HEROSE 4186 Series User manual

herose.com

HEROSE GMBH ARMATUREN UND METALLE

Original

Operating and Installation Instructions

Combi-Regulator 4186

E

N

Operating and Installation Instructions

herose.com

Page 1

Operating and Installation Instructions

Combi-Regulator

Type 4186-1 and Type 4186-3

IMPORTANT:

PLEASE READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

HEROSE GMBH

ARMATUREN UND METALLE

Elly-Heuss-Knapp-Straße 12

23843 Bad Oldesloe

Tel: 04531 509-0

Fax: 04531 509-120

Web: http://www.herose.com

5th edition 07/2016

© HEROSE 2015

Disclosure and reproduction of this document as well as utilisation and communication

of its content are prohibited unless explicitly permitted Infringements will attract claims

for compensation. All rights for registration of patents or design reserved.

Operating and Installation Instructions

herose.com

Page 2

Contents

1. Schematic Illustration of Combi-Regulator.............................................................4

1.1. Illustration 4186-1..............................................................................................4

1.2. Illustration 4186-3..............................................................................................5

2. General information About These Operating Instructions......................................6

3. Safety ....................................................................................................................6

3.1. Symbols and Signal Words ...............................................................................6

3.2. Safety Related Definitions.................................................................................7

3.3. Basic Safety Information ...................................................................................7

3.4. Qualified Personnel...........................................................................................8

4. Transport and Storage...........................................................................................8

4.1. Transport...........................................................................................................8

4.2. Storage..............................................................................................................8

5. Technical Data.......................................................................................................8

5.1. Purpose and Field of Use..................................................................................8

5.2. Function ............................................................................................................9

5.2.1. Pressure Build-up Function...........................................................................9

5.2.2. Pressure Build-up/Economizer Function.......................................................9

5.2.3. Safety Function.............................................................................................9

5.3. Product Data .....................................................................................................9

5.3.1. Operating Data 4186-1 ...............................................................................10

5.3.2. Operating Data 4186-3 ...............................................................................10

5.3.3. Technical Data 4186-1................................................................................10

5.3.4. Technical Data 4186-3................................................................................10

6. Installation ...........................................................................................................10

6.1. Handling Prior to Installation of the Regulator.................................................10

6.2. Information of Hazards During Installation, Operation and Maintenance ........10

6.3. Basic Installation Notes...................................................................................11

6.4. General Installation Notes...............................................................................11

6.5. Product-specific Installation Position and Installation Notes............................12

Operating and Installation Instructions

herose.com

Page 3

7. Operation and Maintenance ................................................................................12

7.1. Commissioning................................................................................................12

7.2. Adjusting the Nominal Working Pressure........................................................12

7.3. Maintenance and Repair of the Valve .............................................................14

7.4. Dismantling the Valve......................................................................................14

8. Other Applicable Documents...............................................................................15

9. Warranty..............................................................................................................15

10. EU Declaration of Conformity..................... Fehler! Textmarke nicht definiert.

11. Notes...............................................................................................................17

