Preventive Maintenance

CAUTION: The greatest single cause of failure in hydraulic equipment is dirt. Keep the service jack clean and well

lubricated to prevent foreign matter from entering the system. If the jack has been exposed to rain, snow, sand, or grit,

it must be cleaned before it is used.

1. Store the jack in a well-protected area where it will not be exposed to corrosive vapors, abrasive dust, or any other

harmful elements.

2. Regularly lubricate the moving parts in the wheels, arm, and handle.

3. Replace the oil in the reservoir at least once per year. To check the oil level, lower the lift arm completely. Remove

the rubber filler plug. Oil level should be at the bottom of the filler plug hole. If necessary, add automatic transmission

fluid, and install the filler plug. CAUTION: The use of alcohol or hydraulic brake fluid could damage the seals

and result in jack failure.

4. Inspect the jack before each use. Take corrective action if any of the following problems are found:

a. cracked, damaged housing c. leaking hydraulic fluid e. loose hardware

b. excessive wear, bending, other damage d. scored, damaged piston rod f. modified equipment

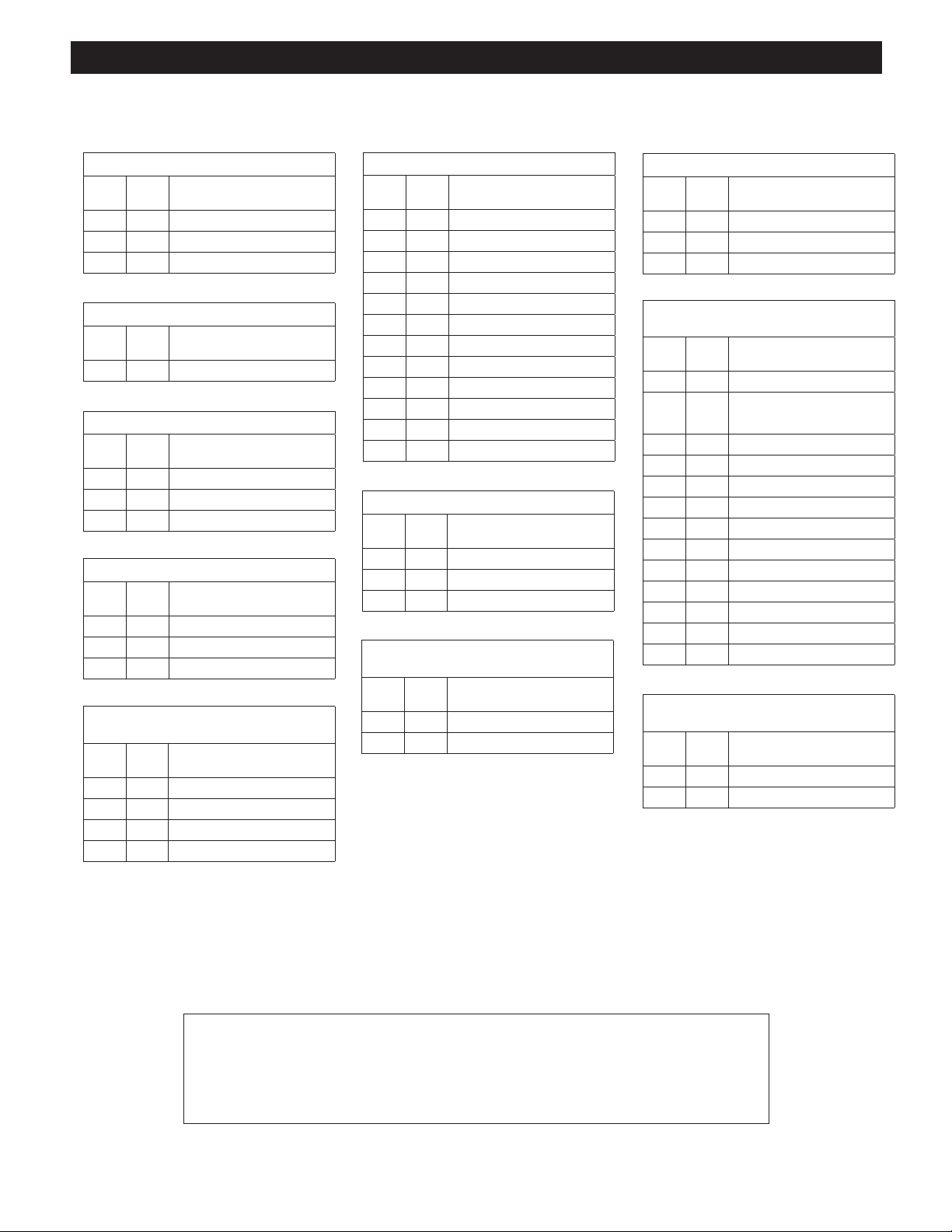

Troubleshooting Guide

Limited One Year Warranty

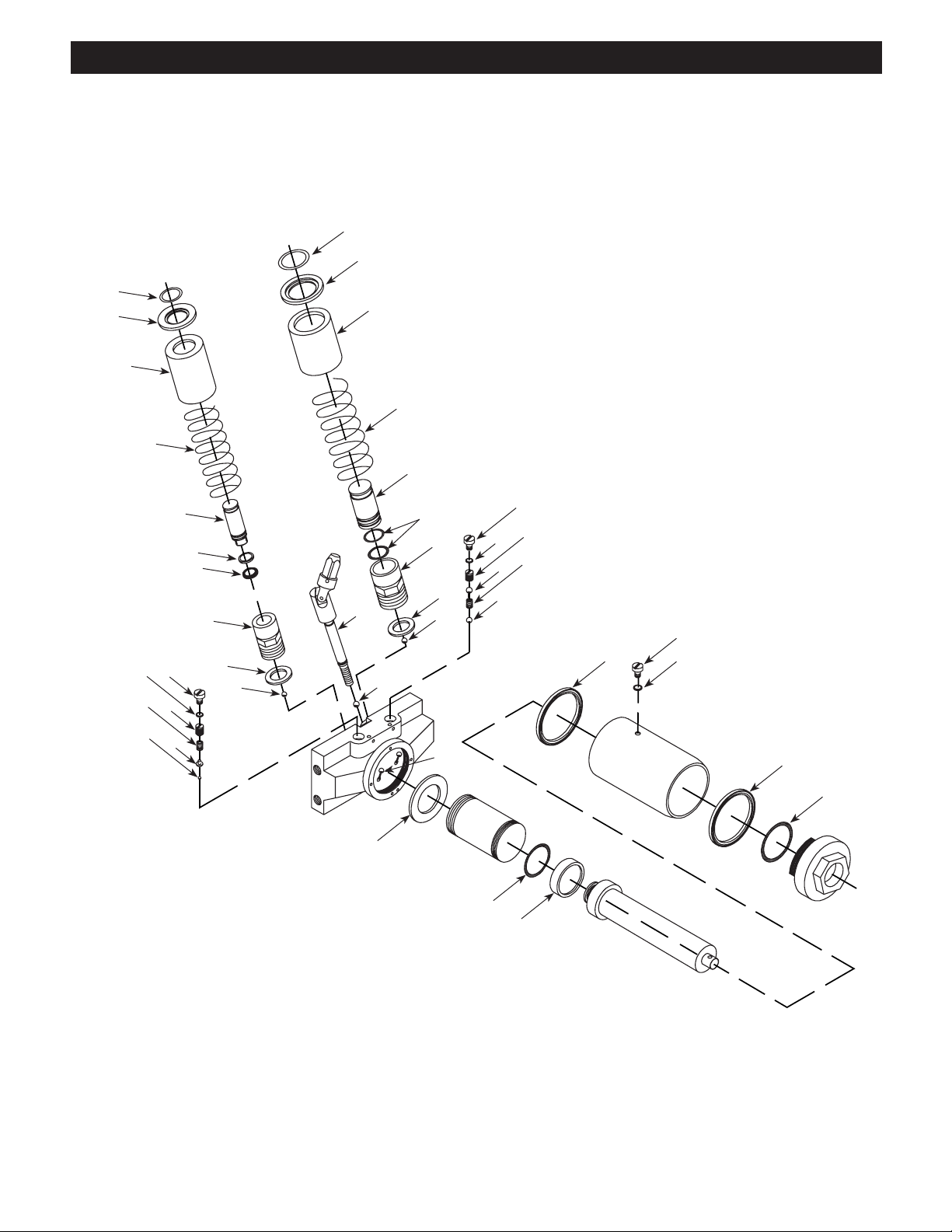

Repair procedures must be performed in a dirt-free environment by qualified personnel who are familiar with this

equipment. CAUTION: All inspection, maintenance, and repair procedures must be performed when the jack is

free of a load (not in use).

Trouble Cause Solution

Jack does not lift

1. Release valve is open. 1. Close release valve.

2. Low/no oil in reservoir. 2. Fill with automatic transmission fluid

and bleed system. Refer to Bleeding Air

from the System

3. Air-locked system. 3. Refer to Bleeding Air from the System .

4. Load is above capacity of jack. 4. Use correct equipment.

5. Delivery valve and/or bypass valve

not working correctly.

5. Clean valve to remove dirt or foreign

matter. Replace oil.

6. Packing worn out or defective. 6. Replace packing.

Jack lifts only partially

