hestan GFDS_241 User manual

1

Installation Manual

UNDERCOUNTER REFRIGERATION

Beer Dispensers

INDOOR / OUTDOOR

EN

©2021 Hestan Commercial Corporation

2

2 SAFETY DEFINITIONS

3 MODEL NUMBERS

3 KEG LAYOUT

4 RATING LABEL

4 REGULATORY/CODE REQUIREMENTS

4 SAFETY

6CABINET INSTALLATION

9DOOR INFORMATION

11 INSTALLATION OF DISPENSING EQUIPMENT

17 CONNECTING THE REGULATOR TO THE CO2CYLINDER

19 DISPOSAL

TABLE OF CONTENTS

SAFETY DEFINITIONS

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY

BEFORE INSTALLING OR USING YOUR APPLIANCE TO REDUCE

THE RISK OF FIRE, SHOCK HAZARD, OR OTHER INJURY. KEEP

THIS MANUAL FOR FUTURE REFERENCE.

IMPORTANT!IMPORTANT! The installation of the actual beer dispenser cabinet should

happen prior to installing the dispensing equipment. Refer to the Cabinet

Installation section of this manual for step-by-step instructions.

IMPORTANT!IMPORTANT! Read and understand all information in this manual before

attempting the installation. All plumbing and electrical work must be performed

by a qualified technician and conform to all applicable state and local codes.

INSTALLER: LEAVE THIS MANUAL WITH THE OWNER OF THE APPLIANCE.

HOMEOWNER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

THIS INDICATES A HAZARD THAT WILL RESULT IN SERIOUS

INJURY OR DEATH IF PRECAUTIONS ARE NOT FOLLOWED.

THIS INDICATES A HAZARD THAT MAY RESULT IN SERIOUS

INJURY OR DEATH IF PRECAUTIONS ARE NOT FOLLOWED.

THIS INDICATES A HAZARD WHERE MINOR INJURY

OR PRODUCT OR PROPERTY DAMAGE MAY OCCUR IF

PRECAUTIONS ARE NOT FOLLOWED.

THIS INDICATES THAT PRODUCT OR PROPERTY DAMAGE MAY

OCCUR IF PRECAUTIONS ARE NOT FOLLOWED.

DANGER

DANGER

RISK OF FIRE OR EXPLOSION - FLAMMABLE REFRIGERANT USED. Consult

repair manual/owners guide before attempting to service this product. All

safety precautions must be followed. To be repaired by trained service personnel only. Use caution

when handling, moving and using the product to avoid damaging the refrigerant tubing or increasing

the risk of a leak.

All service work shall be performed by factory authorized service personnel and

all component parts shall be replaced with like components to minimize the risk

of possible ignition due to incorrect parts or improper service.

If service is necessary, repair work must be performed by a Hestan authorized

servicer. Work done by unqualified individuals could potentially be dangerous

and will void the warranty.

NOTICE

EN

©2021 Hestan Commercial Corporation

3

One 1/4 barrel

Standard = Ø16-1�8” x 13-7�8” H - 7.75 Gal [29.3 l]

Slim = Ø11-1�8” x 23-3�8” H - 7.75 Gal [29.3 l]

Two 1/6 barrel

Ø9-1�4” x 23-3�8” H - 5.16 Gal [19.8 l]

MODEL NUMBERS

Model No. Description

GFDS_241 INDOOR / OUTDOOR SINGLE FAUCET BEER DISPENSER, SOLID DOOR, 24”

GFDS_241-XX INDOOR / OUTDOOR SINGLE FAUCET BEER DISPENSER, SOLID DOOR, COLOR, 24”

GFDS_242 INDOOR / OUTDOOR DOUBLE FAUCET BEER DISPENSER, SOLID DOOR, 24”

GFDS_242-XX INDOOR / OUTDOOR DOUBLE FAUCET BEER DISPENSER, SOLID DOOR, COLOR, 24”

_= Right (R) or Left (L) Hinged Model

GFDSR241

shown GFDSR242

shown

KEG LAYOUT

The following standard beer kegs fit inside these units.

R600a Refrigerant

NOTICE

This product contains blown foam insulation using blowing agent R-611 (Methyl

Formate). The foam in this product does not contain HFC’s, CFC’s, or HCFC’s.

All models covered in this manual are manufactured using refrigerant R600a (Isobutane). R600a is

a hydrocarbon. This refrigerant is flammable and is only allowed for use in appliances which fulfill

the requirements of UL/IEC 60335-1 and UL/IEC 60335-2-24 (To cover potential risk originated from

the use of flammable refrigerants). Consequently, R600a is only allowed to be used in refrigerating

appliances which are designed for this refrigerant and fulfill the above-mentioned standard.

• R600a is heavier than air. The concentration will always be highest at the floor level.

• The explosion limits are as follows:

o Lower Limit: 1.8% by volume

o Upper Limit: 8.4% by volume

o Ignition Temperature: 860ºF [460°C]

SAFETY DEFINITIONS

(continued)

EN

©2021 Hestan Commercial Corporation

4

RATING LABEL

The rating label contains important information about your Hestan appliance such as the model and

serial number, and refrigerant information if service is required.

RATING LABEL

REGULATORY / CODE REQUIREMENTS

Installation of this appliance must be made in accordance with local codes. In the absence of local

codes, this unit should be installed in accordance with the National Electrical Code and local codes.

