Ins RAS-X10-13-18CCK_ (EN2) 1

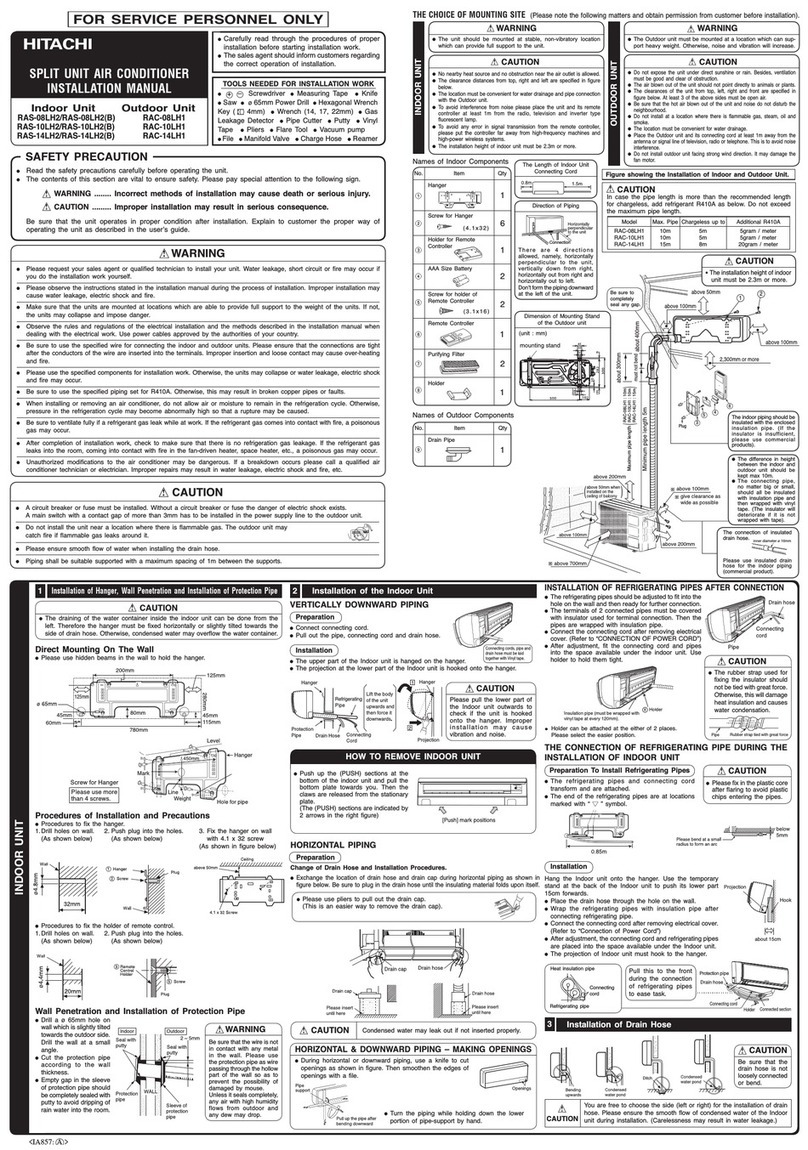

TINUROODTUO

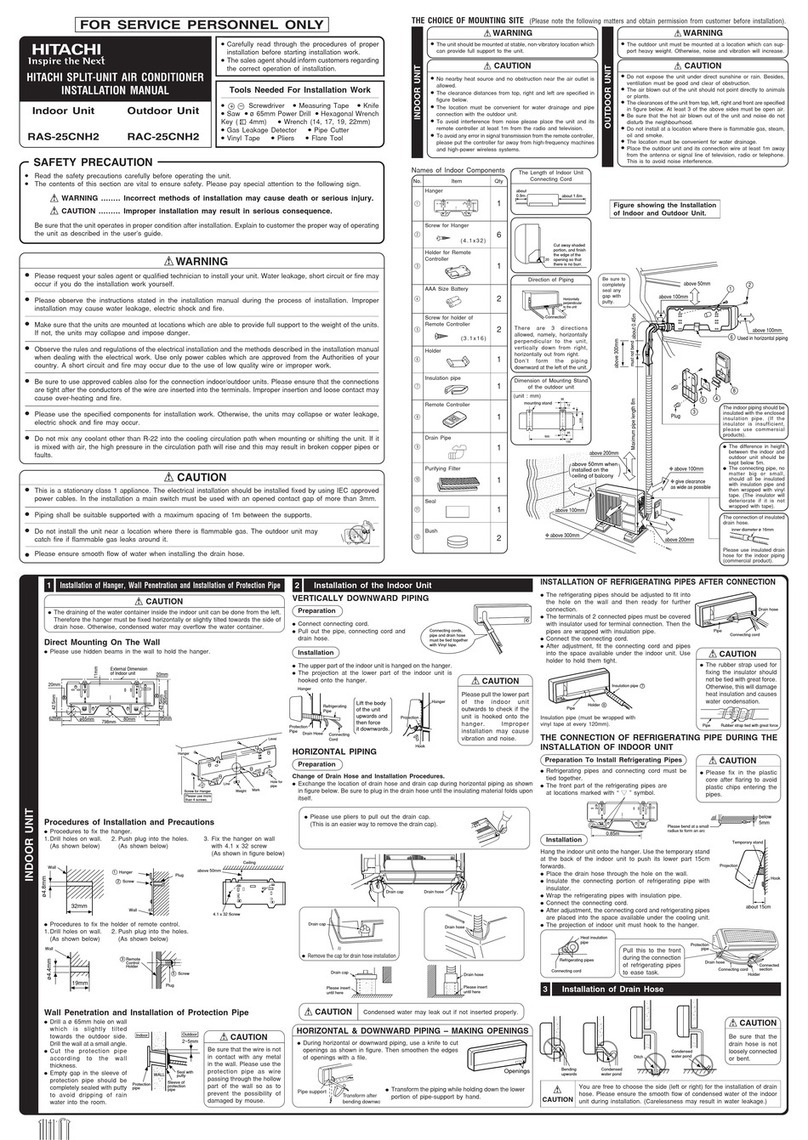

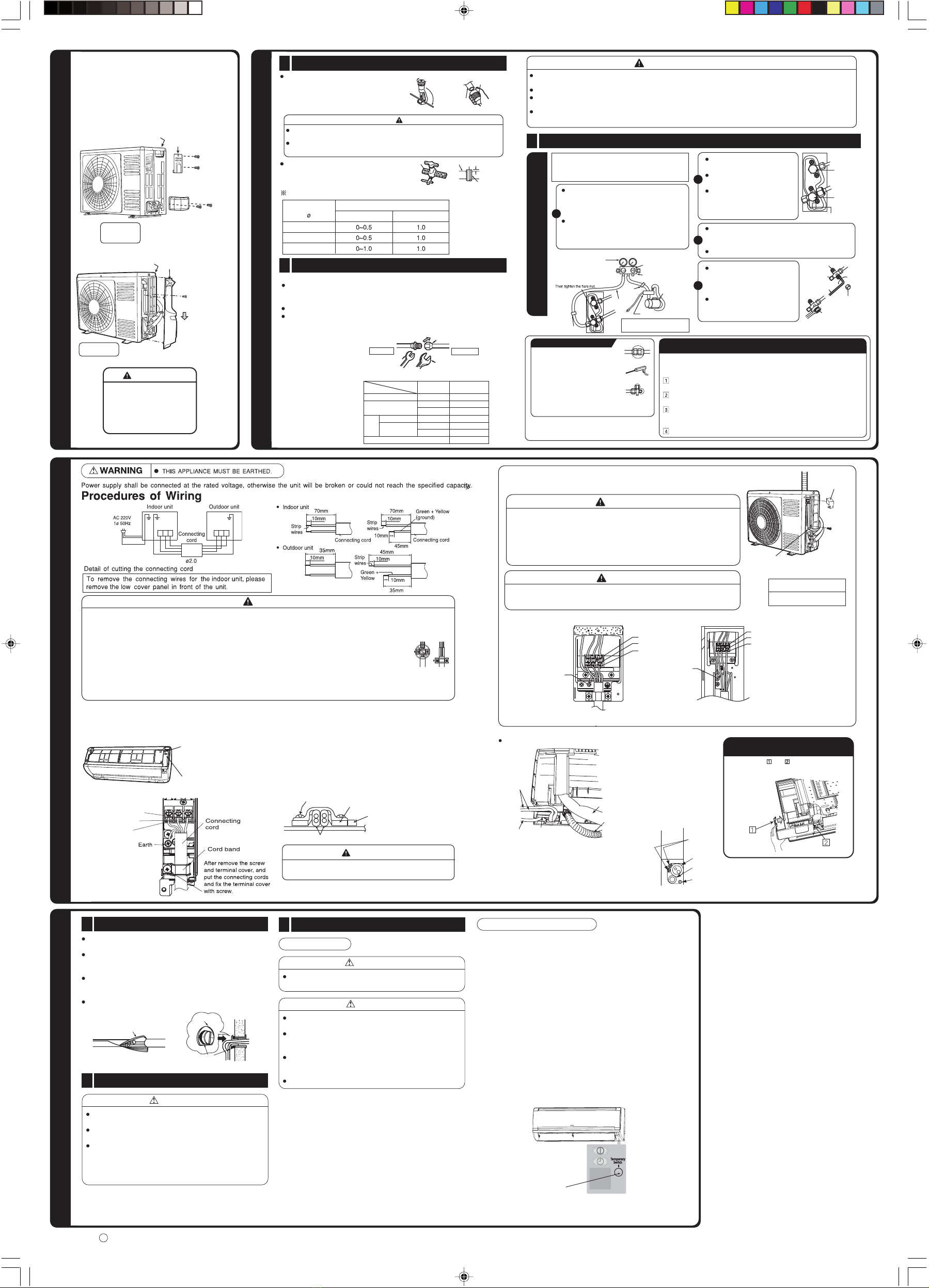

•Please mount the Outdoor unit of stable ground to

