INST.No.INE-868G [DB600] General Instruction Manual

- 2 -

Table of contents

Introduction....................................................... 1

Table of contents .............................................. 2

1Before use ........................................ 4

1-1 For safe use of the product...................... 4

1-1-1

Preconditions for use.............................. 4

1-1-2

Cautions for long term usage.................. 4

1-1-3

Symbol mark........................................... 5

1-1-4

Request for opening and handling.......... 5

1-1-5

Important ................................................ 6

1-2 Before use ............................................... 7

1-2-1

Confirm the accessories ......................... 7

1-2-2

Confirm the exterior ................................ 7

1-2-3

Confirm the model code ......................... 7

1-2-4

Model code list........................................ 8

1-3 Mounting condition................................. 13

1-3-1

Environment ......................................... 13

1-3-2

Surrounding condition........................... 13

1-3-3

Mounting conditions.............................. 13

1-3-4

Others................................................... 13

2Mounting and wiring....................... 14

2-1 External dimensions .............................. 14

2-1-1

Unit dimensions .................................... 14

2-1-2

Panel cutout and mounting dimensions 15

2-2 Mounting ................................................ 17

2-2-1

Panel mounting..................................... 17

2-2-2

Waterproof specifications ..................... 18

2-3 Wiring..................................................... 19

2-3-1

Precautions during wiring ..................... 19

2-3-2

Insulation block..................................... 20

2-3-3

Terminal number and functionality ........ 20

2-3-4

Basics of wiring..................................... 30

2-3-5

Example of wiring ................................. 32

2-4 Trial operation ........................................ 35

2-4-1

Confirmations before operation ............ 35

2-4-2

Procedure of trial operation .................. 36

2-5 Initial settings ......................................... 37

2-5-1

Initialize parameter ............................... 38

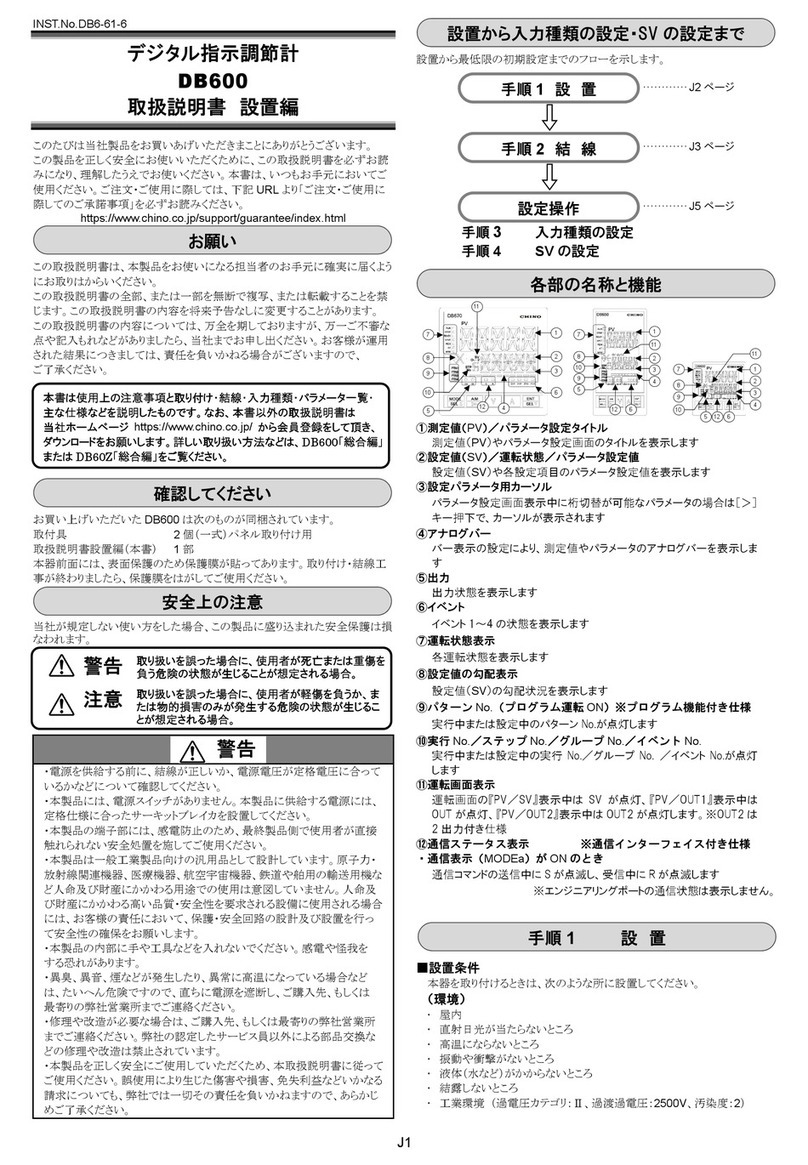

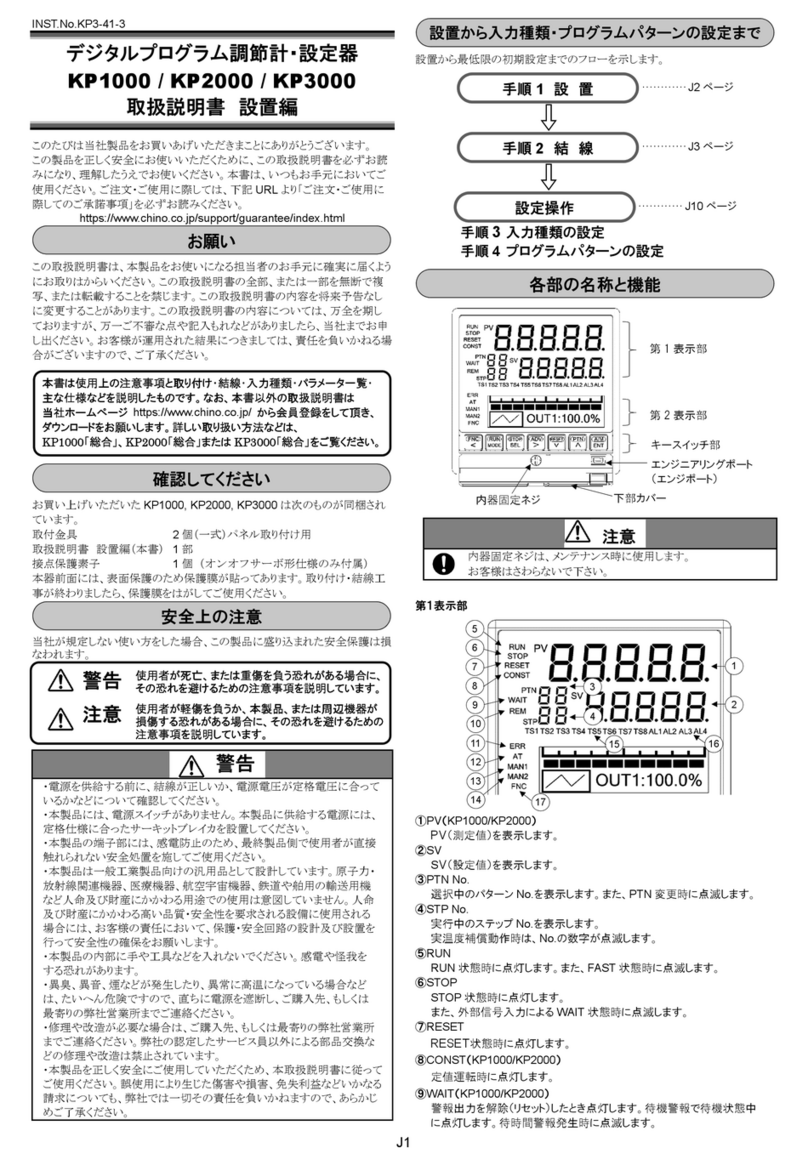

3Names of various parts.................. 39

3-1 Entire overview ...................................... 39

3-2 Name and function of display ................ 40

3-3 Character display................................... 42

3-4 Name and function of key ...................... 42

4Operation ........................................ 43

4-1 Cautions on power ON .......................... 43

4-2 Operation on power ON........................ 43

4-3 Constant value operation....................... 44

4-3-1

Setting overview ................................... 44

4-3-2

Setting item screen and function .......... 44

4-3-3

RUN/READY status.............................. 51

4-4 Program operation ................................. 52

4-4-1

Setting overview ................................... 52

4-4-2

Setting item screen and function .......... 52

4-4-3

Program operation method................... 60

4-5 AUTO

/

MANUAL output operation ............ 61

4-6 Cautions for operation ........................... 62

4-6-1

Setting/changing a parameter during

operation............................................... 62

4-6-2

Cautions for SV slope operation ........... 62

