4

A311K Assembly Instructions

A311K Kit Contents

Ref# Qty. Part Number Description

11 1 3EL1412 Elbow, Hose 90° 1/4" MPT x 1/2" HB

12 8 6806052 Hose Clamp, 1/2" - 29/32" SS

13 2 6816052 Hose Clamp, 11/16" - 1-1/2" SS

14 2 6820052 Hose Clamp, 3/4" - 1-3/4" SS

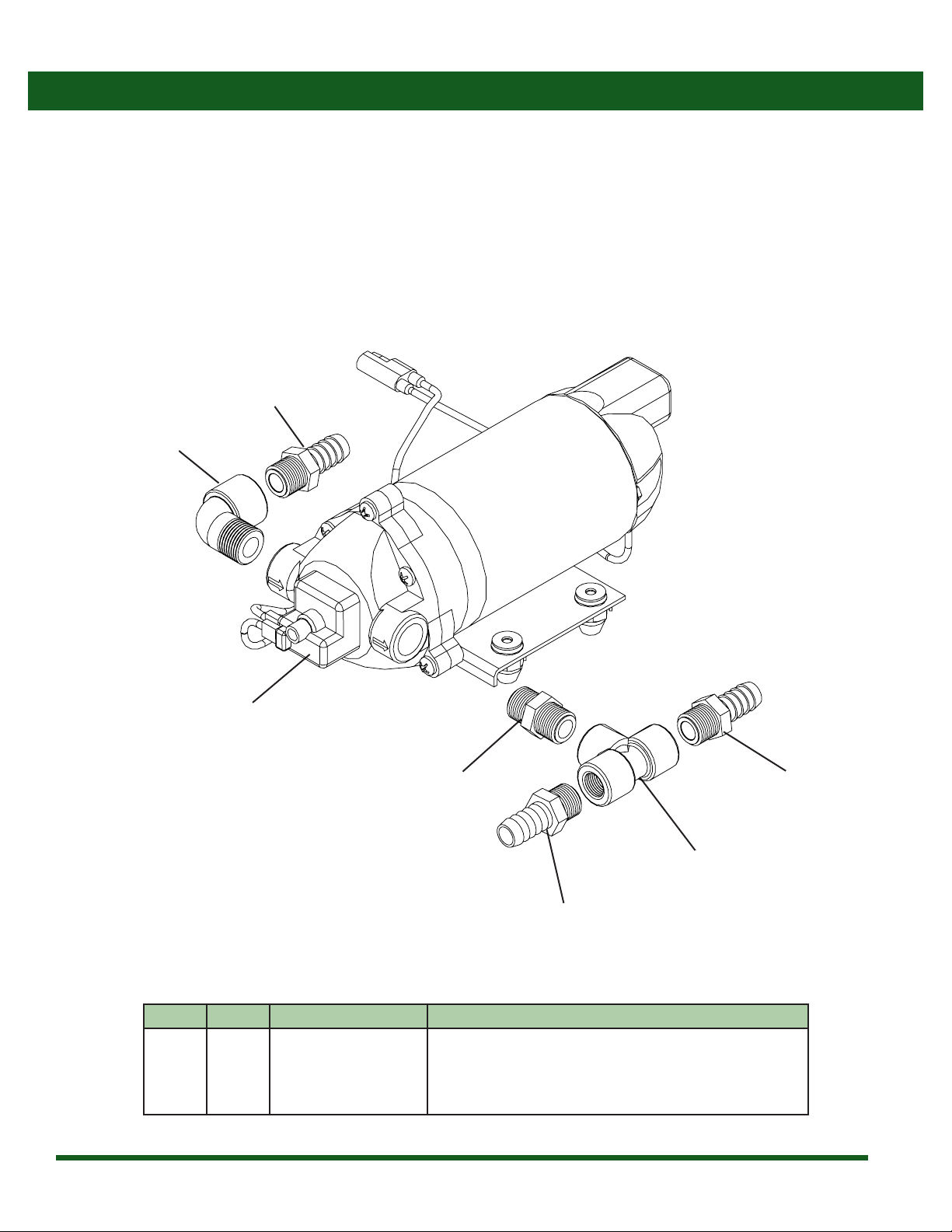

15 1 8007-594-838 Pump, 12V w/Switch & Fuse 2.1 GPM Vi-Santo

16 1 8M38 Nipple, 3/8" MPT x short, sch 80 poly

17 1 8RB134 Bushing, Reducer 1" MPT x 3/4" FPT Sch 80 Poly

18 1 8SE38 Elbow, Street 90° Poly 3/8" NPT Sch 80

19 1 8TT100 Tee, 1" FPT Sch 80 Poly

20 1 8TT38 Tee, 3/8" FPT Sch 80 Poly

21 1 90FMB14 Valve, Ball 1/4" FPT x 1/4" MPT 300 PSI

22 1 A311KAM Assembly manual, Kit: Powerwash and jug rinse

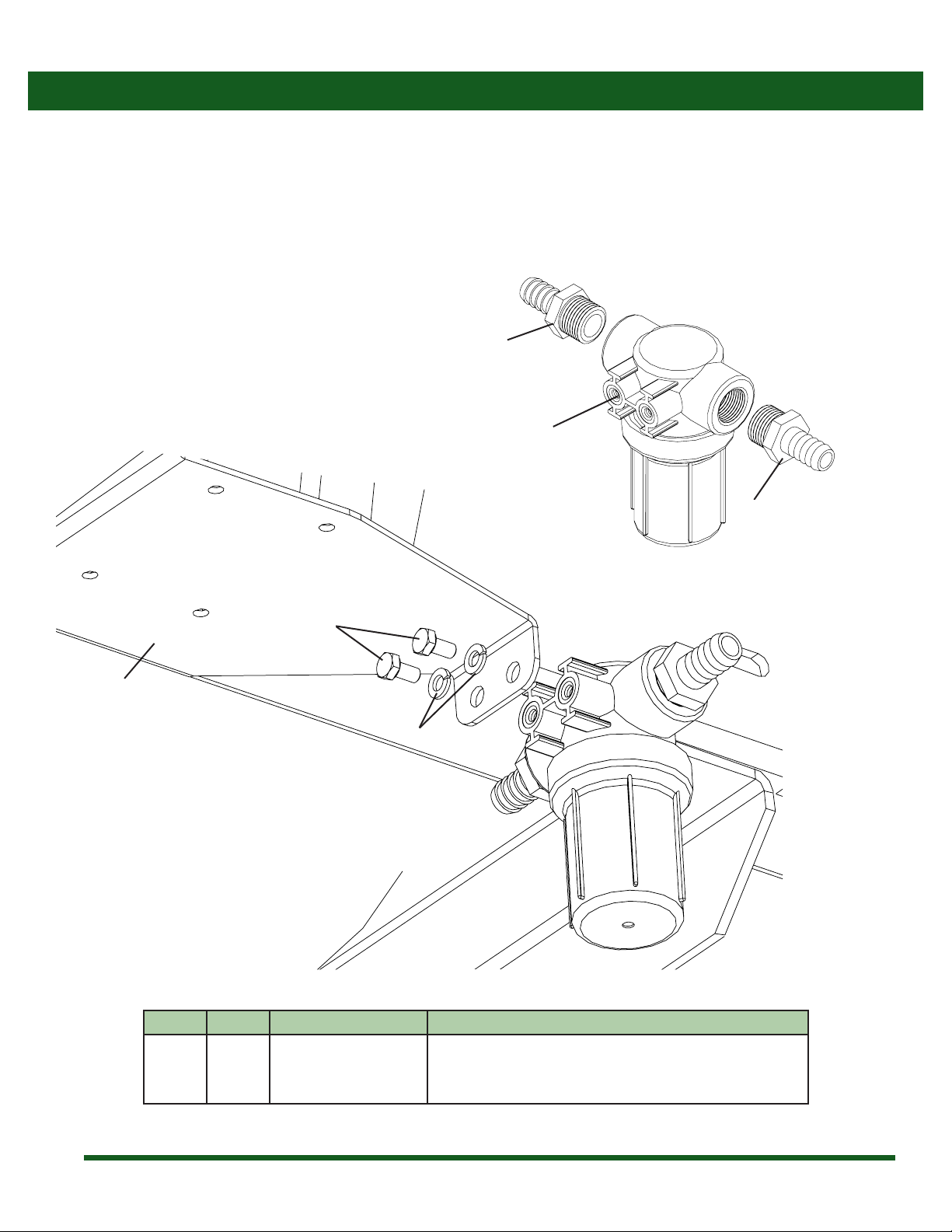

23 1 AA122ML12PP50 Strainer, Line 1/2" FPT 50 MS w/Mounting Holes

24 3 CB38*34G5 Bolt, Carriage 3/8-16 x 3/4" Gr 5

25 1 CP12094NYB Body, Nozzle Type-1/4 Inlet-NYB Nylon

