H.E.R.O. INDUSTRIES LTD. 330SES / 330SEL MANUAL -“B” VERSION

6

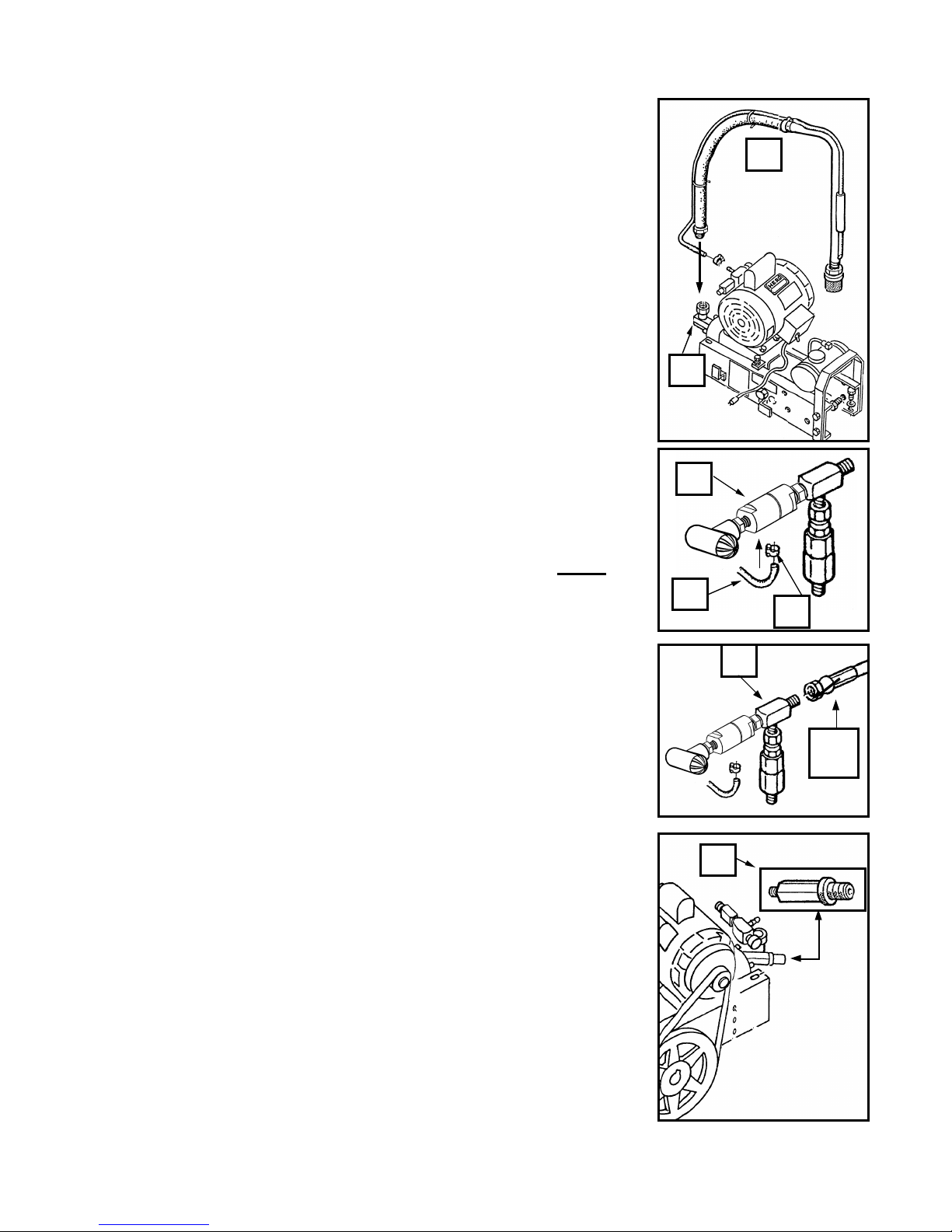

SETTING UP TO SPRAY

1Remove unit from shipping carton.

2Attach intake siphon assembly (ref# 7) to intake elbow (ref# 8). Use

caution to avoid over tightening which may result in cracked or broken

fittings.

3Attach prime hose (ref# 50) to prime valve (ref# 49). Secure with clamp

(ref# 51).

4Attach paint hose to outgo tee (ref# 35).

5Attach gun to paint hose. NOTE; Spray tip and tip guard should be

attached to gun prior to attaching to hose.

6Place intake siphon assembly into a clean 5 gallon pail.

7Install strainer bag (accessory item 5GAL SB) in pail and secure with large

rubber band ( accessory item 106). NOTE; Strainer bag must remain 4

inches from the bottom of pail

8Trigger gun to release any pressure in the unit. Use extreme caution to

ensure that the gun is not directed towards anyone or any object which may

be damaged. NOTE; Unit may contain storage solution.

