HIAB 410K PRO User manual

HIAB 410K PRO

Operator's Manual GB

This operator’s manual is an Original Instruction and applies to cranes with serial number from:

4100056.

2021-07

Congratulations with your new crane!

You are now the owner of a quality product from Cargotec, built to the highest standards of safety

and quality.

The aim of this manual is to help you handle your crane safely and with full satisfaction.

Please read the complete manual. It provides detailed information about the crane, control system

and the practical management and maintenance of the crane.

We advise you to read it carefully and familiarize yourself with your crane before you start to use it.

Help us to improve this manual. Please send your comments and suggestions to

This manual includes interactive contents.

Download the 'Hiab AR+ App' for the interactive content in this manual. Look for the AR+

symbol. Use your device to scan the image next to the symbol.

The interactive contents in the Hiab AR+ App will display suggestions to make the crane

operation easier for you to understand. However, note that some of the content included in the

'Hiab AR+ App' may differ from the actual configuration of your crane and is subject to updates

and changes from Hiab without prior notice.

Table of Contents

1. Introduction ......................................................................................... 5

1.1. This Operator's Manual is intended for operators of this crane. ................... 5

1.2. Cleanliness certificate ................................................................... 6

1.3. Indications in the Operator’s Manual .................................................. 6

2. Structure and parts of the crane ................................................................. 9

2.1. Main groups .............................................................................. 9

2.2. Crane base with column and slewing system ........................................ 9

2.3. Stabiliser system ........................................................................ 9

2.4. Boom system .......................................................................... 10

2.5. Ladder .................................................................................. 11

2.6. Operating system - hydraulic components ......................................... 12

2.7. LHV Load holding valves ............................................................. 13

2.8. Description of HIAB 410K Pro ....................................................... 13

3. Safety precautions and warnings .............................................................. 14

3.1. Operating conditions .................................................................. 14

3.2. Wind speeds ........................................................................... 15

3.3. Definition of this loader crane ........................................................ 15

3.3.1. Noise declaration ............................................................ 17

3.3.2. Signs on the crane .......................................................... 17

3.3.3. Maximum load [AR+] ........................................................ 17

3.3.4. Maximum load moment ..................................................... 19

3.4. Signals when using a crane [AR+] .................................................. 21

3.5. Use of the crane ....................................................................... 25

3.5.1. Preparations for use ........................................................ 26

3.5.2. Crane operation ............................................................. 28

3.5.3. Driving with the crane ....................................................... 31

3.5.4. Use of lifting equipment .................................................... 32

3.5.5. Use of demountable cranes ................................................ 32

3.5.6. Ending crane operation ..................................................... 33

4. The Safety system ............................................................................... 34

4.1. Safety System SPACE 3000 ......................................................... 34

4.2. How the safety system works ........................................................ 34

4.3. Components of SPACE 3000 Safety System ...................................... 35

4.4. Operating components ................................................................ 35

4.5. Standard symbols and functions of the crane and the stabiliser system ........ 35

4.6. Main control valve ..................................................................... 37

4.7. Different stabiliser control valves .................................................... 37

4.8. High seat ............................................................................... 38

4.9. Selector valve .......................................................................... 38

4.10. OPS Operator Protection System [option] ........................................ 38

4.11. User panel SPACE 3000 ............................................................ 39

4.11.1. Indicator lights on User Interface SPACE 3000 ........................ 39

5. Starting crane operation ........................................................................ 41

5.1. Starting operations [AR+] ............................................................. 41

5.2. Stabiliser system and ground conditions ........................................... 43

5.3. Extend the stabiliser extensions ..................................................... 44

5.4. Set the stabiliser legs [AR+] .......................................................... 45

HIAB 410K PRO 3

5.5. Operate the boom system out of transport position ............................... 46

6. During operation ................................................................................. 49

6.1. OLP (Overload protection) ........................................................... 49

7. Ending crane operation ......................................................................... 51

7.1. Operate the crane to parking position ............................................... 51

7.2. Placing the stabiliser extensions and legs in transport position [AR+] .......... 52

7.3. Switching off the safety system ...................................................... 54

7.4. Emergency operation Valve-V91 .................................................... 54

7.5. Transport warning [option] ............................................................ 55

8. Maintenance and Service ....................................................................... 56

