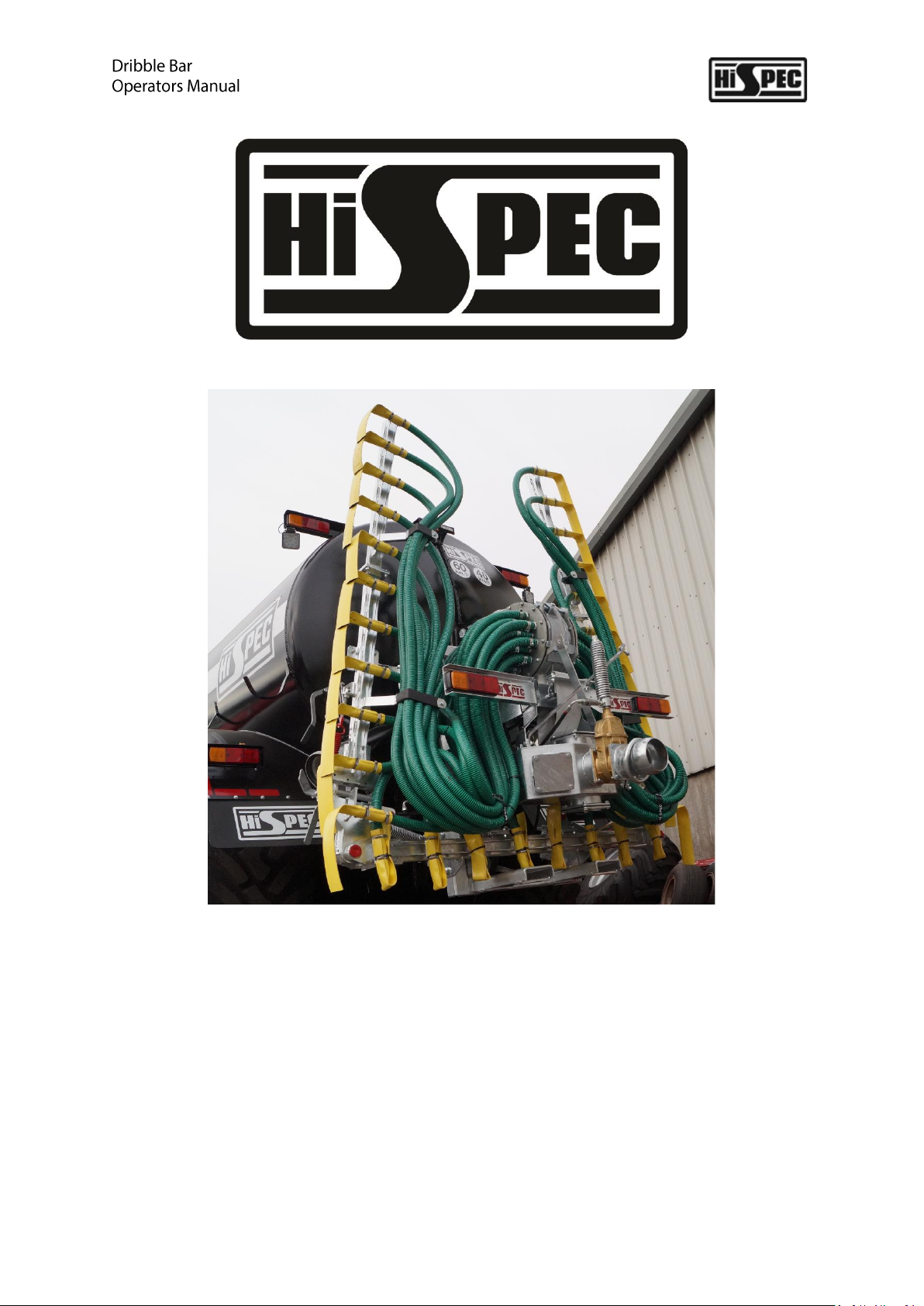

Hi-Spec 7.5 Dribble Bar User manual

1

Manufacturers of Agricultural Machinery since 1988

Hi-Spec Dribble Bar

User Manual

Models: 7.5 Dribble Bar

Revision no. ___________

2

Contents

Introduction 3

Foreword 4

Designated use of machine 4

Safety 5

General safety 6

Safety check list 7

Description of safety warnings and instructions 8

Getting started 9

Machine Requirements 9

Fitting Trailing Shoe 10

Fitting hydraulics 12

Fitting electrics 13

Operating Instructions 14

Road transportation 17

Maintenance 18

Daily 18

Weekly 18

Annually 18

Greasing Points 19

Dimensions 20

Trouble Shooting 21

Sales and Service 22

Warranty 23

Registration Forms 24

Declaration of Conformity 26

3

1.

Introduction

Congratulations on Purchasing your Hi-Spec Dribble Bar!

Please Read the Following Manual Before Using Machine.