9To remove storage solution, add one gallon of thinner, compatible with the

type of paint to be used, to the siphon pail.

10 Turn pressure control knob (ref# 71) counter clockwise to lowest pressure

setting.

11 Be sure motor switch is in "OFF" position. Plug unit into 115V, 15 amp.,

grounded circuit. NOTE; If using an extension cord, you MUST use a

#12/3 wire grounded cord, up to 50 feet or #10/3 wire grounded cord, up

to 100 feet. DO NOT EXCEED 100 FEET OF EXTENSION CORD.If

distance is greater, purchase and install additional lengths of airless spray

hose.

12 Turn motor switch "on".

13 Turn prime valve knob (ref# 45) counter clockwise until fully open. Allow

thinner to circulate back into the siphon pail for a few minutes. Then turn

the prime valve knob clockwise to close the valve ( close tightly ), and

direct the flow to the paint hose and gun. Leave the pressure setting low.

14 Trigger gun into waste container.

15 Pour paint through strainer bag into siphon pail.

16 Repeat steps 13 and 14, until paint flows freely. NOTE; Never turn prime

valve back to "prime" position when the unit is under pressure.

17 Spray a test pattern. Begin by spraying a test pattern onto old newspaper or

other scrap material.

18 Increase the pressure, slowly at first, by turning the pressure control knob

clockwise. Continue increasing the pressure until the spray pattern is

uniformed from top to bottom, with no heavy areas. Secure pressure

control setting, by turning the silver lock ring (ref# 72) counter clockwise

until snugly against the face of the pressure control knob. If heavy areas are

still visible at maximum pressure setting, thin the paint with the correct

thinner, according to the paint manufacturer's recommendations.

7

8

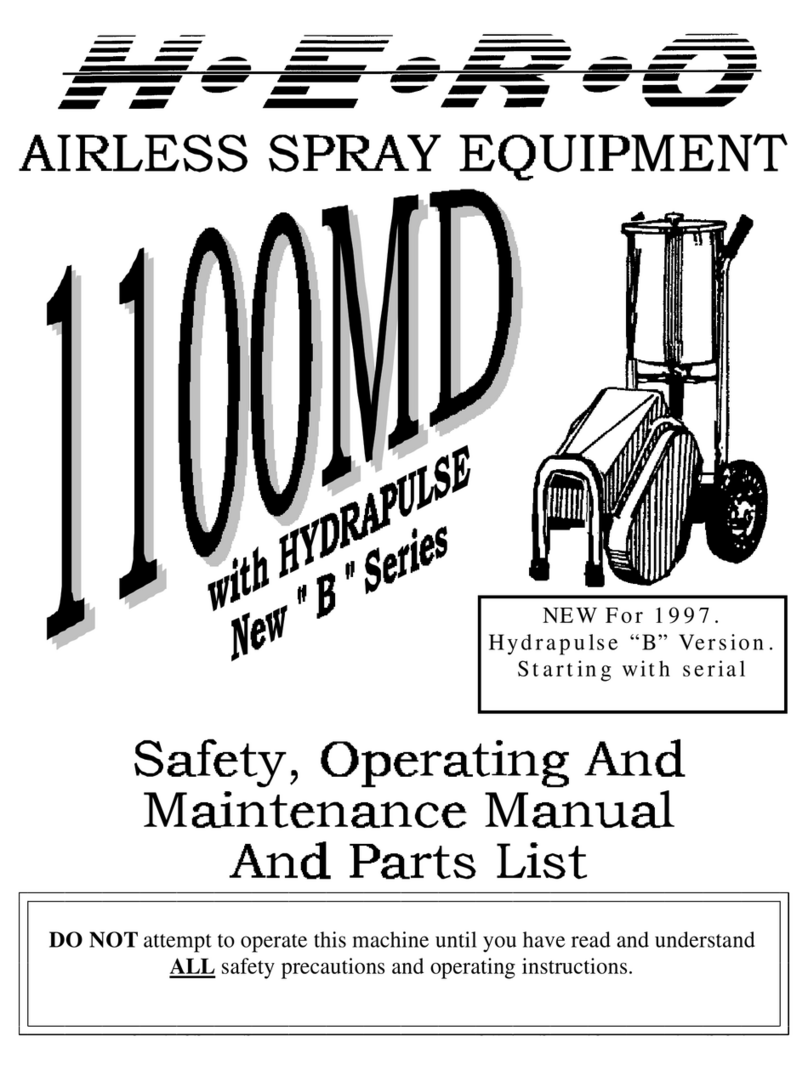

Paint

Hose

35

70

49

51

50