This appliance must be electrically grounded in accordance with local codes or in the absence of

local codes with the National Electrical Code

ANSI/NFPA 70

, or Canadian Electrical code

CSA

C22.1

.

SAFETY

CHILD SAFETYCHILD SAFETY

DANGER

Risk of child entrapment. Before you throw away your old

refrigerator or freezer:

• Take off the doors.

• Leave the shelves in place so that children may not easily climb inside.

NEVER allow children to play inside the appliance.

PRIOR TO INSTALLATIONPRIOR TO INSTALLATION

Carefully inspect cabinet for hidden damage. If damage is discovered, file your

claim immediately with the transport company. Hestan is not responsible for

damage in transit. Remove any packaging materials before operating.

DANGER

RISK OF FIRE OR EXPLOSION - FLAMMABLE REFRIGERANT USED.

Use caution when handling, moving and using the product to avoid damaging

the refrigerant tubing or increasing the risk of a leak.

When moving the unit, be sure to protect finished flooring with appropriate

material to avoid damage from moving the unit. Do not lift unit by drawer,

shelving or door handles, as damage to the unit could occur if not moved as instructed.

To prevent personal injury, a minimum of two people are required to lift the

unit. Larger units may require additional personnel.

Before moving the unit, secure the door shut with tape to prevent door from swinging open while

being moved. Carefully move unit to installation site and place in front of opening.

If unit has been laid on its back or sides, place unit upright and allow a

minimum of 24 hours before connecting power.

PLUMBINGPLUMBING

Aside from connections to the beer tap and keg (see page 11), no other plumbing connections are

required. Condensate from the cooling coil is automatically evaporated through a condensate pan

located in the condensing section of the unit.

The rating label is attached to

the inside top of the cabinet.

EN

©2021 Hestan Commercial Corporation

5

DANGER

HIGH-PRESSURE GASHIGH-PRESSURE GAS

• Keep CO2cylinder away from heat. The rupture disc vents at 122°F [50°C] max.

• Do not drop or throw regulator or CO2cylinder.

• Allow only properly trained and experienced personnel to handle high-pressure gas.

• Do not apply oil to the regulator!

DANGER

ELECTRICAL SHOCK HAZARDELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing appliance. Failure to do so can result in death or

electrical shock.

ELECTRICAL GROUNDINGELECTRICAL GROUNDING

• This appliance must be grounded. Grounding reduces the risk of electric

shock in the event of a short circuit.

• DO NOT ground to a gas pipe.

• DO NOT use an extension cord with this appliance.

• DO NOT have a fuse in the NEUTRAL or GROUNDING circuit. A fuse in

the NEUTRAL or GROUNDING circuit could result in an electrical shock.

ELECTRICAL SUPPLYELECTRICAL SUPPLY

A 115 volt AC, 60 Hz, 15 Amp circuit breaker and electrical supply is required. A Ground Fault Circuit

Interrupter (GFCI) protected circuit must be used when installed outdoors.

This appliance is NOT designed for installation in manufactured (mobile) homes or recreational park

trailers.

All units are provided with a 5 ft [1.5 m] cord with three-prong grounding plug. It is imperative that

this plug be connected to a properly grounded three-prong receptacle. If the receptacle is not the

proper grounding type, contact an electrician. The receptacle must be flush or recessed into the wall

surface behind the unit.

• Never remove the grounding prong from this plug.

• Never use a 2-prong adapter.

• If a 2-prong receptacle is encountered, or a longer power cord is required, contract a qualified

electrician to have it replaced in accordance with applicable electrical codes.

Inspect the electrical cord and plug for damage prior to energizing the unit to

avoid potential electric shock.

NOTICE

The unit must NOT be totally enclosed or damage may occur. Air circulation must not

be restricted. The condenser at the cabinet front must be provided with a minimum of

2” [5 cm] air space. Be sure to provide access so the front cover can be removed to clean the condenser.

Do not attempt to operate the equipment on any power source / voltage other

than that listed on the Electrical Specification Plate attached to the unit.

DANGER

Do not store flammable liquids (i.e. Gasoline or Lighter Fluid) or vapors near the

appliance to avoid a fire.

ADDITIONAL GENERAL INFORMATIONADDITIONAL GENERAL INFORMATION

All electrical instructions assume the outlet is located 4 - 10” [10 - 25 cm] above the floor surface.

Floor must be level in area of installation. Leg levelers are used for fine-tune adjustment only and

should not be used to compensate for floor differences exceeding 1/2” [13 mm].

SAFETY

(continued)

EN

©2021 Hestan Commercial Corporation

6

CABINET INSTALLATION

DANGER

RISK OF FIRE OR EXPLOSION - FLAMMABLE REFRIGERANT USED.

Use caution when handling, moving and using the product to avoid damaging

the refrigerant tubing or increasing the risk of a leak.

CASTER KIT (OPTIONAL)CASTER KIT (OPTIONAL)

A Caster Kit (AGCK24) is available for Hestan refrigeration models. Refer to the instructions

supplied with the caster kit for proper installation.

Note: Installation of the kit adds 3.75” [9.5 cm] to overall height of the unit.

ANTI-TIP BRACKETSANTI-TIP BRACKETS

Unit may tip forward if loaded racks/shelves are all pulled out at the same time. To prevent tipping,

and to provide stable installation, the unit must be secured in place with the anti-tip brackets

supplied with the unit. The anti-tip brackets, when properly installed, should secure the rear legs/

glides to the mounting surface and prevent the unit from tipping forward.

