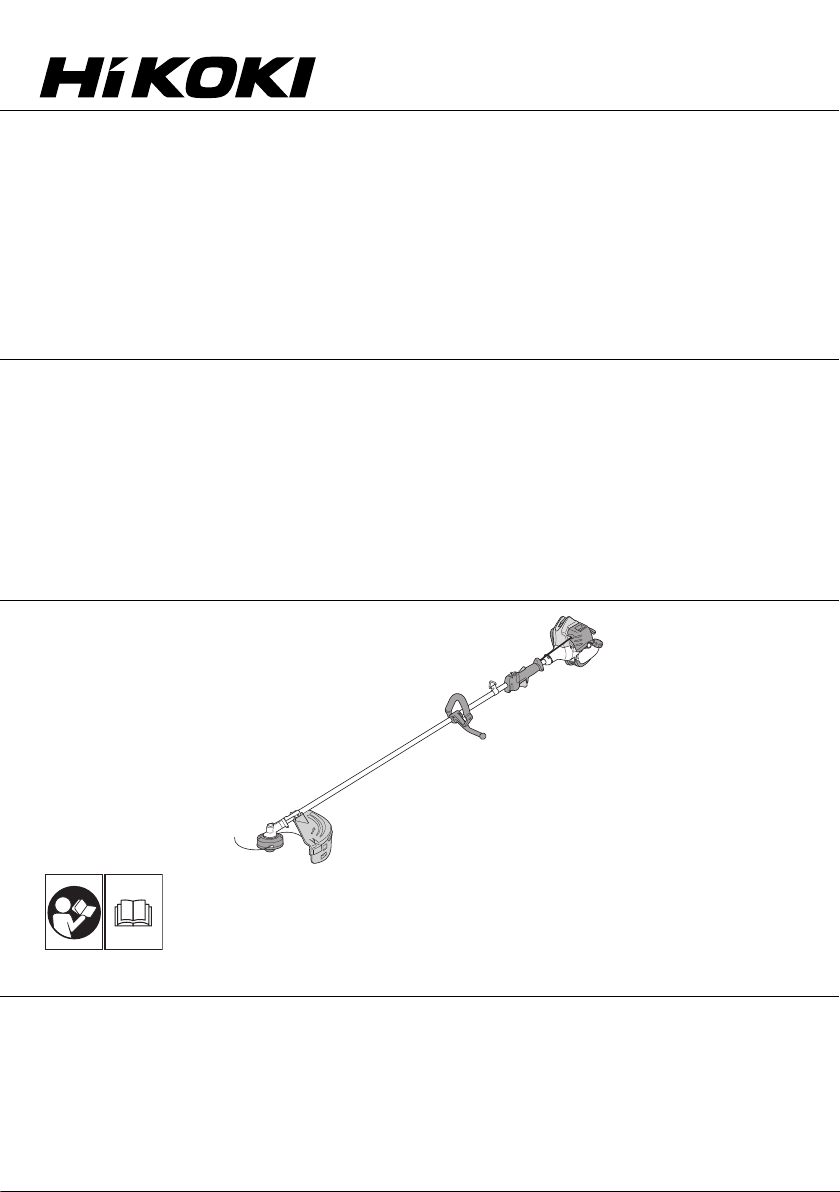

HIKOKI CG24EBSP User manual

Grass Trimmer/Brush Cutter

Rasentrimmer/Motorsense

Coupe- Herbes/Débroussailleuse

Bordatore/Decespugliatore

Motor Zeis/Motor bosmaaier

Motoguadañas/Desbrozadoras

Foice a motor/Roçadora

Read the manual carefully before operating this machine.

Lesen Sie vor der Verwendung diese Anleitung sorgfältig durch.

Lire attentivement le manuel avant d’utiliser la machine.

Leggere attentamente il manuale prima di mettere in funzione questa apparecchiatura.

Lees de handleiding zorgvuldig door voordat u de machine bedient.

Antes de utilizar esta máquina, lea cuidadosamente el manual.

Leia o manual atentamente antes de operar esta máquina.

Handling instructions

Bedienungsanleitung

Mode d’emploi

Istruzioni per l’uso

CG24EBSP (SL)

Gebruiksaanwijzing

Instrucciones de manejo

Instruções de uso

CG 24EBSP (SL) / CG 24EBSP (S) / CG 24EBS (SL)

CG 24EBS (S) / CG 24EBDP (SL) / CG 24EBDP (SLN)

CG 24EBD (SL) / CG 24EBD (SLN) / CG 27EBSP (SL)

CG 27EBSP (S) / CG 27EBS (SL) / CG 27EBS (S)

CG 27EBDP (SL) / CG 27EBDP (SLN) / CG 27EBD (SL)

CG 27EBD (SLN)

000BookCG24EBSP(SL)WE.indb1000BookCG24EBSP(SL)WE.indb1 2019/01/1515:52:172019/01/1515:52:17

2

12

345

678

91011

3

5

4

6

9

15

13

16

12

11

10

14

7

8

1

2

17

7

000BookCG24EBSP(SL)WE.indb2000BookCG24EBSP(SL)WE.indb2 2019/01/1515:52:172019/01/1515:52:17

3

12 13 14

15 16

17 18 19

20 21 22

23

21

22

20

1918

20

24

25

A

B

27

000BookCG24EBSP(SL)WE.indb3000BookCG24EBSP(SL)WE.indb3 2019/01/1515:52:172019/01/1515:52:17

4

15 m

24

T

28

0.6 mm

29

30

10 cm

23 24 25

26 27 28

29 30 31

32 33 34

000BookCG24EBSP(SL)WE.indb4000BookCG24EBSP(SL)WE.indb4 2019/01/1515:52:172019/01/1515:52:17

5

31

10 cm

31

10 cm

32

34

33

35

11–14 cm 11–14 cm

35 36 37

38 39

000BookCG24EBSP(SL)WE.indb5000BookCG24EBSP(SL)WE.indb5 2019/01/1515:52:172019/01/1515:52:17

6

English (Original instructions)

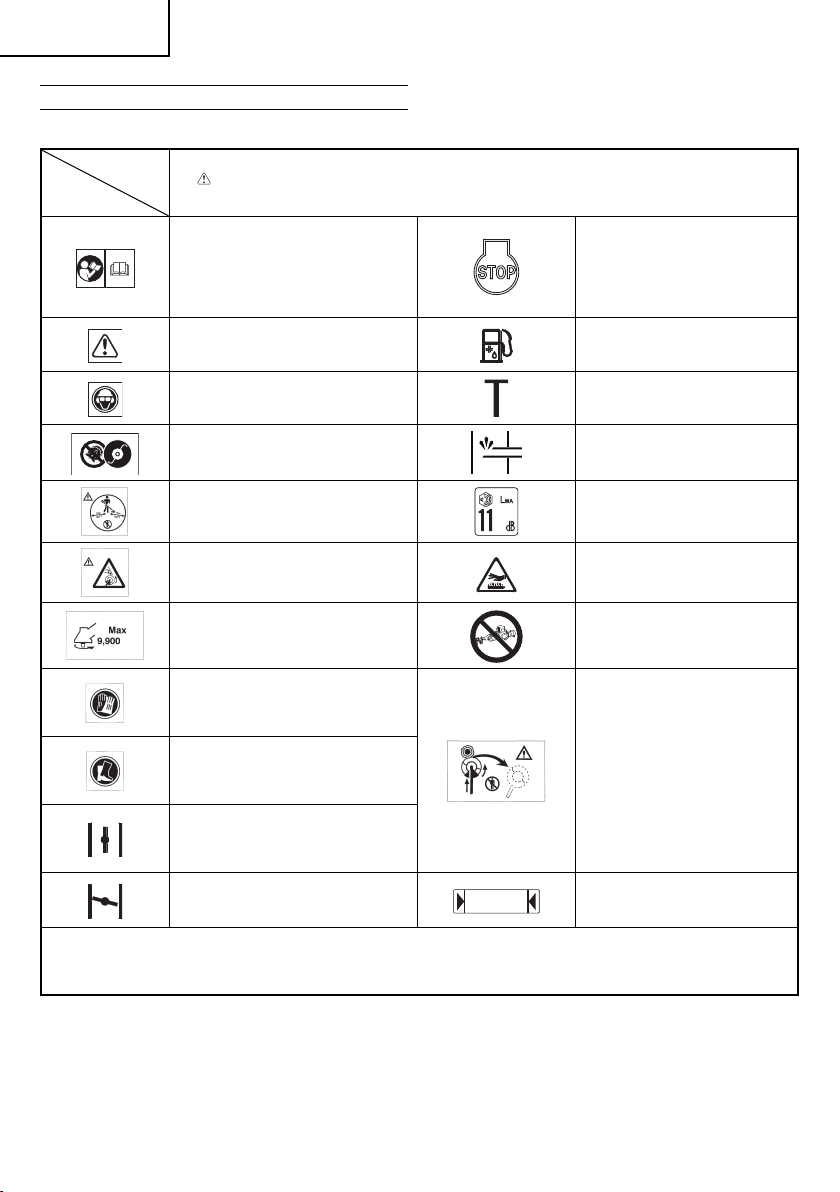

MEANINGS OF SYMBOLS

NOTE: Some units do not carry them.

Symbols

WARNING

The following show symbols used for the machine. Be sure that you understand their meaning before use.

It is important that you read, fully

understand and observe the following

safety precautions and warnings. Careless

or improper use of the unit may cause

serious or fatal injury.

Ignition stop

Read, understand and follow all warnings

and instructions in this manual and on

the unit.

Fuel and oil mixture

Always wear eye, head and ear protectors

when using this unit. Idle speed adjustment

Do not use metal/rigid blades when this

sign is shown on the unit. Priming pump

Keep all children, bystanders and helpers

15 m away from the unit. If anyone

approaches you, stop the engine and

cutting attachment immediately.

4

Guaranteed Sound power level

Be careful of thrown objects. Hot Surface –Contact with hot surface

can cause serious burns.

min-1

Shows maximum shaft speed. Do not use

the cutting attachment whose max rpm is

below the shaft rpm.

The hedge trimmer attachment cannot

be used on models with this label.

Gloves should be worn when necessary,

e.g., when assembling cutting equipment.

Blade thrust may occur when the

spinning blade contacts a solid object

in the critical area. A dangerous

reaction may occur causing the entire

unit and operator to be thrust violently.

This reaction is called blade thrust. As

a result, the operator may lose control

of the unit which may cause serious or

fatal injury. Blade thrust is more likely

to occur in areas where it is difficult to

see the material to be cut.