The way you care for and maintain this machine will decide its future performance. This manual has

been carefully written to help you maintain the condition of your machine. Read this manual

carefully to learn how to operate and service your machine correctly. Failure to do so could result in

personal injury or machine damage.

Hi-Spec Dribble Bars have been designed and manufactured in compliance with the following

directives and standards;

Machinery Directive 2006/42/EEC.

Harmonised standards;

EN ISO 12100-1:2003, Safety of machinery Part 1: Basic terminology, methodology

EN ISO 12100-2:2003, Safety of machinery Part 2: Technical principles

EN ISO 4254-1:2005, Agricultural machinery -- Safety -- Part 1: General requirements

BS EN 707:1999+A1:2009, Agricultural machinery, Slurry Tankers, Safety

This manual should be kept within the vicinity of the machine at all times and should be considered a

permanent part of your machine. It should remain with the machine should you decide to sell it.

Warranty is provided as a part of Hi-Spec Engineering’s support program for customers who operate

and maintain this machine and equipment as described in this manual. This warranty provides you

the assurance that Hi-Spec Engineering will back its machines should defects appear within the

warranty period. If the machine is abused, or modified to change its performance beyond the

original factory specifications, the warranty will become void and improvements may be denied.

All information, illustrations and specifications in this manual are based on the latest product

information available at the time of publication.

It is the policy of Hi-Spec Engineering to improve its products and designs whenever it is practical

and possible to do so. We reserve the right to make changes or improvements at any time without

incurring any obligation to make such changes on products sold previously

Thank You for Choosing Hi-Spec Engineering

4

2.

Foreword

To ensure personal safety and the safety of others, please ensure that everybody that operates the

machine reads and fully understands this manual prior to operation. It is essential that you observe

all safety instructions. It is the responsibility of the owner to advise the operator of the operating

instructions and make sure they fully understand all instructions. Failure to do so may lead to

personal injury and/or machine damage. Using the dribble bar is a one person operation therefore

there should be no other person(s) in the vicinity of the machine while in use. Person under the age

of 16 must not operate the machine

Designated Use of Machine

Hi-Spec Engineering will not be held responsible for any loss or damage resulting from machine

applications other than those specified above. Any other use the machine may be put to is entirely

at the owners/operators risk. The Designated use of a dribble bar includes that the operating,

maintenance and repair instructions given by the manufacturer will be strictly fulfilled. Designated

use means operating the dribble bar is exclusively for persons familiar with the machine and fully

aware of the associated risks involved in operating it.

Intended Use:

Dribble Bar –Machine for distributing slurry, sludge or water.

5

3.

Safety

Recognise Safety Information.

Please pay attention to these signs for your own safety

This is a safety alert symbol. When you see this symbol on your machine or in this

manual be alert to the potential for personal injury.

Follow the recommended guidelines for safe operating practice:

Understand signal words: - On machine safety signs, signal words give the level of the hazard.

Danger

Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

Warning

Indicates a potentially more hazardous situation which, if not avoided, could

result in death or serious injury.

Caution

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. You will find these signs located near specific hazards

on your machinery.

6

Safety signs should be maintained and replaced when necessary.

They can often become dirty, torn or unreadable due to dirt and wear and tear.

If you need a replacement sign or have lost your user manual, please contact your Hi-Spec

authorised dealer or Hi-Spec engineering directly and we would be happy to issue you with a

replacement.

General Safety

Keep a first-aid kit and a fire extinguisher close by at all times, if possible, on your tractor with this

operator instruction manual.

•Have an emergency plan.

•Keep all emergency numbers close by; write them into your manual.

•Inspect your machine carefully each time before use; this will only take a minute.

•Remember that the first step to avoiding danger is to recognise the hazards.

7

Safety Checklist

“ DO’S “

•Always disconnect all power sources before carrying out any adjustment or

maintenance.

•Always check around the machine making sure everything is in order; this will only take

a minute.

•Study this manual. Provide training to new users. Like all farm machinery, any machine is

potentially dangerous when under the control of untrained personnel.

•Always ensure guards and other safety devices are kept in good working order. Replace

if necessary.

•Keep clear of all moving parts.

•Always keep all hydraulic hoses and electric cables clear from PTO shaft.

•Always apply the handbrake before unhitching and park the machine in a level area.

•Always take extra precautions when using the machine on hilly or sloping ground.

•Before unfolding the machine, ensure that no one is standing in the operating area.

•Before traveling on roadways set machine in transport position.

“ DON’T’S “

XNever permit untrained personnel to operate the machine without reading this manual and

or receiving training.

XNever operate the machine without having all guards in place; they are there for your safety

and protection against serious injury and death.

XNever remove guards while there is still power going into the machine, all power must be

off!

XNever operate the machine if you think there could be large stones or foreign objects inside,

they could cause serious damage to your machine.

XNever leave the machine running when unattended.

