HESCH HE 5760 User manual

# 372449 | Version 3.2

Filter Control

HE 5760

Operating instructions

(Translation of Original German version)

2

HE 5760 Operating Instructions

# 372449| Version 3.2

Imprint

HESCH Industrie-Elektronik GmbH

Boschstraße 8

31535 NEUSTADT, GERMANY

Phone: +49 5032 9535–0

Fax: +49 5032 9535-99

Internet: www.hesch-automation.com

Email: [email protected]

District Court Hanover

HRB 111184

VAT.-Id. No. DE813919106

General Management

Werner Brandis

Published by:

HESCH Industrie-Elektronik GmbH, Documentation Department

Copyrights

© Copyright 2021 HESCH Industrie-Elektronik GmbH. All rights reserved.

The content including pictures and the design of these operating

instructions are subject to copyright protection and other laws for the

protection of intellectual property. The modification of the contents of this

operating instructions is prohibited. In addition, this content may not be

copied, distributed, modified or made available to third parties for

commercial purposes.

HE 5760 Operating Instructions

# 372449 | Version 3.2

3

Document history

Date / Version

Description / Author

04.07.2014 / 3.0

Document history added. Version no. added. Layout change title page,

imprint added. Section 3.5 amended): Description changed. Section 1.3

amended. HE 1149 Image updated. Chapter 1.3.4 (HE 5410) Picture

updated.

18.01.2019 / 3.1

System expansion: I&C interface (Modbus / Profibus) / Bg

15.12.2020 / 3.2

Document transferred to new layout, new parameters, chapter 12

Central dust monitoring added / Bg

4

HE 5760 Operating Instructions

# 372449| Version 3.2

TABLE OF CONTENTS

1LEGAL PROVISIONS................................................................................................................................... 6

2SAFETY INFORMATION ............................................................................................................................. 7

2.1 SYMBOLS AND BASIC SAFETY INSTRUCTIONS...................................................................................................... 7

2.2 SIGNAL WORDS............................................................................................................................................ 7

2.3 SAFETY IN THE INDIVIDUAL OPERATING PHASES................................................................................................... 8

3TECHNICAL DATA.................................................................................................................................... 10

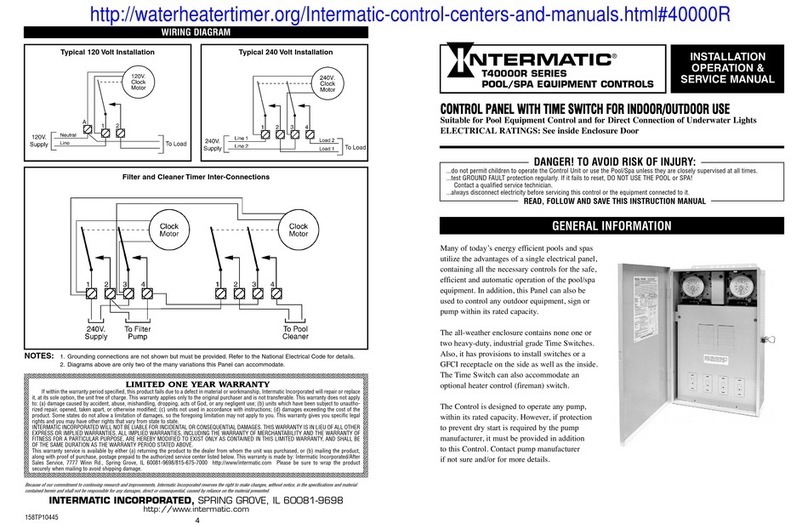

4MOUNTING ............................................................................................................................................ 11

4.1 DIMENSIONS ............................................................................................................................................. 11

5SYSTEM OVERVIEW ................................................................................................................................ 12

5.1 SYSTEM COMPONENTS ................................................................................................................................ 12

5.1.1 Master control HE 5760................................................................................................................. 12

5.1.2 HE 5725 ......................................................................................................................................... 13

5.1.3 HE 1149 ......................................................................................................................................... 13

5.1.4 Differential pressure transmitter HE 5410 .................................................................................... 14

5.2 FILTER SYSTEM........................................................................................................................................... 14

6DISPLAY AND OPERATING ELEMENTS ..................................................................................................... 15

7ELECTRICAL COMMISSIONING ................................................................................................................ 16

7.1 ELECTRICAL CONNECTION HE 5760............................................................................................................... 17

7.1.1 Local operation through control signals........................................................................................ 18

7.2 ELECTRICAL CONNECTION HE 5725............................................................................................................... 19

7.3 CAN NETWORK CONFIGURATION................................................................................................................... 20

7.3.1 CAN address assignment............................................................................................................... 20

7.3.2 CAN address setting on HE 5725 ................................................................................................... 21

7.3.3 CAN termination............................................................................................................................ 21

7.3.4 Termination on HE 5760 and HE 5725........................................................................................... 22

7.4 SYSTEM START-UP ...................................................................................................................................... 23

8OPERATION ............................................................................................................................................ 24

8.1 ACTUAL VALUE IMAGE................................................................................................................................. 24

8.2 ALARM SCREENS ........................................................................................................................................ 25

8.3 CHAMBER CONTROL.................................................................................................................................... 26

8.4 INFO SCREEN ............................................................................................................................................. 26

8.5 COMMUNICATION STRUCTURE...................................................................................................................... 27

9PARAMETERISATION .............................................................................................................................. 28

9.1 SMARTTOOL.............................................................................................................................................. 28

9.2 PARAMETER TABLE ..................................................................................................................................... 29

9.3 DESCRIPTION OF THE PARAMETERS ................................................................................................................ 31

9.3.1 System description ........................................................................................................................ 31

9.3.2 On site service ............................................................................................................................... 32

9.3.3 Interfaces....................................................................................................................................... 32

9.3.4 Valve control ................................................................................................................................. 33

9.3.5 Overall cleaning (cleaning process)............................................................................................... 35

9.3.6 Chamber control............................................................................................................................ 36

9.3.7 Operating hours ............................................................................................................................ 36

9.3.8 Service ........................................................................................................................................... 37

9.3.9 Autostart / Timeout....................................................................................................................... 37