Use anti-slip and sturdy footwear.

Choke - Run position (Open)

Choke - Start position (Closed) Indicate handle location. Arrows which

show limits for handle positioning.

Before using your machine

• Read the manual carefully.

• Check that the cutting equipment is correctly assembled and adjusted.

• Start the unit and check the carburetor adjustment. See “MAINTENANCE”.

Contents

WHAT IS WHAT .................................................................................7

WARNINGS AND SAFETY INSTRUCTIONS ...................................8

SPECIFICATIONS .............................................................................9

ASSEMBLY PROCEDURES............................................................10

OPERATING PROCEDURES..........................................................11

MAINTENANCE...............................................................................12

TROUBLESHOOTING.....................................................................15

000BookCG24EBSP(SL)WE.indb6000BookCG24EBSP(SL)WE.indb6 2019/01/1515:52:172019/01/1515:52:17

7

English

10 10

13

8

6

2

5

4

17

13

12

24

23

3

13

119

8

11

9

15

2

14

911

7

15

14 6

2

29

11

13

8

7

6

514

4

19

18

20

5

22

22

22

CG24EBSP (S)

CG24EBS (S)

CG27EBSP (S)

CG27EBS (S)

CG24EBSP (SL)

CG24EBS (SL)

CG27EBSP (SL)

CG27EBS (SL)

7

5

4CG24EBDP (SL)

CG24EBD (SL)

CG27EBDP (SL)

CG27EBD (SL)

8

7

CG24EBDP (SLN)

CG24EBD (SLN)

CG27EBDP (SLN)

CG27EBD (SLN)

1

16

21

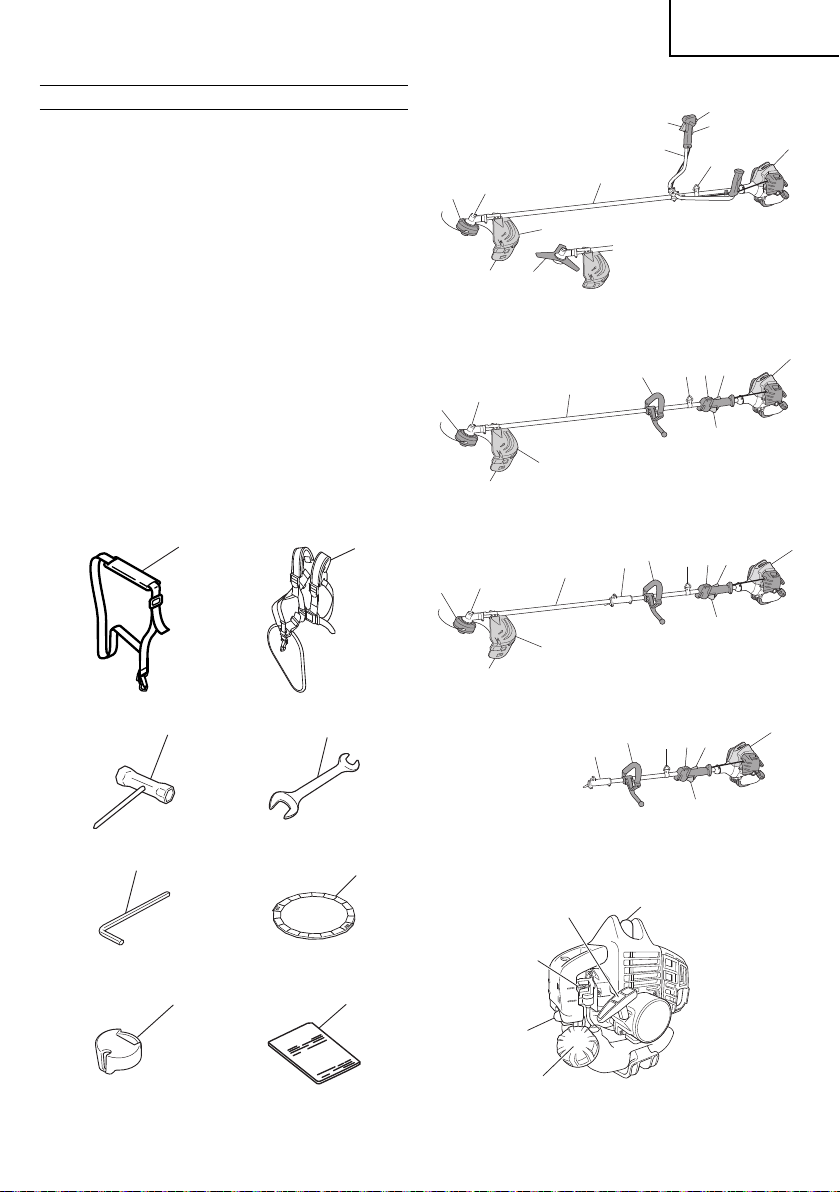

WHAT IS WHAT

Since this manual covers several models, there may be some

difference between pictures and your unit. Use the instructions that

apply to your unit.

1. Fuel cap

2. Throttle trigger

3. Starter handle

4. Cutting attachment guard

5. Cutting attachment

6. Drive shaft tube

7. Handle

8. Suspension eyelet

9. Ignition switch

10. Harness

11. Throttle trigger lockout

12. Choke lever

13. Engine

14. Angle transmission

15. Joint case

16. Combi box spanner

17. Spanner (if so equipped)

18. Hex bar wrench

19. Blade cover (if so equipped)

20. Swivel cap

21. Handling instructions

22. Guard extension

23. Spark plug

24. Priming bulb

000BookCG24EBSP(SL)WE.indb7000BookCG24EBSP(SL)WE.indb7 2019/01/1515:52:182019/01/1515:52:18

8

English

WARNINGS AND SAFETY INSTRUCTIONS

Operator safety

○Always wear a safety face shield or goggles.

○Always wear heavy, long pants and non-slip boots and gloves.

Do not wear loose clothing, jewelry, short pants, sandals or go

barefoot. Secure hair so it is above shoulder length.

○Do not operate this tool when you are tired, ill or under the

influence of alcohol, drugs or medication.

○Do not operate the tool at night or under bad weather conditions

when visibility is poor. And do not operate the tool when it is

raining or right after it has been raining.

Working on slippery ground could lead to an accident if you

lose your balance.

○Never let a child or inexperienced person operate the machine.

○Long-term exposure to noise can result in permanent hearing

impairment. Wear approved hearing protection. Pay attention

to your surroundings. Be aware of any bystanders who may be

signaling a problem. Remove safety equipment immediately

upon shutting offengine.

○Wear head protection.

○Never start or run the engine inside a closed room or building.

Breathing exhaust fumes can kill.

○Keep handles free of oil and fuel.

○Keep hands away from cutting equipment.

○Do not grab or hold the unit by the cutting equipment.

○Gloves should be worn when installing or removing the cutting

attachment. Failure to do so may result in injury.

○When the unit is turned off, make sure the cutting attachment

has stopped before the unit is set down.

○When operation is prolonged, take a break from time to time

so that you may avoid possible Hand-Arm Vibration Syndrome

(HAVS) which is caused by vibration.

WARNING

○Antivibration systems do not guarantee that you will not sustain

Hand-Arm Vibration Syndrome or carpal tunnel syndrome.

Therefore, continual and regular users should monitor closely

the condition of their hands and fingers. If any symptoms of the

above appear, seek medical advice immediately.

○If you are using any medical electric/electronic devices such

as a pacemaker, consult your physician as well as the device

manufacturer prior to operating any power equipment.

Unit/machine safety

○Inspect the entire unit/machine before each use. Replace

damaged parts. Check for fuel leaks and make sure all

fasteners are in place and securely tightened.

○Replace parts that are cracked, chipped or damaged in any

way before using the unit/machine. Faulty parts may increase

the risk of accidents and may lead to an injury.

○Make sure the safety guard is properly attached.

○Keep others away when making carburetor adjustments.

○Use only accessories as recommended for this unit/machine by

the manufacturer.

WARNING

○Never modify the unit/machine in any way. Do not use your unit/

machine for any job except that for which it is intended.

○Tampering with the engine voids the EU type approval of this

engine.

○Non-authorized modifications and/or accessories may result in

serious personal injury or the death of the operator or others.

Fuel safety

○Mix and pour fuel outdoors and where there are no sparks or

flames.

○Use a container approved for fuel.

○Do not smoke or allow smoking near fuel or the unit/machine or

while using the unit/machine.

○Wipe up all fuel spills before starting engine.

○Move at least 3 m away from fueling site before starting engine.

○Stop engine before removing fuel cap.

○Empty the fuel tank before storing the unit/machine. It is

recommended that the fuel be emptied after each use. If fuel is

left in the tank, store so fuel will not leak.

○Store unit/machine and fuel in area where fuel vapors cannot

reach sparks or open flames from water heaters, electric

motors or switches, furnaces. etc.

WARNING

Fuel is easy to ignite or get explosion or inhale fumes, so that

pay special attention when handling or filling fuel.

Cutting safety

○Do not cut any material other than grass and brush.

○Inspect the area to be cut before each use. Remove objects

which can be thrown or become entangled.

○For respiratory protection, wear an aerosol protection mask

when cutting the grass after insecticide is scattered.

○Keep others including children, animals, bystanders and

helpers outside the 15 m hazard zone. Stop the engine

immediately if you are approached.

○Always keep the engine on the right side of your body.

○Hold the unit/machine firmly with both hands.

○Keep firm footing and balance. Do not over-reach.

Losing your balance during work may lead to an injury.

○Keep all parts of your body away from the muffler and cutting

attachment when the engine is running.

○Keep cutting attachment below knee level.

○When relocating to a new work area, be sure to shut offthe

machine and ensure that all cutting attachments are stopped.

○Never place the machine on the ground when running.

○Always ensure that the engine is shut offand any cutting

attachments have completely stopped before clearing debris or

removing grass from the cutting attachment.

○Always carry a first-aid kit when operating any power

equipment.

○Never start or run the engine inside a closed room or building

and/or near inflammable liquids. Breathing exhaust fumes can

kill.

○If the tool is operating poorly and produces strange noise or

vibrations, turn offthe engine immediately and ask your dealer

to have it inspected and repaired.

Continued use under these conditions could lead to injury or

tool damage.

○Use in accordance with local laws and regulations.

Maintenance safety

○Maintain the unit/machine according to recommended

procedures.

○Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

○Keep others away when making carburetor adjustments.