XIf the machine should become blocked with a stone or foreign object, do not attempt to free

the object while the tractor is running.

8

Description of Safety Warnings and Instructions

The following is a list of safety signs and warning labels on the Hi-Spec Dribble Bar. Look carefully

and make sure you know where on the machine they are positioned and what they mean.

Cut/sever hazard

Always read the manual before operating the machine

Always turn off the machine before carrying out any

maintenance

9

4

Getting Started

4.1

Machine Requirements

•1x double acting service set to 70L/min (for the folding and unfolding service as well as

running the macerator )

•1x 12volt power supply(cab mounted diverter switch)

10

4.2

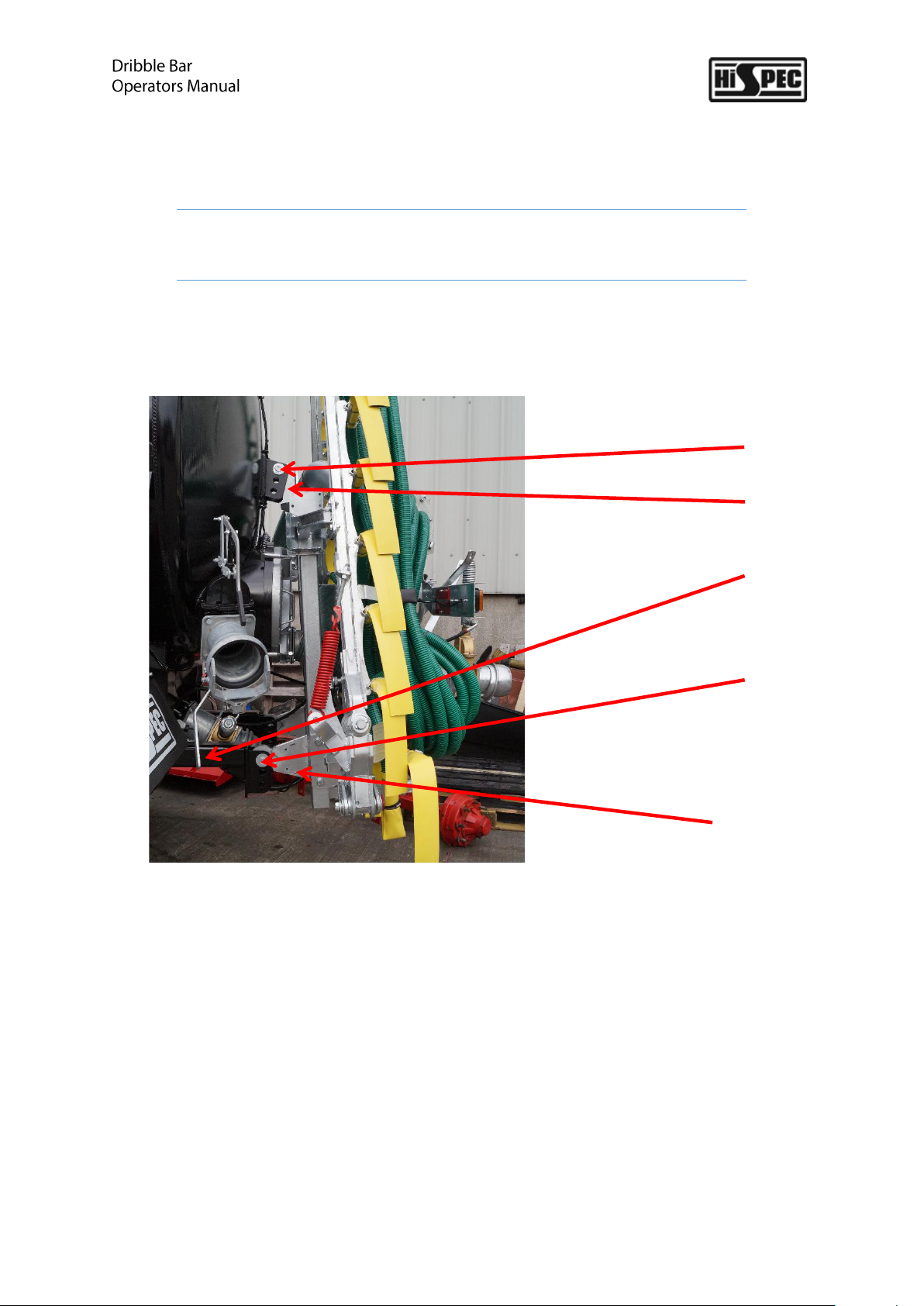

Fitting Dribble Bar to machine

The dribble bar is mounted to the tanker at three points. The two lower points use a hook and pin

type coupling, this is to allow the machine to be lifted on to the tanker easily. The top point is

coupled by a pin this secures the trailing shoe to the taker.

Top pin

Top mount

Bottom

mounts

Bottom pin

Bottom hook

11

➢Preform installation on flat level ground.