9.3.10 Passwords...................................................................................................................................... 37

9.3.11 Measuring ranges.......................................................................................................................... 38

HE 5760 Operating Instructions

# 372449 | Version 3.2

5

9.3.12 Error evaluation............................................................................................................................. 38

9.3.13 Dust monitoring............................................................................................................................. 39

9.3.14 dp regulation ................................................................................................................................. 41

10 ERROR MESSAGES............................................................................................................................... 43

10.1 SYSTEM START-UP ...................................................................................................................................... 43

10.2 ALARM SCREENS ........................................................................................................................................ 44

10.2.1 Sensor error ................................................................................................................................... 44

10.2.2 Misprint ......................................................................................................................................... 45

10.2.3 Valve control Bus error .................................................................................................................. 45

10.2.4 Valve error..................................................................................................................................... 46

10.2.5 Valve control tank pressure sensor error....................................................................................... 46

10.2.6 Valve control Tank pressure error (sensor is OK)........................................................................... 46

11 COMMUNICATION.............................................................................................................................. 47

11.1 MASTER (HE 5760) -SLAVE (HE 5725) COMMUNICATION .............................................................................. 47

11.2 DATA DIRECTION PROCESS CONTROL TO HE 5760 ............................................................................................ 48

11.3 DATA DIRECTION HE 5760 TO PROCESS CONTROL ............................................................................................ 50

11.4 DIAGNOSIS HE 5760 ON PROCESS CONTROL ................................................................................................... 53

12 CENTRAL DUST MONITORING (APPLIES FROM SOFTWARE VERSION 2.10).......................................... 55

12.1 RESET OF DUST VALVES................................................................................................................................ 56

13 MAINTENANCE AND SERVICE.............................................................................................................. 57

14 GLOSSARY........................................................................................................................................... 58

6

HE 5760 Operating Instructions

# 372449| Version 3.2

1 Legal Provisions

Manufacturer

HESCH Industrie-Elektronik GmbH, Boschstraße 8, 31535 NEUSTADT | GERMANY

Intended use

The HE 5760 is a master-slave control for the cleaning process of industrial dust

extraction systems.

The expansion to a complete cleaning control system is carried out with the HE 5725

valve controllers, each of which controls 12 valves. Up to 48 valve controllers can be

centrally controlled as CAN slaves by the HE 5760. The valves are assigned to so-

called filter chambers. The control is set to the existing number of chambers and

valves using the parameter menu. Parameterisation can also be carried out with the

PC software 'SmartTool' via the USB interface.

The HE 5760 control unit is located in a front-mounted housing with membrane

keypad and graphic display and is designed for installation in control cabinets. Local

operation at the control cabinet with switchgear and signal lamps that are connected

directly is possible.

The device can be operated within the operating and environmental conditions

approved in these operating instructions without impairing its safety.

The manufacturer is not liable for improper use and any resulting personal injury or

material damage; the risk is borne solely by the user. Failure to comply with the above

criteria for intended use will result in the expiry of the warranty and liability for the

device.

Personnel qualification

All work on the differential pressure transducer may only be carried out by qualified

electricians with sufficient knowledge in the field of electrical engineering.

Device Safety

The device has been constructed and tested in accordance with VDE 0411 / EN 61010-1 and

has left the factory in perfect safety condition. To maintain this condition and ensure safe

operation, the user must follow all instructions and warnings in this quick guide.

HE 5760 Operating Instructions

# 372449 | Version 3.2

7

2 Safety Information

2.1 Symbols and Basic Safety Instructions

This chapter contains important safety regulations and notes. To protect against personal

injury and material damage, it is necessary to read this chapter carefully before working with

the device.