Operating and Installation Instructions

herose.com

Page 4

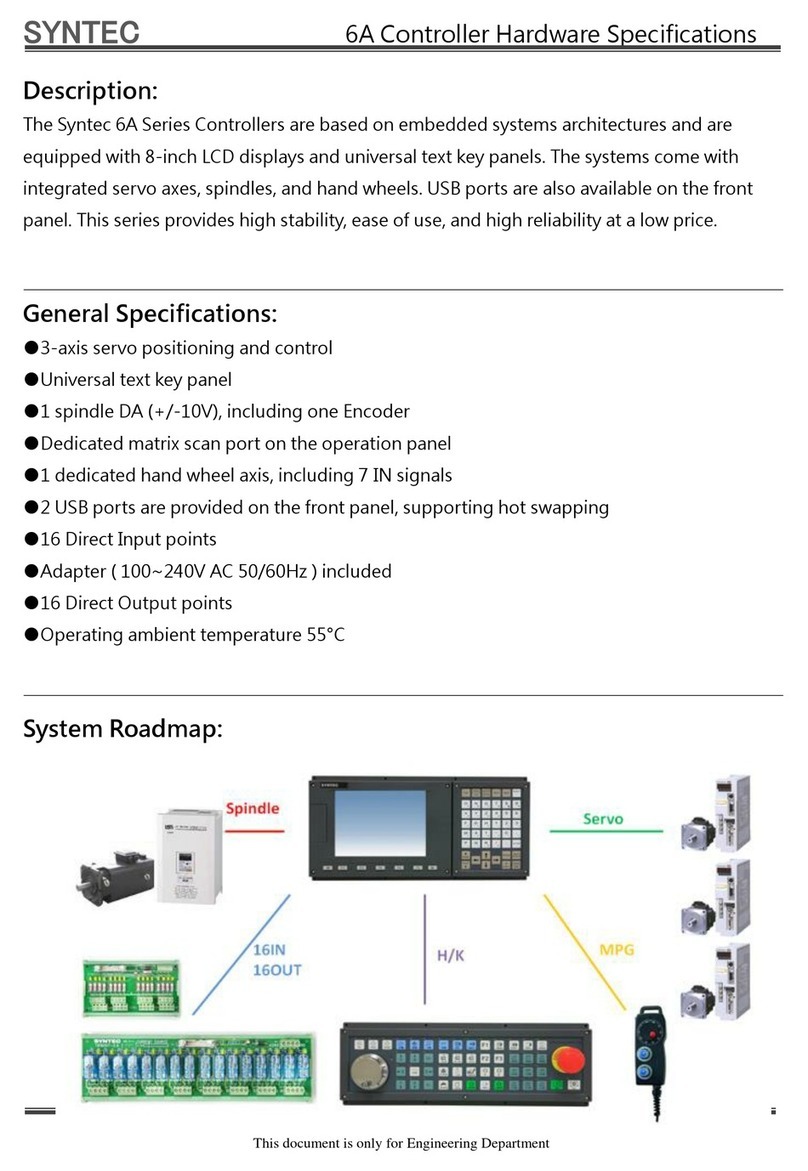

1. Schematic Illustration of Combi-Regulator

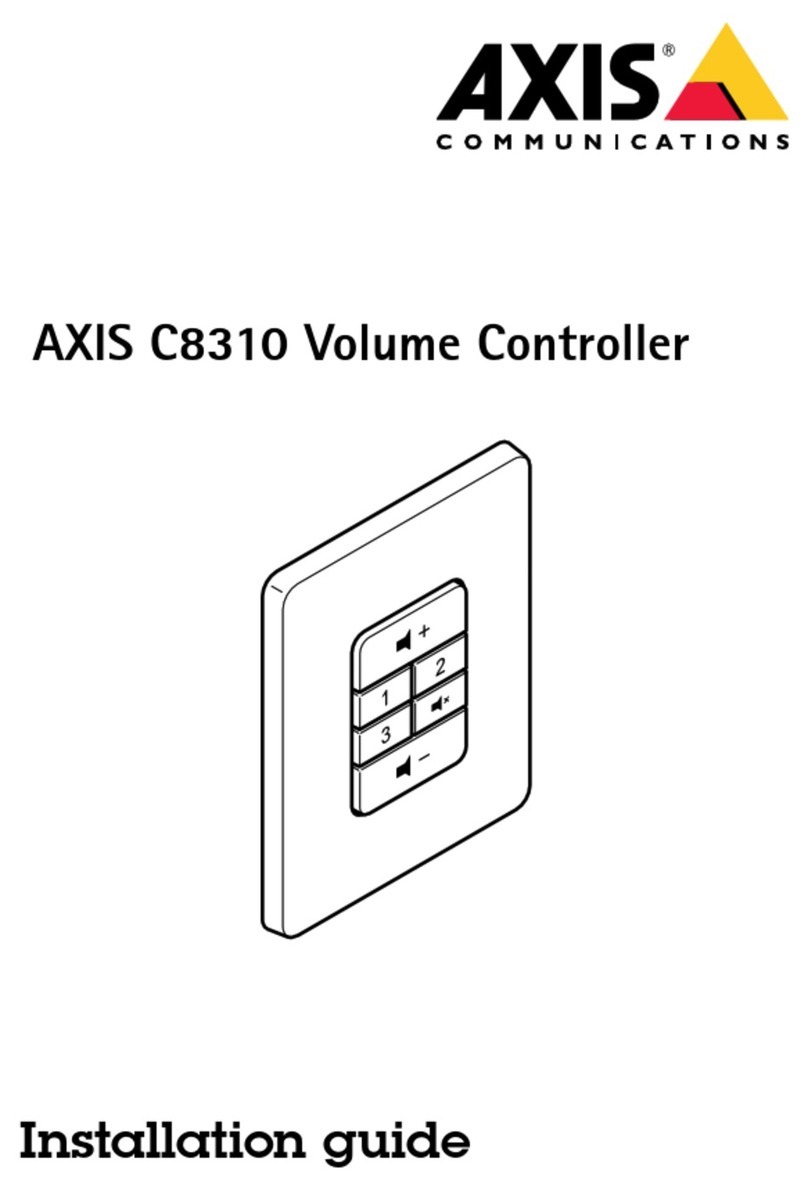

1.1. Illustration 4186-1

A

B

C

Einstellschraube SW 27

Kontermutter SW 30

Ø

Locknut SW 30

Set point screw SW 27

Operating and Installation Instructions

herose.com

Page 5

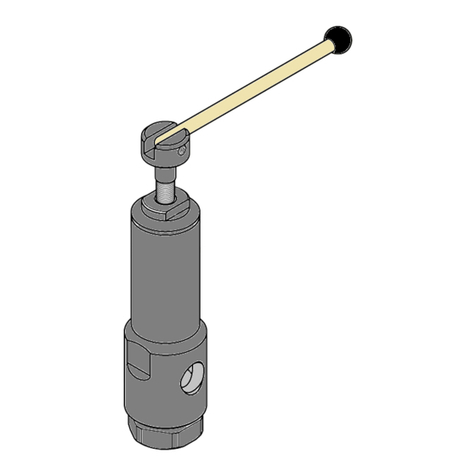

1.2. Illustration 4186-3

Locknut SW 19

Set point screw SW 14

Operating and Installation Instructions

herose.com

Page 6

2. General information About These Operating Instructions

These Operating Instructions contain the instructions for the safe installation and

operation of the valve in the proper manner. If difficulties occur, which cannot be

resolved with the aid of these Operating Instructions, please contact HEROSE

GMBH ARMATUREN UND METALLE for further information.

These Operating Instructions comply with the relevant currently valid EU safety

standards as well as the currently valid rules and regulations of the Federal

Republic of Germany. For use of the valve outside of the Federal Republic of

Germany, the operator, or the company responsible for the design of the system

must ensure that the current national regulations are complied with. HEROSE

GMBH reserves the right to make technical modifications and improvements at

any time. The use of these Operating Instructions assumes that the user is

qualified as described under section 2.4 "Qualified personnel". The operating

personnel must be instructed according to these Operating Instructions.

Certain rules and regulations apply according to the system and the medium.

These rules and regulations must be observed. In addition to the information in

these Operating and Installation Instructions, the general Industrial Health and

Safety regulations must be observed. Environmental regulations must also be

observed.

3. Safety

3.1. Symbols and Signal Words

Symbol / Signal Word

Significance

Indicates the use and effect of safety information.

