hilscher PKV 50 Series Application guide

Device Manual

PKV 50-XXX

Target System for Ethernet-/Fieldbus Applications

Edition: 3

Language: English (EN)

Hilscher Gesellschaft für Systemautomation mbH

Rheinstraße 15

D-65795 Hattersheim

Germany

Tel. +49 (6190) 99070

Fax. +49 (6190) 990750

Sales: +49 (6190) 99070

Hotline and Support: +49 (6190) 990799

Email Hotline and Support: hotline@hilscher.com

Web: www.hilscher.com

2 •

••

•Introduction PKV50

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

List of Revisions

Index Date Version Chapter Revision

1 25.01.00 V1.000 all created

2 26.07.02 all revised

3 22.07.03 all Ported to Microsoft Word

PKV50-MBP

Although this appliance has been developed with great care and intensively

tested, Hilscher Gesellschaft für Systemautomation mbH cannot guarantee

the suitability of this appliance for any purpose not confirmed by us in

writing.

Guarantee claims shall be limited to the right to require rectification. Liability

for any damages which may have arisen from the use of this appliance or

its documentation shall be limited to cases of intent.

We reserve the right to modify our products and their specifications at any

time in as far as this contributes to technical progress. The version of the

manual supplied with the appliance applies.

PKV50 Table of Contents •

••

•3

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

Table of Contents

1 INTRODUCTION .........................................................................................................4