prevent vibration and increase of noise level.

•Decide the location for piping after sorting out the

different types of pipe available.

Please face this side (suction

side) of the unit to the wall.

Please remove terminal

cover when connecting

the piping and connecting

cord.

Please remove terminal

cover when connecting

the piping and connecting

cord.

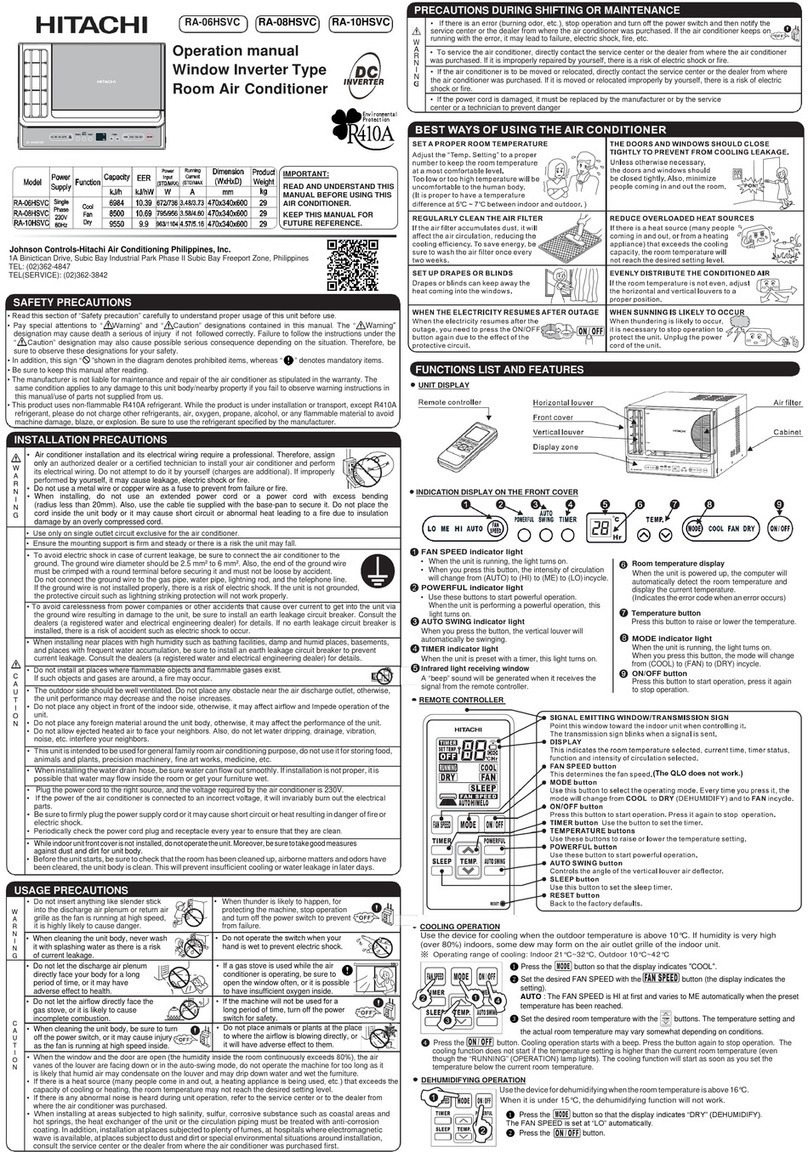

CAUTION

•Do not touch the suction

port, bottom surface, or

aluminum fin of the outdoor

unit.