Indicates possible material damage and other important

information.

Indicates a hazardous situation which may cause slight to

moderate injuries if it is not avoided.

Indicates a hazardous situation which may cause serious

injuries or death if it is not avoided.

Indicates a hazardous situation which will cause serious

injuries or death if it is not avoided.

Operating and Installation Instructions

herose.com

Page 7

3.2. Safety Related Definitions

The signal definitions DANGER, WARNING, WARNING and NOTE are used in

these Operating Instructions for information with regard to special hazards or for

extraordinary information which requires special labelling.

However, observation of the other transport, installation, operation and

maintenance information which is not specially emphasised, as well as the

technical data (in the Operating Instructions, the product documentation and on

the device itself) is equally important in order to prevent faults, which in turn may

directly or indirectly cause injury or damage.

3.3. Basic Safety Information

The safety and warning information is structured as follows:

Source of hazard

Results if the hazard is ignored.

Measures to prevent the hazard and avoid injuries.

Hazardous Media

Poisoning, caustic burns, burns, injuries.

Use suitable protective equipment

Use suitable collection containers

Wear suitable protective equipment

Foreign Bodies in the Regulator

Hazards due to failure or leaking regulator

Flush the system before installation.

Check the regulator for foreign bodies

Remove foreign bodies.

Residual Medium in the Regulator

Poisoning, caustic burns, burns, injuries.

Wear suitable protective equipment

Remove residual medium.

Leaking Regulator

Hazard due to media escaping because of damaged seals or sealing surfaces.

Protect the regulator from shocks and impacts, especially during

transport and installation.

Regularly check the regulator for leaks.

Operating and Installation Instructions

herose.com

Page 8

Hot Medium

Burns or scalds.