1.1 Scope of Performance..............................................................................................4

2 STRUCTURE OF THE GATEWAY..............................................................................5

2.1 ISO/OSI Reference Model ........................................................................................5

3 GENERAL DEVICE DESCRIPTION............................................................................6

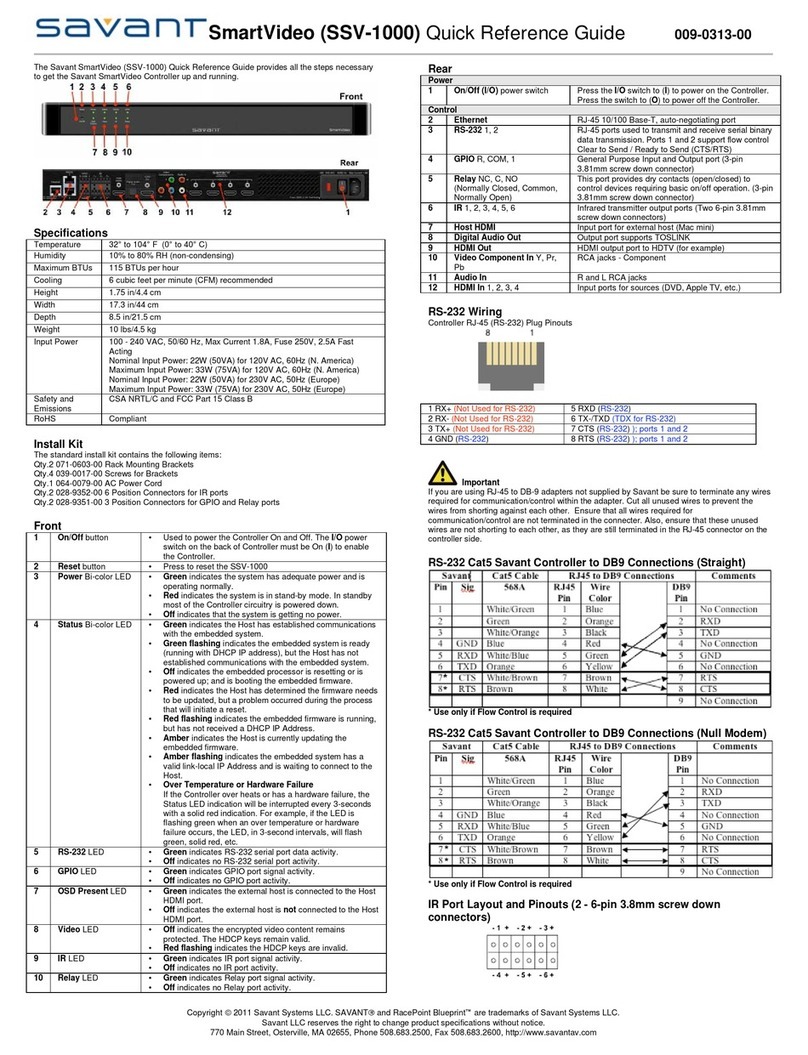

3.1 Hardware Description PKV50 ...................................................................................6

3.2 Configuration of the Gateway with the SyCon System Configurator .........................7

3.2.1 Loading Files into the Gateway ........................................................................... 8

3.2.2 Loading Files on to the Host PC .......................................................................... 9

3.2.3 Deleting Files ..................................................................................................... 10

3.2.4 Setting the IP Address ....................................................................................... 11

3.2.5 Starting Applications .......................................................................................... 11

3.3 Connecting the Supply Voltage (X2).......................................................................12

3.4 Interfaces ...............................................................................................................13

3.4.1 Ethernet-Interface (X4) ...................................................................................... 13

3.4.2 Fieldbus Interface (X6) ...................................................................................... 14

3.4.3 Diagnostic Interface (X3) ................................................................................... 16

3.5 Status Displays.......................................................................................................17

3.6 Mechanical Dimensions and Technical Data ..........................................................19

4 LISTS.........................................................................................................................20

4.1 List of Figures.........................................................................................................20

4.2 List of Tables..........................................................................................................21

4 •

••

•Introduction PKV50

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

1 Introduction

1.1 Scope of Performance

In automation technology it is becoming obvious that Ethernet with the

TCP/IP protocol from the classical conductor field is moving continuously

forward into the fieldbus region. Although attempts are being made to lead

Ethernet up to the individual I/O modules, yet neither all the technical

aspects been satisfactorily solved nor can it be realized with a sufficient

effort.

This trend is further strengthened by the requirement for unbroken

communication from the office world up to the individual data point in the

industrial installation. Remote maintenance via the Internet is the buzzword

now.

This is where our fieldbus Gateway PKV 50 comes into its own. It connects

the Internet-/Ethernet world with the harsh industrial environment of

established fieldbus technology.

It consists of a Master interface connection, which, by means of one of the

standardized fieldbus systems, exchanges data between the connected I/O

devices and the internal process data memory. This data can be accessed

for reading and writing by means of TCP/IP telegrams.

The Microsoft Windows CE operating system is used on the Gateway.

Here, further tasks, such as SoftPLCs, are simply added in order to

incorporate extensions of the functions. The development system is

economical to build up and many engineers are familiar with the

development environment. All our interfaces are open so that the

experienced user can also bring his own applications into use on the

Gateway.

A further highlight is the integrated Web-Server. HTML pages can be

created on a corresponding editor and then loaded on to the Gateway.

Process data can be linked via Java Applets. All that is still needed to

access the data of the Gateway via the Internet is a Web Browser such as

for example, Microsoft Explorer or Netscape Navigator.

The configuration of the Gateways is carried out locally with our SyCon

System Configurator via the RS232C serial diagnostic interface or remotely

via TCP/IP.

The PKV 50 fieldbus Gateway is now offered for the most important

fieldbus systems.

Customer-specific solutions can be implemented by us or by the customer

himself.

Structure of the Gateway 5

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

2 Structure of the Gateway

2.1 ISO/OSI Reference Model

Modern communication systems are structured in accordance with the

ISO/OSI reference model (ISO IS 7498). This is based on a 7-layer

structure. Here, every layer makes the services of the next higher layer

available but only uses the services of the next lower layer itself.

The Gateway fulfills this structure.