NOTICE

Anti-tip brackets are only used for stationary cabinets and should not be installed on

cabinets with accessory casters.

If installing on a concrete floor, concrete fasteners are required and not included with the anti-tip kit.

Some installation sites may require modifications to provide a secure surface for attaching the

brackets.

A set of anti-tip brackets is supplied with the unit. These brackets should be attached to the floor at

the rear of the unit. Each bracket must be located to engage the rear legs when the cabinet is pushed

back into position. Refer to Figure 1 (shown below) for anti-tip bracket mounting locations.

PREPARING THE SPACEPREPARING THE SPACE

If the unit is to be installed under a countertop, it is recommended that the countertop be supported

by a structure other than the unit itself to prevent damage to the unit.

Make sure the floor under the unit is level with the surrounding finished floor. Protect a finished

floor with plywood, cardboard, or some other suitable material before moving the unit into place.

Failure to do this may result in damage to the floor.

Figure 1. 24” Anti-Tip Kit

15⁄16”

3⁄16”

22-3⁄16”BRACKETS

EN

©2021 Hestan Commercial Corporation

7

CABINET INSTALLATION

(continued)

To assure maximum performance, fresh air must be allowed to circulate through the machinery

compartment. Do not place anything in front of the unit that would obstruct air flow at these front

grilles. Do not place the unit in an unventilated small room.

NOTICE

Cabinet should be leveled front to back, then side to side.

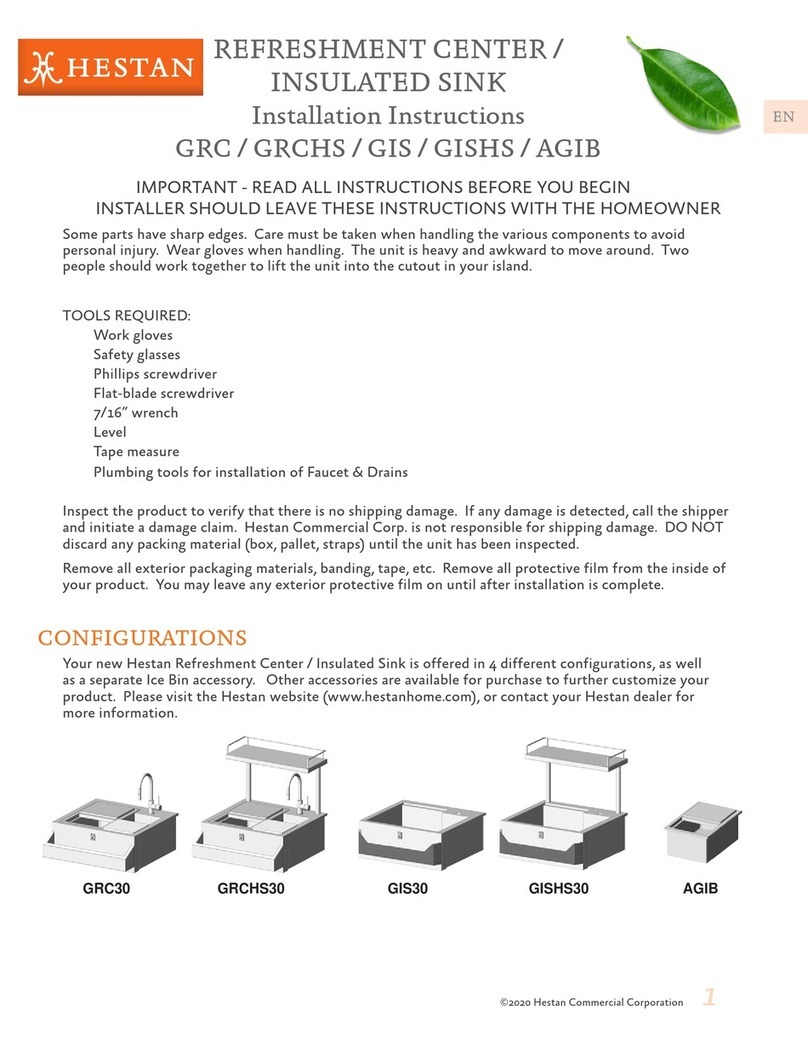

1. Make sure the space opening is correctly sized for the unit. See typical appliance dimensions

below, and the chart below for finished rough opening requirements:

HEIGHT WIDTH DEPTH

34-3/8” [87.3 cm] min.

35-1/2” [90.2 cm] max. 24” [61 cm] 24” [61 cm]

2. Check that the following are level and square:

• Front and interior opening

• Installation opening and floor surface

• Countertop bottom front edge

NOTE: For a door to open properly, the door must open a minimum of 90°. Use a minimum 3” [7.6

cm] filler in corner installations to assure a full 90° opening. Allow 25” [64 cm] clearance in front of

unit for full door swing and shelf/drawer pull out.

NOTE: The floor under the unit must be at the same level as the surrounding finished floor.