Wear suitable protective equipment

Hot Surfaces

Burns

Wear suitable protective equipment

Aggressive Medium

Caustic burns

Wear suitable protective equipment

3.4. Qualified Personnel

These are persons who are familiar with the installation, assembly, commissioning

and operation of the product and are properly qualified for their work and

functions. This includes, e.g. instruction and obligation to compliance with all

regional and company regulations and requirements for use, training or instruction

according to safety standards, with regard to the care for and use of proper safety

and industrial protective equipment, training in first-aid etc. (see also BetrSichV

[German Health and Safety Regulations] and its TRBS [Technical Rules for

Operating Safety]).

4. Transport and Storage

4.1. Transport

- Transport temperature: - 20°C to + 65°C

- - Protect against external effects (shock, impact, vibration and dirt)

4.2. Storage

- Storage temperature - 20°C to 65°C, dry and free from dirt

- In damp areas: Desiccant or heating is necessary to prevent the formation of

condensation.

5. Technical Data

5.1. Purpose and Field of Use

The HEROSE Combi-Regulator is used for automatic pressure regulation in fixed

tanks for liquid and cryogenic technical gases. Without auxiliary energy, the

Combi-Regulator ensures that in spite of temperature fluctuations, a constant, pre-

defined specified pressure is maintained in the tank during the entire period of

operation.

In addition to the pressure build-up function and the pressure

reduction/economizer function, the Combi-Regulator is equipped with a safety

function which protects the inlet piping and its components.

Operating and Installation Instructions

herose.com

Page 9

The field of use of the Combi-Regulator - under largely constant pressure

conditions - is the responsibility of the system planner. Special labelling of the

valve must be observed.

- Permitted operating media: Oxygen, nitrogen, argon, krypton, carbon dioxide,

nitrous oxide, chlorotrifluoromethane, trifluoromethane, carbon monoxide,

methane, ethane and ethylene

-Valves for use with oxygen are permanently marked with “O2”.

-Observe the max. P/T 30bar/60°C

It is essential to consult HEROSE in case of use with media which

require or exclude particular materials.

Compatibility between the medium and the housing or sealing

material is the responsibility of the operator.

5.2. Function

5.2.1. Pressure Build-up Function

If the pressure in the vessel is less than the nominal working pressure which is set,

the Combi-Regulator opens in order to restore the nominal working pressure.

Flow direction AB

5.2.2. Pressure Build-up/Economizer Function

If the pressure in the vessel exceeds the nominal working pressure by 0.5 bare,

the economizer function of the Combi-Regulator responds in order restore the

nominal working pressure.

Flow direction BC

5.2.3. Safety Function

If the pressure in the inlet line (upstream of connection A) exceeds the nominal

working pressure of the vessel by 5bar +10% (max. 5,5bar), the safety function

triggers and reduces the pressure in the corresponding section of the piping.

Flow direction AB+C

5.3. Product Data

The principle dimensions of the HEROSE Combi-Regulator can be obtained from the

illustrations on page 4 and page 5 of the Operating Instructions.

Operating and Installation Instructions

herose.com

Page 10

5.3.1. Operating Data

4186-1

5.3.2. Operating Data

4186-3

Nominal pressure:

PN50

PN40

Operating

temperatures

Medium

-196°C to +200°C

Ambient temperature

-40°C to +65°C

Max. working pressure

38bar

Care must be taken that the Combi-Regulator is only used in areas

where the temperatures, media and operating pressures stated in these

Operating Instructions are complied with.

5.3.3. Technical Data

4186-1

5.3.4. Technical Data

4186-3

KVS-/CV- Value

KVS=1.2 m³/h /

CV=1.4 gal/min

KVS=3.2 m³/h /

CV=3.7 gal/min

Safety function

Response pressure

5.0bar+10% (max.5.5bar) above working

pressure

Economizer function

Response pressure:

0.5 bar above working pressure

Working pressure

ranges

1-12bar

6-24bar

16-38bar

2-10bar

8-22bar

20-38bar

6. Installation

6.1. Handling Prior to Installation of the Regulator

If the valves are provided with protective caps, these must only be removed

immediately prior to installation.

Protect from dirt and weather, e.g. dampness.

Correct handling prevents damage!

The valves are free of oil and grease for use with oxygen. Only open the

packaging for use.

Clean all tools before starting work. Make sure they are free of oil and

grease.

6.2. Information of Hazards During Installation, Operation and Maintenance

Safe operation of the valve is only ensured if it is installed, commissioned and

maintained by qualified personnel (see Section 3.4 "Qualified personnel") in

accordance with the warning information in these Operating Instructions.