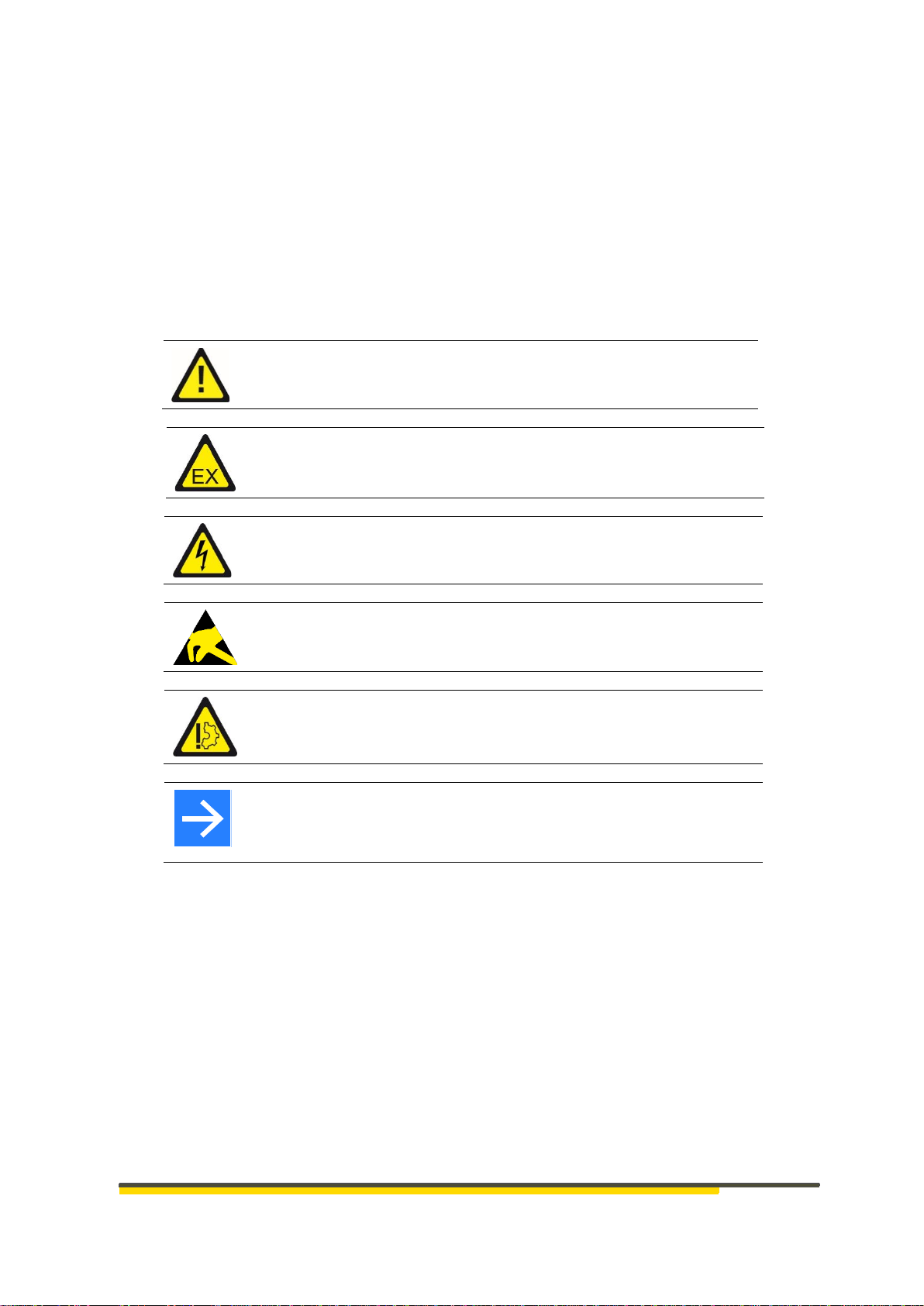

Symbols used

The following symbols are used in this manual. All safety instructions have a uniform structure.

Personal Injury Warning!

The severity of the danger is indicated by the respective signal word.

Explosive region warning sign!

High Voltage Warning!

Warning of material damage caused by electrostatic charge!

Property Damage Warning!

Note!

Identifies possible malfunctions and indicates optimum operating

conditions.

2.2 Signal words

DANGER!

Indicates an imminently hazardous high risk situation, which, if not avoided, will result in death

or serious injury.

WARNING!

Indicates a potentially hazardous medium risk situation, which, if not avoided, could result in

death or serious injury.

CAUTION!

Indicates a hazardous low risk situation, which, if not avoided, could result in minor or

moderate injury.

8

HE 5760 Operating Instructions

# 372449| Version 3.2

2.3 Safety in the individual operating phases

When installing the device and during operation, the following safety instructions must be

observed.

Danger of Electrocution!

Before working on the device, switch off all power supplies used. The

electrical cables must be laid according to the respective national

regulations (in Germany VDE 0100). The measuring cables must be laid

separately from the power lines. The connection between the connector

for the functional earth (in the respective equipment carrier) and a

protective earth must be established.

Danger of Electrocution!

Any interruption of the protective earth in the equipment carrier can result

in the device becoming a hazard. Intentional interruptions are not

permitted. If there is a suspicion that it is no longer possible to operate

the device safely, it must be shut off and secured against being

unintentionally switched on.

Danger of Electrocution!

Do not open the device when it is connected to the voltage! When

opening the devices or removing covers and parts, live parts may be

exposed. Connection points can also be live!

Attention!

The device must never be put into operation even if damage is

recognisable.

Attention!

During installation, commissioning, maintenance and troubleshooting,

observe the accident prevention regulations applicable to your system,

e.g. DGUV Regulation 3 "Electrical installations and equipment".

Attention!

Clean dirty contacts with oil-free compressed air or ethyl alcohol and a lint-

free cloth.

Warning of material damage caused by electrostatic charge!

Observe the safety measures according to BS EN 61340-51/-3 to avoid

electrostatic discharge!

HE 5760 Operating Instructions

# 372449 | Version 3.2

9

Power Connection!

The electrical cables must be laid according to the respective national

regulations (in Germany VDE 0100). The measuring cables must be laid

separately from the power lines.

Troubleshooting!

At the beginning of troubleshooting, all possible sources of faults on

additional devices or supply lines (measuring lines, wiring, downstream

devices) should be taken into consideration. If the fault is not found after

checking these points, we recommend sending the device to the supplier.

Decommissioning!

Switch off the power supply on all poles if the device is to be

decommissioned. Secure the device against being unintentionally

switched on!

If the device is linked to other devices and/or equipment, consider the

impacts and take appropriate precautions before switching it off.