24" 611

3

16

" 84

5

1234" 323

15

12

" 394

24

1516

"633

16

"

7

214

8

11

1516

"303

11" 279

1

58

" 42

3

12

" 89

21

38

" 543 26

916

" 674

1

1516

" 49

87234

5

"*

16

20" 508

14" 356

3

12

" 89

21

38

" 543

63224

78

"

*3

1516

" 100

606

"

8

7

23

9

16

" 252

15

11

78

" 302

18

316

" 461

6

58

" 168

1

16

" 49

15

6

14

" 159

22

116

" 560

1618" 410

CUTOUT DIMENSIONS:

34-3⁄8” H - 24” W - 24” D

[873] H - [609] W - [609] D

TYPICAL APPLIANCE

DIMENSIONS

MIN. CLEARANCE

FOR DOOR SWING

90° SWING

REQUIRED FOR

PULL-OUT SHELF

CLEARANCE

POWER CORD

5 FT. LONG

3-1⁄4” [83] MIN. CLEARANCE

FROM A CORNER TO

ACHIEVE 90° SWING

*- Leg levelers can add

3/4” to these dimensions

when fully extended.

Shelf included

with dispensing

cabinets.

Also fits two 1/6

barrels when

shelf is removed.

Portable Drainer

Typical 1/4 barrel.

EN

©2021 Hestan Commercial Corporation

8

CABINET INSTALLATION

(continued)

To prevent possible damage to the countertop, do not place heavy objects on

countertop directly over unit.

INSTALLING THE UNIT INTO THE SPACEINSTALLING THE UNIT INTO THE SPACE

1. Plug the unit into the 15 amp grounded electrical outlet located within the installation opening.

With power applied to the unit, check that the lighting and cooling functions operate properly.

Turn off the power to the wall outlet at the circuit breaker.

2. With all surfaces in the installation opening square and level, refer to Figure 2 below and perform

the following steps to level the unit:

• At the front of the opening, measure from the floor to the bottom of the front edge of the

countertop.

• Measure from the floor surface to the top of the unit at the rear corners.

• Adjust the unit legs so these two measurements are equal. Using an adjustable wrench or

pliers, turn legs clockwise to lower the unit or counterclockwise to raise it.

NOTE: Legs should not extend more than 3/4” [19 mm] from the bottom of the unit.

3. Slide the unit into position in the opening. Make sure the rear leveling legs slide under the ant-

tip brackets. Push the unit into the opening until the bottom front edge of the unit is flush with

the surrounding cabinetry, or until the rear legs are tight against the anti-tip brackets.

4. Shim the front of the unit so the front face is flush with the surrounding cabinetry. Adjust the

front legs to support the countertop at the shimmed height. Using an adjustable wrench or

pliers, turn the legs clockwise to lower the unit or counterclockwise to raise it. Countertop

should be resting on top of the unit.

NOTE: Countertop should be resting evenly

on entire top of the unit. Shim if necessary to

prevent damage to the countertop.

5. Check interior door openings to make sure

the unit is level and square. Install shelving.

6. Turn on the power to the wall outlet at the

circuit breaker.

Measure front of opening

from floor surface to bottom

edge of countertop.

Measure at both rear corners

of unit from floor surface to

bottom of countertop.

Figure 2. Leveling the Unit

EN

©2021 Hestan Commercial Corporation

9

CABINET INSTALLATION

(continued)

INSTALLING THE FRONT GRILLE COVERINSTALLING THE FRONT GRILLE COVER

Once the unit is secured in place, install the

louvered front grille cover. Secure the cover

by snapping the latch into the latch catch on

the unit (Figure 3).

The vent grille must be removed to service the

unit. The floor cannot interfere with removal,

and the louvered sections must not be covered

or obstructed. Obstructions could prevent

proper air circulation, which may damage the

unit.

NOTE: To achieve maximum performance,

interior louver openings and fan guard

openings should never be obstructed.

Latch

Catch

Latch

Figure 3. Front Grille Cover Installation

DOOR INFORMATION

DOOR OPTIONSDOOR OPTIONS

Hestan residential units can be converted from stainless steel to overlay panels to match existing

cabinetry. Solid doors are shipped from the factory with stainless steel panels and handles in place

on the unit. All stainless steel doors are convertible to fully integrated models, ready to accept

custom panels from your cabinetry supplier. You can contact Hestan Customer Care to send you any

of the following templates, or download directly from the Hestan website at

www.hestanoutdoor.com.

028370 - Template, Overlay, 24” Solid Door, Undercounter Refrigeration

028371 - Template, Overlay, 24” Toe Kick/Grille, Undercounter Refrigeration

028374 - Installation Instructions, Overlay Door/Drawer, Undercounter Refrigeration

Take care in choosing the correct template for your specific unit. The original appliance handle or

custom cabinet handle can be installed onto your overlay panel.

HANDLE INSTALLATIONHANDLE INSTALLATION

The handle mounting on the wood overlay should be mounted on the overlay only (not the actual

door) to avoid damage to the factory door. Proper woodworking materials and equipment should be

used to avoid damage or errors in workmanship.

1. Handle must be attached to the overlay before mounting the overlay onto the door. Mark the

rear of the wood overlay panel with handle fastening locations.

2. Drill through the wood overlay panel at marked locations, taking care not to damage the panel.

3. Countersink screw heads so that screw heads are flush with the back side of the panel. Attach

the handle to the overlay panel.

EN

©2021 Hestan Commercial Corporation

10

Mounting Bracket

Screw

Lockwasher

Lock Striker

Nut

Lock Bracket

Lock

Cylinder

Figure 5. Installing Door Lock

DOOR LOCK INSTALLATIONDOOR LOCK INSTALLATION

Proper woodworking materials and equipment

should be used to avoid damage or errors in

workmanship.