○Use only genuine HiKOKI replacement parts as recommended

by the manufacturer.

Transport and storage

○Carry the unit/machine by hand with the engine stopped and

the muffler away from your body.

○Allow the engine to cool, empty the fuel tank before storing or

transporting.

Secure the machine during transport to prevent loss of fuel,

damage or injury.

○Empty the fuel tank before storing the unit/machine. It is

recommended that the fuel be emptied after each use. If fuel is

left in the tank, store so fuel will not leak.

○Store unit/machine out of the reach of children.

○Clean and maintain the unit carefully and store it in a dry place.

○Make sure engine switch is offwhen transporting or storing.

○When transporting and storing, cover blade with blade cover.

○You have to secure the machine during transport to prevent

loss of fuel, damage or injury.

If situations occur which are not covered in this manual, take care

and use common sense. Contact HiKOKI Authorized Service

Centers if you need assistance. Pay special attention to statements

preceded by the following words:

WARNING

Indicates a strong possibility of severe personal injury or loss of

life, if instructions are not followed.

000BookCG24EBSP(SL)WE.indb8000BookCG24EBSP(SL)WE.indb8 2019/01/1515:52:182019/01/1515:52:18

9

English

CAUTION

Indicates a possibility of personal injury or equipment damage,

if instructions are not followed.

NOTE

Helpful information for correct function and use.

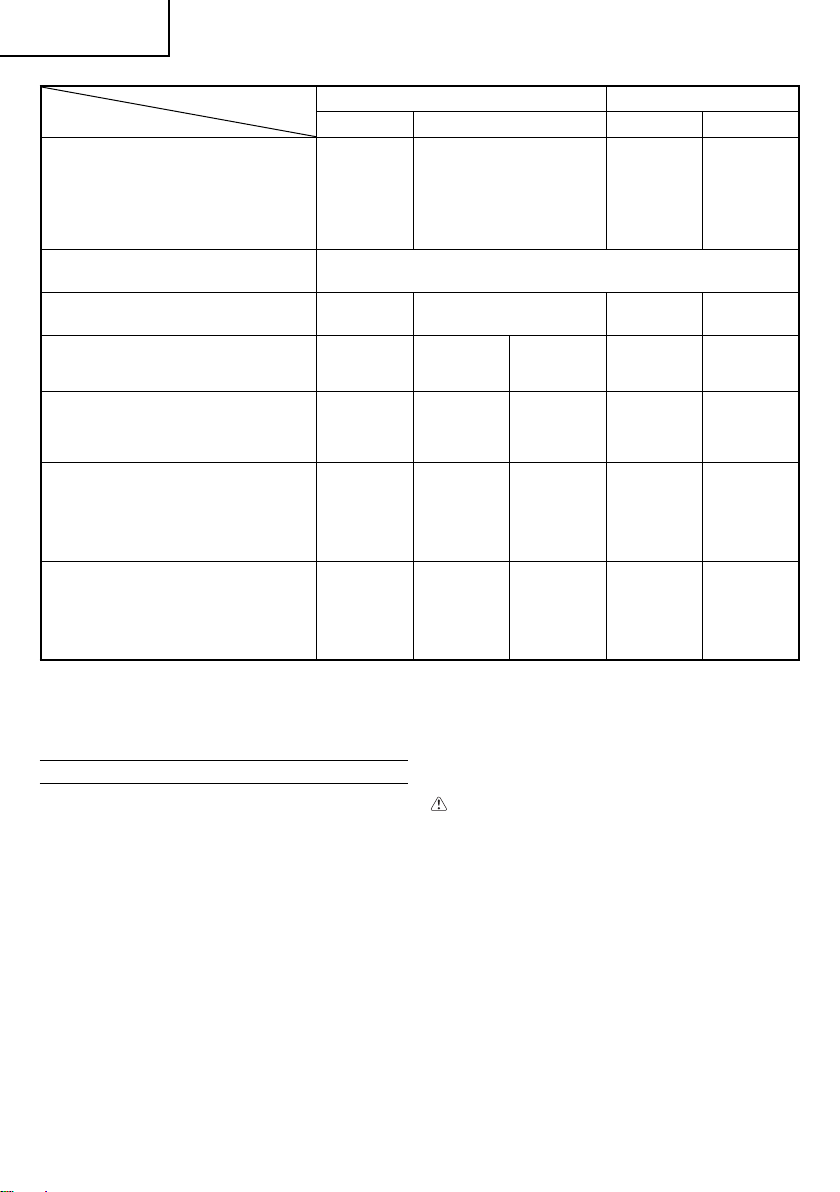

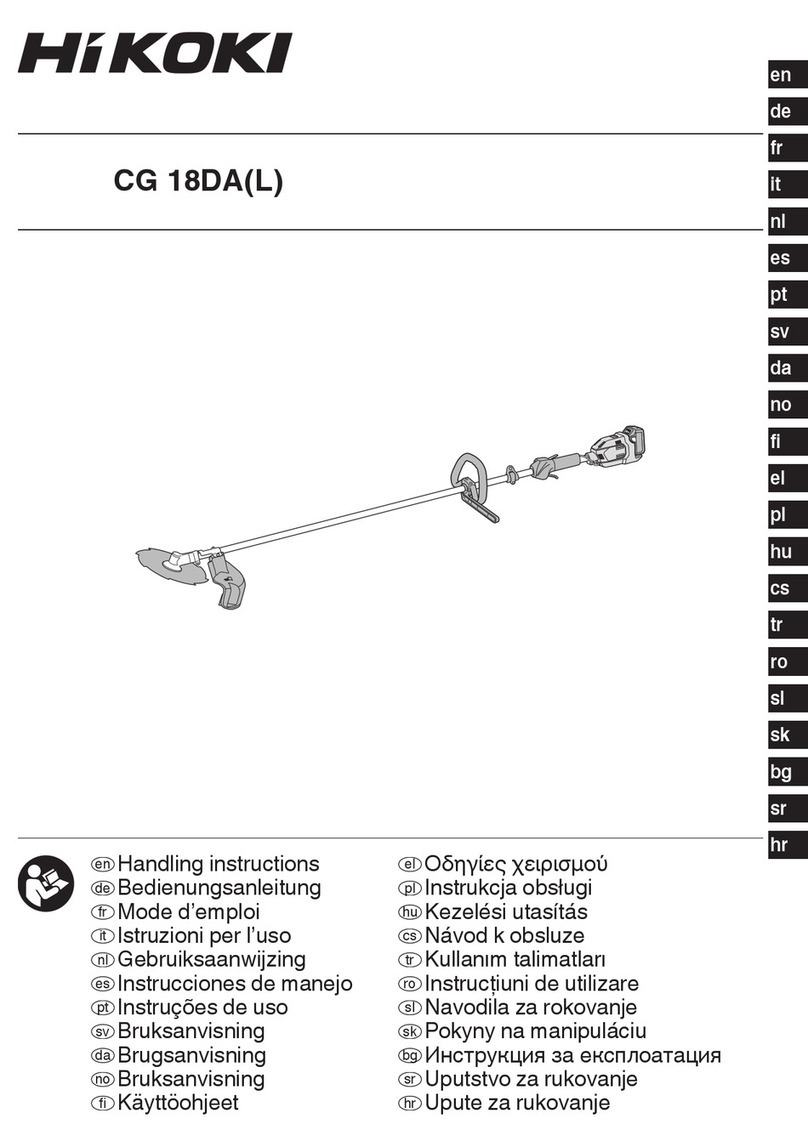

SPECIFICATIONS

Model CG24EBSP / CG24EBS CG24EBDP / CG24EBD

(SL) (S) (SL) (SLN)

Engine

Displacement (cm3)

Spark plug

Idling speed (min-1)

Speed of output shaft (min-1)

Max. engine output (kW)

23.9

NGK BMR7A

2800 –3200

7600

0.8

23.9

NGK BMR7A

2800 –3200

7600

0.8

23.9

NGK BMR7A

2800 –3200

7600

0.8

23.9

NGK BMR7A

2800 –3200

7600

0.8

Fuel tank capacity (cm3)520

Dry weight (kg) 5.0 5.2 5.3 4.4

Cutting attachment Type / Dia. (mm) Nylon cord Nylon cord Metal blade

(255) Nylon co rd ------

Sound pressure

level LpA

(dB (A))

(ISO22868)

Equivalent*

Uncertainty

99

3

99

3

96

3

99

3

99

3

Measured sound

power level LwA (dB (A))

Guaranteed sound

power level LwA (dB (A))

(2000/14/EC)

Racing

(2000/14/EC)

Racing

108

111

108

111

105

108

108

111

------

------

Vibration level (m/s2) (ISO22867)

Equivalent (Front / Left handle)*

Equivalent (Rear / Right handle)*

Uncertainty

5.6

4.0

2.0

3.9

2.7

1.2

3.1

2.8

1.2

6.2

3.4

2.0

------

------

------

CAUTION

Do not disassemble the recoil starter. You may get a possibility

of personal injury with recoil spring.

000BookCG24EBSP(SL)WE.indb9000BookCG24EBSP(SL)WE.indb9 2019/01/1515:52:182019/01/1515:52:18

10

English

ASSEMBLY PROCEDURES

Drive shaft to engine (Fig. 1)

Loosen tube locking bolt (1) about ten turns so that the bolt point will

not obstruct drive shaft tube to be inserted. When inserting drive

shaft tube, hold the tube locking bolt outward preventing inside

fitting from obstructing as well.

Insert the drive shaft into the clutch case of the engine properly until

the marked position (2) on the drive shaft tube meets the clutch

case.

Some models may come with the drive shaft already installed.

NOTE

When it is hard to insert drive shaft up to the marked position on

the drive shaft tube, turn drive shaft by the cutter mounting end

clockwise or counter-clockwise. Tighten tube locking bolt lining

up the hole in the shaft tube. Then tighten clamp bolt securely.