26 1 DC56NY Core, TeeJet Nylon Black

27 8 FT DC784 Loom, Flex-Gard 3/8"

28 1 DE111 Decal, powerwash label

29 1 DE113 Decal, Jug Rinse Label

30 1 DVP6 Orice Disc, Polymer Red

31 1 F1204 Foamer tank bolt, 5/16-18 x 1 1/2"

32 3 FN38 Nut, Flange 3/8-16

33 4 FW10 Washer, Flat #10 SS

34 2 H6*12M Bolt, Hex 6mm x 12mm 1.0 Pitch

35 1 L14S Elbow, 90° 1/4" NPT SS

36 2 LW14 Washer, Lock 1/4"

37 4 MR1024*114 Screw, Machine Rd Hd 10-24 x 1-1/4"

38 1 N14*2S Nipple, 304 SS pipe 1/4" MPT x 2"

39 1 N14X4S Nipple, 304 SS Pipe 1/4" MPT x 4"

40 4 NNC1024 Nut, Lock Nylon 10-24 SS

41 1 NNC516 Nut, Lock Nylon 5/16-18

42 1 RM1414 Washer, Buna N Rubber 1/4" x 1-1/4" x 1/16"

43 1 SKU28315 Fitting, Bulkhead Brass 1/4" NPT Female to Male

44 1 SPT-WHE-96-16G Harness, Wire 8 Ft 14G Extension

45 1 T1029 Powerwash pump and lter mount

46 1 T513 Hose hanger, rinse system

47 1 CB516*34G5 Bolt, Carriage 5/16-18 x 3/4" Gr 5