8.1. Service .................................................................................. 56

8.2. Warranty ................................................................................ 57

8.3. Follow the maintenance instructions! ............................................... 57

8.3.1. Daily inspection .............................................................. 60

8.3.2. Monthly inspection and maintenance ..................................... 64

8.3.3. Annual maintenance ........................................................ 65

8.4. Lubrication .............................................................................. 65

8.4.1. Lubrication schedule ........................................................ 66

8.4.2. Greasing the upper column bearing and three-point bridge ............ 67

8.4.3. Lubrication of slide pads in boom system ................................ 68

8.4.4. Lubrication of the hooks .................................................... 68

8.5. Checking and topping up oil levels .................................................. 69

8.5.1. Slewing housing: checking the oil level and topping up ................ 69

8.5.2. Checking of the oil level of the tank ....................................... 70

8.6. Replacement of filters ................................................................. 72

8.7. Bleeding air from the hydraulic system ............................................. 73

8.8. Troubleshooting ........................................................................ 74

8.8.1. Main fuses ................................................................... 74

8.8.2. Faults on the crane .......................................................... 74

9. Decommissioning ................................................................................ 77

9.1. Decommissioning a crane ............................................................ 77

10. Technical Data .................................................................................. 79

10.1. Documentation ....................................................................... 79

10.2. Identification of the loader crane ................................................... 79

10.3. Daily inspection checklist ........................................................... 80

10.4. Monthly inspection checklist ........................................................ 81

4 HIAB 410K PRO

1. Introduction

1.1. This Operator's Manual is intended for operators of this

crane.

This manual describes:

• Operation

• Safety precautions and warnings

• The crane control system

• Maintenance and troubleshooting

Enclosed to this manual the Installer will provide:

• Technical Data for your crane

• Technical Data and manuals for add on equipment if fitted

Study these instructions carefully

DANGER

If you do not study the complete Operator’s Manual for your crane carefully, it

could lead to fatal accidents or serious damage.

Therefore you should:

• Study the entire Operator’s Manual carefully.

• Study the operating manuals for other add-on equipment,

if fitted.

• Use the crane only after having done so.

• Follow the directions for use, operation and maintenance

of the crane and add on equipment exactly.

• Store the Technical Data and manuals from the Installer,

together with this Operator's manual.

NOTE

The manufacturer reserves the right to change specifications, equipment,

operating instructions and maintenance instructions without prior notice.

Introduction

HIAB 410K PRO 5

NOTE

Hiab shall at all times have the right to:

• install, maintain and dismantle remote diagnostics tools or similar sensor-based

connectivity capabilities (“Connectivity”) in and from the Equipment; and

• access, send, receive, collect, store and use any and all information and data

gathered through the Connectivity, including but not limited to, information

concerning efficiency, availability, downtime, operation, operating environment,

movement, condition, logon, location and similar information relating to the

Equipment (the “Information”). Such Information may be used for optimizing the

Equipment, or any related equipment or services as well as for Hiab's internal

business and/or operating purposes. Hiab shall be responsible for complying

with applicable laws and regulations related to such Information.

The customer/user shall not in any way remove, disable, or interfere with the

Connectivity or the Information. Any intellectual property rights or other right and

title in and to the Connectivity features and the Information and all their further

developments shall at all times be and remain the exclusive property of Hiab.

1.2. Cleanliness certificate

All Hiab equipment has been tested and certified at the

factory according to the Hiab Standard C250.52 that

defines the Cleanliness Requirements for Hydraulic

Systems. This means that they fulfil the cleanliness class

20/18/14 measured by the ISO 4406 standard.

All hydraulic functions have been individually tested and

fully comply with the defined requirements.

1.3. Indications in the Operator’s Manual

What must you do and not do?

The following indications are used in the Operator’s Manual:

DANGER

Danger to life for yourself or to bystanders.

Follow the instructions carefully!

WARNING

Danger of injury to yourself or to bystanders, or danger of serious damage to the

crane or other objects.

Follow the instructions carefully.

Introduction

6 HIAB 410K PRO

CAUTION

Hazard for the crane or crane components. Follow the instructions carefully.

Important:

If actions are numbered

1. Do this

2. Do that

3. ......

4. .....

5. .....

you should carry them out in numerical order!

NOTE

Extra information that can prevent problems.

TIP

Tip to make the work easier to carry out.

The symbol for reference to a component in an illustration.

(1) Refers to a component in an illustration.

[option]: Indication for parts that are not standard for the

crane, but are optional. Not all options are available for

your crane.

Illustrations used in this manual are for guidance only, and

the illustrations are provided to help identify the general

area of a crane/installation referenced in the text.

DANGER

Only persons with the requisite knowledge and experience with cranes may use

the crane. Never operate the crane when you are sick, tired, under the influence of

medicines, alcohol, or other drugs.

• Take the delivery instructions from your Hiab authorised service workshop, or receive instruction

from an experienced person from your own company before you start to operate your crane.