NOTE: Lock installation information is available

on the above-mentioned template drawings.

Take care in choosing the correct template for

your specific model.

When installing to an overlay panel, perform the

lock installation before mounting the overlay to

the door!

1. See Figure 5. Attach mounting bracket to

overlay panel.

2. Insert lock body and attach with nut. Re-

install remaining parts as shown.

OVERLAY INSTALLATIONOVERLAY INSTALLATION

Before beginning installation, check all components for proper fit and finish.

NOTE: For more detailed installation information, please request or download document 028374

mentioned on the previous page.

For best performance and functionality, the overlay panels should be 3/4” [19

mm] thick. The weight of the overlays should not exceed 20 lbs [9 kg] for

solid doors.

1. With the unit secured in position, open the door, CAREFULLY remove the door gasket (it can

tear), and make sure panel pre-drilled holes align with door frame holes.

2. Loosely attach four corners of overlay panel to the door using #10 x 3/4” wood screws, installed

through the door frame from the rear.

3. Check the overall fit of the overlay panel, position, and function. Make minor adjustments as

necessary. When panel is properly aligned, tighten mounting screws securely. Install the rest of

the mounting screws and tighten securely.

4. Re-install the gasket making sure the dart is securely pressed inside the slot on the door frame.

Start at the four corners and firmly press your way inwards.

5. Verify that the gasket is fully seated onto the door frame when completed.

Do not overtighten overlay panel attachment screws, as this may damage the

factory supplied door frame.

DOOR INFORMATION

(continued)

EN

©2021 Hestan Commercial Corporation

11

INSTALLATION OF DISPENSING EQUIPMENT

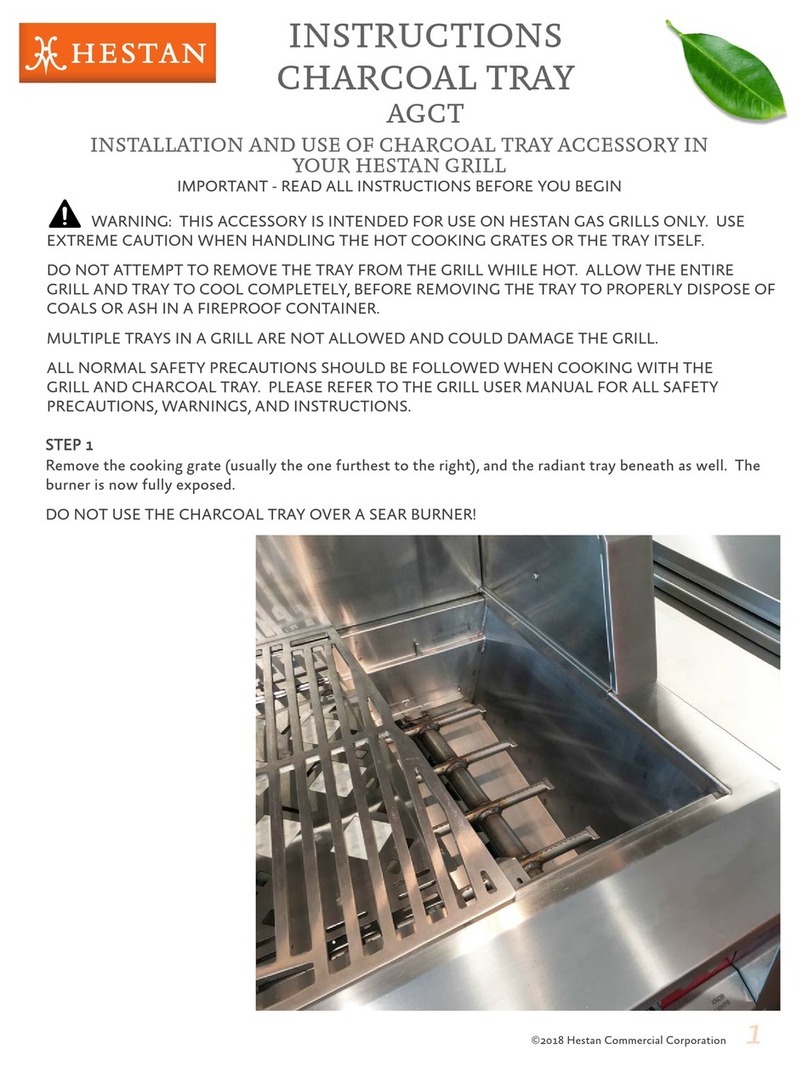

BEFORE INSTALLATIONBEFORE INSTALLATION

Open the tapping kit box and become familiar with its components.

If the dispensing head is going to be mounted on a countertop directly above the refrigerated cabinet,

have the countertop pre-drilled using the printed template in the Appendix of this manual.

Make sure that the access hole in the refrigerated cabinet is in line with the countertop holes.

Remove any obstructions from the access hole of the refrigerator.

FILLING THE COFILLING THE CO22CYLINDERCYLINDER

The 5 lb. CO2cylinder is not filled. A local welding supply store, locations that fill fire extinguishers,

local home brew shops, and sporting stores that sell paint ball guns are among the most likely places

to get your CO2cylinder filled.

ABOUT KEG COUPLERS (TAPS)ABOUT KEG COUPLERS (TAPS)

Your Hestan Beer Refrigerator is supplied with a low-profile coupler for “D” system kegs, commonly

used for beers of the United States and Mexico.