Failure to do so may cause

an injury.

•When removing side cover, please pull the handle

after undoing the hook by pulling it downward.

Reinstall the side cover in the reverse order of the

removal.

RAC-X10CCK

RAC-X13CCK

Pull downward

Please face this side (suction

side) of the unit to the wall.

RAC-X18CCK

()

12.7 (1/2”)

6.35 (1/4”)

9.52 (3/8”)

Wrench Torque wrench

Flare nut

Half union

Female side

Male side

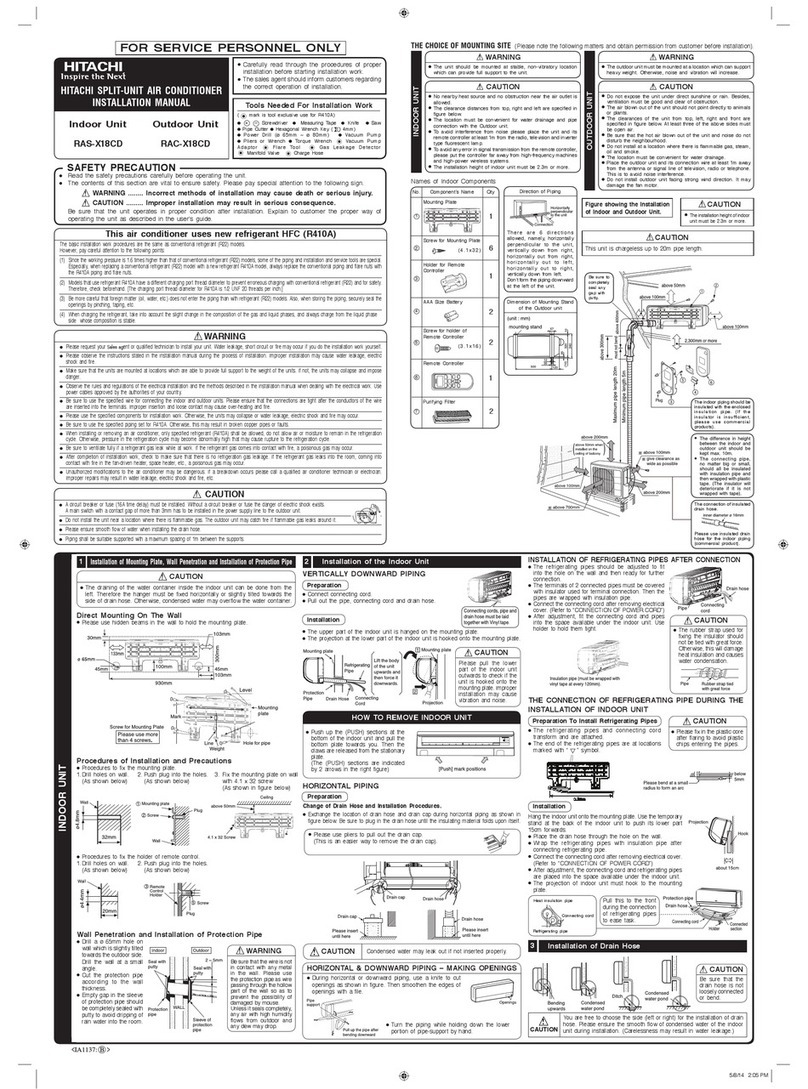

Remove the flare nut from the pipe of the indoor unit by removing the flare nut

(female side)

with a spanner while holding down the half union (male side)

with a spanner.

Do not crush the pipe while bending it.

Apply refrigerant oil on the connection part. After carrying out the center

alignment and

manual tightening of the flare nut,tighten theflare nut

securely with a torque wrench (spanner).

* Tightening torque must be as shown in the table below.