• Make sure that you comply with the regulations of the country in which you use the crane (for

example, certificate, safety helmet, and other personal protection devices).

1

Introduction

HIAB 410K PRO 7

DANGER

• Carry out yourself only the service and

maintenance work you have the requisite

knowledge and experience of.

• All other maintenance work may only be

carried out by a Hiab authorised service

workshop.

• Make sure that every defect is rectified

immediately, according to the instructions.

• Follow the instructions exactly!

• All other work to rectify faults must be

performed by personnel in a Hiab

authorised service workshop!

WARNING

• Never clean the electronic system, plastic components, signs, or bearings with a

high-pressure jet cleaner. It could cause damage.

• Never expose the electronic system to high electrical voltages. This could

damage the control system.

• Never immerse the controller in water or other liquid. This will make the

controller unusable.

If your crane is equipped with add-on lifting equipment (hoist, rotator, etc.):

• The operation of the crane with add-on lifting equipment can differ from the

operation as described in this manual.

• You should therefore study the Operating Manual for the add-on equipment

carefully before you use the crane.

• Take particular note when placing the crane into or out of the transport position.

Introduction

8 HIAB 410K PRO

2. Structure and parts of the crane

2.1. Main groups

This HIAB crane consists of the following main groups:

• Crane base with column and slewing system

• Stabiliser system

• Boom system

• Operating system - hydraulic components

Some accessories can be fitted depending on your crane configuration:

• Add-on lifting accessories [option]

• Hooks [option]

• Separate lifting accessories [option]

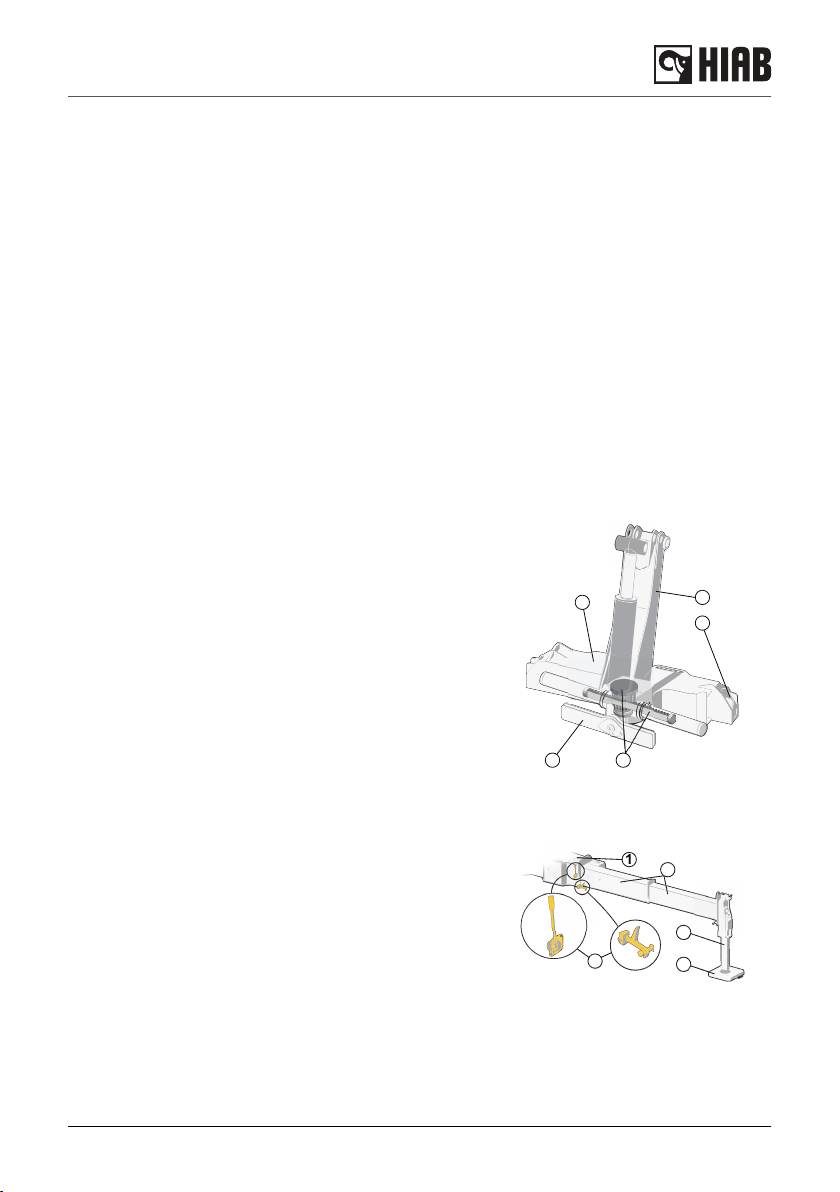

2.2. Crane base with column and slewing system

The crane base, column and the slewing system

consist of the following components:

(1) Crane base

(2) Stabiliser beam

(3) Three-point bridge

(4) Column

(5) Rack and pinion slewing system.