5Setting operations ......................... 63

5-1 Basics of setting......................................63

5-1-1

Setting item screen display ...................63

5-1-2

Basic operations on the setting screen .64

5-1-3

How to operate parameter setting.........65

5-1-4

Precautions for setting ..........................67

5-2 MODE0 [Executing parameter]...............68

5-2-1

Setting overview ...................................68

5-2-2

Setting item screen and function...........68

5-2-3

Changing an executing step .................71

5-2-4

Output limiter ........................................71

5-3 MODE1 [Constant value operation

parameter] ..............................................72

5-3-1

Setting overview ...................................72

5-3-2

Setting item screen and function...........72

5-3-3

SV rate of change .................................73

5-3-4

Constant value operation PV start ........73

5-4 MODE2 [Program parameter].................74

5-4-1

Setting overview ...................................74

5-4-2

Setting item screen and function...........74

5-4-3

Program pattern setting ........................80

5-4-4

Selecting the start method for program

operation...............................................82

5-4-5

Execution No. selection for program

operation...............................................82

5-4-6

Program pattern link (connection).........82

5-4-7

Output at program end (output 1 and 2 at

END).....................................................82

5-5 MODE3 [Group parameter] ....................83

5-5-1

Setting overview ...................................83

5-5-2

Setting item screen and function...........83

5-5-3

Setting 8 parameters for each group ....85

5-6 MODE4 [Event parameter] .....................86

5-6-1

Setting overview ...................................86

5-6-2

Setting item screen and function...........86

5-6-3

Event mode...........................................88

5-6-4

Event extension function.......................88

5-6-5

Event deadband....................................89

5-6-6

Event output phase...............................89

5-7 MODE5 [Input parameter] ......................90

5-7-1

Setting overview ...................................90

5-7-2

Setting item screen and function...........90

5-7-3

Input type, measuring range, and linear

scale .....................................................92

5-7-4

Input correction .....................................93

5-7-5

SV limiter ..............................................93

5-8 MODE6 [Control parameter]...................94

5-8-1

Setting overview ...................................94

5-8-2

Setting item screen and function...........94

5-8-3

Pulse cycle............................................97

5-8-4

Feedback input .....................................98

5-8-5

PID deadband/output deadband ...........98

5-8-6

Control action........................................98

5-8-7

Output variation limiter ..........................99

5-8-8

Fixed output setting ..............................99

5-8-9

Control algorithm ..................................99

5-9 MODE7 [Output 2 parameter]...............100

5-9-1

Setting overview .................................100

5-9-2

Setting item screen and function.........100

5-9-3

Output 2 control system......................103

5-10 MODEa [Communication parameter] ...104

5-10-1

Setting overview .................................104

5-10-2

Setting item screen and function.........104