➢Lift dribble bar with pallet forks at designated points.

➢Lift dribble bar into position on the tanker.

➢Line up the lower hooks with the mounts on the tanker

➢Lower the dribble bar making sure that the hooks are seated on the pins.

➢Move the dribble bar until the top hole lines up with the corresponding hole on the tanker

and install the pin.

Pallet fork lifting points

12

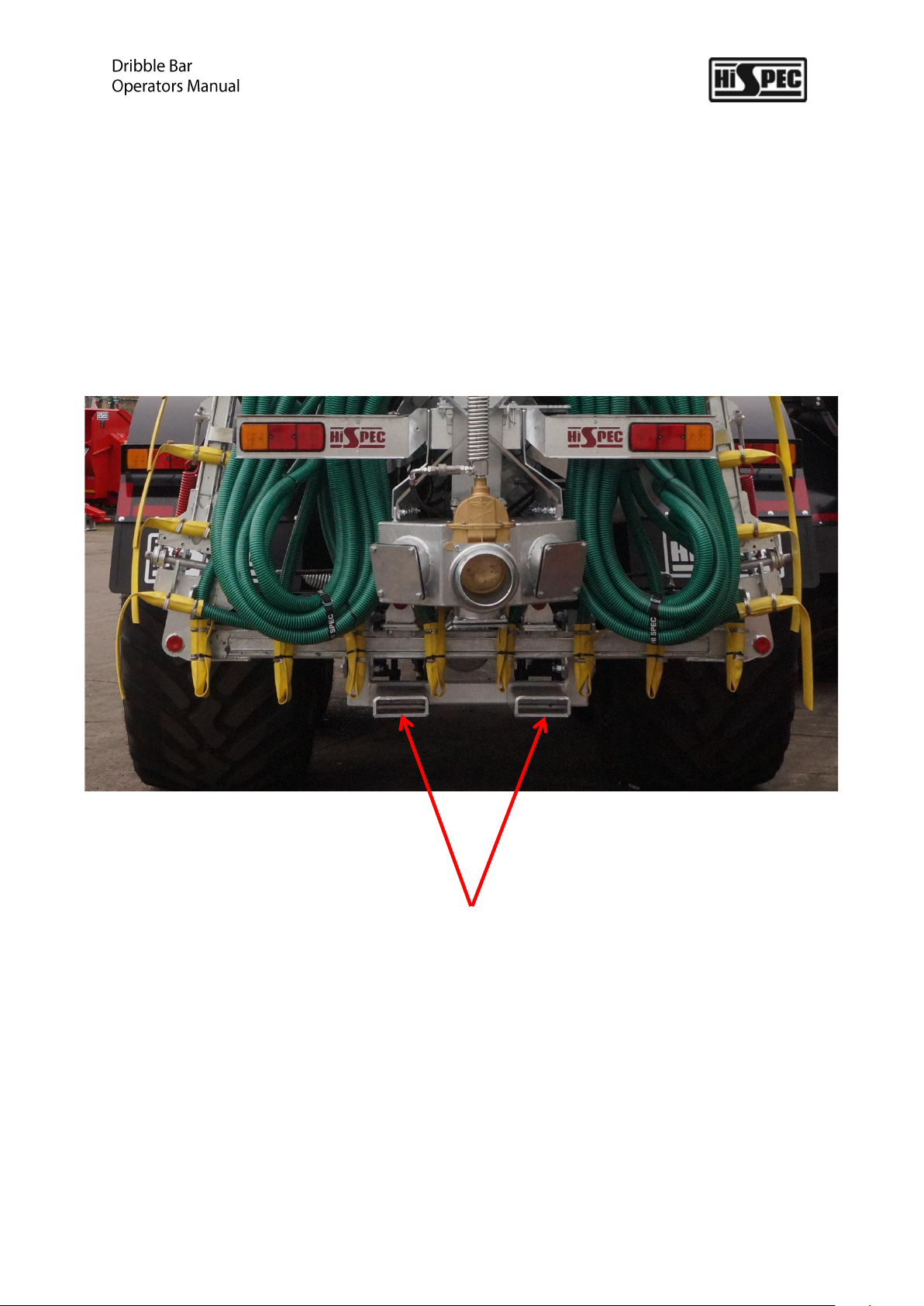

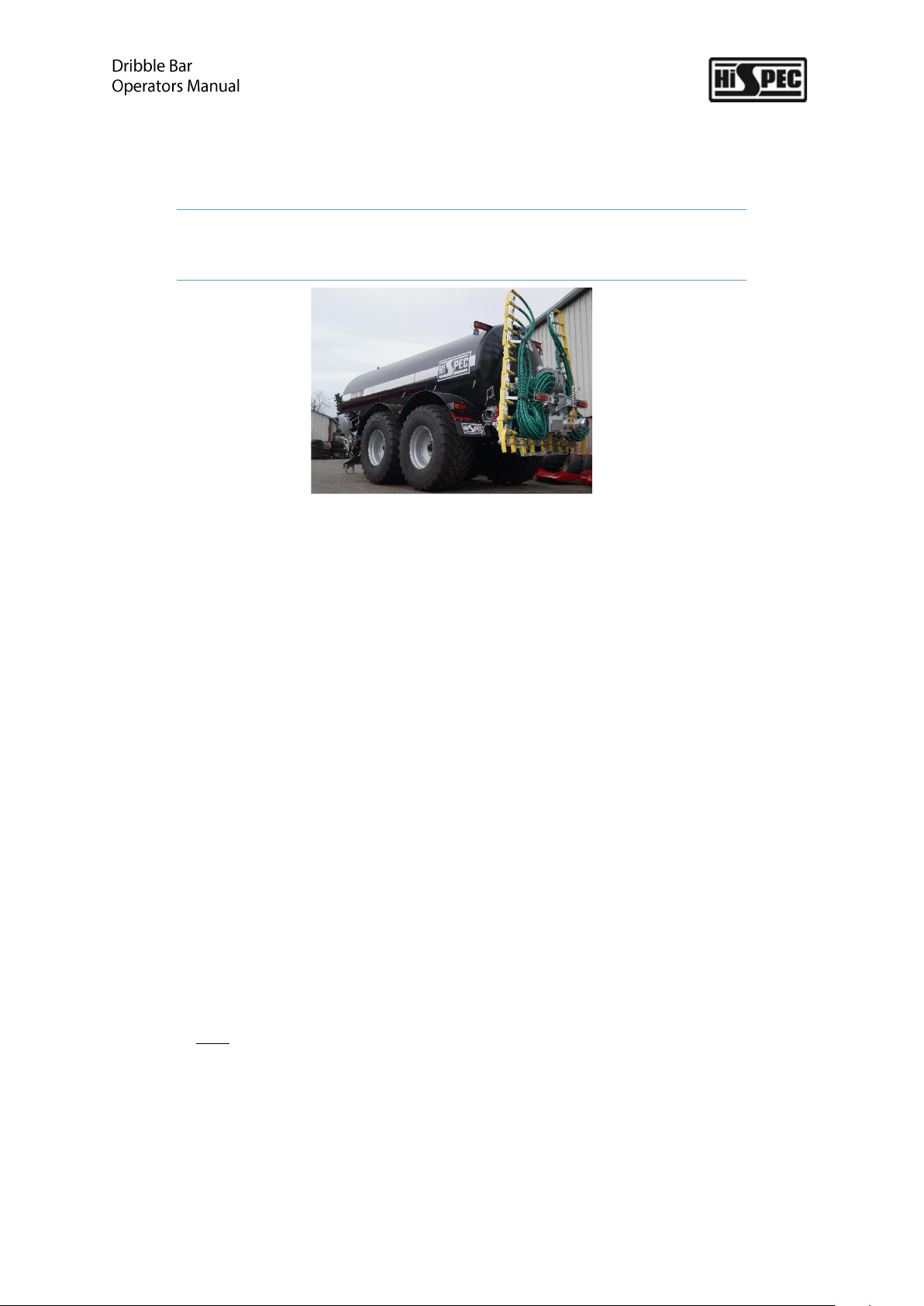

4.3

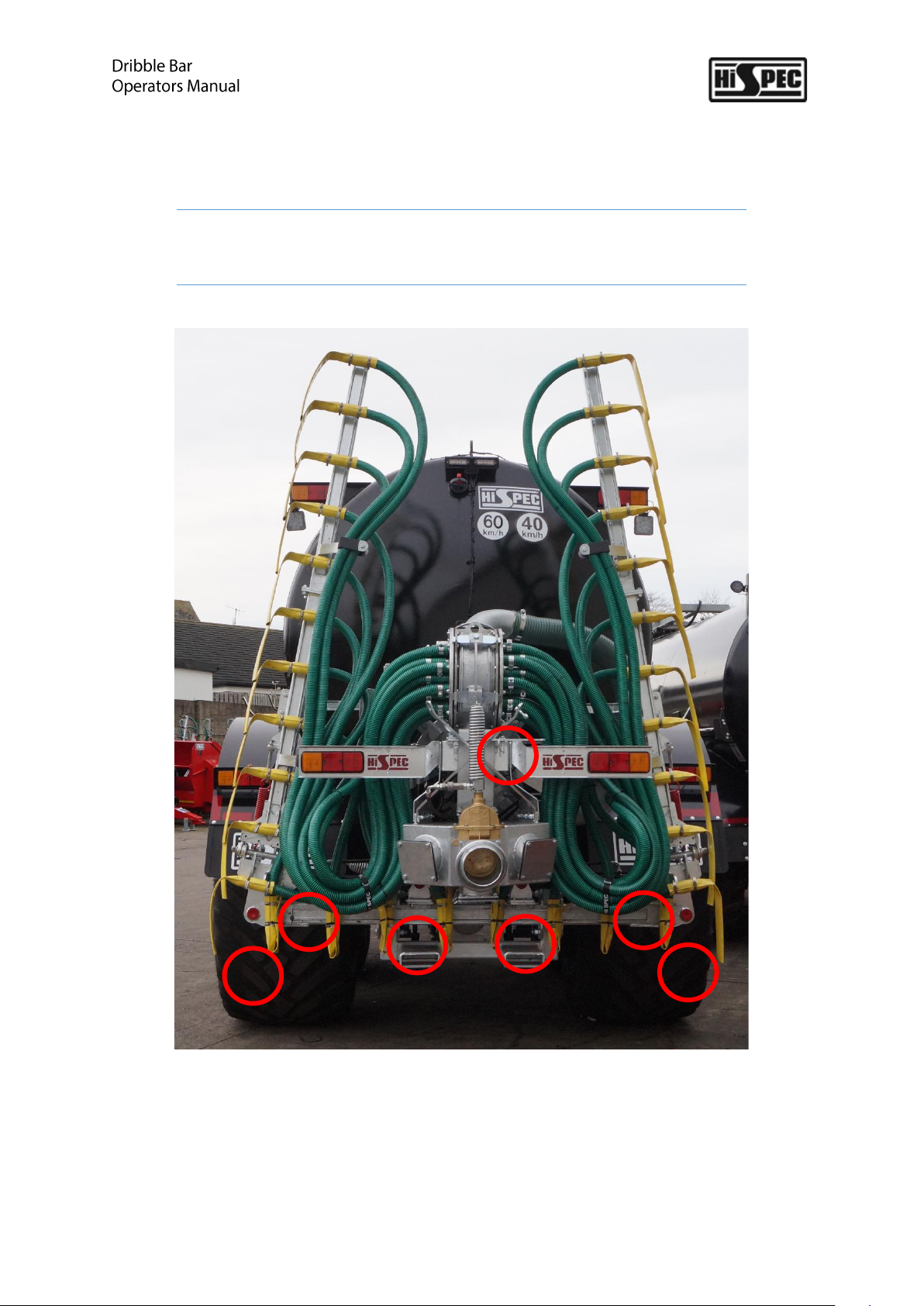

Fitting hydraulics

The hydraulic services for the dribble bar are located at the back of the tanker. This is to allow the

removal of the dribble bar unit from the back of the tanker (as shown in picture below). These

services control the folding/unfolding of the boom, the macerator and gate and the raising /

lowering of the trailing shoe.

The macerator and gate service are shared with the folding and unfolding service, this is selected by

using the electronic control box.

•Ensure hydraulic quick –connect fittings are clean and dirt free

•Ensure all hydraulic fitting are properly connected to the tractor

•Hydraulic services are colour coded by function

Hydraulic & Electric services location

Green = Macerator and Gate / Fold and Unfold

13

4.4

Fitting electrics

The electrical services are located at the back of the tanker in the same place as the

hydraulics. These are to supply power to the lights and to the electrical solenoid valve for

controlling the hydraulics.

•The lights are supplied with power by a 7-pin plug, which is connected at the back of the cab

•The electrical functions are supplied with power via 3-pin plug, connected inside the cab.