2.3. Stabiliser system

HIAB cranes (except stationary mounted) have two

stabiliser extensions and two stabiliser legs. Auxiliary

stabiliser systems may be needed for bigger cranes. The

stabiliser system consists of:

(1) Stabiliser beam

(2) Stabiliser extensions

(3) Stabiliser legs

(4) Stabiliser locking devices [option]

(5) Extra support plates

1

2

3

4

5

1

2

3

4

5

Structure and parts of the crane

HIAB 410K PRO 9

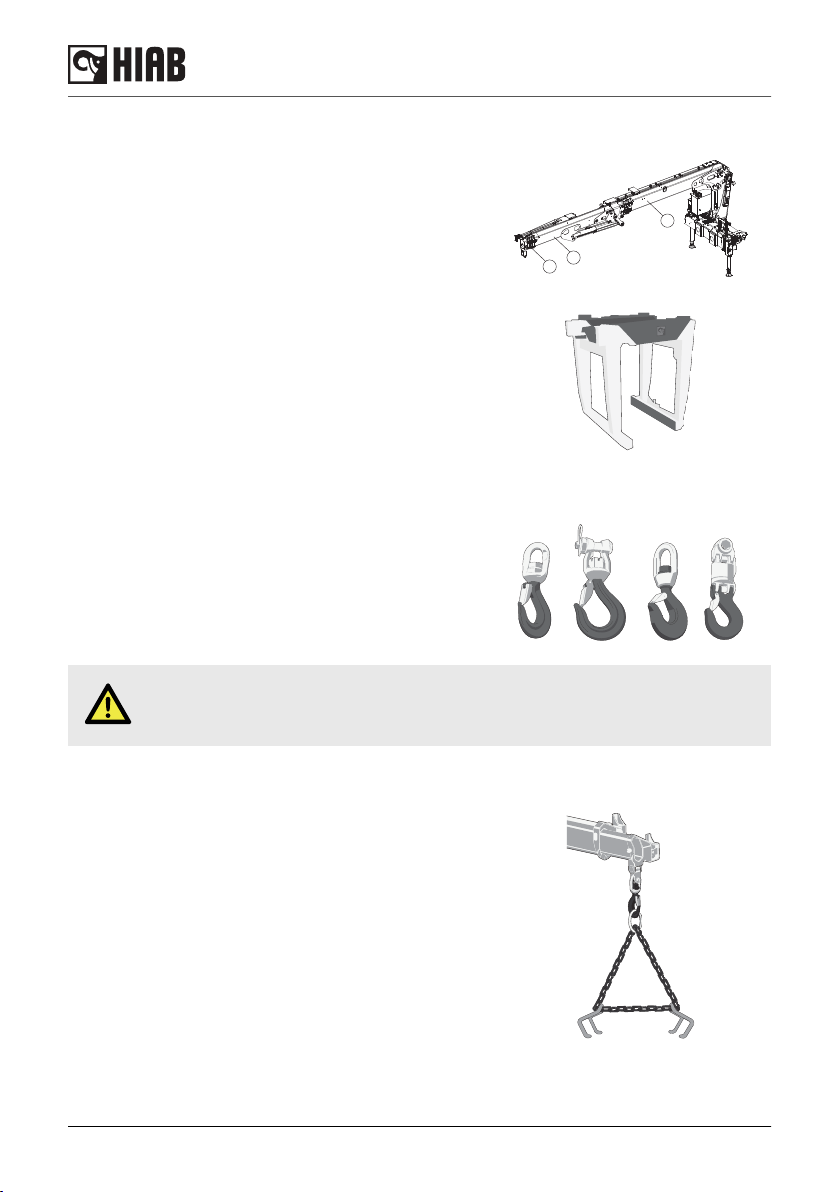

2.4. Boom system

The boom system consists of the following components:

• 1st boom (1)

• 2nd boom (2)

• Hydraulic extensions (3)

The extensions are operated by hydraulic cylinders

placed inside the extensions.

•Add-on lifting accessories [option]

Add-on lifting accessories are placed between the boom tip

and the load (e.g. pallet fork, grapple, rotator).

Hooks [option]

Different hooks can be mounted depending on the crane

model.

DANGER

Never exceed the maximum permissible loading of the hook.

Separate lifting accessories [option]

Separate lifting accessories, help to make or use a slinging

device: shackles, eye-bolts etc.

3

2

1

Structure and parts of the crane

10 HIAB 410K PRO

2.5. Ladder

The access to the high seat is through a ladder placed at

one side of the base.

Structure and parts of the crane

HIAB 410K PRO 11

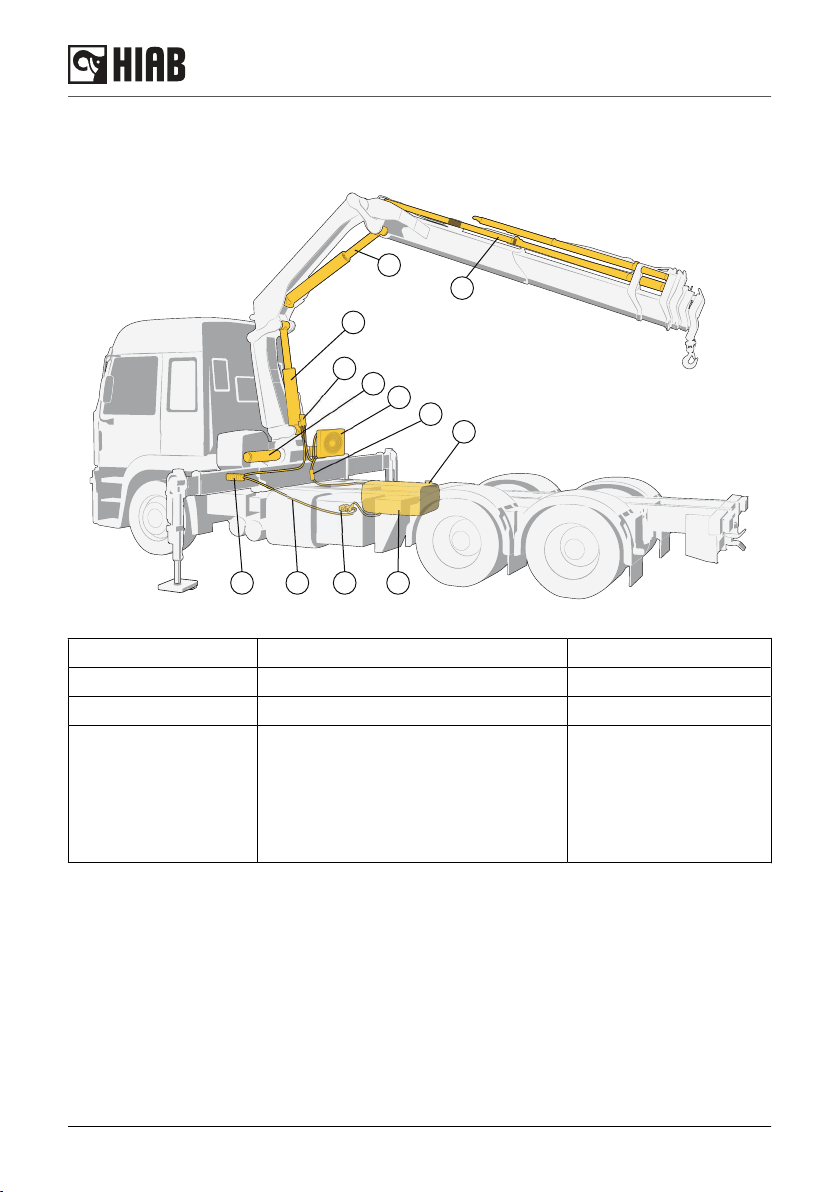

2.6. Operating system - hydraulic components

The operating system consists of the following hydraulic components:

12

3

4

5

6

7

8

9

10

11

12

(1) Oil tank (5) Stabiliser control valve [option] (11) Return filter

(2) Hydraulic pump (6) Hydraulic hoses and lines (12) Load holding valve

(3) Oil cooler [option] (7) Slewing cylinders / Slewing motors Pressure filter [option]

(4) Main control valve Actuators:

(8) First boom cylinder

(9) Second boom cylinder

(10) Extension cylinder/s

Structure and parts of the crane

12 HIAB 410K PRO

2.7. LHV Load holding valves

All cylinders are equipped with load-holding valves as a

safety device. After a crane movement, they hold the crane

in position, also in the unlikely event of a burst hose.

If there is a leak or a component fractures, such as a pipe,

hose or coupling, the load-holding valves will stop the

booms from collapsing down, even when the hydraulic

system is switched off, and you operate a particular crane

lever.

To operate a hydraulic cylinder equipped with a load

holding valve, an opening pressure is required.

2.8. Description of HIAB 410K Pro

The HIAB 410K Pro are compact, fully hydraulically operated goods cranes.

Stress history class S1 according to EN 13001-1.

Lifting capacity:

• HIAB 410K = 29.7 tonne metres (214800 lbs.ft)

The cranes are supplied in a version:

• HIAB 410K-3 reach: 22.5 metres (73' 9" ft)

The main control valve V91 and the SPACE 3000 safety system are standard equipment on the

HIAB 410K Pro.

The crane type and the manufacturer are marked on the serial number plate.

NOTE

The exact technical information for your crane is shown in the Technical Data.

Structure and parts of the crane

HIAB 410K PRO 13

3. Safety precautions and warnings

3.1. Operating conditions

You may use the crane ONLY if:

• You are outdoors or in a space with sufficient ventilation.

• With a mean wind velocity of less than 13.3 m/sec (approx. 29.7 mph). See the wind speed

table.

DANGER

•Do not use the crane in a confined space because you could suffocate from the

exhaust gases from the vehicle.

•Never use the crane in a high wind or storm. When the mean wind velocity

exceeds 13.3 m/sec (approx. 29.7 mph) the crane will behave unpredictably.

Never use the crane during a thunderstorm.

•Never use the crane at temperatures below -30°C (-22°F), as the steel's

properties deteriorate below this temperature.

WARNING

• At temperatures below 0°C (32°F), do not

touch the operating levers during the first

few minutes.

• In cold weather, the wear on the hydraulic

system is greater than at normal working

temperatures.

In cold weather, start the crane as follows:

• Engage the power take-off at low rpm.

• Allow the system to idle for a few minutes.

• Operate stabiliser legs up and down for

one minute, in order to warm up the oil.

Safety precautions and warnings

14 HIAB 410K PRO

3.2. Wind speeds

Wind speed averaged over 10 minutes at a height of 10 m

Wind

Force

Above flat ground Characteristics

m/s Wind type

0 0.0 - 0.2 Calm Calm, smoke rises vertically or nearly

vertically

1

2

0.3 - 1.5

1.6 - 3.3

Slight breeze Wind direction recognisable from smoke

plumes, the wind begins to be noticeable on

the face; leaves begin to rustle and weather

vanes can start to move.

3

4

3.4 - 5.4

5.5 - 7.9

Moderate wind Leaves and twigs in continuous movement,

small branches begin to move. Dust and

paper begin to move over the ground.

5 8.0 - 10.7

Fairly strong

wind

Small leaved branches make swaying

movements; crested waves form on lakes

and canals.

6 10.8 - 13.8

Strong wind Large branches move; you can hear the

wind whistling in telephone wires; umbrellas

can only be held with difficulty.

7 13.9 - 17.1 Severe wind Entire trees move; the wind causes difficulty

when you walk into it.

8 17.2 - 20.7 Stormy wind Twigs break off, walking is difficult.

9 20.8 - 24.4

Storm Causes superficial damage to buildings

(chimney pots, roof-tiles, and TV antennae

are blown off).

10 24.5 - 28.4 Severe storm Uprooted trees; considerable damage to

buildings etc. (occurs infrequently on land).

11 28.5 - 32.6 Very severe

storm

Causes extensive damage (occurs very infre

quently on land).

12 > 32.6 Hurricane

3.3. Definition of this loader crane

Usage of the crane

The HIAB loader crane is used to lift and move loads in the working area permitted by the load

plate and the load diagram. The cranes are normally mounted on a vehicle but they can also be

mounted on a fixed base plate. The crane can be equipped with a number of accessories.

Loader cranes are designed for loading and unloading the vehicle, as well as for other duties as

specified:

Safety precautions and warnings

HIAB 410K PRO 15

Permitted duties:

• Loading and unloading cargo from/to a vehicle

• Lifting of loads from the ground/vehicle to a higher place

• Installation work (beams, concrete plates, windows...) in building constructions

• Lifting construction material (wall boards, bricks, blocks…) on a pallet fork to a building, taking

the material from the vehicle on which the crane is mounted, from another vehicle or from the

ground

• Hoisting, e.g. beams, concrete plates and any other material and equipment used in building

construction

• Moving filling material at a construction site with a bucket

• Handling large loads (containers, boats, machinery, vehicles…)

• Collection of waste and recycling material (glass, paper, cardboard, plastic…)

• Installation of informative posts, road signs, notice boards, traffic lights, street lights…

Forbidden duties:

• Crane mounted onboard ships or floating structures, only permitted in cases authorised by Hiab

• Continuous use as a production crane in assembly lines, foundries…, except for cranes prepared

for that purpose

• Handle loads, work with submerge boom system or accessories, in strong currents such as

rivers

• Pressure against the ground, unless the crane is specifically prepared for this

• Pushing/pulling with the boom system against any type of obstacle (wall, ground…)

• Putting loads on structures if you do not know their resistance

• Lifting loads with the wrong side of the boom system

• Lifting a mass that is partially loaded or attached to another equipment/structure/element

CAUTION

There is a risk of tipping the truck and/or damaging the crane, the load or other

structures inside the working area.

Safety precautions and warnings

16 HIAB 410K PRO

DANGER

Lifting people with a crane is never allowed unless it is a MEWP crane.

3.3.1. Noise declaration

The following values for emitted noise may be taken as general and conservative values for

ordinary installations of loader cranes on normal diesel engine powered trucks. Declared dual-

number noise emission values in accordance with ISO 4871:

• Emitted A-weighted sound power level for basic loader cranes in accordance with ISO 3744:

LwA = 103 dB (Uncertainty: KwA = 2 dB).

• Emitted A-weighted sound power level for loader cranes with hoist in accordance with ISO 3744:

LwA = 107 dB (Uncertainty: KwA = 2 dB).

• A-weighted sound pressure level at loader crane control stations in accordance with ISO 11201:

LpA = 95 dB (Uncertainty: KpA = 4 dB).

Particular installations can be quieter, in which case a post installation noise measurement in

accordance with clause 6.3 of EN 12999:2011 may be used to prove this.

3.3.2. Signs on the crane

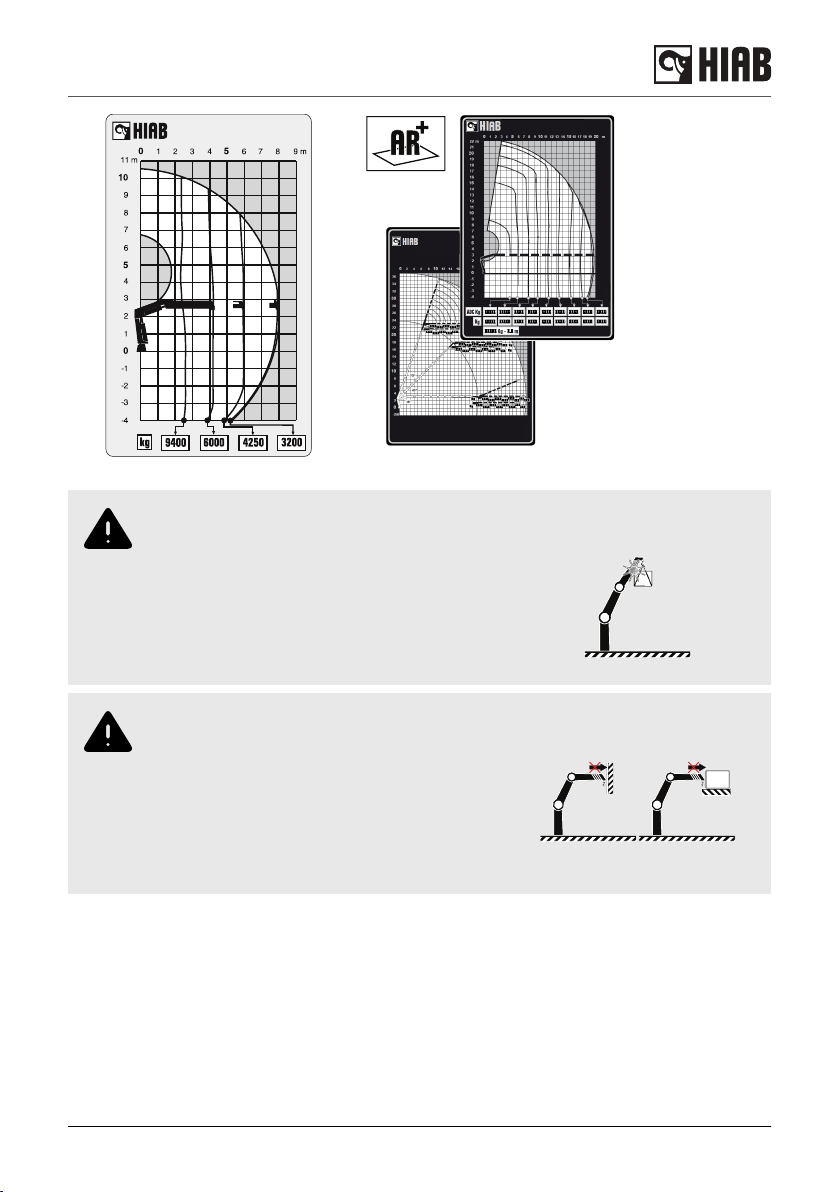

3.3.3. Maximum load [AR+]

Lifting capacity

Safety precautions and warnings

HIAB 410K PRO 17

Your crane has a certain lifting capacity, expressed in kNm or tm. This lifting capacity is also known