Installation of attachment (EBDP / EBD model only)

1. Join the attachment in place of it.

2. Make sure the lock pin (3) fits in the location hole (4) of tube and

that the tube will not come off. (Fig. 2)

3. Tighten the knob nut (5) securely. (Fig. 2)

Model CG27EBSP / CG27EBS CG27EBDP / CG27EBD

(SL) (S) (SL) (SLN)

Engine

Displacement (cm3)

Spark plug

Idling speed (min-1)

Speed of output shaft (min-1)

Max. engine output (kW)

26.9

NGK BMR7A

2800 –3200

7600

0.9

26.9

NGK BMR7A

2800 –3200

7600

0.9

26.9

NGK BMR7A

2800 –3200

7600

0.9

26.9

NGK BMR7A

2800 –3200

7600

0.9

Fuel tank capacity (cm3)520

Dry weight (kg) 5.2 5.4 5.4 4.5

Cutting attachment Type / Dia. (mm) Nylon cord Nylon cord Metal blade

(255) Nylon co rd ------

Sound pressure

level LpA

(dB (A))

(ISO22868)

Equivalent*

Uncertainty

99

3

99

3

97

3

99

3

99

3

Measured sound

power level LwA (dB (A))

Guaranteed sound

power level LwA (dB (A))

(2000/14/EC)

Racing

(2000/14/EC)

Racing

108

111

108

111

108

111

108

111

------

------

Vibration level (m/s2) (ISO22867)

Equivalent (Front / Left handle)*

Equivalent (Rear / Right handle)*

Uncertainty

6.7

4.1

2.0

4.1

3.0

1.2

3.7

2.6

1.2

5.3

3.4

2.0

------

------

------

NOTE

Equivalent noise level/vibration level are calculated as the time-weighted energy total for noise/vibration levels under various

working conditions with the following time distribution:

* 1/2 Idle, 1/2 racing.

All data subject to change without notice.

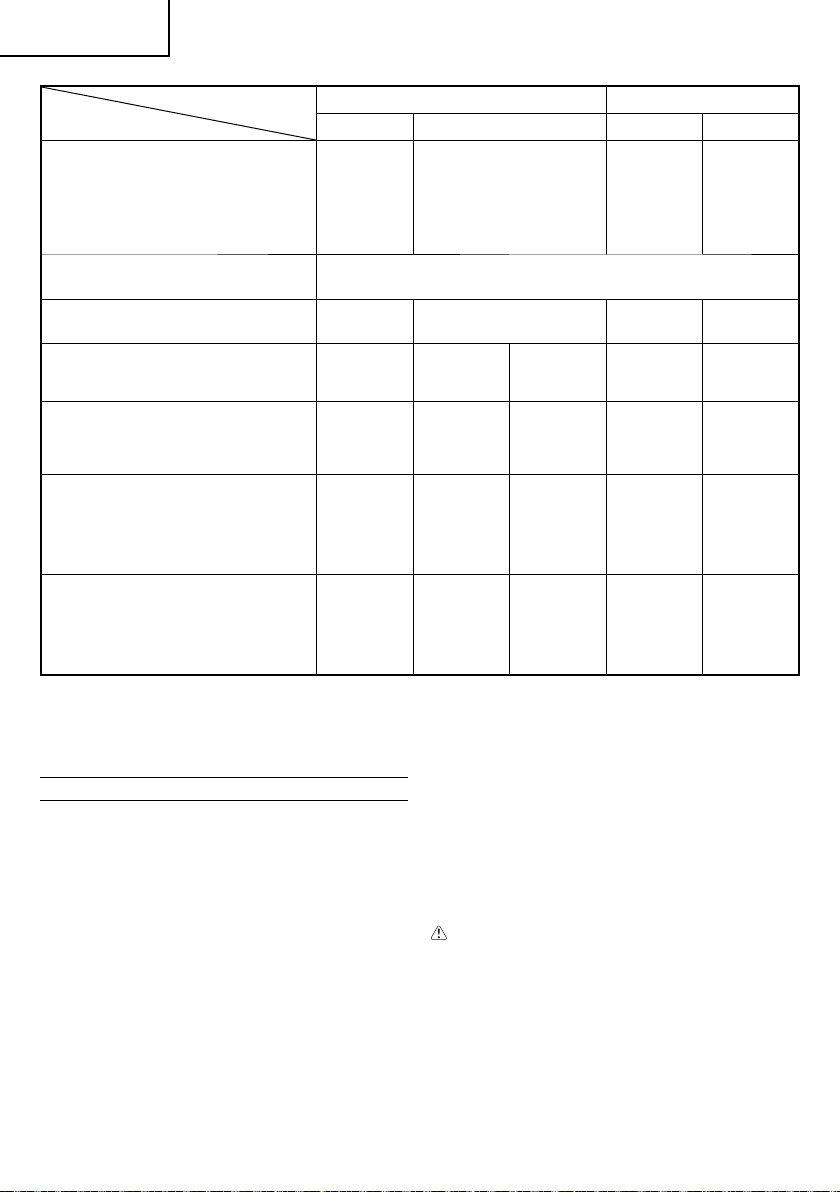

Installation of handle

(1) Loop handle type ((SL),(SLN) model)

WARNING

Always use a barrier bar (6) and shoulder harness with the loop

handle. (Fig. 3)

Attach the handle to the drive shaft tube with the angle towards the

engine.

Adjust the location to the most comfortable position before

operation.

NOTE

If your unit has handle location label on drive shaft tube, follow

the illustration.

(2) Bike handle type ((S) model)

Remove the handle bracket (7) from the assembly. (Fig. 4)

Place the handles and attach the handle bracket with four bolts

lightly. Adjust to appropriate position. Then attach it firmly with

the bolts.

Attach the protection tube to the drive shaft or handle using

cord clamps (8). (Fig. 5)

000BookCG24EBSP(SL)WE.indb10000BookCG24EBSP(SL)WE.indb10 2019/01/1515:52:182019/01/1515:52:18

11

English

Throttle wire / stop cord

Press the upper tab (9) and open the air cleaner cover. (Fig. 6)

Connect stop cords. (Fig. 7)

If the throttle outer end (10) is threaded on your unit, screw it and the

earth terminal (11) (if so equipped) into the cable adjuster stay (12)

all the way, and then tighten this cable end using the adjuster nut

(13) against the cable adjuster stay (12).

Connect throttle wire end (14) to carburetor (15) and install swivel

cap (16) (if so equipped) where is included in tool bag, onto swivel

(15) (Fig. 8).

Press the upper tab (9) and close the air cleaner cover. (Fig. 6)

Store stop cords (17) into the air cleaner cover. (Fig. 9)

Some models may come with the parts installed.

Installation of cutting attachment guard (Fig. 10 – 12)

NOTE

The guard bracket may come already mounted to the gear case

on some models.

Install the cutting attachment guard on drive shaft tube against

angle transmission. Tighten the guard bracket firmly so that the

cutting attachment guard does not swing or move down during

operation.

Install the cutting attachment guard to the guard bracket, which also

secures the guard to the gear case using the two guard mounting

screws.

WARNING

If an incorrect or faulty guard is fitted, this may cause serious

personal injury.

CAUTION

Some cutting attachment guards are equipped with sharp line

limiters. Be careful with handling it.

When using a trimmer head with two piece type cutting attachment

guard, attach the guard extension to the cutting attachment guard.

(Fig. 11)

NOTE

○When attaching the guard extension to the cutting attachment

guard, the sharp line limiter must be removed from the cutting

attachment guard, (if so installed).

○To remove the guard extension, refer to the drawings. Wear

gloves as the extension has a sharp line limiter, then push the

three square tabs on the guard one by one in order. (Fig. 12)

Installation of cutting attachment

WARNING

Install the cutting attachment properly and securely as

instructed in the handling instructions.

If not attached properly or securely, it may come offand cause

serious and/or fatal injury.

Installation of semi-auto cutting head

1. Function

Automatically feeds more nylon cutting line when it is tapped at

low rpm (not greater than 4500 min-1).

Specifications

Code No. Type of

attaching screw

Direction of

rotation

Size of

attaching screw

6696454 Female screw Counterclockwise M10×P1.25-LH

6698639

Applicable nylon cord

Cord diameter: Φ2.4 mm Length: 4 m

2. Precautions

○The case must be securely attached to the cover.

○Check the cover, case and other components for cracks or

other damage.

○Check the case and button for wear.

If the wear limit mark (18) on the case is no longer visible or

there is a hole in the bottom (19) of the button, change the new

parts immediately. (Fig. 13)

○The cutting head must be securely mounted to the unit’s gear

case.

○For outstanding performance and reliability, always use HiKOKI

nylon cutting line. Never use wire or other materials that could

become a dangerous projectile.

○If the cutting head does not feed cutting line properly, check

that the nylon line and all components are properly installed.

Contact HiKOKI Authorized Service Centers if you need

assistance.

3. Installation (Fig. 14)

○Install cutting head on gear case of grass trimmers/brush

cutters. The mounting nut is left-hand-threaded. Turn clockwise

to loosen/counterclockwise to tighten.

NOTE

○Since the cutter holder cap is not used here, keep it for when a

metal blade is used, if so equipped.

○Press the stopper pin (20) of the gear case in order to lock the

cutter holder.

4. Adjusting line length

○Set the engine speed as low as possible and tap the head on

the ground. The nylon line will be drawn out about 3 cm with

each tap. (Fig. 15)

Also, you can extend the nylon line by hand but the engine must

be completely stopped. (Fig. 16)

○Adjust the nylon line to the proper length of 11–14 cm before

each operation.

Installation of cutting blade (Fig. 17)

(If so equipped)

When installing a cutting blade, make sure that there are no cracks

or any damage in it and that the cutting edges are facing the correct

direction.

NOTE

○When installing cutter holder cap (21), be sure to set concave

side upward.

○Press the stopper pin (20) of the angle transmission in order

to lock the cutter holder (22). Please note that the cutter fixing

bolt or nut (23) has left-handed threads, (clockwise to loosen/

counter-clockwise to tighten). Tighten the fixing bolt or nut with

the box wrench. [Tightening torque : 12 ―16 N∙m]

CAUTION

○Before operation, make sure the blade has been properly

installed.

○If your unit is equipped with protection cover under a cutting

blade, check it for wear or cracks before operation. If any

damage or wear is found, replace it, as it is an article of

consumption.

○You have to wear gloves when handling the cutting blade.

WARNING

For HiKOKI heads, use only flexible, non-metallic line

recommended by the manufacturer. Never use wire or wire

ropes. They can break offand become a dangerous projectile.

OPERATING PROCEDURES

Fuel (Fig. 18)

WARNING

○The trimmer is equipped with a two-stroke engine. Always run

the engine on fuel, which is mixed with oil.

Provide good ventilation, when fueling or handling fuel.

000BookCG24EBSP(SL)WE.indb11000BookCG24EBSP(SL)WE.indb11 2019/01/1515:52:182019/01/1515:52:18

12

English

○Wear the harness as shown in the figure (if so equipped). The

blade turns counter-clockwise, therefore, be advised to operate

the unit from right to left for efficient cutting. Keep onlookers out

of working area at least 15 m.