Figure 1: The Gateway in the ISO/OSI reference mode

6 •

••

•General Device Description PKV50

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3 General Device Description

3.1 Hardware Description PKV50

The Gateway consists of a basic circuit board with a power supply circuit

with DC/DC transformers in which all the required auxiliary voltages are

created. The fieldbus communication interface is based on the basic circuit

board, too.

The Elan SC520 processor board is inserted into the basic circuit board. It

contains a built-in timer, interrupt- and DMA-Controller and thus only

requires few external modules. The computing power is adequate for

processing even large quantities of data. Furthermore, the processor

ensures efficient software development in a high level language. The

firmware and the configuration data are stored in a FLASH-EPROM. This

can be programmed within the switching and retains its data even when the

operating voltage is switched off.

The proper function of the Gateway and its internal operating voltage is

monitored by a Watchdog circuit. In the case of error it triggers a Reset at

the processor.

The internal supply voltage is generated by means of a switched mode

regulator. Its input voltage is filtered via a current-transformed toroidal

choke and filter capacitors. A transient diode is available as spike and

polarity reversal protection. In the case of malfunction, a semiconductor

fuse switches the device down to a low residual current until the

malfunction is cleared. This means that the changing of an internal

sensitive fuse is dispensed with. Besides this, a charging capacitor is

available that blocks the voltage dips that occur in the switching of fuses.

The operational readiness and an error in the communication interface are

displayed by LEDs.

PKV50 General Device Description •

••

•7

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

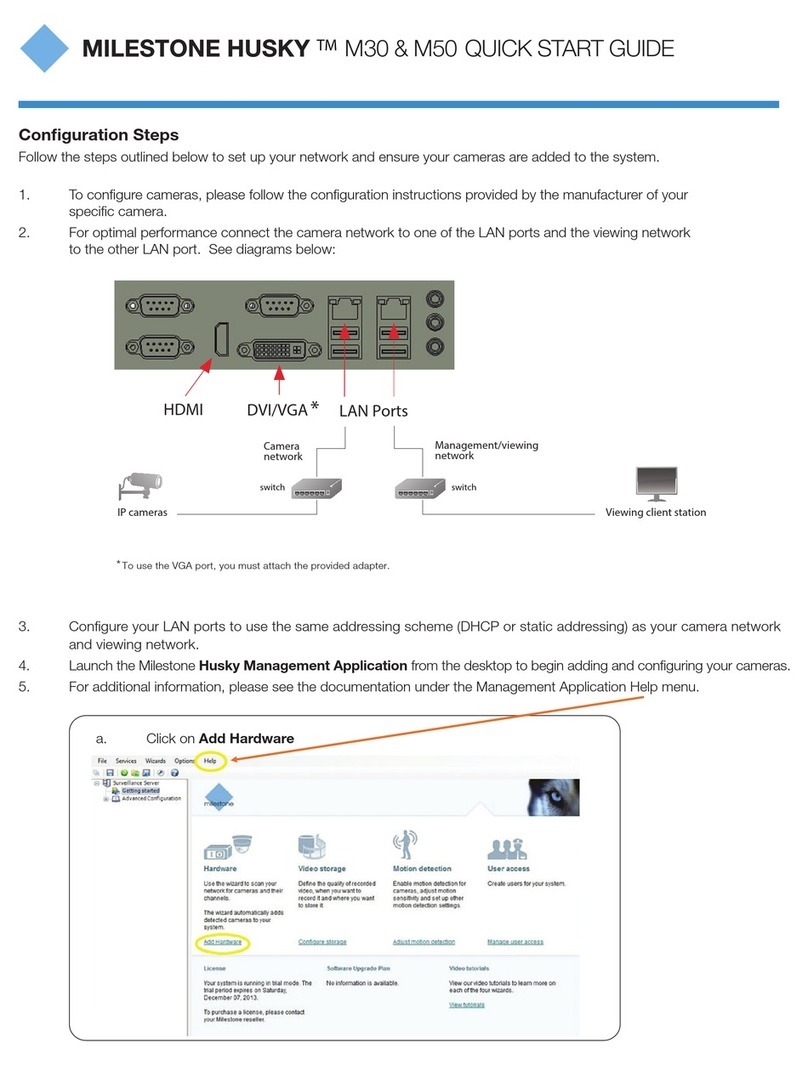

3.2 Configuration of the Gateway with the SyCon System

Configurator

The loading of new files on to the Gateway or the setting of the IP address

of the Gateway is carried out by means of the tools contained in SyCon.