10

HE 5760 Operating Instructions

# 372449| Version 3.2

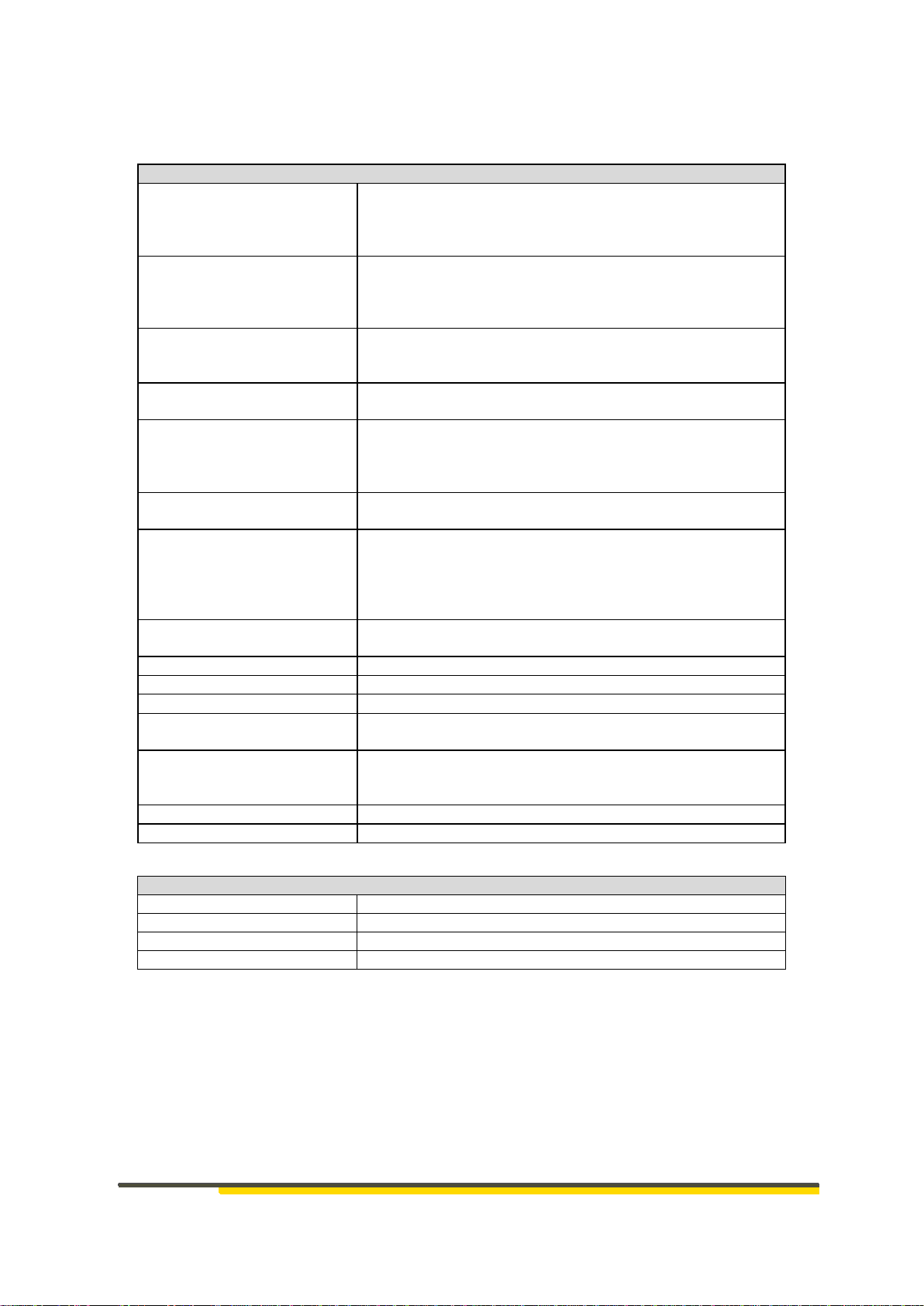

3 Technical data

Subject to technical changes without notice!

Technical Data

Supply:

-24 V( 22…26 V AC)

-galvanically separated

-0.3 A typical

-5 A maximum

Display:

-graphic LC display

-Resolution: 128 × 64 7938

-display area: 66 × 33 mm

-Colour: yellow green

LEDs

-operation: green

-Cleaning active: yellow

-Alarms: red

Keys:

-menu operation: ESC, F1, F2, ENTER

-navigation and value entry: LEFT, RIGHT, UP, DOWN

Processor:

-Fujitsu MB96F348

-544 kB Flash / 280 kB RAM

-1 MB flash for parameters and data

-Real-time clock optional

Ports

-CAN interface, galvanically isolated, 50 kBit/s

control interface: Modbus RTU, Profibus

Inputs:

-5 Digital inputs 24 V DC, galvanically isolated, for local

operation: Operation on the control cabinet with keys and

indicator lights

-2 analogue inputs 4...20 mA for system pressure and

differential pressure, accuracy: 0.1%

Outputs:

4 digital outputs 24 V DC, 1A, short-circuit proof, for local

operation

Housing

Switch panel housing

Dimensions:

196 × 126 × 40 mm (W × H × D)

Excerpt:

166 × 96 mm (W × H)

IP protection class:

-IP 65 Front

-IP 20 Rear

Electrical connections

USB interface connector type B,

Screw terminals for supply, CAN, local operation,

measurement

Interference immunity:

DIN EN 61000-6-2 and DIN EN 61326-1

Emitted interference

DIN EN 61000-6-3 and DIN EN 61326-1

Environmental Weather Conditions

Operation:

-10…+55 °C

Storage:

-25…+60 °C

Transport

-25…+85 °C

Ambient humidity:

75% rel. humidity, no condensation

HE 5760 Operating Instructions

# 372449 | Version 3.2

11

4 Mounting

The ambient temperature at the installation point must not exceed the

permissible temperature for nominal use specified in the technical data.

4.1 Dimensions

The HE 5760 is a panel-mounted unit with the following dimensions:

Figure 1 HE 5760 Dimensions

Scope of Delivery

HE 5760 Premium

Operating instructions

Note!

Check the delivery upon receipt for completeness and for visible defects.

In the event of a complaint, contact our HESCH Service immediately (see

chapter 13 Maintenance and Service).

