distance is greater,

purchase and install additional lengths of airless spray hose.

11. Turn motor switch "on" and increase pressure slowly. Trigger gun into a

waste container. Continue spraying until pump runs dry and all thinner and

holding solution has been removed. Keep pressure low.

12. Pour paint through strainer bag into paint tank.

NOTE; Pour paint (particularly thick paints ) slowly, to allow paint to

enter the intake hose while at the same time allowing air the opportunity to

escape up the intake tube. Pouring paint in quickly can trap air in the intake

tube ( air lock ) and make priming difficult.

13. Replace paint tank lid. Keep tank covered at all times to prevent

contaminates from falling into the paint.

14. Increase the pressure, slowly at first, by turning the pressure control knob

clockwise. Spray a test pattern.

NOTE; Begin by spraying a test pattern onto old newspaper or other scrap

material.Continue increasing the pressure until the spray pattern is

uniformed from top to bottom, with no heavy areas. Secure pressure control

setting, by turning the silver lock ring (ref# 73) counter clockwise until

snugly against the face of the pressure control knob. If heavy areas are still

visible at maximum pressure setting, thin the paint with the correct thinner,

according to the paint manufacturer's recommendations.

FLUSHING THE UNIT AT SHUTDOWN

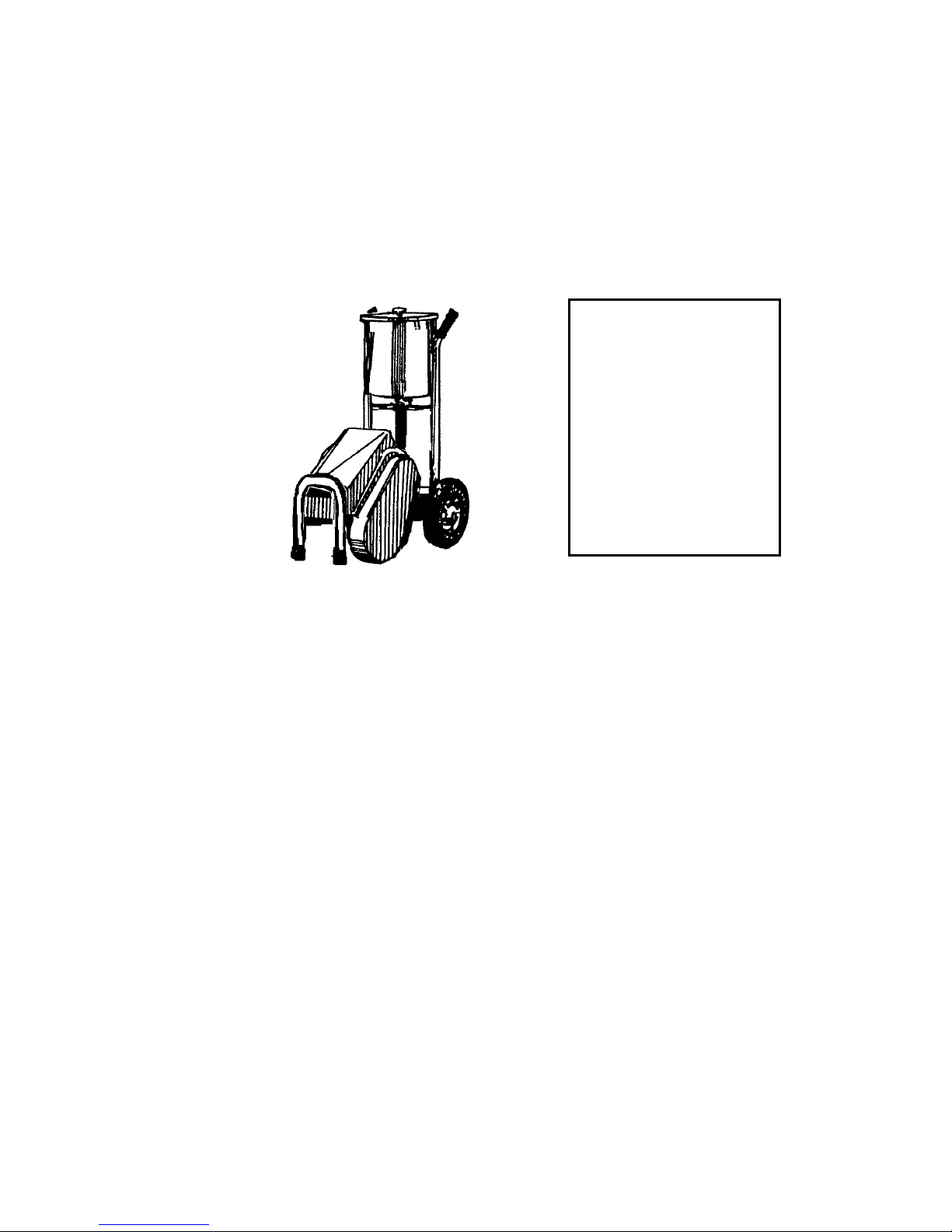

70

43

Paint

Tank

outline

Liner

3GAL PL

Strainer

bag

3GAL SB

Rubber

band

106

Paint

in

Air

out