14

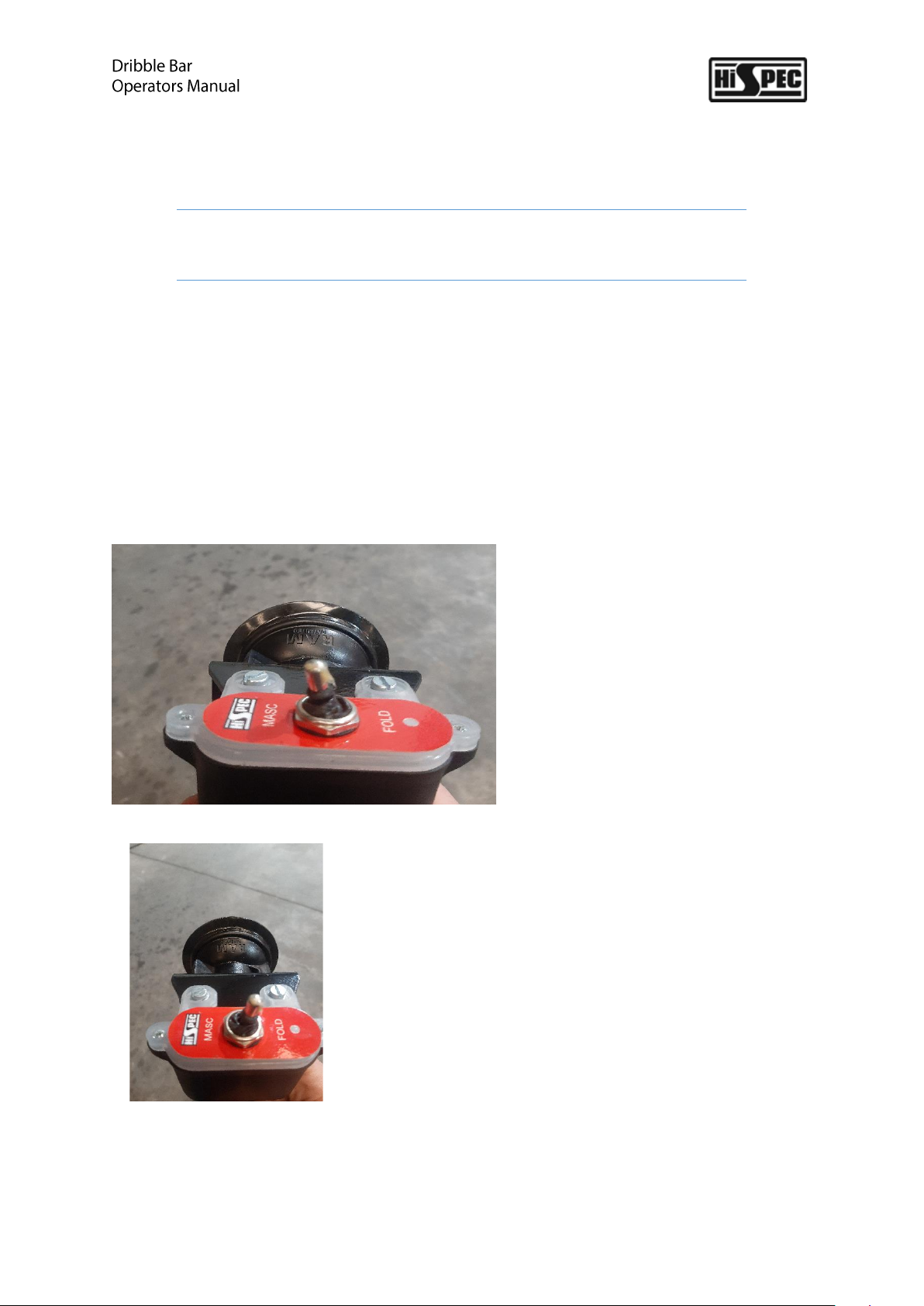

4.5

Using the Diverter Valve

To reduce the number of double acting services needed to operate the machine, a diverter

valve is used. This valve is electronically controlled from a switch box, which is mounted

inside the cab of the tractor. This valve allows the operator to select between using the

macerator/ gate and the fold/ unfold function, with the same hydraulic spool valve.

In the first position shown below, the switch is set to control the folding / unfolding of the

machine. Using the spool valve now will fold or unfold the machine.

In the second position shown, the switch is set to control the macerator and gate valve. The

gate valve is opened automatically by the backpressure created by the motor on the

macerator. The light on the switch will turn on when the macerator is selected.

Switch set in macerator / gate position (light is on)

Switch set to fold / unfold position

15

4.6

Operating Instructions

The following combinations will give quickest cycle time.

Dribble Bar Operation

1. Unfold dribble bar using the double acting service.

2. Set vacuum pump to spread

3. Engage PTO and operate at 540 RPM max.

4. Select correct forward speed for spreading rate.

5. Ensure that the diverter switch in the cab is set operate the macerator

6. Operate the double acting service and start the macerator. This should also open the gate to

the macerator. (The hydraulic line from the splash plate can be moved to the gate for

manual operation.)

7. When finished spreading reverse step 1-7.

Allow 5 seconds between turning off the macerator and switching over to folding the boom. As

the macerator takes time to slow down. If the oil cannot escape back to tank, the back pressure

will open the gate slightly causing problems when filling.

Set lever to float when stopping the macerator.

To reduce wear on the macerator blades, the direction of drive should be reversed every second

cycle. This is done by operating the double acting spool in the opposite direction.

N.B. Never run the PTO shaft when it is not straight.

Never run the macerator dry for more than 30 seconds.

16

Splash plate operation

1. Set vacuum pump to spread.

2. Engage PTO and operate at 540 RPM max.

3. Select the correct forward speed for spreading rate.

4. Open the splash plate gate by using the single acting service.

5. When finished spreading reverse step 1-4.

17

6

Road Transportation

•Before bringing your machine onto a public road, it is important to check thoroughly that the

machine is following all of the appropriate guidelines.

•Ensure lights are connected and working correctly.

•Observe local maximum road speeds for this type of machine.

•Hi-Spec Engineering strongly recommends extreme care to be taken by the operator when

travelling on rough roads with a loaded machine. Owners and / or operators do so at their

own risk.

•The operator must ensure that any other regulations regarding road use are adhered to.