12

HE 5760 Operating Instructions

# 372449| Version 3.2

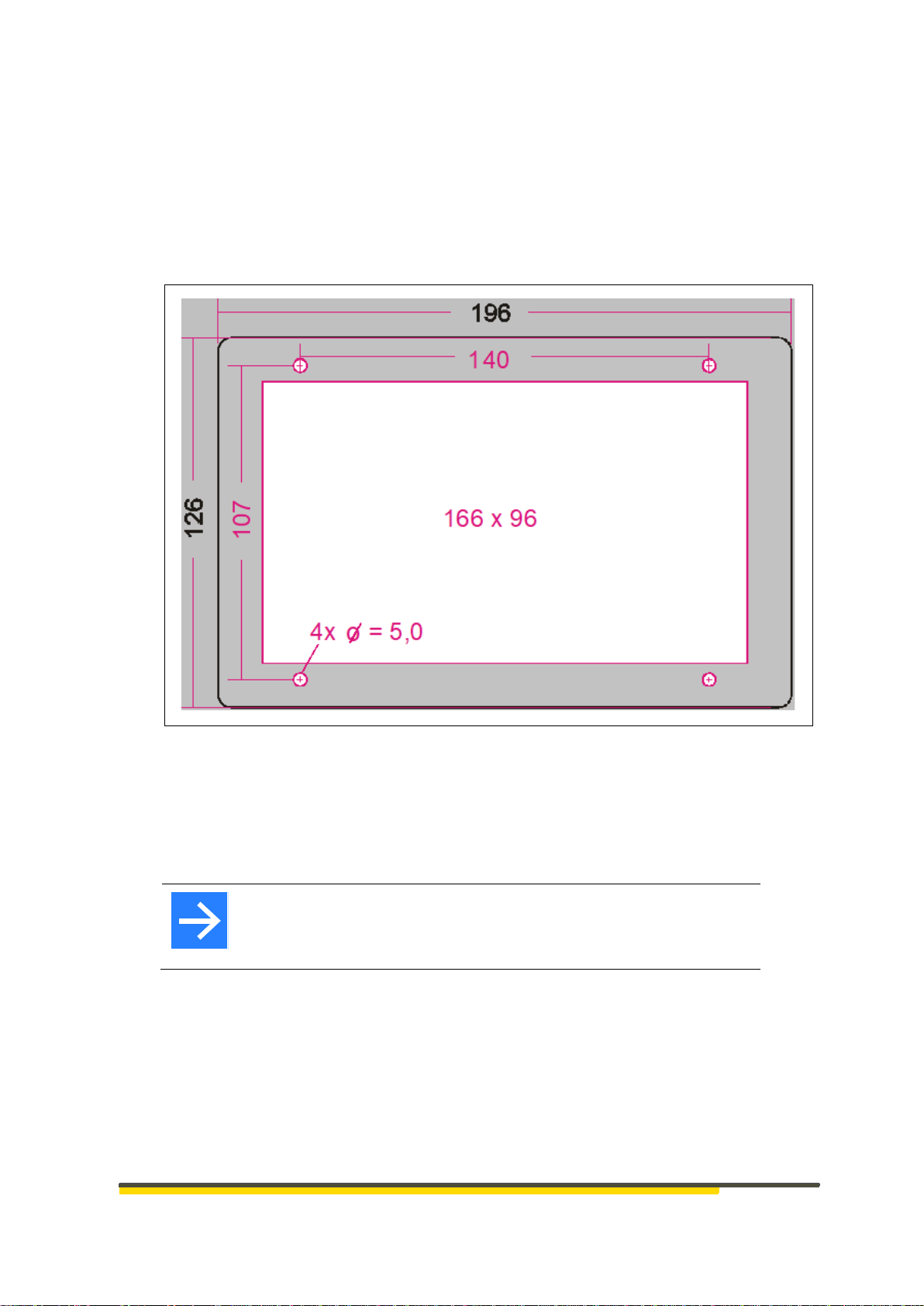

5 System overview

HE5725 HE 5725 HE 5725 HE 5725

CAN

Figure 2 System overview HE 5760 / HE 5725

5.1 System components

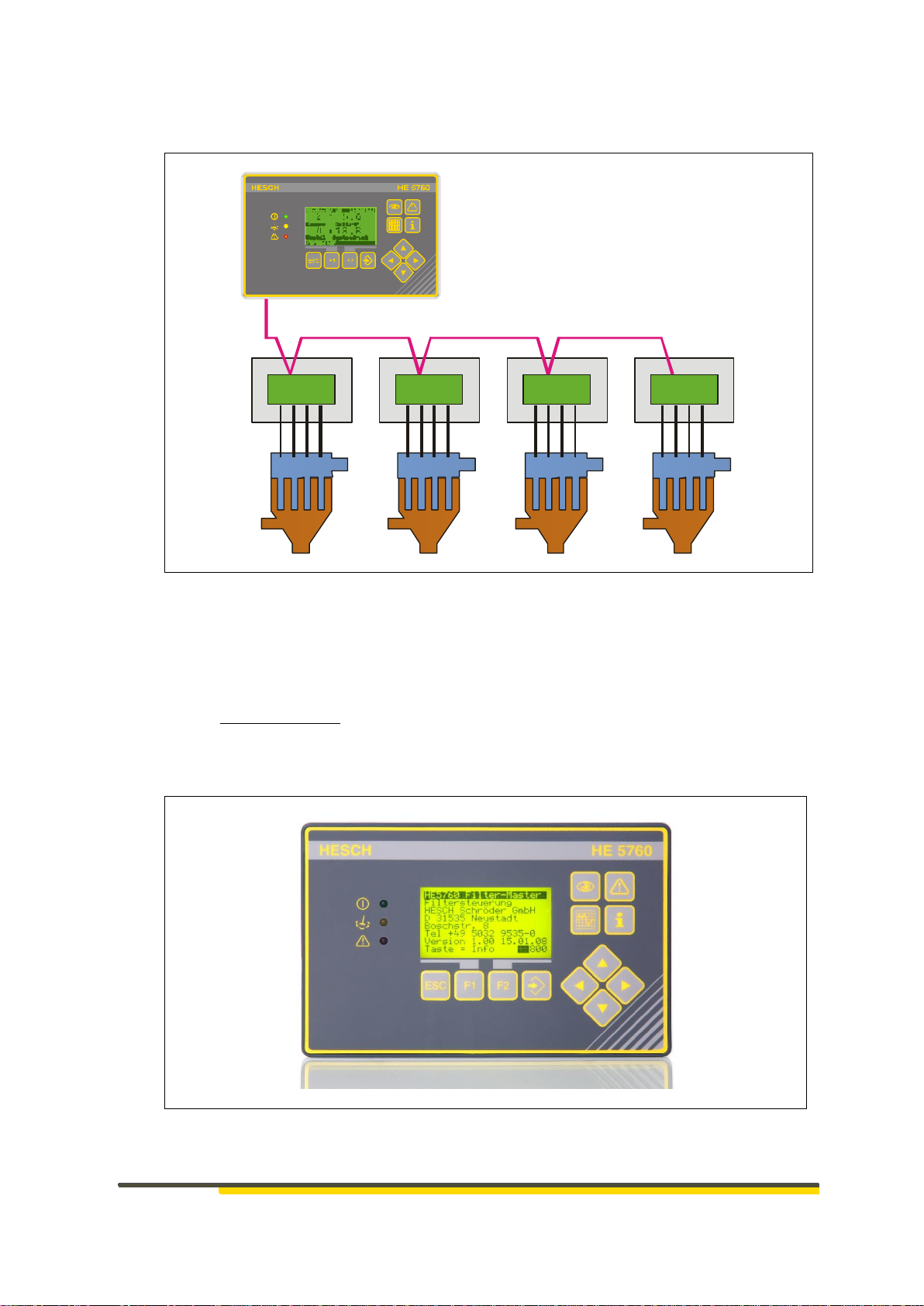

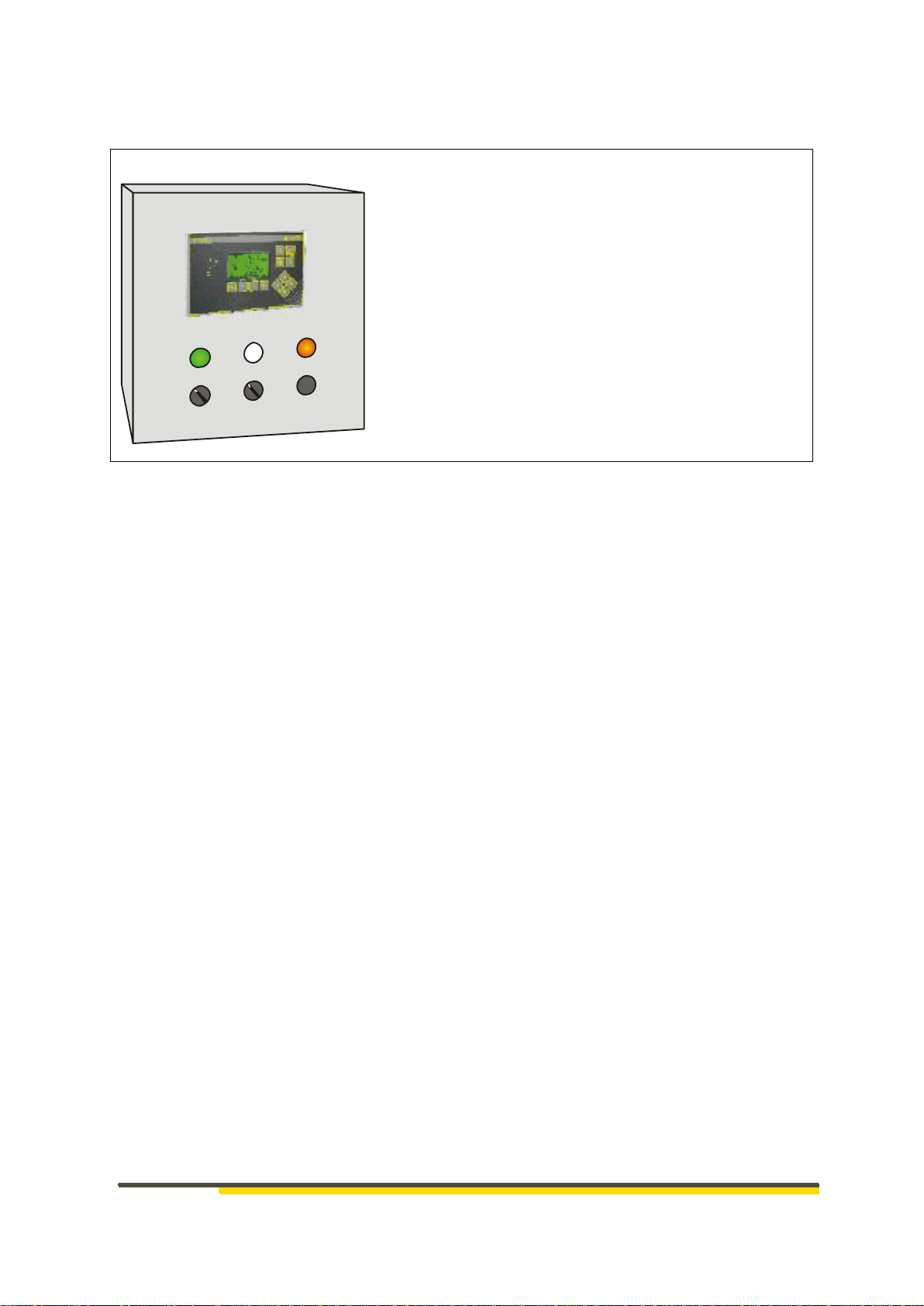

5.1.1 Master control HE 5760

Central control of the filter system

To be connected:

CAN line,

Pressure sensor for system pressure and differential pressure

Keys and indicator lights for local operation, if desired.

Figure 3 HE 5760

HE 5760 Operating Instructions

# 372449 | Version 3.2

13

5.1.2 HE 5725

Valve control as CAN slave

12 valves are connected directly as well as the pressure sensors of the local pressure

tanks

Figure 4 HE 5725

5.1.3 HE 1149

Used to measure the compressed air at the central supply 'system pressure' and at

the local pressure tanks

Measurement range 1.5…10 bar.

