--- 8 ---

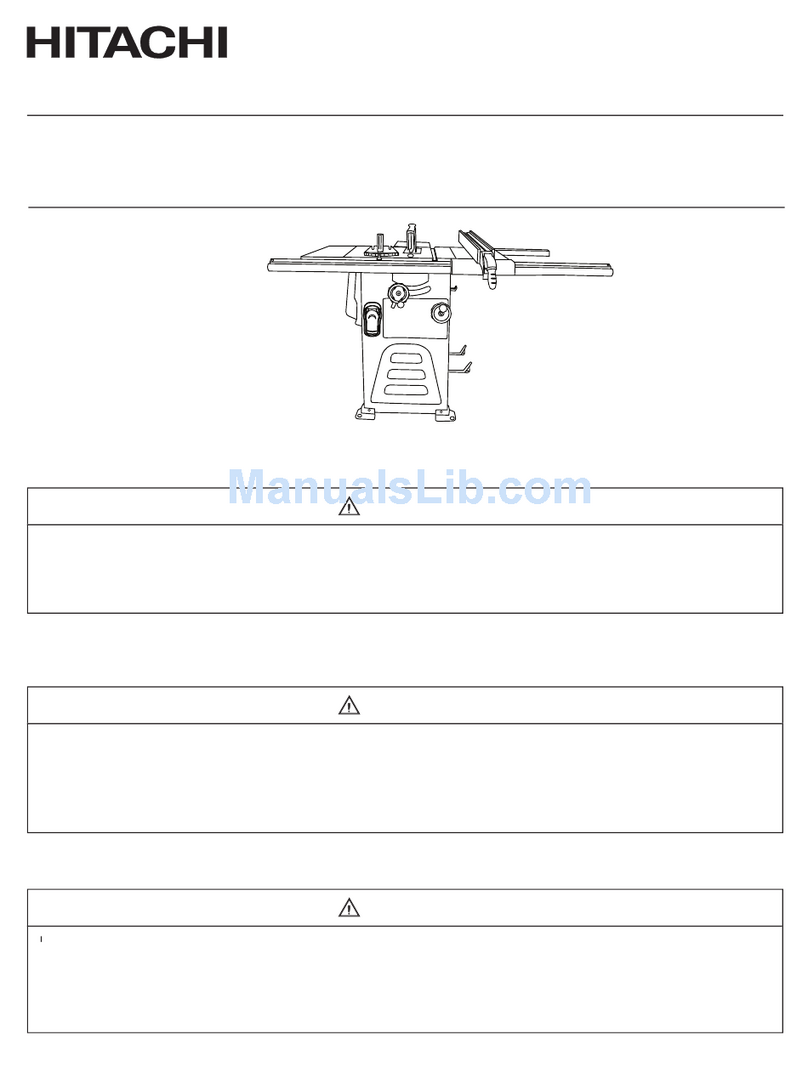

1-5. Assembly Adjustments Requiring Particular Attention:

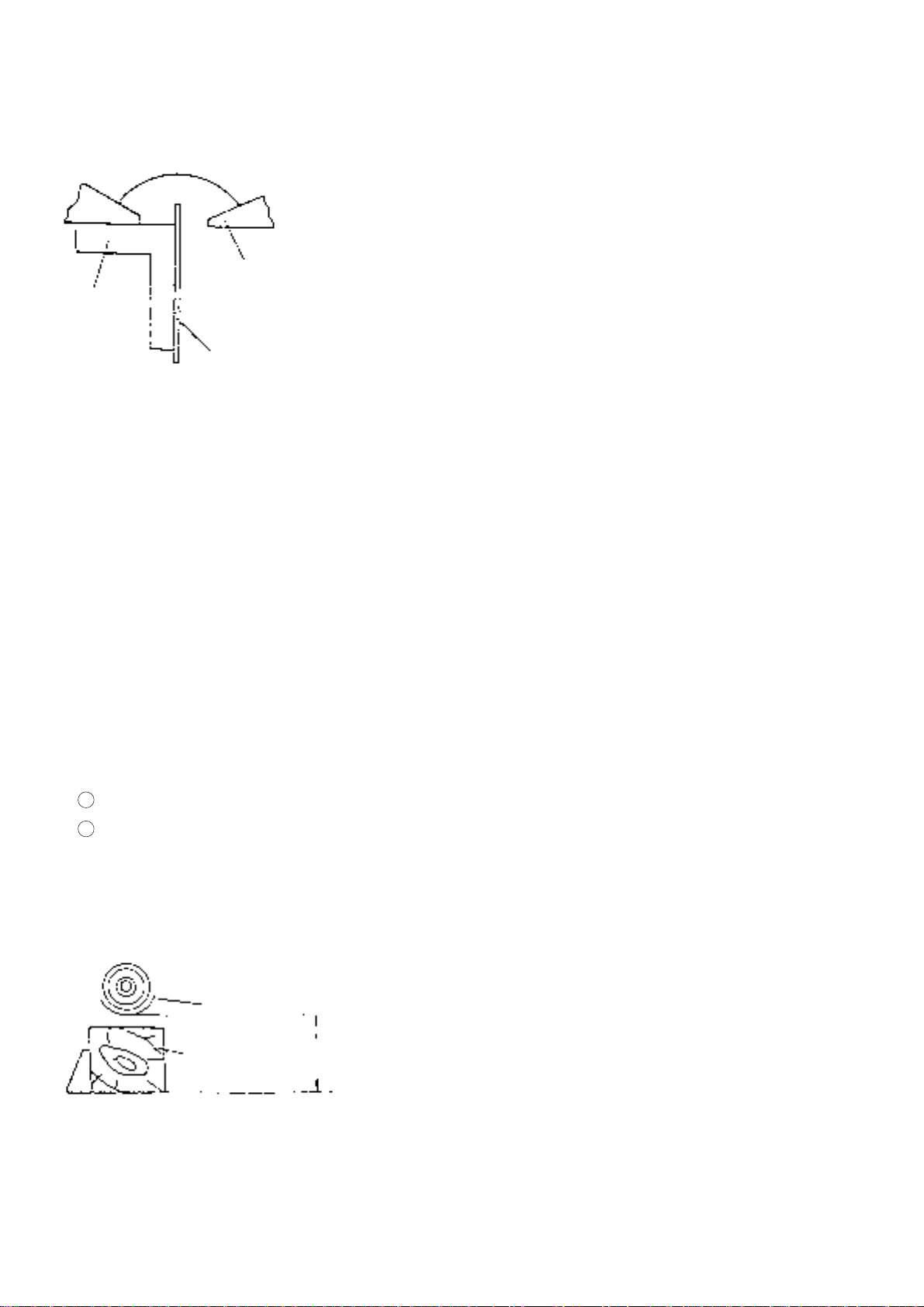

(1) Adjustment of Saw Blade and fence Perpendicularity:

After disassembly/reassembly or replacement of the Base [37], Turn

Table [35], Fence [32], Hinge [8], or Hinge Holder [15], it is necessary to

check the perpendicularity between the Saw Blade (or dummy disc*)

and the Fence, and perform adjustment as necessary if they are not at

an exact right-angle with relation to each other. Adjustment procedure is

as follows:

First, position the Saw Blade (or dummy disc) so that it is in the exact

center of the groove on the Turn Table which houses the Table Insert,

and then tighten the three M6 x 22 Hex Socket Hd. Bolts (w/Flange) [6]

to fix the Hinge Holder [15] in position.

Next, as illustrasted in Fig. 3, place a square so that it is flush against

the side surface of the Saw Blade (or dummy disc), and move the Fence

[32] as necessary so that it is at an exact right angle in relation to the

Saw Blade (or dummy disc). Finally, tighten the two M6 x 30 Bolts

(w/Washers) [31] to fix the Fence [32] in position.

*Dummy Disc: A dummy disc is a toothless disc with the same external

diameter as a saw blade, and is used to perform accuracy inspections

and adjustments.

Fence

Saw Blade

(or dummy disc)

Square

Fig. 3

(2) Adjustment of Saw Blade Lower Limit Position:

When adjusting the lower limit of the Saw Blade, be sure to use a saw blade with an external diameter of

216 mm.

Failure to properly adjust the lower limit position of the Saw Blade may result in the following problems:

1 inability to obtain the maximum cutting capacities of the machine; and

2 there is a danger that the Saw Blade may come in contact with and cut into the Turn Table.

Lower the Saw Blade and confirm without fail that it does not come in contact with the Turn Table. For

adjustment procedures, please refer to Paragraph*, [Confirmation of Saw Blade Lower Limit Positioning].

(3) Adjustment of Saw Blade Height:

Prior to shipment, the Saw Blade height (when fully lowered) is

adjusted so that the dimension from the bottom surface of the Gear

Case and the surface of the Turn Table is between 62.3 mm and

63 mm, as illustrated in Fig. 4.

The operator can adjust the height of the Saw Blade to meet the

needs of the cutting operation. For adjustment procedures, please

refer to Paragraph*, [Confirmation of Saw Blade Lower Limit

Positioning].

Gear Case

Workpiece 62.3 ---

63 mm

Fig. 4