○Use in accordance with local laws and regulations.

NOTE

Press the quick release button or pull emergency release flap

(If so equipped) in the event of emergency. (Fig. 25)

WARNING

If cutting attachment should strike against stones or other

debris, stop the engine and make sure that the attachment and

related parts are undamaged. When grass or vines wrap around

attachment, stop engine and attachment and remove them.

Stopping (Fig. 27)

Decrease engine speed and run at an idle for a few minutes, then

turn offignition switch (24).

WARNING

A cutting attachment can injure while it continues to spin after

the engine is stopped or power control is released. When the

unit is turned off, make sure the cutting attachment has stopped

before the unit is set down.

Semi-auto cutting head

○When cutting, operate engine at over 6500 min-1. Extended

time of use at low rpm may wear out the clutch prematurely.

○Cut grass from right to left.

WARNING

A cutting attachment can injure while it continues to spin after

the engine is stopped or power control is released. When the

unit is turned off, make sure the cutting attachment has stopped

before the unit is set down.

Automatically feeds more nylon cutting line when it is tapped at low

rpm (not greater than 4500 min-1).

MAINTENANCE

MAINTENANCE, REPLACEMENT OR REPAIR OF THE EMISSION

CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED

BY ANY NON-ROAD ENGINE REPAIR ESTABLISHMENT OR

INDIVIDUAL.

Carburetor adjustment (Fig. 28)

WARNING

○The cutting attachment may be spinning during carburetor

adjustments.

○Never start the engine without the complete clutch cover and

tube assembled! Otherwise the clutch can come loose and

cause personal injuries.

In the carburetor, fuel is mixed with air. When the engine is test

run at the factory, the carburetor is basically adjusted. A further

adjustment may be required, according to climate and altitude. The

carburetor has one adjustment possibility:

T = Idle speed adjustment screw.

Idle speed adjustment (T)

Check that the air filter is clean. When the idle speed is correct, the

cutting attachment will not rotate. If adjustment is required, close

(clockwise) the T-screw, with the engine running, until the cutting

attachment starts to rotate. Open (counter-clockwise) the screw

until the cutting attachment stops. You have reached the correct idle

speed when the engine runs smoothly in all positions well below the

rpm when the cutting attachment starts to rotate.

If the cutting attachment still rotates after idle speed adjustment,

contact HiKOKI Authorized Service Centers.

NOTE

Standard Idle rpm is 2800 –3200 min-1.

○Fuel contains highly flammable and it is possible to get the

serious personal injury when inhaling or spilling on your body.

Always pay attention when handling fuel. Always have good

ventilation when handling fuel inside building.

Fuel

○Always use branded 89 octane unleaded gasoline.

○Use genuine two-cycle oil or use a mix between 25:1 to 50:1,

please consult the oil bottle for the ratio or HiKOKI Authorized

Service Centers.

○If genuine oil is not available, use an anti-oxidant added quality

oil expressly labeled for air-cooled 2-cycle engine use (JASO

FC GRADE OIL or ISO EGC GRADE). Do not use BIA or TCW

(2-stroke water-cooling type) mixed oil.

○Never use multi-grade oil (10 W/30) or waste oil.

○Always mix fuel and oil in a separate clean container.

Always start by filing half the amount of fuel, which is to be used.

Then add the whole amount of oil. Mix (shake) the fuel mixture. Add

the remaining amount of fuel.

Mix (shake) the fuel-mix thoroughly before filling the fuel tank.

Fueling

WARNING

○Always shut offthe engine before refueling.

○Slowly open the fuel tank, when filling up with fuel, so that

possible over-pressure disappears.

○Tighten the fuel cap carefully, after fueling.

○Always move the trimmer at least 3 m from the fueling area

before starting.

○Always wash any spilled fuel from clothing immediately with

soap.

○Be sure to check for any fuel leakage after refueling.

Before fueling, clean the tank cap area carefully, to ensure that

no dirt falls into the tank. Make sure that the fuel is well mixed by

shaking the container, before fueling.

Starting

CAUTION

Before starting, make sure the cutting attachment does not

touch anything.

1. Set ignition switch (24) to forward away from stop position.

(Fig. 19)

* Push priming bulb (25) about ten times so that fuel flows into

carburetor. (Fig. 20)

2. Set choke lever (27) to START position (closed) (A) (Fig. 21)

3. Pull recoil starter briskly, taking care to keep the handle in your

grasp and not allowing it to snap back. (Fig. 22)

4. When you hear the engine want to start, return choke lever to

RUN position (open) (B). Then pull recoil starter briskly again.

NOTE

If engine does not start, repeat procedures from 2 to 4.

5. Then allow the engine about 2–3 minutes to warm up before

subjecting it to any load.

6. Check that the cutting attachment does not rotate when the

engine is idling.

Cutting (Fig. 23 – 26)

○When cutting, operate engine at over 6500 min-1. Extended

time of use at low rpm may wear out the clutch prematurely.

○Cut grass from right to left.

○Blade thrust may occur when the spinning blade contacts a

solid object in the critical area.

A dangerous reaction may occur causing the entire unit and

operator to be thrust violently. This reaction is called blade

thrust. As a result, the operator may lose control of the unit

which may cause serious or fatal injury. Blade thrust is more

likely to occur in areas where it is difficult to see the material to

be cut.

000BookCG24EBSP(SL)WE.indb12000BookCG24EBSP(SL)WE.indb12 2019/01/1515:52:182019/01/1515:52:18

13

English

WARNING

When the engine is idling the cutting attachment must under no

circumstances rotate.

Air filter (Fig. 29)

The air filter must be cleaned from dust and dirt in order to avoid:

○Carburetor malfunctions

○Starting problems

○Engine power reduction

○Unnecessary wear on the engine parts

○Abnormal fuel consumption

Clean the air filter daily or more often if working in exceptionally

dusty areas.

Cleaning the air filter

Open the air filter cover and the filter (28). Rinse it in warm soap

suds. Check that the filter is dry before reassembly. An air filter

that has been used for some time cannot be cleaned completely.

Therefore, it must regularly be replaced with a new one. A damaged

filter must always be replaced.

Fuel filter (Fig. 30)

Drain all fuel from fuel tank and pull fuel filter line from tank. Pull

filter element out of holder assembly and rinse element in warm

water with detergent.

Rinse thoroughly until all traces of detergent are eliminated.

Squeeze, do not wring, away excess water and allow element to air

dry.

NOTE

If element is hard due to excessive dirt buildup, replace it.

Spark plug (Fig. 31)

The spark plug condition is influenced by:

○An incorrect carburetor setting

○Wrong fuel mixture (too much oil in the gasoline)

○A dirty air filter

○Hard running conditions (such as cold weather)

These factors cause deposits on the spark plug electrodes, which

may result in malfunction and starting difficulties. If the engine

is low on power, difficult to start or runs poorly at idling speed,

always check the spark plug first. If the spark plug is dirty, clean it

and check the electrode gap. Re-adjust if necessary. The correct

gap is 0.6 mm. The spark plug should be replaced after about 100

operation hours or earlier if the electrodes are badly eroded.

NOTE

In some areas, local law requires using a resistor spark plug

to suppress ignition signals. If this machine was originally

equipped with resistor spark plug, use same type of spark plug

for replacement.

Angle transmission (Fig. 32)

Check angle transmission or angle gear for grease level about every

50 hours of operation by removing the grease filler plug on the side

of angle transmission.

If no grease can be seen on the flanks of the gears, fill the

transmission with quality lithium based multipurpose grease up to

3/4. Do not completely fill the transmission.

Semi-auto cutting head

Nylon line replacement

(1) Remove the case (29) by firmly pushing inward the locking tabs

with your thumbs as shown in Fig. 33.

(2) After removing the case, take out the reel and discard the

remaining line.

(3) Fold the new nylon line unevenly in half as shown in picture.

Hook the U-shaped end of the nylon line into the groove (30) on

the center partition of the reel.

One side of the cord should be about 10 cm longer than the

other side.

Wind both halves of the line on the reel in the same direction,

keeping each half of the line on its own side of the partition.

(Fig. 34)

(4) Push each line into the stopper holes (31), leaving the loose

ends approx. 10 cm in length. (Fig. 35)

(5) Insert both loose ends of the line through the cord guide (32)

when placing the reel in the case. (Fig. 36)

NOTE

When placing a reel in the case, try to line up the stopper holes

(31) with the cord guide (32) for easier line release later.

(6) Place the cover over the case so that the cap locking tabs (33)

on the case meet the long holes (34) on the cover. Then push

the case securely until it clicks into place. (Fig. 37)

(7) The initial cutting line length should be approx. 11–14 cm and

should be equal on both sides. (Fig. 38)

Blade (Fig. 39)

WARNING

Wear protective gloves when handling or performing

maintenance on the blade.

○Use a sharp blade. A dull blade is more likely to snag and

thrust. Replace the fastening nut if it is damaged and hard to

tighten.

○When replacing blade, purchase one recommended by

HiKOKI, with a 25.4 mm (one inch) fitting hole.

○In the case of a 3 tooth blade (35), it can be used on either side.

○Use the correct blade for the type of work.

○When replacing blades, use appropriate tools.

○When cutting edges become dull, re-sharpen or file as shown

in the illustration. Incorrect sharpening may cause excessive

vibration.

○Discard blades that are bent, warped, cracked, broken or

damaged in any way.

NOTE

When sharpening blade it is important to maintain an original

shape of radius at the base of the tooth to avoid cracking.

Maintenance schedule

Below you will find some general maintenance instructions. For

further information please contact HiKOKI Authorized Service

Centers.

Daily maintenance

○Clean the exterior of the unit.

○Check that the harness is undamaged.

○Check the cutting attachment guard for damage or cracks.

Change the guard in case of impacts or cracks.

○Check that the cutting attachment is properly centred, sharp,

and without cracks. An off-centre cutting attachment induces

heavy vibrations that may damage the unit.

○Check that the cutting attachment nut is sufficiently tightened.

○Make sure that the blade transport guard is undamaged and

that it can be securely fitted.

○Check that nuts and screws are sufficiently tightened.

○Check that the unit is undamaged and free of defects.

Weekly maintenance

○Check the starter, especially the cord and return spring.

○Clean the exterior of the spark plug.

○Remove it and check the electrode gap. Adjust it to 0.6 mm, or

change the spark plug.

○Check that the angle gear is filled with grease up to 3/4.

○Clean the air filter.