Figure 5 HE 1149

14

HE 5760 Operating Instructions

# 372449| Version 3.2

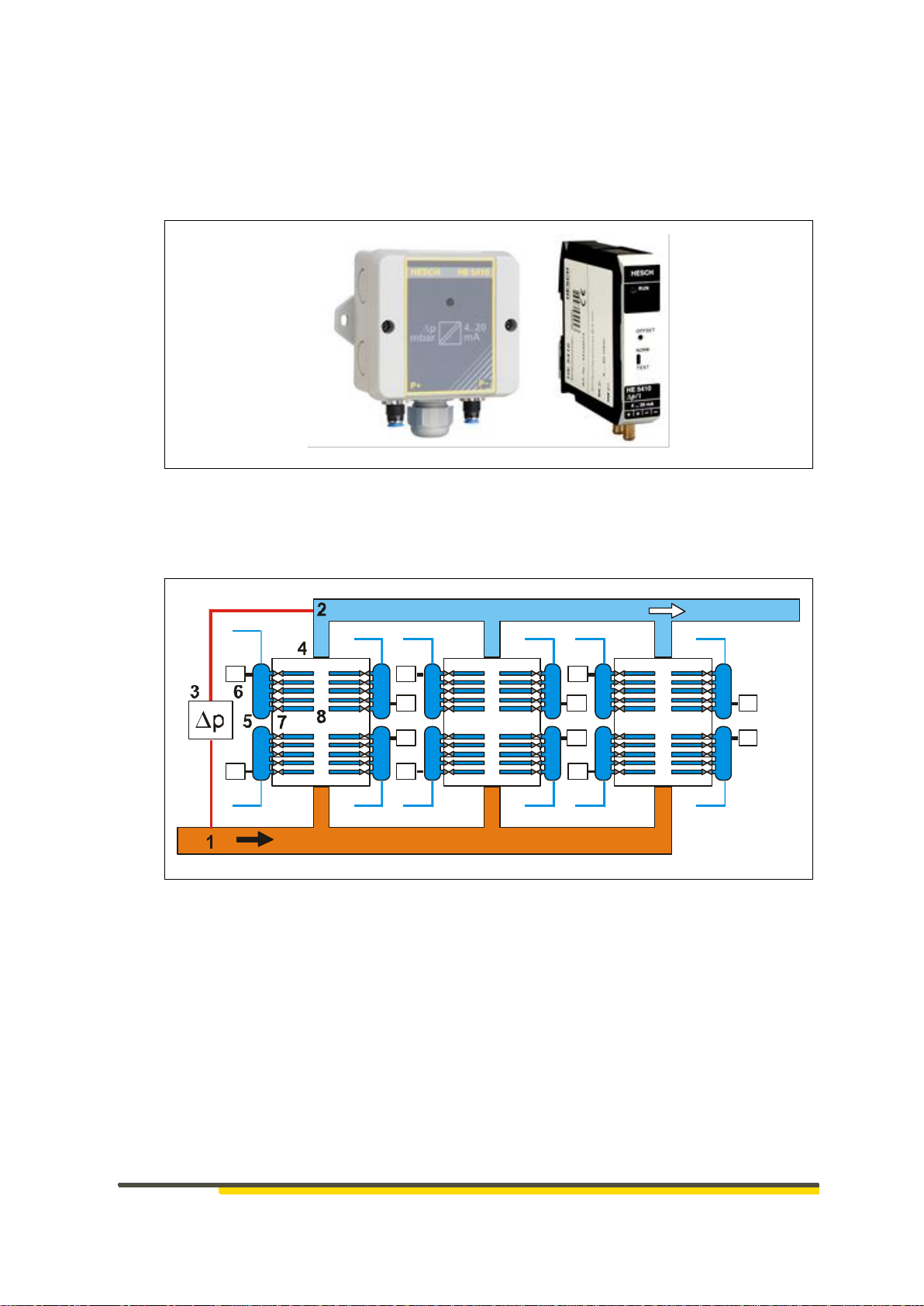

5.1.4 Differential pressure transmitter HE 5410

Differential pressure is measured between clean gas and raw gas side

Measured value is used as a measure of the contamination of the filter system

Measuring range 0...100 mbar

Figure 6 HE 5410

5.2 Filter system

P

P

Figure 7 Filter sketch

1 Raw gas

2 Clean gas

3 Differential pressure measurement raw gas clean gas

4 Chamber as spatial unit of the filter elements

5 Local pressure tanks

6 Pressure measurement at the local pressure tank

7 Valves for compressed air cleaning of the filter elements

8 Filter elements

HE 5760 Operating Instructions

# 372449 | Version 3.2

15

6 Display and operating elements

Figure 8 Display and Operating Elements HE 5760

Symbols:

Display Elements Meaning

LED indicators

Operation

The operating voltage is present and the control unit is ready for operation.

Cleaning active

The status of the control is thus visible, even if no valve is activated at the

moment.

Alarms present

The alarm key can be used to view current alarms and the alarm list.

Command and control keys

Exit the current menu without changing the value

Context menu keys, meaning is shown in the lowest text line of the display.

Selection of the current value. Acceptance of the changed value.

Hot Keys

Function keys for system operation

The function keys call up the operating and display options of normal

operation. By pressing several times, more screens become visible.

See also section 8 Operation.

Navigation keys

Line selection, value change for selected values

-Backlight brightness

-Page switching for longer lists

Decimal position for value representation

16

HE 5760 Operating Instructions

# 372449| Version 3.2

7 Electrical commissioning

Before switching on the device, observe the following points:

Connect the cable firmly to the glands. The power supply must correspond to the voltage

indicated on the nameplate.

The unit may only be operated when installed.

The temperature limitations specified for the use of the device must be complied with before

and during operation.

The protective conductor connection in the corresponding equipment rack must be conductively

connected to the protective conductor.

Danger of Electrocution!

Electrical installation must only be carried out when the power is

disconnected.

Warning of material damage caused by electrostatic charge!

Observe the safety measures according to DIN EN 61340-51/-3 to avoid

electrostatic discharge!

Note!

Work on the electronic parts may only be carried out by qualified

personnel.