In order to be able to use the configuration tools in SyCon, it is necessary

to lay down a configuration with a PKV 50 Gateway in SyCon. Now the

menu entry PKV50-XXX (XXX here stands for the selected fieldbus

system) appears in the Tools menu point. This makes it possible to choose

between a serial RS232 connection and a TCP/IP connection.

A crossed RS232 cable is necessary for operation at the serial interface

and this can be obtained from the Company Hilscher (CAB-SRV).

The configuration via TCP/IP can also be carried out via a point to point

connection with a crossed cable or, for example, via a Hub with commercial

Ethernet cables.

The Gateway is supplied with a default IP address (see information sheet).

Figure 2: Configuration dialog for the PKV 50-XXX Gateway via TCP/IP

The procedure for the serial configuration or the TCP/IP configuration is

basically the same. First an IP address must be entered into the field

provided for it or the serial interface with which the Gateway is connected

must be selected. Then the Connect switch must be activated. If a valid

connection to the Gateway has been established, then the menu entries

and the switches for configuration of the Gateway are released.

In order to ensure communication via TCP/IP, the TCP/IP protocol on the

PC must be configured in such a way that a connection with the default IP

address is possible.

8 •

••

•General Device Description PKV50

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3.2.1 Loading Files into the Gateway

This function enables to load files into the User FLASH of the Gateway and

to carry out applications after downloading or after the start of the operating

system.

Before a new application or a new and already available DLL can be

downloaded, any running older versions of the application or programs that

use DLLs must be ended. For this purpose, the corresponding running

processes can be displayed under the Configuration > View Running

Tasks menu. If an entry has been selected, then the Stop Process button

can be activated and the selected process is stopped.

In order to transfer a new file, select the File > Copy to PKV menu or

activate the Copy to PKV button. Select the file to be loaded in the dialog

that appears now.

Figure 3: Dialog for loading files on to the PKV 50 Gateway

The path and name can be entered directly into the Source (PC) text field

or select the path and file via the ... button. The Destination (PKV) field

cannot be edited at present. All the files to be copied are read into the

Windows directory of the Gateway. According to requirements, now mark

the buttons Save persistent, Execute after download and Execute after

PKV boot. Now activate the Download button and the software is

transferred to the Gateway.

PKV50 General Device Description •

••

•9

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3.2.2 Loading Files on to the Host PC

It is also possible to load files from the Gateway on to the Host-PC. For

this purpose select the Copy to PC entry in the File menu.

Figure 4: Dialog for loading files from the PKV 50 Gateway to the Host PC

Now the path of the file that is to be loaded can be entered directly into the

Source (PKV) field or the contents of the FLASH can be viewed via the ...

button and a file can be selected.

The target place and target name can be entered now in the Destination

(PC) field or selected via the ... button.

After activating the Upload button, the file is loaded onto the Host PC.

10 •

••

•General Device Description PKV50

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3.2.3 Deleting Files

In order to delete files, the menu point File > View Flash Dir can be

selected after building up the connection successfully. A list of files that are

permanently stored in the User FLASH memory is displayed now. Now

previously selected files can be deleted with the Delete button.

PKV50 General Device Description •

••

•11

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3.2.4 Setting the IP Address

Figure 5: Dialog for setting the IP Address

It is possible to allocate a new IP address to the Gateway with the

Configuration > Setting IP address menu. For this purpose, a connection

with the Gateway is necessary as already mentioned.