Operating and Installation Instructions

herose.com

Page 11

A

B

C

Top

Bottom

Set point screw

Locknut

In addition, compliance with the general installation and safety regulations for pipe

or plant construction, as well as the proper use of tools and protective equipment

must be ensured. It is essential that the Operating Instructions for the valve or the

instructions for using the valve are observed for all work. Failure to comply with

this may result in injury or material damage.

If sealing tape or liquid sealants are used, there is a danger that parts of

these may enter into the valve and impair its function or seal.

Avoid damage during installation!

Set the tightening torque so that damage to the connections is avoided.

Only use suitable tools, such as open-ended or ring spanners (ensure

suitability for O2)

6.3. Basic Installation Notes

Tension free installation must be ensured

The valve must not serve as a fixed point, it is supported by the piping

system,

The connecting piping must be connected without force or torsion.

Valves must be protected against dirt, especially during construction work

: Free from oil and grease for use with O2,

Expansion of the piping due to heat must be compensated by the use of

compensators,

Do not paint!

6.4. General Installation Notes

In addition to the basic installation

regulations, the following points must be

taken into account:

Visual examination of the labelling

(see 5.3) with regard to the conditions

of use and operating pressure

Visual examination for external

damage. Do not install damaged

valves.

Remove protective caps or covers if

present.

The space inside the valve and the

pressure vessel must be free of foreign

bodies.

At low or high surface temperatures,

appropriate protection must be

provided or the operating personnel

must be informed.

Figure 1: Installation position

Operating and Installation Instructions

herose.com

Page 12

6.5. Product-specific Installation Position and Installation Notes

The HEROSE Combi-Regulator must be installed in the system according to the

flow direction (AB) with the major axis –in which the two connections A and B

are located –in a horizontal installation position without tension. During and after

installation, connection C must point vertically upward.

The set point screw for the working pressure points vertically downwards. (see

Figure 1) This installation position applies to both the Combi-Regulator 4186-1 and

the Combi-Regulator 4186-3. The illustration is purely schematic.

The Combi-Regulator must be installed in the system so that it is easily

accessible, e.g. for maintenance and changes to the nominal working pressure.

The system planner must design the plant system for at least the working pressure

plus the response pressure of the safety function.

7. Operation and Maintenance

7.1. Commissioning

Prior to commissioning, the details of the material, pressure, temperature and

installation position must be checked against the plan of the piping system.

The BetrSichV [German Health and Safety Regulations] and its TRBS

[Technical Rules for Operating Safety] must be observed,

Residues in the piping and valve (dirt, welding beads, etc.) will inevitably

result in leaks.

The following must be ensured before each commissioning of a new system or the

recommissioning of a system after repairs or conversion work:

Correct completion of all installation and assembly work,

Commissioning must only be carried out be "Qualified personnel" (see

Section 3.4)

The correct functional position of the valve must be ensured and

Existing guards must be installed or repaired.

7.2. Adjusting the Nominal Working Pressure

On delivery, the Combi-Regulator is set to a pre-defined working pressure.

Depending on the delivered working pressure range, the Combi-Regulator is set

accordingly. At the request of the customer, the Combi-Regulator can be pre-set to

a specific working pressure.

Working pressure range

Combi-Regulator

4186-1

Combi-Regulator

4186-3

1-12bar

6-24bar

16-38bar

2-10bar

8-22bar

20-38bar

Pre-set nominal working

pressure

8bar

12bar

20bar

8bar

12bar

20bar

Nominal working

pressure change per

rotation

1.3bar

2bar

3bar

0.8bar

1.7bar

2.7bar

Table 1: Nominal working pressure

Operating and Installation Instructions

herose.com

Page 13

0

5

10

15

20

25

30

35

40

0 1 2 3 4 5 6 7 8 9 10 11 12

Nominal working pressure [bar]

Rotations of set point screw

Adjustment diagram: Nominal working

pressure

Combi-Regulator 4186-3

20-

8-

2-

To set or correct a nominal working pressure, adjust the set point screw of the

Combi-Regulator:

Clockwise rotation

The nominal working pressure is increased

Counter-clockwise rotation

The nominal working pressure is reduced

The value for the change to the nominal working pressure per rotation of the screw

must be obtained either from Table 1 or Adjustment diagram 1.