1. Too much or not enough oil. 1. Check oil level.

Jack advances slowly

1. Pump not working correctly. 1. Rework pump.

2. Leaking seals. 2. Replace seals. Seal kit No. 577275 is

available from Jackco.

Jack lifts load, but doesn't hold

1. Cylinder packing is leaking. 1. Replace packing.

2. Valve not working correctly

(suction,delivery, release, or bypass).

2. Inspect valves. Replace if necessary.

3. Air-locked system. 3. Refer to Bleeding Air from the System .

Jack leaks oil

1. Worn or damaged seals. 1. Replace seals. Seal kit No. 577275 is

available from Jackco.

Jack will not retract

1. Release valve is closed. 1. Open release valve all the way

counterclockwise (CCW). May be

necessary to clean release valve.

Jack retracts slowly

1. Cylinder damaged internally. 1. Send jack to Jackco

2. Return spring(s) is damaged. 2. Replace return spring(s).

3. Link section is binding. 3. Lubricate link sections.

Jackco Transnational Inc. (Jackco) warrants all Jackco equipment and tools to the original purchaser against any manufacturing defect in material

or workmanship for a period of one (1) year from the original date of purchase. If the defective equipment or tool is determined to be covered

under this warranty, it shall be repaired or replaced at manufacturer's discretion without charge, provided that the equipment or tool must be

returned with proof of purchase to the dealer and freight prepaid, if returned to the manufacturer. This warranty shall not apply to damage due to

accident, negligent use, lack of maintenance, abuse or applications other than the specific function the equipment or tool is designed for.

No other warranties, expressed or implied, including those of merchantability or fitness for particular purpose shall be applicable to Jackco except

as specifically stated herein. In no event shall Jackco be liable to any party for any special, direct, indirect, consequential, punitive damage of any

nature caused by the sale or use of the equipment or tool.

Note: This warranty gives the original purchaser specific legal rights which may very from state to state.