Note: The gateway has to be restarted to take over the IP Address.

Now enter the desired valid IP address into the corresponding field. Press

the Set button and the new address is allocated to the Gateway.

If the alteration of the IP was successful, it will be displayed. A request for

restarting the Gateway will appear.

Please note that the newly allocated IP address is only valid after a restart

of the Gateway.

3.2.5 Starting Applications

Applications that have already been entered on to the Gateway can also be

started manually. For this purpose the Configuration > Start Application

menu has to be selected. Now enter the name of the application into the

field provided for this purpose and press the OK button.

12 •

••

•General Device Description PKV50

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3.3 Connecting the Supply Voltage (X2)

The Gateway requires a supply voltage of 24 Volt. A three-phase rectified

supply or a simple rectified switching with charge capacitor is sufficient. The

supply voltage must be led to ground. It is connected by means of a plug-in

screwed clamp. Use is made of a 3-pin COMBICON plug from the

PHOENIX company (MSTB 2,5/3-ST-5,08).

Connection Symbol Signal

1 +24V +24V supply voltage

2 0V Reference potential

3 PE Equipment grounding conductor

Table 1: Connector pin assignment of the operating voltage connection X2

PKV50 General Device Description •

••

•13

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3.4 Interfaces

The PKV 50 Gateway possesses three independent interfaces.

First interface (X3). The first interface can be operated as a diagnosis /

configuration interface.

Second interface (X6). The second interface is designed for operation at

the fieldbus.

Third interface (X4). The third interface is used for connection to a

10/100BaseT network.

3.4.1 Ethernet-Interface (X4)

Connection Input/Output Signal designation

1 Output TXDE+

2 Output TXDE-

3 Input RXDE+

6 Input RXDE-

Table 2: Pin assignment of the Ethernet interface

The Ethernet interface is carried out by means of an 8 pin RJ45 socket for

a 10/100BaseT connection.

14 •

••

•General Device Description PKV50

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3.4.2 Fieldbus Interface (X6)

The following tables describe the pin assignment for the individual fieldbus

systems available on the PKV 50 Gateway.

3.4.2.1 PROFIBUS Interface for PKV 50-DPM

Connection

9 pin D-SUB

socket

Input/ Output Signal designation Signal

- - PE Earth ground

1- PE PNO recommend not to

use this signal

6 - VP Power supply

3 Input/

Output

RXD/TXD-A Data line

8 Input/

Output

RXD/TXD-B Data line inverse

4 Output CNTR-A Repeater control signal

5 - DGND Data reference potential

Table 3: Pin assignment of the PKV50-DPM at the plug X6

3.4.2.2 CAN-Bus Interface for PKV 50-COM, PKV 50-DNM

Connector

Connection

9 pin D-SUB

plug

Connection

5 pin

COMBICON

for DeviceNet

Input/

Output

Signal

designation

Signal

- - - PE Earth ground

95-+V

24V external power 1

3 - - DGND Data reference potential

7 4 Input/

Output

CANH Data line high

2 2 Input/

Output

CANL Data line low

6 1 - DGND Data reference potential

- 3 - shield shield of bus cable

Table 4: Pin assignment of the PKV 50-COM and PKV 50-DNM at the plug X6

PKV50 General Device Description •

••

•15

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3.4.2.3 Modbus Plus Interface for PKV 50-MBP

9 pol. DSub

female

connector

Symbol Signal Remark

1 Shield Is connected internal via 100 Ohm

with PE

2 DATA * Daten inverted

3 DATA Daten not inverted

RS485-signal level potential free

with transmitter

Table 5: Pin assignment of the PKV 50-MBP at the plug X6

16 •

••

•General Device Description PKV50

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3.4.3 Diagnostic Interface (X3)

The connection of a (Host) PC to the Gateway is also possible via the first

serial interface (X3). It corresponds to the RS232C standard according to

CCITT or DIN. However, only the required signals are available.