Monthly maintenance

○Rinse the fuel tank with gasoline.

○Clean the exterior of the carburetor and the space around it.

○Clean the fan and the space around it.

000BookCG24EBSP(SL)WE.indb13000BookCG24EBSP(SL)WE.indb13 2019/01/1515:52:182019/01/1515:52:18

14

English

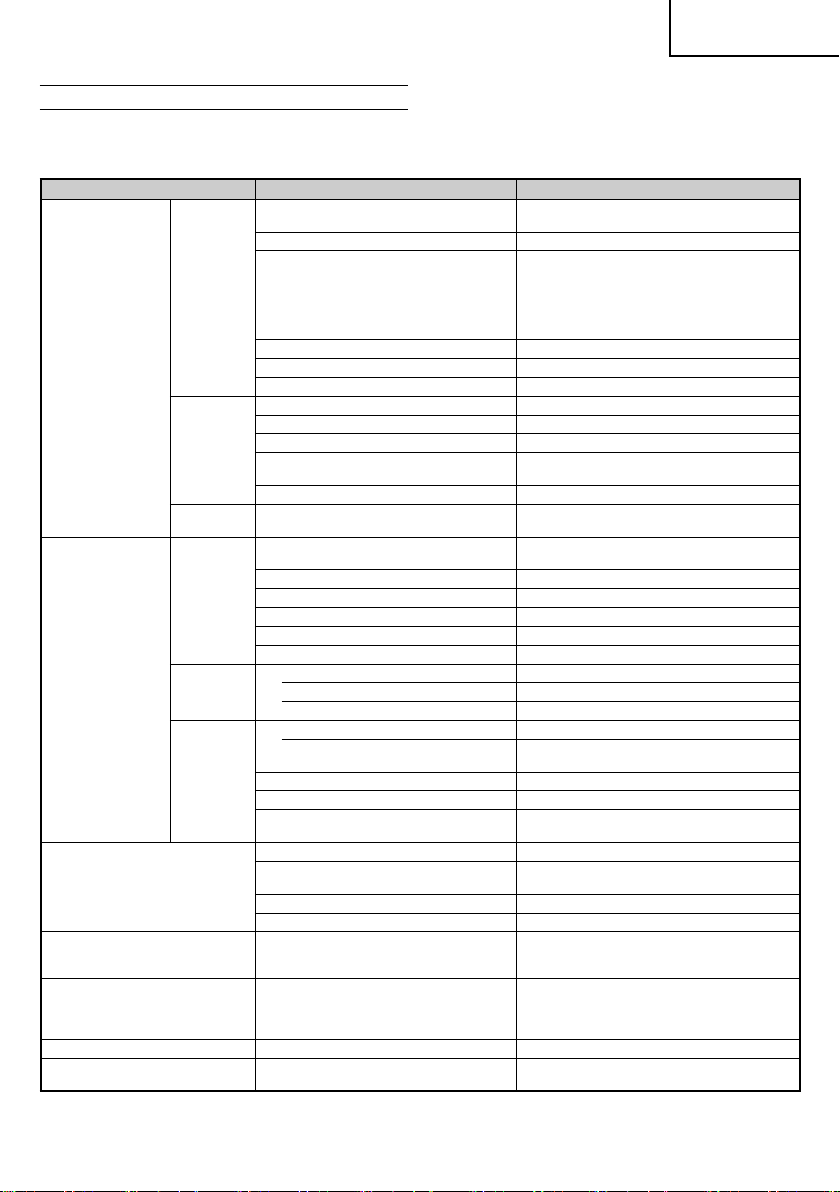

List of recommended accessories

Type Name

Specification LOOP HANDLE BIKE HANDLE MULTI PURPOSE

Diameter

Feed System Adapter or

No. of Teeth (Blade)

Blade Thickness (mm)

or

Trimmer line Diameter (mm)

CG24EBSP (SL)

CG24EBS (SL)

CG27EBSP (SL)

CG27EBS (SL)

CG24EBSP (S)

CG24EBS (S)

CG27EBSP (S)

CG27EBS (S)

CG24EBDP (SL)

CG24EBD (SL)

CG27EBDP (SL)

CG27EBD (SL)

ALUMINUM HEADS

NYLON HEAD

CH-100

(W/NYLON LINE) 4” Pre-Cut Line 2.2 –3.0

●●●●●●

NYLON HEAD

CH-100 ●●●●●●

NYLON HEAD

CH-300

(W/CUTTER

HOLDER CAP) 5” Manual line

feed 2.2 –2.7

●●●

NYLON HEAD

CH-300 ●●●

TAP & GO NYLON

HEADS

NYLON HEAD

BF-5 5”

L M10 x 1.25

Nut

L M8 x 1.25

2.2 –3.0 ●●●●●●

BLADES

BLADE

B3/10/2.0 10” 3 2.0 ●

BLADE

B3/12/3.0 12” 3 3.0 ●

BLADE

B4/9/1.6 9” 4 1.6 ●●

BLADE

B4/10/1.6 10” 4 1.6 ●●

000BookCG24EBSP(SL)WE.indb14000BookCG24EBSP(SL)WE.indb14 2019/01/1515:52:182019/01/1515:52:18

15

English

TROUBLESHOOTING

Use the inspections in the table below if the tool does not operate

normally. If this does not remedy the problem, consult your dealer

or the HiKOKI Authorized Service Center.

Condition Cause Remedy

Engine does not start

Fuel system

Fuel tank is empty or fuel level is low Fill the fuel tank with the correct fuel mix (25:1-

50:1)

Fuel tank contains old fuel (offensive odor) Replace with new fuel

Too much fuel is absorbed and spark plug

is wet

1.Disconnect the spark plug and allow to dry

2.Pull the starter handle 5 or 6 times to remove

the surplus fuel

3.Attach the spark plug

4.Set the choke lever to RUN position and pull the

starter handle

Fuel filter is clogged with dirt Clean the fuel filter

Fuel pipe is bent or disconnected Ensure that the fuel flows smoothly

Carburetor malfunction Contact HiKOKI Authorized Service Centers

Electrical

system

Stop switch lead has short-circuited Contact HiKOKI Authorized Service Centers

Spark plug is dirty Replace or clean the spark plug

Electrode gap is too big Adjust the gap to 0.6mm

Poor connection between high tension cable

and spark plug Reconnect

Electrical system malfunction Contact HiKOKI Authorized Service Centers

Other Muffler exhaust port is clogged with carbon Contact HiKOKI Authorized Service Centers for

repair

Engine starts but cuts

out straightaway

Engine is apt to

cut out

Fuel system

Fuel tank is empty or fuel level is low Fill the fuel tank with the correct fuel mix (25:1-

50:1)

Fuel tank contains old fuel (offensive odor) Replace with new fuel

Two-cycle oil has not been added Contact HiKOKI Authorized Service Centers

Choke lever is in START position Set the choke lever to RUN position

Air has got into fuel system Reconnect the fuel pipe or joint

Carburetor malfunction Contact HiKOKI Authorized Service Centers

Electrical

system

Ignition failure

Spark plug failure Replace with new spark plug

Electrical system failure Contact HiKOKI Authorized Service Centers

Other

Engine overheating

Wrong spark plug model Replace with designated part

See “SPECIFICATIONS”

Dirty air cleaner Clean

Carbon clogging (muffler exhaust port) Clean

Insufficient compression (piston, piston ring,

cylinder) Contact HiKOKI Authorized Service Centers

Abnormal vibration

Cutting attachment is not properly installed See “Installation of cutting attachment”

Handle, handle bracket or other fastening

part is loose Check and tighten

Blade is bent or damaged Replace with new blade

Grass is wrapped round gear case Remove grass

Engine is running but blade does

not move

Movement is poor

Grass is wrapped round gear case Remove grass and dirt

Engine does not stop Stop switch failure

Set the choke lever to START position to stop the

engine

Cease use immediately and contact HiKOKI

Authorized Service Centers

Engine stops when throttle is closed Idle speed is too low Contact HiKOKI Authorized Service Centers

Blade continues rotating when

throttle is closed

Idle speed is too high

Throttle wire is too taut Contact HiKOKI Authorized Service Centers

000BookCG24EBSP(SL)WE.indb15000BookCG24EBSP(SL)WE.indb15 2019/01/1515:52:182019/01/1515:52:18

Deutsch

16

(Übersetzung der Original-Gebrauchsanweisung)

SYMBOLBEDEUTUNGEN

HINWEIS: Nicht alle Geräte sind mit diesen Symbolen versehen.

Symbole

WARNUNG

Die folgenden Symbole werden für diese Maschine verwendet. Achten Sie darauf, diese vor der Verwendung

zu verstehen.

Es ist wichtig, dass Sie sich mit den

nachfolgenden Vorsichtsmaßnahmen

und Warnungen vertraut machen und

diese befolgen. Unvorsichtige oder

unsachgemäße Handhabung des Geräts

kann schwere oder tödliche Verletzungen

zur Folge haben.

Zündungsstopp

Lesen, verstehen und befolgen Sie alle

Warnungen und Anweisungen in dieser

Anleitung und am Gerät selbst.

Kraftstoff-Öl-Gemisch

Bei Gebrauch des Geräts immer Gesichts-,

Kopf- und Gehörschutz tragen. Leerlaufdrehzahleinstellung

Wenn dieses Zeichen am Gerät angebracht

ist, keine starren Messer/Metallmesser

verwenden.

Ansaugpumpe

Kinder und Zuschauer in einem Abstand

von 15 m vom Gerät halten. Falls sich

jemand nähert, den Motor und das Zubehör

sofort ausschalten.

4

Garantierter Schallleistungspegel

Auf hochgeschleuderte Gegenstände

achten.

Heiße Oberfläche –Eine Berührung

der heißen Oberfläche kann schwere

Verbrennungen verursachen.

min-1

Zeigt die maximale Drehzahl der Welle

an. Verwenden Sie kein Schneidzubehör,

dessen Maximaldrehzahl unter diesem

Wert liegt.

Das Heckenscheren-Anbauwerkzeug

kann nicht an Modellen mit diesem

Schild verwendet werden.

Handschuhe sind dann zu tragen, wenn

dies notwendig ist, z.B. bei der Montage

der Schneidausrüstung.

Ein Messerstoß ist möglich, wenn das

rotierende Messer im kritischen Bereich mit

einem massiven Gegenstand in Berührung

kommt. In diesem Fall kann es zu einer

gefährlichen Reaktion kommen, bei der

das gesamte Gerät und der Bediener

einem heftigen Stoß ausgesetzt werden.