•Extreme care must be taken when negotiating acute bends with high speed tractors.

•Observe local maximum road speeds for this type of machine.

•The operator must ensure that any other regulations regarding road use are adhered to.

18

7

General Maintenance

Daily:

•Empty stone trap, to empty the stone trap simply unfold the emptying hose to release

any unwanted material.

•Grease macerator

Weekly:

•Check that all controls operate freely.

•Grease all grease nipples.

•Check all hoses for cracks. Replace if necessary.

•Wash out macerator air ducts out with water

•Tighten all nuts and bolts to ensure that they don’t come lose.

Annually:

•Wash the macerator by spreading water.

•Open macerator and check for wear.

Note! If the machine is to be stored for a long period of time, grease the macerator knife

and plates.

19

8

Greasing Points

20

9

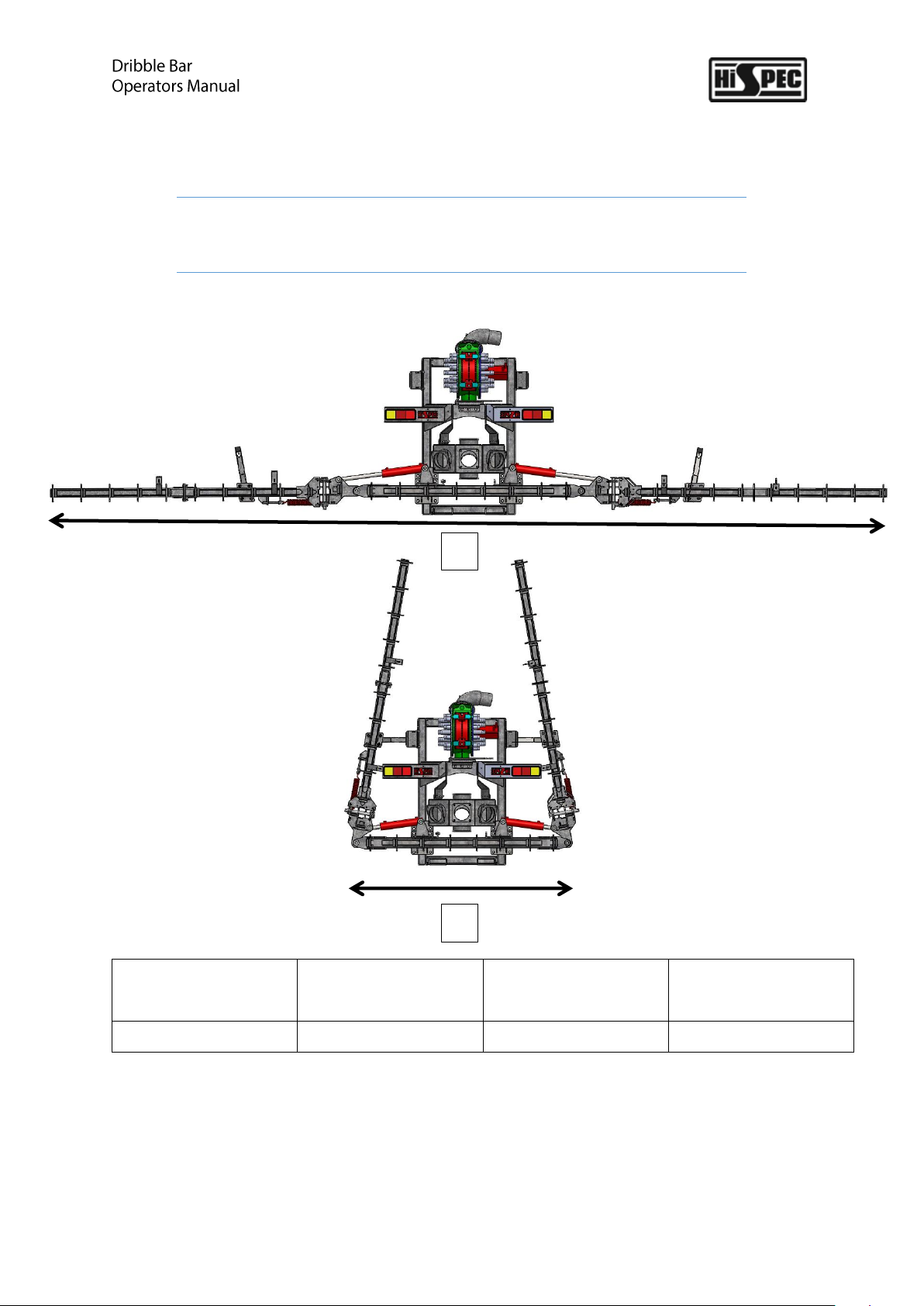

Dimensions

Model

Working width

(mm) A

Transport width

(mm) B

Unladen weight

(kg)

7.5 Dribble Bar

7650

2150

475

B

A

Table of contents

Other Hi-Spec Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions