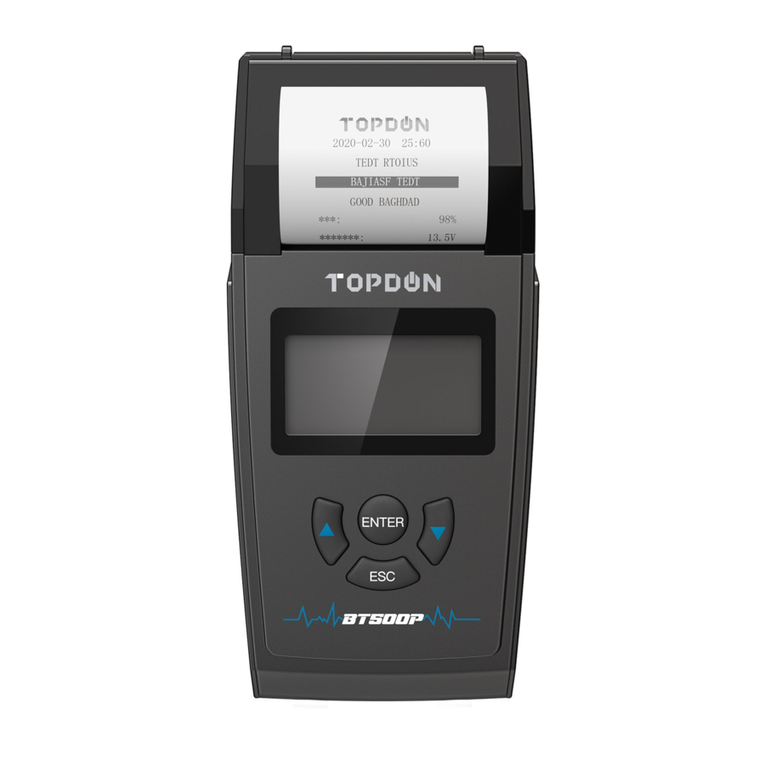

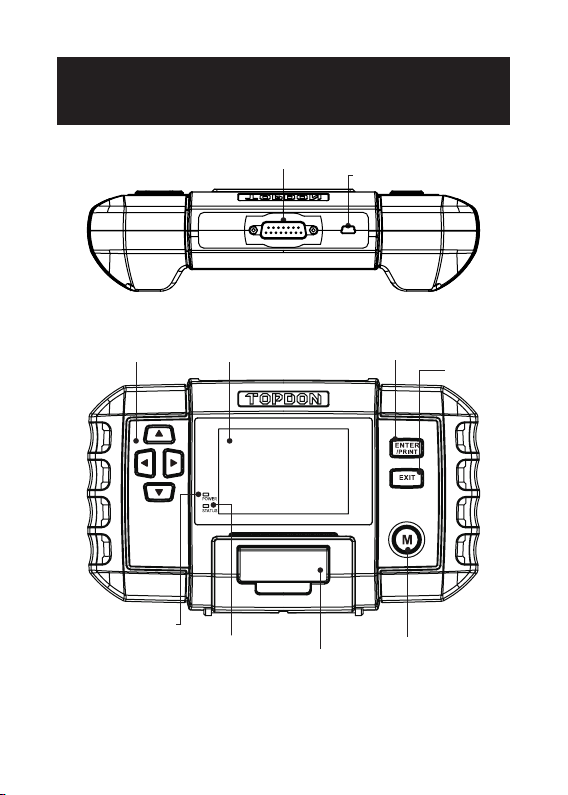

Topdon BT600 User manual

Other manuals for BT600

1

Table of contents

Languages:

Other Topdon Test Equipment manuals

Topdon

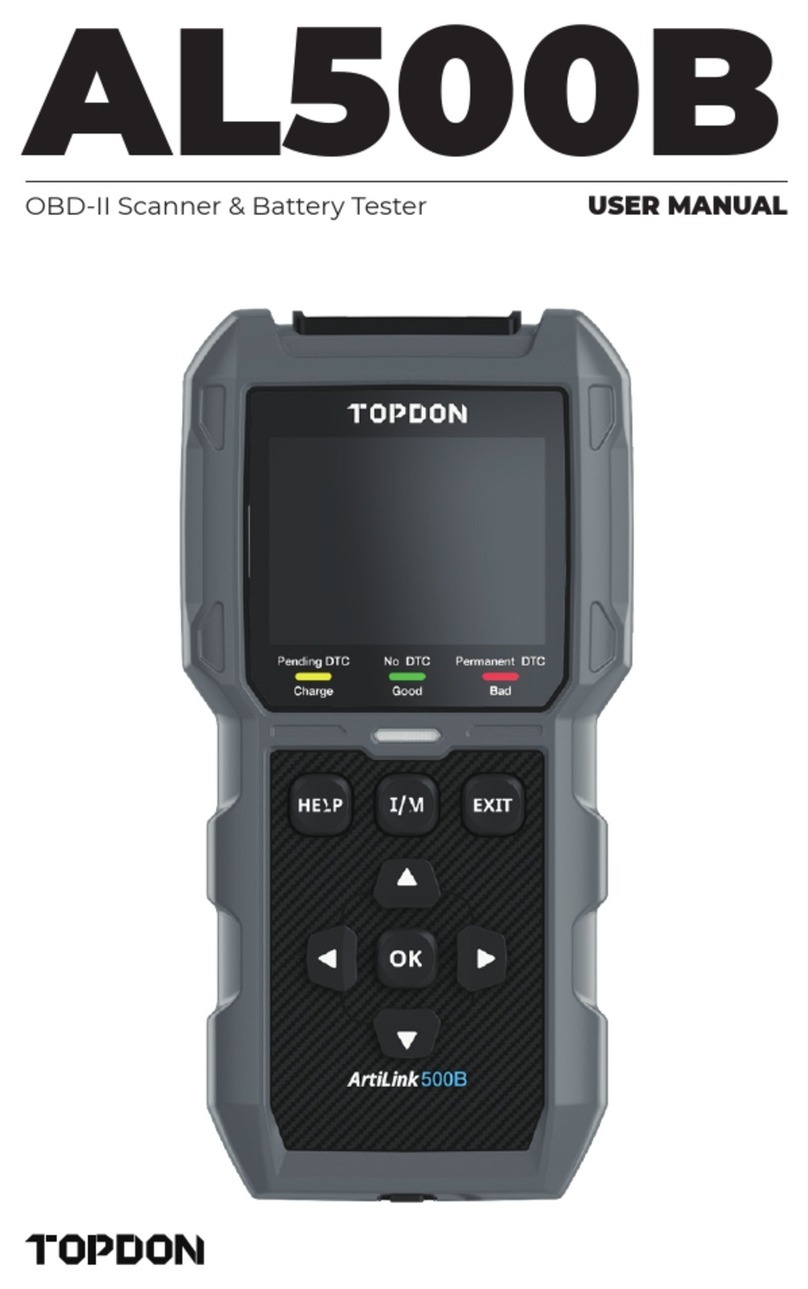

Topdon AL500B User manual

Topdon

Topdon BT100 User manual

Topdon

Topdon BT MOBILE User manual

Topdon

Topdon BT20 User manual

Topdon

Topdon BT300P User manual

Topdon

Topdon BT100W User manual

Topdon

Topdon Ultrascan OBDCAN PLUS User manual

Topdon

Topdon BT600 User manual

Topdon

Topdon BT50 User manual

Topdon

Topdon BTMOBILE PROS User manual

Topdon

Topdon Phoenix Plus User manual

Topdon

Topdon TB6000Pro User manual

Topdon

Topdon BT100 User manual

Topdon

Topdon BT300P User manual

Topdon

Topdon BT50 User manual

Topdon

Topdon BT200 User manual

Topdon

Topdon BTMOBILE lite User manual

Topdon

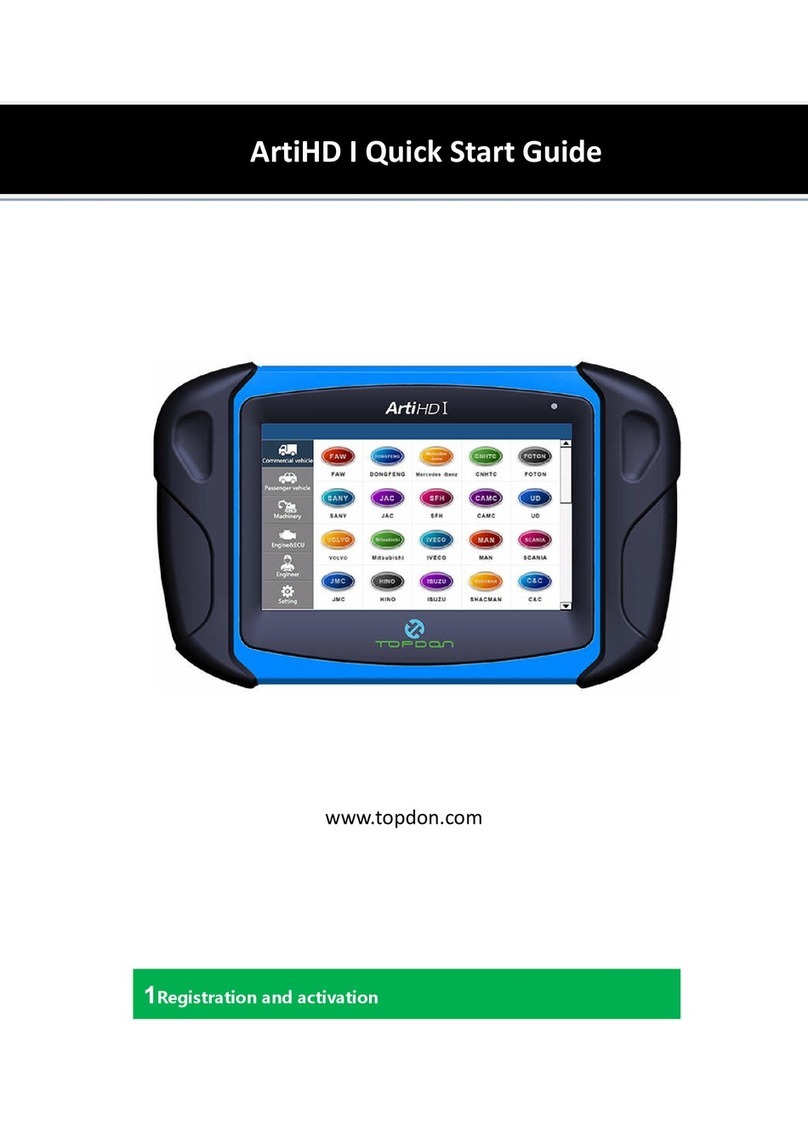

Topdon ArtiHD I User manual

Topdon

Topdon BT200 User manual

Topdon

Topdon BT20 User manual

Popular Test Equipment manuals by other brands

Electronics

Electronics Almen Gage TSP-3 instruction manual

Promax

Promax RG5410A-E User's operating manual

Flo-tech

Flo-tech FT520 instruction manual

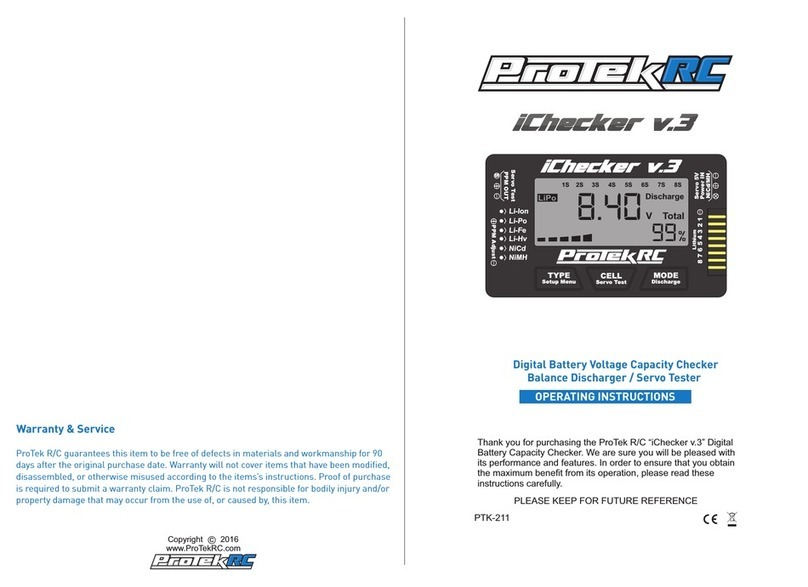

Protek RC

Protek RC iChecker v3 operating instructions

Blackline Safety

Blackline Safety G7 DOCK Getting started guide

Sea & Sea

Sea & Sea YS-D2 instruction manual