Figure 9 HE 5760 Rear with electrical connections

Analogue input 1

Analogue input 2

Option: Modbus / Profibus

connection

HE 5760 Operating Instructions

# 372449 | Version 3.2

17

7.1 Electrical connection HE 5760

Supply 24 V DC Supply

1

24 V DC

2

GND

3

FE Functional Earth

CAN communication

4

CAN-H

5

CAN-L

6

CAN -GND

Termination / Bus termination switchable

Digital Out 24 V DC status signals

7

Operation = green LED

8

Cleaning = yellow LED

9

Malfunction = red LED

10

Pulse

11

Out-GND

Analogue In 4...20 mA Pressure

measurement

18

Filter dp +

Analogue input 1

19

4...20 mA -

20

System p +

Analogue input 2

21

4...20 mA -

Digital In 24 V DC control signals

12

Local/Remote

13

Acknowledge

14

Start

15

Stop

16

Post-Cleaning

17

IN-GND

18

HE 5760 Operating Instructions

# 372449| Version 3.2

7.1.1 Local operation through control signals

123

456

Figure 10 Example of the possible use of the control signals

1 Operation

2 Cleaning

3 Malfunction

4 Local/Remote

5 Start/Stop

6 Acknowledge

HE 5760 Operating Instructions

# 372449 | Version 3.2

19

7.2 Electrical connection HE 5725

Figure 11 Electrical connection HE 5725

Supply 24 V DC Supply

1

+ 24 V DC 1A

2

GND

3

PE

Valves 1 to 6, 24 V DC

4

Valve 1 +

18

Valve 1 GND

32

Valve 1 PE

5

Valve 2 +

19

Valve 2 GND

33

Valve 2 PE

6

Valve 3 +

20

Valve 3 GND

34

Valve 3 PE

7

Valve 4 +

21

Valve 4 GND

35

Valve 4 PE

8

Valve 5 +

22

Valve 5 GND

36

Valve 5 PE

9

Valve 6 +

23

Valve 6 GND

37

Valve 6 PE

Pressure 1

16

+ 24 V DC Out

30

Sensor 1 GND

44

PE

IN

Out

CAN Connection

46

50

CAN-H

47

51

CAN-L

48

52

CAN-GND

49

53

Umbrella

Valves 7 to 12, 24 V DC

10

Valve 7 +

24

Valve 7 GND

38

Valve 7 PE

11

Valve 8 +

25

Valve 8 GND

39

Valve 8 PE

12

Valve 9 +

26

Valve 9 GND

40

Valve 9 PE

13

Valve 10 +

27

Valve 10 GND

41

Valve 10 PE

14

Valve 11 +

28

Valve 11 GND

42

Valve 11 PE

15

Valve 12 +

29

Valve 12 GND

43

Valve 12 PE

Pressure 2

17

+ 24 V DC Out

31

Sensor 2 GND

45

PE

20

HE 5760 Operating Instructions

# 372449| Version 3.2

7.3 CAN network configuration

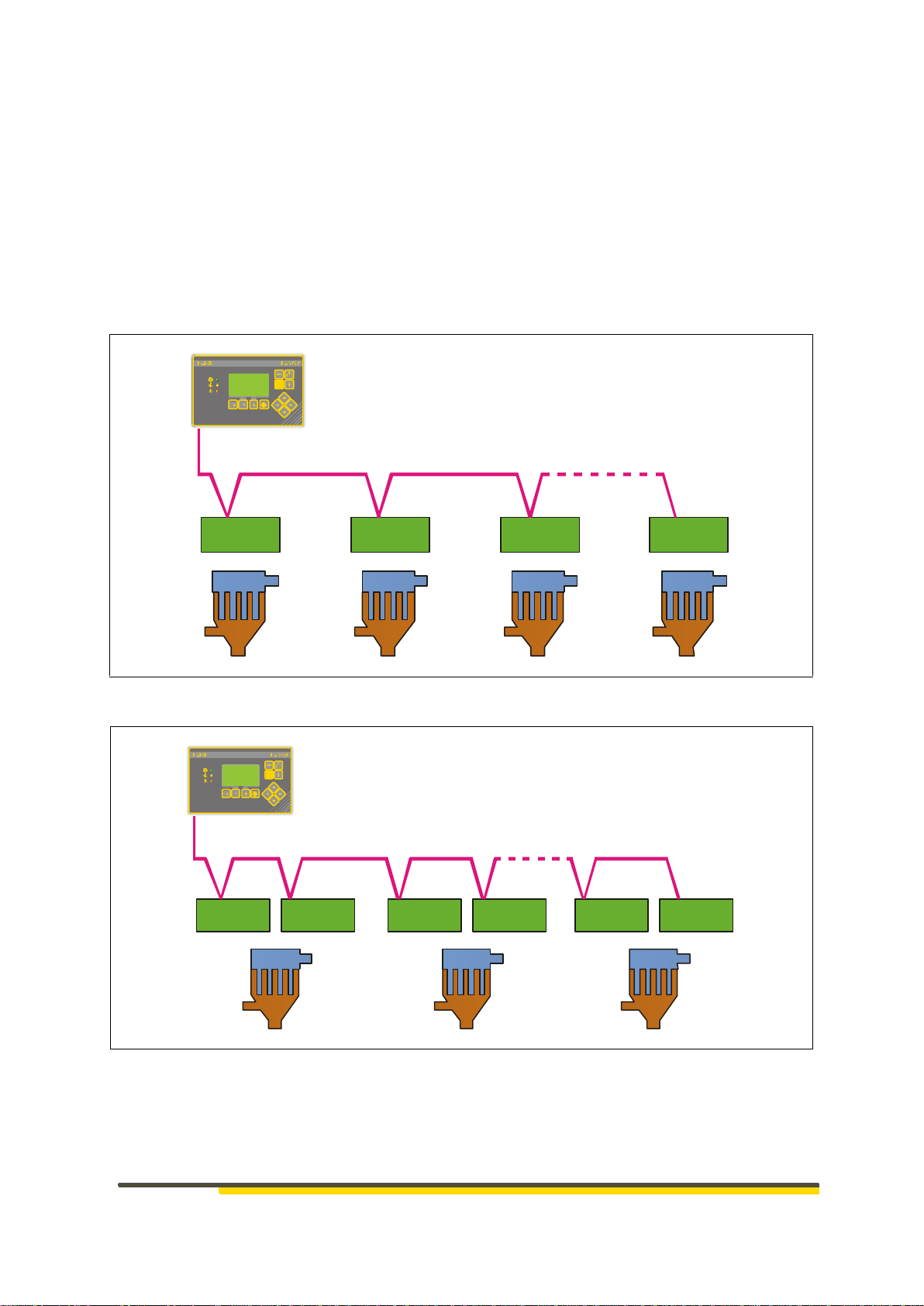

7.3.1 CAN address assignment

Each device in the CAN network is addressed with its CAN node number. The assignment of

the CAN addresses must comply with certain rules.

The HE 5760 control unit does not require a CAN address.

With the HE 5725 valve controls, a distinction is made between:

one HE 5725 per chamber, consecutive numbering, 1, 2, 3, ... 48

two HE 5725 per chamber, split numbering, 1, 25, 2, 26, ... 24, 48

HE 5725 HE5725 HE 5725 HE 5725

CAN

1 2 3 . . . 48

Figure 12 CAN numbering 1 slave per chamber

HE 5725 HE 5725 HE 5725HE 5725 HE 5725 HE 5725

CAN

125 26..2.. 24 48

Figure 13 CAN numbering 2 slaves per chamber

Table of contents

Other HESCH Control Unit manuals

Popular Control Unit manuals by other brands

Anval

Anval SG Series Installation & maintenance manual

IFM Electronic

IFM Electronic Ecomat100 CR1083 PDM360 NG installation instructions

Data Video

Data Video CCU-200 instruction manual

Koganei

Koganei F Series manual

Jetter

Jetter JX3-PS1 user manual

OSF

OSF SAUNA exclusiv 9kW Installation and operating instructions