The control signals are served or evaluated as follows:

RTS is switched to high after the function readiness and not altered again.

CTS must be connected by means of a wire bridge with Pins 4 and 8 of the

D-Sub plug.

The transfer between Host PC and Gateway is at 9.600 Baud and the

following data format: 8 Data bits, 1 Stop bit and even parity. The 3964R

procedure is utilized as transfer protocol.

The connection of the PC is carried out with a three-wire cable which must

not be longer than 15 meters. The wiring of the cable is given below. For

better interference suppression, the cable shielding also on the side of the

Host PC should be grounded over the plug housing.

9 pin Dsub

f

e

m

a

l

e

co

nn

ec

t

o

r

Shield at connector

casing

9 pin Dsub

f

e

m

a

l

e

co

nn

ec

t

o

r

Table 6: Connecting cable between Gateway and Host PC

PKV50 General Device Description •

••

•17

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3.5 Status Displays

There are eight LEDs are the PKV 50 Gateway acting as status displays:

Display Color Condition Meaning

SYS,

CON,

ST1,

ST2

The condition of these LEDs

are application-dependent

and are described in the

corresponding manuals

RDY (*)(**) Yellow On

Cyclically flashing

Irregularly flashing

Off

Gateway ready

Bootstrap loader active

Hardware or system error

Hardware defect

RUN (**) Green On

Irregularly flashing (see

below).

Off

Fieldbus communication running

Parameterizing error (field bus)

No fieldbus communication

ERR / NET

/ CH_A

Fieldbus dependent Error on the

STA / MOD

/ CH_B

Fieldbus dependent

Table 7: Status Displays

Note (*): With a device defect, a cyclical flashing of the RDY-LED can also

be caused by the continuous accessing of the Watchdog monitoring.

Note: (**): These LEDs are not supported by the PKV50-MBP.

After switching on, the Gateway carries out a self-test. If this has been run

through successfully, then the yellow LED RDY is switched on. Otherwise

the LED begins to flash irregularly and the further processing of the

program is aborted.

If no fieldbus Firmware is loaded on the Gateway, then the Bootstraploader

shows this by a cyclical flashing of the RDY-LED in a 1-second rhythm.

During the loading of the Firmware the blink rhythm increases to

approximately 5 Hz.

If the LED remains off, then there is a defect of the Gateway.

18 •

••

•General Device Description PKV50

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

If a fieldbus Protocol Task recognizes a parameterizing error, the Task is

displayed by the RUN-LED in accordance with the following figure.

If there is no error and communication could be started, then the RUN-LED

is switched on.

If the communication operation is blocked, the RUN-LED remains off.

Figure 6: Display of the tasks that have indicated a parameterizing error

PKV50 General Device Description •

••

•19

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

3.6 Mechanical Dimensions and Technical Data

The Gateway is built into an aluminum profile housing. This permits direct

installation into the switching cupboard on a carrier rail (TS35 according to

DIN EN 50022).

The mechanical dimensions, the arrangement of the plugs and the

technical data of the PKV 50 are described in the Booklet of the PKV 50 on

the System Software CD.

20 •

••

•Lists PKV50

Copyright •Hilscher Gesellschaft für Systemautomation mbH •De:PKV50#3EN

4 Lists

4.1 List of Figures

Figure 1: The Gateway in the ISO/OSI reference mode 5

Figure 2: Configuration dialog for the PKV 50-XXX Gateway via TCP/IP 7

Figure 3: Dialog for loading files on to the PKV 50 Gateway 8

Figure 4: Dialog for loading files from the PKV 50 Gateway to the Host PC 9

Figure 5: Dialog for setting the IP Address 11

Figure 6: Display of the tasks that have indicated a parameterizing error 18

Other manuals for PKV 50 Series

1

Table of contents

Other hilscher Network Hardware manuals