Outer diameter Torque N•m

)mcfgk()ø(ep ipfo

Small diameter side 6.35 (1/4

”

) 13.7~18.6 (140~190)

Large diameter side 9.52 (3/8

”

) 34.3~44.1 (350~450)

12.7 (1/2

”

) 44.1~53.9 (450~550)

Small diameter side 6.35 (1/4

”

) 19.6~24.5 (200~250)

Large diameter side 9.52 (3/8

”

) 19.6~24.5 (200~250)

12.7 (1/2

”

) 19.6~24.5 (200~250)

Valve core cap 12.3~15.7 (125~160)

Valve

head

cap

•

CAUTION

Remove burr

If burr is not removed, it may cause leakage.

Point the sideto be trimmed downwards during trimming to

prevent copper chips from entering thepipe.

Copper pipe

Die

A

Die

Before flaring,please put on the flare nut.

Please use exclusive tool for refrigerant R410.

Outer Diameter A (mm) Rigid Flaring Tool

For R410A tool For R22 tool

1Preparation of Pipe

Pipe Connection

2

Copper pipe

Trimming tool

Use a pipe cutter to cut the pipe and

remove burr.

Valve head cap

for the service

valve at small

diameter side

Valve head

cap for the

service valve

at large

diameter side

Cap of valve core

Removal Of Air From The Pipe And Gas Leakage Inspection

3

When removing flare nut of the indoor unit, first remove the nut of small diameter

side.

Prevent water from entering into the piping when connecting.

Be sure to tighten the flare nut to the specified torque with a torque wrench.

If the flare nut is overtightened, it may split after sometime and may cause refrigerant leak.

When using a control valve, make sure that the packing is not deteriorated and

avoid excessive

tightening of the handle. Otherwise, gas may leak from the service

valve.

From the viewpoint of global environment

protection, air purge type should be vacuum

pump method.

1

Remove the valve head cap

of the service valve.

Remove the cap of valve core

and

connect the charge hose.

Connect the vacuum pump

adapterto the vacuum pump

and connect the charge hose

to the adapter.

Loosen the spindle of the service valve with small

diameter by 1 / 4 turn and tighten the spindle

immediately after 1 to 2 seconds.

Remove the charging hose from the service valve.

Unscrew the spindle of both the

service valves in anticlockwise

direction to allow the flow of

refrigerant (unscrew halfway).

Tighten the cap of valve head.

Check and make sure that there

is no gas leakage.

Fully tightenthe “ Hi ” shuttle of the

manifold valve and completely unscrew

the “Lo” shuttle. Run the vacuum pump.

(Adapter is switched on)

Make sure the meter

reaches -0.1MPa (-76cmHg)

during pumping. Closed

When pumping starts, slightly loosen

the flare nut to check if air sucked in.

Meter showing pressure

R410A Manifold valve

Vacuum pump

Ball valve

Vacuum pump adapter

Charge hose

Ball valve

Valve

Please leave the ball valve fully

open at all times.

3

4

2

Body of service valve

Hexagonal

wrench key

Cap of valve

head

Cap of valve

head

Cap of

valve core

Works to be done when transferring or removing air conditioner

From the viewpoint of global environmentprotection, refrigerant

should be recovered (pumped down) when the air conditioner is

transferred or removed.

Perform force-cooling operation (refer to “Force-cooling operation”

on page 12) for about 5 minutes as a preliminary operation.

Tighten the spindle of the service valve at small diameter side in

clockwise direction.

Continue the force-cooling operation for another 1-2 minutes, and

then tighten the spindle of the service valve at large diameter side

in clockwise direction.

Stop the force-cooling operation.

Gas Leakage Inspection

Please use gas leakage detector

to check if leakage occurs at

connection of Flare nut as shown

on the right.

If gas leakage occurs , further

tighten the connection to stop

leakage. (Be sure to use R410A

detector.)

After pumping for about 10 -15 minutes,

completely loosen the “ Lo ” shuttle and

switch off the vacuum pump . (Adapter is

switched off)

Otherwise the nut of big diameter side will fly out.

CAUTION

VOMERRIADNASEPIPTNALOOCFONOITALLATSN LAI

LAVOMERRIA

Wiring Of The I ndoor Unit

WARNING

• If the supply cord is damaged, it must be replaced by a special cord (Maker’s service parts) available from the manufacturer

or its service agent.

• The naked part of the wire core should be 10mm fix it to the terminal tightly. Then try to pull the individual wire to check if the

contact is tight. Improper insertion may burn the terminal.

• Be sure to use only wire specified for the use of air-conditioner.

• Please refer to the manual for wire connection, the wiring technique should meet the standard of the electrical

installation.