This coupler MUST be used when using Slim 1/4 kegs or 1/6 kegs (23-3/8” [59.4 cm] tall). If you are

using other kegs with A, G, M, S, or U couplers, you must use a standard 1/4 keg (13-7/8” [35.2 cm]

tall) to be able to fit inside the cabinet.

CLEANING THE TAPCLEANING THE TAP

Wash tapping devices thoroughly. Flush beer and faucet lines, as well as the tapping device (keg

coupler) with fresh water.

A beer tap cleaning kit AGDFK is available for purchase separately.

See instructions on the

following pages to properly

install the tapping equipment on

your Hestan unit.

CLEANING JAR

w/ HAND PUMP

SPANNER

WRENCH

FAUCET

BRUSH

CLEANING

CHEMICAL

53g

BALL

LIFTER

INSTRUCTIONS

BEER TAP CLEANING KIT (AGDFK)

EN

©2021 Hestan Commercial Corporation

12

Dispensing Head

Faucet Lead

Apply silicone to

bottom flange

Air Distributor

Flange Sleeve

All hose connections

use worm-drive

hose clamps (view

enlarged to verify)

Distributor is only on

multiple keg units, each

keg is connected to a

valve on the air distributor.

Single keg connected

directly to the regulator.

Keg

Keg Coupler

Beer Connection

NOTE: Image does not accurately reflect positions of the

different elements within the unit. Postions and hose lengths

shown are to clearly illustrate proper connection methods only.

Regulator

INSTALLATION OF DISPENSING EQUIPMENT

(continued)

EN

©2021 Hestan Commercial Corporation

13

INSTALLATION OF DISPENSING EQUIPMENT

(continued)

1. Locate the dispensing head , black

beer line(s), and hose clamp(s). Slide

one end of each beer line onto the

stainless steel tubes which protrude

out the bottom of the dispensing head

and clamp tight.

2. Remove transit tape with a utility

knife around the hole in the top of the

unit from both inside and outside of

the cabinet. Gently punch out foam

w/screwdriver and remove. Insert

the beer line(s) through the hole in

the countertop. Move head aside

and apply a bead of silicone around

perimeter of hole, and then position

the head back in place. Fasten using

the 4 chrome screws included with

the dispensing head. Wipe off excess

silicone to complete the seal.

3. Use the 3/8” -thick foam pad included

in the tapping kit and roll into a

cylinder. From inside the cabinet,

insert the foam tube up through the

hole in the countertop until it is firmly

against the insulation in the dispensing

head. Mark, then cut away any excess

foam.

EN

©2021 Hestan Commercial Corporation

14

INSTALLATION OF DISPENSING EQUIPMENT

(continued)

4. Install the Air Scoop Kit. Start by

removing the upper set of screws

located above the fan on the back wall

of the cabinet.

5. Assemble components from the kit as

follows – Insert black snap bushing

into air scoop mounting bracket,

then insert one end of the air snorkel

through the snap bushing. A zip-tie

can be inserted behind the mounting

bracket to keep the tube in place.

6. Insert end of the snorkel up into the

tower and screw air scoop mounting

bracket into vacated holes above the

fan.

EN

©2021 Hestan Commercial Corporation

15

INSTALLATION OF DISPENSING EQUIPMENT

(continued)

7. If installing a two faucet system,

a CO2manifold will need to be

installed. Locate the red CO2lines,

CO2manifold and a #10 x 1/2” sheet

metal screw. Slide one end of each

hose onto the barbed fittings on the

manifold and clamp. On the left rear

side wall of the beer compartment

there is a double row of screws which

run vertically. Remove one of the

two top screws and discard. Insert

the sheet metal screw through the

manifold and into the hole vacated

previously.

8. On a single beer system, locate the

red CO2hose. Slide one end onto the

barbed fitting of regulator assembly

and clamp. On systems with two

beers, locate the CO2line that comes

off the backside of the manifold

assembly. Slide the hose onto the

barbed fitting of regulator assembly

and clamp. For detailed information

on connecting the regulator to the

CO2cylinder, see page 17.

9. Locate the low profile keg coupler(s).

Slide one of the red CO2lines onto

the larger barbed fitting of the keg

coupler and clamp. Locate one of

the black beer lines and slide onto

the smaller barbed fitting of the

keg coupler and clamp. Repeat for

additional couplers.

Note:

See page 11 for info on Keg Couplers.

EN

©2021 Hestan Commercial Corporation

16

INSTALLATION OF DISPENSING EQUIPMENT

(continued)

10. On the right rear sidewall there is a

double column of screws. Remove

the left screw. Locate the safety

chain and a #10 x 1/2” sheet metal

screw from the parts bag. Insert the

screw through the closed end link of

the chain and tighten in the vacant

screw hole. The chain can now be

used to secure the CO2cylinder with

“S” hook, preventing damage to the

regulator.

11. CO2cylinders are shipped empty

and must be filled prior to use. Turn

the adjusting knob on the regulator

counter-clockwise until the outlet

pressure gauge (top) reads zero. Make

sure that the valve at the bottom of

the regulator where the red hose is

connected, is in the OFF position

as shown on page 18. Watching

the outlet pressure gauge, turn the

regulator adjusting knob clockwise

until the pressure is at 15 psi.

Adjustments can later be made based

on flow rates.

12. Locate the beer faucet(s) and install

onto the dispensing head shanks.