Diese Reaktion wird als Messerstoß

bezeichnet. Das Resultat ist u.U., dass

der Bediener die Kontrolle über das Gerät

verliert und schwere oder lebensgefährliche

Verletzungen davonträgt. Messerstöße

sind in Arbeitsbereichen, wo das zu

schneidende Vegetationsmaterial nur

schwer einsehbar ist, wahrscheinlicher.

Rutschfestes Schuhwerk tragen, das guten

Halt bietet.

Choke –Betriebsposition (offen)

Choke –Startposition (geschlossen) Bezeichnet den Griffstangenplatz.

Pfeile, die den Grenzwert für die

Griffposition anzeigen.

Vor dem Gebrauch Ihres Geräts

• Bedienungsanleitung sorgfältig durchlesen.

• Montage und Einstellung der Schneidausrüstung kontrollieren.

• Gerät starten und Vergasereinstellung prüfen. Siehe “WARTUNG”.

Inhalt

TEILEBEZEICHNUNGEN................................................................17

WARN- UND SICHERHEITSHINWEISE.........................................18

TECHNISCHE DATEN.....................................................................19

ZUSAMMENBAU.............................................................................20

BETRIEB..........................................................................................22

WARTUNG.......................................................................................23

FEHLERSUCHE UND -BESEITIGUNG ..........................................26

000BookCG24EBSP(SL)WE.indb16000BookCG24EBSP(SL)WE.indb16 2019/01/1515:52:182019/01/1515:52:18

Deutsch

17

10 10

17

19

18

20

16

21

13

8

6

2

5

4

13

12

24

23

3

13

119

8

11

9

15

2

14

911

7

15

14 6

2

29

11

13

8

7

6

514

4

5

22

22

22

CG24EBSP (S)

CG24EBS (S)

CG27EBSP (S)

CG27EBS (S)

CG24EBSP (SL)

CG24EBS (SL)

CG27EBSP (SL)

CG27EBS (SL)

7

5

4CG24EBDP (SL)

CG24EBD (SL)

CG27EBDP (SL)

CG27EBD (SL)

8

7

CG24EBDP (SLN)

CG24EBD (SLN)

CG27EBDP (SLN)

CG27EBD (SLN)

1

TEILEBEZEICHNUNGEN

Da dieses Handbuch für mehrere Modelle gilt, können die

Abbildungen gegebenenfalls von Ihrem Gerät abweichen.

Verwenden Sie die für Ihr Gerät geltenden Anweisungen.

1. Benzintank

2. Gashebel

3. Startgriff

4. Schneid-Vorsatzschutz

5. Schneid-Vorsatzgerät

6. Antriebswellenrohr

7. Griff

8. Tragegurtöse

9. Zündschalter

10. Tragegurt

11. Gashebelsperre

12. Chokehebel

13. Motor

14. Winkelgetriebe

15. Schäftungsgehäuse

16. Kombischlüssel

17. Spanner (falls vorhanden)

18. Sechskant-Inbusschlüssel

19. Messerschutz (falls vorhanden)

20. Drehkopf

21. Bedienungsanleitung

22. Schutzerweiterung

23. Zündkerze

24. Ansauglampe

000BookCG24EBSP(SL)WE.indb17000BookCG24EBSP(SL)WE.indb17 2019/01/1515:52:182019/01/1515:52:18

Deutsch

18

WARN- UND SICHERHEITSHINWEISE

Bedienersicherheit

○Immer einen Gesichtsschutz bzw. eine Schutzbrille tragen.

○Tragen Sie immer dicke, lange Hosen, rutschfeste Schuhe und

Handschuhe. Das Arbeiten mit lockerer Kleidung, Schmuck,

kurzen Hosen, Sandalen oder barfuß ist zu vermeiden. Das

Haar ist so zu sichern, dass es nicht bis zu den Schultern

herunterhängt.

○Das Gerät darf nicht von Personen bedient werden, die

übermüdet oder krank sind oder unter Alkohol- oder

Medikamenteneinfluss stehen.

○Das Gerät nicht bei Nacht oder schlechten

Witterungsverhältnissen mit eingeschränkter Sicht bedienen.

Das Gerät zudem nicht bei Regen oder kurz nach einem

Regenschauer betätigen.

Arbeit auf rutschigem Untergrund kann zu Unfällen führen,

wenn Sie das Gleichgewicht verlieren.

○Unter keinen Umständen zulassen, dass ein Kind oder eine

unerfahrene Person mit dem Gerät arbeitet.

○Langfristige Aussetzung zu lauten Geräuschen kann

zu bleibenden Hörschäden führen. Tragen Sie einen

zugelassenen Gehörschutz. Die Umgebung im Auge behalten.

Auf Beistehende achten, die unter Umständen ein Problem

signalisieren. Die Schutzbekleidung erst nach Abstellen des

Motors wieder ablegen.

○Kopfschutz tragen.

○Der Motor darf nie innerhalb geschlossener Räume oder

Gebäude gestartet bzw. betrieben werden. Einatmen der

Abgase kann den Tod zur Folge haben.

○Die Griffe frei von Öl und Kraftstoffhalten.

○Hände von den Schneiden fernhalten.

○Das Gerät nicht an der Schneidgarnitur fassen bzw. halten.

○Beim Montieren oder Entfernen des Schneidwerkzeugs

müssen Handschuhe getragen werden.

Nichtbeachtung kann eine Verletzung zur Folge haben.

○Das Gerät nach dem Ausschalten des Motors erst am

Boden abstellen, wenn das Schneidwerkzeug zum Stillstand

gekommen ist.

○Bei Dauereinsatz von Zeit zu Zeit eine Pause einlegen als

vorbeugende Maßnahme gegen die Weißfingerkrankheit, die

durch ständige Vibration verursacht wird.

WARNUNG

○Vibrationsdämpfungssysteme sind kein garantierter Schutz

gegen die Weißfingerkrankheit bzw. das Karpaltunnelsyndrom.

Daher ist bei regelmäßigem Dauereinsatz des Geräts der

Zustand von Fingern und Handwurzel aufmerksam zu

beobachten. Falls Symptome der obengenannten Krankheiten

auftreten, sofort einen Arzt aufsuchen.

○Träger eines medizinischen elektrischen bzw. elektronischen

Geräts (Herzschrittmacher u. dgl.) sollten sich vor dem

Gebrauch eines Motorgeräts von Ihrem Arzt sowie dem

Hersteller des Geräts diesbezüglich beraten lassen.

Geräte-/Maschinensicherheit

○Das Gerät vor jedem Einsatz einer eingehenden Kontrolle

unterziehen. Beschädigte Teile ersetzen. Das Gerät auf

auslaufenden Kraftstoffuntersuchen und sicherstellen, dass

alle Befestigungsteile vorhanden und sicher angezogen sind.

○Gerissene, ausgebrochene oder auf andere Weise

beschädigte Teile sind vor dem Einsatz des Gerätes durch

neue zu ersetzen. Defekte Teile vergrößern das Unfallrisiko

und können eine Verletzung zur Folge haben.

○Es ist darauf zu achten, dass die Schutzvorrichtung

ordnungsgemäß angebracht ist.

○Während der Vergasereinstellung dürfen sich andere Personen

nicht in der Nähe aufhalten.

○Nur das vom Hersteller für dieses Gerät empfohlene Zubehör

darf verwendet werden.

WARNUNG

○Keinesfalls das Gerät in irgendeiner Weise abändern. Das

Gerät nur für die Zwecke verwenden, für die es bestimmt ist.

○Durch Eingriffe am Motor erlischt die EU-Betriebserlaubnis für

diesen Motor.

○Nicht autorisierte Änderungen und/oder Zubehörteile können

eine schwere Körperverletzung oder den Tod des Bedieners

oder Anderer zur Folge haben.

Kraftstoffsicherheit

○Kraftstoffim Freien und von Funken und Feuer entfernt

mischen und einfüllen.

○Einen für Kraftstoffe zugelassenen Behälter verwenden.

○In der Nähe des Kraftstoffs, des Geräts sowie beim Arbeiten mit

dem Gerät ist das Rauchen zu unterlassen.

○Vor dem Starten des Motors muss eventuell verschütteter

Kraftstoffrestlos entfernt werden.

○Zum Starten des Motors das Gerät mindestens 3 m von der

Kraftstoffeinfüllstelle entfernen.

○Vor dem Abnehmen des Tankdeckels den Motor ausschalten.

○Vor der Einlagerung des Geräts den Kraftstofftank leeren. Es

wird empfohlen, den Kraftstoffnach jedem Einsatz abzulassen.

Mit gefülltem Tank ist das Gerät so zu lagern, dass kein

Kraftstoffausläuft.

○Gerät und Kraftstoffan einem Ort lagern, wo Kraftstoffdämpfe

nicht mit Funken oder offenen Flammen von Wassererhitzern,

Elektromotoren oder elektrischen Schaltern, Öfen usw. in

Berührung kommen können.

WARNUNG

Kraftstoffist leicht entflammbar, kann explodieren und schadet

den Atemwegen, weshalb bei der Handhabung von und der

Befüllung mit Kraftstoffentsprechend umsichtig vorzugehen

ist.

Schneidsicherheit

○Das Gerät nur zum Mähen von Gras und zum Schneiden von

Buschwerk und Unterholz einsetzen.

○Vor jedem Gebrauch die zu mähende Fläche inspizieren.

Gegenstände entfernen, die hochgeschleudert werden oder

sich im Mähkopf verfangen könnten.

○Zum Schutz der Atmungsorgane beim Mähen von Gras,

auf dem Insektenvernichtungsmittel versprüht wurde, eine

Aerosolschutzmaske tragen.

○Kinder, Tiere, Umstehende, Helfer usw. dürfen sich nicht

innerhalb der 15 m-Gefahrenzone aufhalten. Den Motor sofort

abstellen, wenn sich jemand nähert.

○Der Motor muss sich immer auf der rechten Körperseite

befinden.

○Gerät fest mit beiden Händen halten.

○Auf sicheren Stand und gutes Gleichgewicht achten. Nicht zu

weit vorbeugen.

Wenn man beim Arbeiten das Gleichgewicht verliert, kann dies

eine Verletzung zur Folge haben.

○Schneidwerkzeug und Schalldämpfer bei laufendem Motor

vom Körper fernhalten.

○Die Schneidgarnitur stets unter Kniehöhe halten.

○Bei Standortwechseln unbedingt den Motor ausschalten und

sicherstellen, dass das Schneidwerkzeug still steht.