• Leave some space in the connecting cord for maintenance purpose and be sure to secure it with the cord band.

• Secure the connecting cord along the coated part of the wire using the cord band. Do not exert pressure on the wire as this

may cause overheating or fire.

• There is a AC voltege of 220V between the A and B terminals. Therefore, before servicing, be sure to remove the plug from

the AC outlet.

•For wire connection of the Indoor unit, you need to remove the front cover, the low cover

under the body of the unit and terminal cover.

•Remove the cover from the

terminal base and screw

the cable.

Screw Insulating plate

Cord band

Connecting cord

Securely screw in the power cord and connecting cord so that it will not get

loose or disconnect.

Tightening torque reference value: 1.2 to 1.6 N·m (12 to 16 kgf·cm)

Excessive tightening may damage the interior of the cord requiring replacement.

When putting two connecting cords

through the band.

WARNING

After wiring the indoor unit, make sure to reattach the

terminal cover.

Terminal cover

Terminal cover Screw

Wiring of the Outdoor Unit

Please remove the side cover and terminal cover for wiring connection.

WARNING

•

The connecting cord must be fix with cord band

Otherwise rain water may enter and cause short circuit. Besides, an external

forcemay apply to the connection part of the connecting cord and could result

in heat and fire.

•

The terminal cover and side cover must be installed after work is

done.

Terminal cover

Terminal marking

Cord band

IMPORTANT

Fuse Capacity

1 A time-delay fuse

CAUTION

•

Outdoor supply cords shall not be lighter than polychloroprene

sheathed flexible cord with code designation 60245 IEC 57.

Wiring for the horizontal piping from the right side.

Not to interfere with the

drain hose, fold the cable at

the drain hose side of the

electric box as shown in the

left figure, and pass the

cable just over the electric

box and pull it out.

Cable

Pipe

Drain

Power cord

Electric box

Cable

Power

cord

Pipe

Drain

hose

Form the cable properly so that the

low cover won’t touch the cable in

installation.

Piping and drain hose layout

•Pull at the and in the directionsas

shown by arrows to remove the cover.

Method to remove the low cover

DROCREWOPFONOITCENNOC

Insulation And Maintenance Of Pipe Connection

1

The connected terminals should be completed sealed with

heat insulator and then tied up with rubber strap.

Please tie the pipe and power line together with plastic tape

as shown in the figure of installation of both the indoor and

outdoor units. Then fix their position with holders.

To enchance the heat insulation and to prevent water

condensation, please cover the outdoor part of the drain hose

and pipe with insulation pipe.

Completely seal any gap with putty.

Earth Line And Circuit Breaker

2

Power Source And Operation Test

3

The earth line terminal of the outdoor unit is below the

service valve.

To avoid short circuit, it is necessary to install circuit breaker

depending on the mounting location of the unit.

Do not place earth line near the following objects:

(1) Water pipe

(2) Gas pipe — There is danger of catching fire.

(3) The earth line of lightning conductor and telephone —

short circuit may occur during lightning.

Power Source

Do not alter the plug of power cord.

Do not make extension to the power cord.

Please use a new socket. Accident may occur due to the

use of old socket because of poor contact.

Please plug in and then remove the plug for 2 – 3 times.

This is to ensure that the plug is completely plugged into

the socket.

Keep additional length for thepower cord and do not render

the plug under external force as this may cause poor

contact.

Do not fix the power cord with U-shape nail.

Insulation material for pipe connection

Sleeve of

protection

pipe

Putty

CAUITON

WARNING

CAUTION

NOITALLATSNIFOEGATSLANIF

5

(Only RAC-X18CBK)

<

E4340:

>

Forced cooling operation

The cooling operation can be forcibly performed for collecting

refrigerant and inspecting failures.

Do not perform the forced cooling operation continuously for

long hours,

because the compressor continues to be in operational status,

regardless of room temperature.

<How to start the operation>

・The operation of the unit should be stopped.

・

<How to stop the operation>

・Press and hold the "Temporary operation SW" again.

Or stop the operation using the remote controller.

※During the forced cooling operation,

the "Timer indicator" blinks twice.

Temporary operation switch

Press and hold the "Temporary operation SW"

shown in the right figure for 5 sec.

Connecting cord Connecting cord

EarthEarth

X10CCK、X13CCK X18CCK

1

2

3

1

2

3

1 2 3 1 2 3

1

2

3

1

2

3

3

2

1

31 2

G