Tighten with supplied spanner wrench.

Install black handle(s) onto faucet(s).

IMPORTANT: All pressure adjustments

MUST be made when the shut-off valve is

in the OFF position!

EN

©2021 Hestan Commercial Corporation

17

INSTALLATION OF DISPENSING EQUIPMENT

(continued)

13. Before tapping a keg, make sure the

beer faucet is closed.

To tap a keg, insert the coupler into

the neck of the barrel. Turn the

coupler clockwise until it stops (about

an 1/8 turn), then push down on the

top of the coupler and again turn

clockwise until it stops. Your barrel is

now tapped.

Open the CO2valve on the regulator

as well as the valve on the manifold if

used.

CONNECTING THE REGULATOR TO THE CO2 CYLINDER

HIGH-PRESSURE GASHIGH-PRESSURE GAS

DANGER

CO2cylinders contain high-pressure gas which can be hazardous if not handled properly. Make sure

you READ and UNDERSTAND the following procedures for CO2cylinders BEFORE installation.

• ALWAYS connect the CO2cylinder to a regulator. Failure to do so could result in an explosion

with possible death or injury when the cylinder valve is opened.

• NEVER connect the CO2cylinder directly to the product container (keg). Doing so will result in

an explosion causing possible death or injury.

• ALWAYS follow correct procedures when cylinders are changed.

• ALWAYS secure the cylinder in an upright position with a chain.

• NEVER drop or throw a CO2cylinder.

• ALWAYS keep a CO2cylinder away from heat. The rupture disc vents at 122°F [50°C] max.

Store extra cylinders in a cool place (preferably 70ºF [21°C]). Securely fasten with a chain in an

upright position when storing. NEVER place cylinders in direct sunlight or where temperature

could rise above 130ºF [54°C].

• ALWAYS ventilate & leave the area immediately if CO2gas leakage has occurred. NEVER enter

a closed area where leakage may have occurred.

• ALWAYS check the DOT test date on the cylinder neck before installation. If over five(5) years

old, do not use, return cylinder to gas supplier.

• NEVER connect a product container unless there are two(2) safeties in the pressure system:

(a) one at or on the CO2regulator.

(b) one at or on the product coupler or in the pressure gas line.

• CO2 regulators are delicate instruments and should be checked constantly for creeping,

sluggishness, damaged gauges, or any unusual behavior. If any of these symptoms occur,

discontinue use immediately and return regulator to supplier or manufacturer.

• Allow only properly trained and experienced personnel to handle high-pressure gas.

• Do not apply oil to the regulator!

FAILURE TO CONNECT THE REGULATOR BY PROPERLY FOLLOWING THESE INSTRUCTIONS MAY

RESULT IN LEAKS, EXPLOSIONS, ASPHYXIATION AND CAUSE SERIOUS PERSONAL INJURY OR DEATH.

EN

©2021 Hestan Commercial Corporation

18

CONNECTING THE REGULATOR TO THE CO2 CYLINDER

(continued)

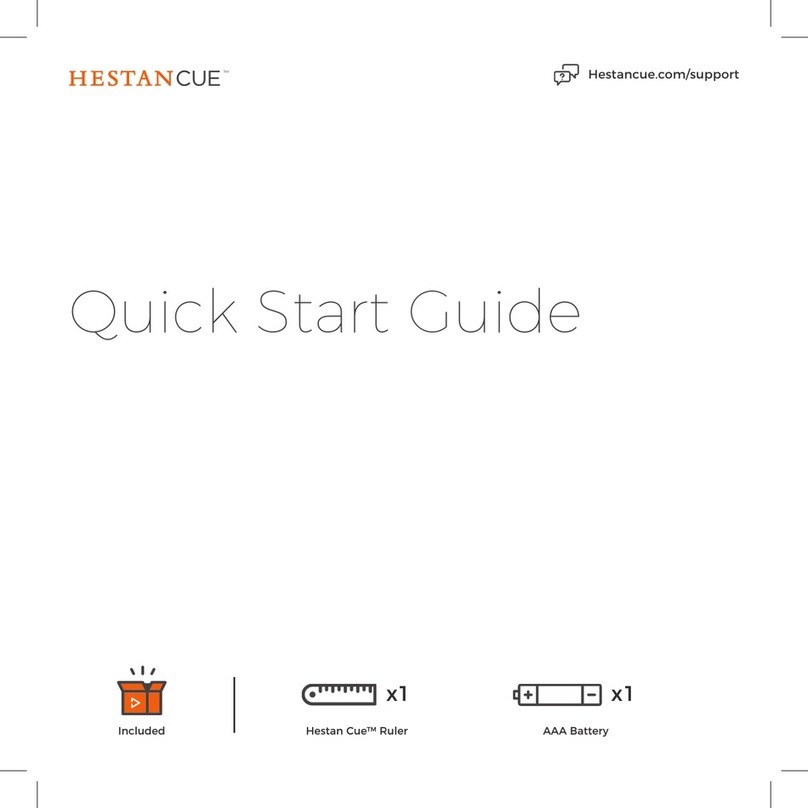

1. Remove the blue plug from the regulator fitting, but do not remove the carbonic washer.

2. Screw regulator onto gas cylinder valve. Tighten the nut with a wrench until vertically straight.

Be sure that the shut-off valve on the regulator is in the OFF (horizontal) position.