○Das Gerät niemals mit laufendem Motor auf dem Boden

abstellen.

○Vor dem Entfernen von Schmutz oder Gras vom

Schneidwerkzeug den Motor ausschalten und sicherstellen,

dass die Kette zum Stillstand gekommen ist.

○Beim Arbeiten mit Motorgeräten stets einen Verbandskasten

mitführen.

○Der Motor darf nie innerhalb geschlossener Räume oder

Gebäude und/oder in der Nähe entflammbarer Flüssigkeiten

gestartet bzw. betrieben werden. Einatmen der Abgase kann

den Tod zur Folge haben.

○Bei schwacher Geräteleistung oder seltsamen Geräuschen

oder Vibrationen des Geräts den Motor sofort abstellen und

das Gerät durch Ihren Fachhändler inspizieren und reparieren

lassen.

Eine weitere Verwendung in diesem Zustand kann zu

Verletzungen oder der Beschädigung des Geräts führen.

○Beim Gebrauch die örtlich gültigen Gesetze und Vorschriften

einhalten.

000BookCG24EBSP(SL)WE.indb18000BookCG24EBSP(SL)WE.indb18 2019/01/1515:52:192019/01/1515:52:19

Deutsch

19

Wartungssicherheit

○Das Gerät vorschriftsmäßig warten.

○Vor Durchführung von Wartungsarbeiten die Zündkerze

entfernen, sofern es sich nicht um eine Vergasereinstellung

handelt.

○Während der Vergasereinstellung dürfen sich andere Personen

nicht in der Nähe aufhalten.

○Nur Original-Ersatzteile von HiKOKI verwenden, wie vom

Hersteller empfohlen.

Transport und Lagerung

○Das Gerät mit ausgeschaltetem Motor tragen und den

Schalldämpfer vom Körper fernhalten.

○Lassen Sie den Motor abkühlen und leeren Sie den

Kraftstofftank, bevor Sie ihn lagern oder transportieren.

Sichern Sie die Maschine während des Transports, um zu

verhindern, dass Kraftstoffverloren geht oder dass Schäden

oder Verletzungen auftreten.

○Vor der Einlagerung des Geräts den Kraftstofftank leeren. Es

wird empfohlen, den Kraftstoffnach jedem Einsatz abzulassen.

Mit gefülltem Tank ist das Gerät so zu lagern, dass kein

Kraftstoffausläuft.

○Das Gerät so lagern, dass es nicht in Kinderhände gerät.

○Das Gerät sorgfältig reinigen und warten, um es dann an einem

trockenen Ort zu lagern.

○Bei Transport oder Lagerung darauf achten, dass der

Zündschalter ausgeschaltet ist.

○Bei Transport und Lagerung den Klingenschutz auf die Klinge

aufsetzen.

○Sie müssen die Maschine beim Transport sichern, um

Auslaufen von Kraftstoff, Schäden, oder Verletzungen zu

verhindern.

In Situationen, die nicht in dieser Anleitung behandelt sind,

entsprechende Vor- und Umsicht walten lassen. Sollten Sie

Hilfe benötigen, wenden Sie sich an einem einer von HiKOKI

autorisierten Service-Werkstatt. Die folgenden Wörter sind

Abschnitten vorangestellt, denen besondere Aufmerksamkeit

gewidmet werden sollte:

WARNUNG

Kennzeichnet Anweisungen, deren Nichtbefolgung eine

schwere Verletzung oder den Tod zur Folge haben kann.

VORSICHT

Kennzeichnet Anweisungen, deren Nichtbefolgung eine

Verletzung oder Sachschaden zur Folge haben kann.

HINWEIS

Kennzeichnet nützliche Informationen für den

vorschriftsmäßigen Gebrauch.

VORSICHT

Den Zugstarter nicht zerlegen. Die Feder der Vorrichtung kann

Verletzungen verursachen.

TECHNISCHE DATEN

Modell CG24EBSP / CG24EBS CG24EBDP / CG24EBD

(SL) (S) (SL) (SLN)

Motor

Hubvolumen (cm3)

Zündkerze

Leerlaufdrehzahl (min-1)

Drehzahl der Ausgangswelle (min-1)

Max. Motorleistung (kW)

23,9

NGK BMR7A

2800 –3200

7600

0,8

23,9

NGK BMR7A

2800 –3200

7600

0,8

23,9

NGK BMR7A

2800 –3200

7600

0,8

23,9

NGK BMR7A

2800 –3200

7600

0,8

Kraftstofftankvolumen (cm3)520

Trockengewicht (kg) 5,0 5,2 5,3 4,4

Schneid-Vorsatzgerät Typ / Durchm.

(mm) Nylonschnur Nylonschnur Metallklinge

(255) Nylons chnur ------

Schalldruckpegel

LpA (dB (A)

(ISO22868)

Äquivalen*

Unsicherheit

99

3

99

3

96

3

99

3

99

3

Gemessener Schallpegel

LwA (dB (A))

Garantierter Schallpegel

LwA (dB (A))

(2000/14/EG)

Volllast

(2000/14/EG)

Volllast

108

111

108

111

105

108

108

111

------

------

Vibrationspegel (m/s2) (ISO22867)

Äquivalent (Vorderer / linker Griff)*

Äquivalent (Hinterer / rechter Griff)*

Unsicherheit

5,6

4,0

2,0

3,9

2,7

1,2

3,1

2,8

1,2

6,2

3,4

2,0

------

------

------

000BookCG24EBSP(SL)WE.indb19000BookCG24EBSP(SL)WE.indb19 2019/01/1515:52:192019/01/1515:52:19

Deutsch

20

Modell CG27EBSP / CG27EBS CG27EBDP / CG27EBD

(SL) (S) (SL) (SLN)

Motor

Hubvolumen (cm3)

Zündkerze

Leerlaufdrehzahl (min-1)

Drehzahl der Ausgangswelle (min-1)

Max. Motorleistung (kW)

26,9

NGK BMR7A

2800 –3200

7600

0,9

26,9

NGK BMR7A

2800 –3200

7600

0,9

26,9

NGK BMR7A

2800 –3200

7600

0,9

26,9

NGK BMR7A

2800 –3200

7600

0,9

Kraftstofftankvolumen (cm3)520

Trockengewicht (kg) 5,2 5,4 5,4 4,5

Schneid-Vorsatzgerät Typ / Durchm.

(mm) Nylonschnur Nylonschnur Metallklinge

(255) Nylons chnur ------

Schalldruckpegel

LpA (dB (A))

(ISO22868)

Äquivalen*

Unsicherheit

99

3

99

3

97

3

99

3

99

3

Gemessener Schallpegel

LwA (dB (A))

Garantierter Schallpegel

LwA (dB (A))

(2000/14/EG)

Volllast

(2000/14/EG)

Volllast

108

111

108

111

108

111

108

111

------

------

Vibrationspegel (m/s2) (ISO22867)

Äquivalent (Vorderer / linker Griff)*

Äquivalent (Hinterer / rechter Griff)*

Unsicherheit

6,7

4,1

2,0

4,1

3,0

1,2

3,7

2,6

1,2

5,3

3,4

2,0

------

------

------

HINWEIS

Die entsprechenden Geräusch-/Vibrationspegel werden als zeitgewichtete Energiesumme für Geräusch-/Vibrationspegel unter

verschiedenen Arbeitsbedingungen mit folgender Zeitaufteilung berechnet:

* 1/2 Leerlauf, 1/2 schnell.

Änderung der technischen Daten jederzeit vorbehalten.

ZUSAMMENBAU

Antriebswelle und Motor (Abb. 1)

Den Rohrblockierungsbolzen (1) um ungefähr zehn

Schraubendrehungen lockern, so dass die Bolzenspitze

das Antriebswellenrohr beim Einschieben nicht behindert.

Halten Sie beim Einschieben des Antriebswellenrohrs den

Rohrblockierungsbolzen so fest, dass Blockierungen durch das

innere Zubehör vermieden werden.

Die Antriebswelle soweit in das Kupplungsgehäuse einschieben,

bis zur Markierung (2) auf dem Antriebswellenrohr am

Kupplungsgehäuse liegt.

Einige Modelle werden mit bereits vormontierter Antriebswelle

geliefert.

HINWEIS

Wenn sich die Antriebswelle nur schwer bis zur

Markierung einschieben lässt, die Antriebswelle am

Schneidvorrichtungsende fassen und beim Einschieben

im oder gegen den Uhrzeigersinn drehen. Den

Blockierungsbolzen so anziehen, dass er in das Loch des

Antriebswellenrohrs eingreift. Dann die Spannschraube fest

anziehen.

Montage der Scheidvorrichtung (nur EBDP / EBD-Modell)

1. Bringen Sie die Schneidvorrichtung an der vorgesehenen Stelle

an.

2. Stellen Sie sicher, dass sich der Spannstift (3) im

Befestigungsloch (4) des Rohrs befindet und das Rohr fest

sitzt. (Abb. 2)

3. Ziehen Sie die Griffmutter (5) fest an. (Abb. 2)

Montage des Handgriffs

(1) Schlaufengriff-Typ ((SL), (SLN) Modell)

WARNUNG

Verwenden Sie stets einen Messerschutz (6) und einen

Tragegurt mit dem Bügelgriff. (Abb. 3)

Den Handgriffzum Motor geneigt an das Antriebswellenrohr

anbringen.

Den Handgriffvor der Inbetriebnahme auf eine komfortable Position

einstellen.

HINWEIS

Falls auf dem Antriebswellenrohr Ihres Geräts ein Schild mit

Informationen zur Handgriffposition angebracht ist, halten Sie

sich an die Darstellung.

000BookCG24EBSP(SL)WE.indb20000BookCG24EBSP(SL)WE.indb20 2019/01/1515:52:192019/01/1515:52:19

Table of contents

Languages:

Other HIKOKI Trimmer manuals

HIKOKI

HIKOKI CG 18DA User manual

HIKOKI

HIKOKI CH 3672DA User manual

HIKOKI

HIKOKI CH 24EA(50ST) User manual

HIKOKI

HIKOKI CG 24ECP User manual

HIKOKI

HIKOKI CH 24EAP User manual

HIKOKI

HIKOKI CG 23EC User manual

HIKOKI

HIKOKI CG 36DB User manual

HIKOKI

HIKOKI CG 24EBSP (SL) User manual

HIKOKI

HIKOKI CH 45Y User manual

HIKOKI

HIKOKI CG 36DC User manual