as the load moment. The lifting capacity is: the payload at hook multiplied by the outreach in

metres that the crane can operate at different positions. The lifting capacity of your crane

determines the maximum load your crane may lift within its working zone. However take careful

note; the greater the operating radius of the crane, the lower the lifting capacity will be because of

the weight of the boom system itself. The load plate and the load diagram on your crane show the

maximum loads you may lift in the operating reach of your crane.

DANGER

• Overloading could result in damage to the crane or in the worst case, personal

injury or death.

• Never increase a hanging load, since that may cause a load holding valve to

open and/or the vehicle to turn over.

• Never use the crane with the OLP system switched off.

NOTE

The extra weight of the lifting accessories has to be added to the load. Thus, with

lifting accessories the load you can lift is less heavy.

Load plate

You will find the load plate next to the control valve. On the

plate is the maximum weight that you may lift at a given

reach, with the 1st boom in the optimum position. In

chapter Technical Data in this manual you will find these

values for your crane.

Optimum position

The weight that your crane can lift will be determined by:

• Stabiliser extensions positioned and legs pressed to ground.

• The reach at which you are working and the optimum position of the boom.

• The optimal position for your crane is on the load plate.

DANGER

Never exceed the maximum weight on the load plate.

Load diagram

The load diagrams are placed on the column and show the maximum loads your crane may lift in

the entire working zone. The load diagram drawing will also be found in the enclosed Technical

Data.

The white area is the working zone of the crane.

The load curves show the maximum load that may be lifted at a given reach and height. For a

given maximum load, the possible working zone is to the left of the load curve. The lifting capacity

for some cranes is limited in the high lifting area.

Safety precautions and warnings

18 HIAB 410K PRO

WARNING

Care must be taken when handling loads in

the high lifting area, so the load/tool does not

come into contact with the boom system.

WARNING

Never operate the hydraulic extensions

against a solid object when the first boom is

completely lifted. Do not try to push or

compress loads when the first boom is fully

lifted, as this could cause damage to the first

boom cylinder.

3.3.4. Maximum load moment

If your crane has reached the maximum load moment (lifting capacity), the OLP gives a warning

and locks any crane movement that will increase the load moment. This is known as an OLP

situation.

Safety precautions and warnings

HIAB 410K PRO 19

If the 2nd boom is raised, the following movements are

locked:

• 1st boom down/up

• 2nd boom down

• extension boom out

If the 2nd boom is down, the following movements are

locked:

• 1st boom up

• 2nd boom up

• extension boom out

• 1st boom down (certain crane types and cases)

Lifting the load

Make sure that you always have the work in clear view. If you cannot see the load properly, you

could cause a fatal accident or serious damage.

Sling length

Always attach the load using the shortest possible sling.

The angle between the legs of the sling must not exceed

120°. The maximum working load, (usually known as the

working load limit (WLL) in standards) of a multi-legged

sling for general purposes, is calculated by multiplying the

WLL of a single leg by a mode factor (refer to the table).

Max angle to the vertical of any

sling leg (degrees)

Mode factor two

legged sling

Mode factor three and

four legged sling

0-45 1.4 2.1

45-60 1.0 1.5

If the angle between the legs of the sling is more than 90°, do not hang the slings directly on the

hook. Use a ring hanging from the hook to attach the sling.

Working close to the load

Always try to lift the load with the extension boom retracted,

however not completely. The crane then has the greatest

lifting capacity. Place the vehicle as close as possible to the

load.

>120º

Safety precautions and warnings

20 HIAB 410K PRO

Table of contents

Other HIAB Construction Equipment manuals

HIAB

HIAB 335K HiPro CD CE User manual

HIAB

HIAB J14S User manual

HIAB

HIAB HIAB T-HiDuo 013 CE User manual

HIAB

HIAB 322 HiPro CD User manual

HIAB

HIAB X-Duo 044 User manual

HIAB

HIAB 422-477 HiPro CD User manual

HIAB

HIAB K-HiPro 285-425-4 Series User manual

HIAB

HIAB L-HiPro 145 User manual

HIAB

HIAB K-HiPro 505 X4 User manual

HIAB

HIAB 435K HiPro CD User manual