If pressure gauges are used in the system it is recommended that the

Combi-Regulator is adjusted according to the values indicated on the pressure

gauge. If the system does not provide this facility adjustment of the nominal

working pressure can be carried out on the basis of Adjustment diagram 1.

To adjust the nominal working pressure, loosen the lock nut and adjust the set

point screw accordingly. Once the required nominal-working pressure has been

set, the set point screw must be secured again with the lock nut.

0

5

10

15

20

25

30

35

40

0 1 2 3 4 5 6 7 8 9 10 11 12

Nominal working pressure [bar]

Rotations of set point screw

Adjustment diagram: Nominal working

pressure

Combi-Regulator 4186-1

16-

6-

1-

Adjustment diagram 1: Nominal working pressure

Operating and Installation Instructions

herose.com

Page 14

7.3. Maintenance and Repair of the Valve

The maintenance and maintenance intervals must be specified by the operator

according to the conditions of use, see BetrSichV [German Health and Safety

Regulations] and the associated TRBS [Technical Rules for Operating Safety]

Series 1000 and 2000.

All maintenance, repair and commissioning work must only be carried out by

qualified personnel who are familiar with the installation, commissioning and

operation of the product.

Hazards may be caused by the operating pressure during maintenance or

dismantling. The section of the system must be depressurised. The Combi-

Regulator must be removed from the piping for maintenance.

During (external) cleaning, take care that no chemical agents are used which

affect the properties of the materials. During cleaning, take care that the

adjustment of the set point screw is not changed and that the lock nut is firmly

screwed against the spring cover.

During repairs, maintenance and cleaning, the condensation drain hole in the

spring cover must be visually inspected regularly and any dirt must be removed.

Repairs may only be performed by HEROSE or by specialist workshops

authorised by HEROSE, with the exclusive use of original spare parts. The contact

details for workshops authorised by HEROSE can be found on the HEROSE

homepage (http://www.herose.com).

7.4. Dismantling the Valve

In addition to the generally valid installation guidelines and the BetrSichV [German

Health and Safety Regulations] and its TRBS [Technical Rules for Operating

Safety] Series 1000 and 2000, the following points must be observed:

The piping system must be depressurised

The medium and the valve must be cooled to the ambient temperature

The system must be drained

Purge the piping system in case of aggressive or caustic media

Installation must only be performed by "Qualified personnel" (see Section

3.4)

Escaping Medium

Hazard to humans and the environment

Take safety precautions appropriate to the medium

Collect the medium from the piping system

Do not allow unauthorised persons into the danger area.

Wear suitable protective equipment

Operating and Installation Instructions

herose.com

Page 15

8. Other Applicable Documents

Pressure equipment directive 2014/68/EU

For installation in Germany

Druckgeräteverordnung (14.ProdSV) [Pressure Equipment Regulation]

Betriebssicherheitsverordnung (BetrSichV) [German Health and Safety

Regulations]

Technical Rules for Operating Safety (TRBS)

Other EU Countries

Relevant national regulations

9. Warranty

The scope and period of warranty is stated in the current version of the "General

Terms and Conditions of Business of HEROSE GMBH" which is valid at the time

of delivery, or in deviation from these, in the purchase contract. No warranty can

be accepted for damage which is due to incorrect handling or failure to observe

these Operating and Installation Instructions, regulations by the employers' liability

insurance associations for industrial health and safety, or EN, DIN, VDE standards

and other rules.

Damage which occurs during operation due to conditions of use which deviate

from the conditions of use specified in the data sheet or in other agreements are

also not subject to warranty. Claims which exceed those covered by the warranty

are excluded. There is no entitlement to the supply of replacements. Maintenance

work, installation of third party components, modifications to the construction as

well as natural wear and tear are excluded from the warranty. Any transport

damage should not be reported to us, but rather to the responsible goods handling

department of the railway or carrier, as otherwise claims for compensation against

these companies may become invalid.

Operating and Installation Instructions

herose.com

Page 16

Operating and Installation Instructions

herose.com

Page 17

10. Notes

This manual suits for next models

2

Table of contents

Other HEROSE Controllers manuals

Popular Controllers manuals by other brands

ABB

ABB ACQ80 Firmware manual

Extron electronics

Extron electronics MediaLink Controllers with IP Link MLC 104 IP... Specification sheet

Lumens

Lumens VS-KB30 Firmware upgrade

Syntec instruments

Syntec instruments 6A Series Hardware specifications

Motoman

Motoman NX100 Function manual

roco

roco MultiMAUS manual