3. Place screw clamp over the end of red air hose and push onto regulator barb fitting. Tighten

clamp with a screwdriver.

4. Turn regulator adjusting knob or screw counter-clockwise until it turns freely.

5. Turn cylinder valve counter-clockwise on the CO2cylinder to the fully open position.

6. Turn regulator adjusting knob or screw clockwise until desired pressure is reached (approximately

12-15 psi [83-103 kPa] ). Tighten stop nut on adjusting screw.

7. Open shut-off valve on bottom of regulator.

8. Dilute a small amount of liquid dishwashing soap and rub the soapy mixture around connections.

If bubbles appear, tighten connection.

CYLINDER

PRESSURE

REGULATOR

ADJUSTMENT

KNOB OR SCREW

OUTLET

PRESSURE

SHUT-OFF VALVE

OFF POSITION

BARB FITTING FOR

RED AIR HOSE

NUT FOR CO2

CYLINDER FITTING

CYLINDER

VALVE

CO2

CYLINDER

EN

©2021 Hestan Commercial Corporation

19

DISPOSAL

DANGER

Risk of child entrapment. Before you throw away your old refrigerator or freezer:

• Take off the door.

• Leave the shelves in place so that children may not easily climb inside.

• Do not allow children to play inside, on, or around the appliance.

Risk of fire or explosion. Please dispose the appliance according to federal or local

regulations for its flammable refrigerant and blowing gas.

NOTES

©2021 Hestan Commercial Corporation

1

FR

1 DÉFINITIONS DE SÉCURITÉ

2 NUMÉROS DE MODÈLE

2 DISPOSITION DES BARILS

3 PLAQUE SIGNALÉTIQUE

3 RESPECT DE LA RÉGLEMENTATION ET DES CODES EN VIGUEUR

3 SÉCURITÉ

5 INSTALLATION DE L’ARMOIRE

8INFORMATION SUR LA PORTE

10 INSTALLATION DE L’ÉQUIPEMENT DE DISTRIBUTION

16 RACCORDEMENT DU RÉGULATEUR AU CYLINDRE DE CO2

18 ÉLIMINATION

TABLES DES MATIERES

DÉFINITIONS DE SÉCURITÉ

LISEZ ATTENTIVEMENT ET COMPLÈTEMENT CES INSTRUCTIONS AVANT

D’INSTALLER OU D’UTILISER VOTRE APPAREIL AFIN DE RÉDUIRE LES RISQUES

D’INCENDIE, DE BRÛLURE OU D’AUTRES BLESSURES. CONSERVER CE MANUEL

POUR RÉFÉRENCE FUTURE.

IMPORTANTE! L’installation de l’armoire de distribution de bière réelle doit avoir lieu

avant d’installer l’équipement de distribution. Reportez-vous à la section Installation

du réfrigérateur de ce manuel pour obtenir des instructions pas à pas.

IMPORTANTE! Lisez et comprenez toutes les informations contenues dans ce manuel

avant de tenter l’installation. Tous les travaux de plomberie et d’électricité doivent être

effectués par un technicien qualifié et conformes à tous les codes nationaux et locaux

applicables.

INSTALLATEUR: LAISSER CE MANUEL AVEC LE PROPRIÉTAIRE DE L’APPAREIL.

PROPRIÉTAIRE: CONSERVEZ CE MANUEL POUR RÉFÉRENCE FUTURE.

CELA INDIQUE UN DANGER QUI ENTRAÎNERA DES BLESSURES

GRAVES OU LA MORT SI LES PRÉCAUTIONS NE SONT PAS SUIVIES.

CECI INDIQUE UN DANGER QUI POURRAIT ENTRAÎNER DES

BLESSURES GRAVES OU LA MORT SI LES PRÉCAUTIONS NE SONT

PAS SUIVIES.

CECI INDIQUE UN DANGER LORSQUE DES BLESSURES OU DES

DOMMAGES MATÉRIELS AU PRODUIT OU À LA PROPRIÉTÉ

PEUVENT SURVENIR SI LES PRÉCAUTIONS NE SONT PAS SUIVIES.

CECI INDIQUE QUE DES DOMMAGES MATÉRIELS AU PRODUIT OU

À LA PROPRIÉTÉ PEUVENT SURVENIR SI LES PRÉCAUTIONS NE

SONT PAS SUIVIES.

DANGER

AVIS

DANGER

RISQUE D’INCENDIE OU D’EXPLOSION - RÉFRIGÉRANT INFLAMMABLE

UTILISÉ. Consultez le manuel de réparation / le guide du propriétaire avant

d’essayer de réparer ce produit. Toutes les précautions de sécurité doivent être suivies. À réparer

uniquement par un personnel qualifié. Soyez prudent lors de la manipulation, du déplacement et de

l’utilisation du produit afin d’éviter d’endommager le tube de réfrigérant ou d’augmenter le risque de

fuite.

Tous les travaux d’entretien doivent être exécutés par le personnel de service

autorisé par l’usine et tous les composants doivent être remplacés par des

composants similaires afin de minimiser le risque d’inflammation possible en raison de pièces

incorrectes ou d’un entretien inapproprié.

Si un entretien est nécessaire, les travaux de réparation doivent être

effectués par un réparateur agréé Hestan. Le travail effectué par des

personnes non qualifiées pourrait être potentiellement dangereux et annulera la garantie.

This manual suits for next models

3

Table of contents

Languages:

Other hestan Kitchen Appliance manuals