INSTALATION AND OPERATION MANUAL FOR PC-P2HTE 3

CAUTION:

-Use the twist (shield) pair cable (2 x 0.75mm²) as

transmitting wire cable for prevention of the

malfunction (The total cable length is max. 500m).

When the total cable length is within 30m, other type

cable (more than 0.3mm²) can be used.

-Keep a distance more than 30 cm between the remote

control cable and the transmission wire of Indoor

units.

-In the case that multiple indoor units are controlled

simultaneously, set the refrigerant cycle number and

the address of Indoor units as indicated below.

Address of Indoor Units:

Main unit 1st unit 2nd unit 3rd unit

4th unit 5th unit 6th unit 7th unit

8th unit 9th unit 10th unit 11th unit

12th unit 13th unit 14th unit 15th unit

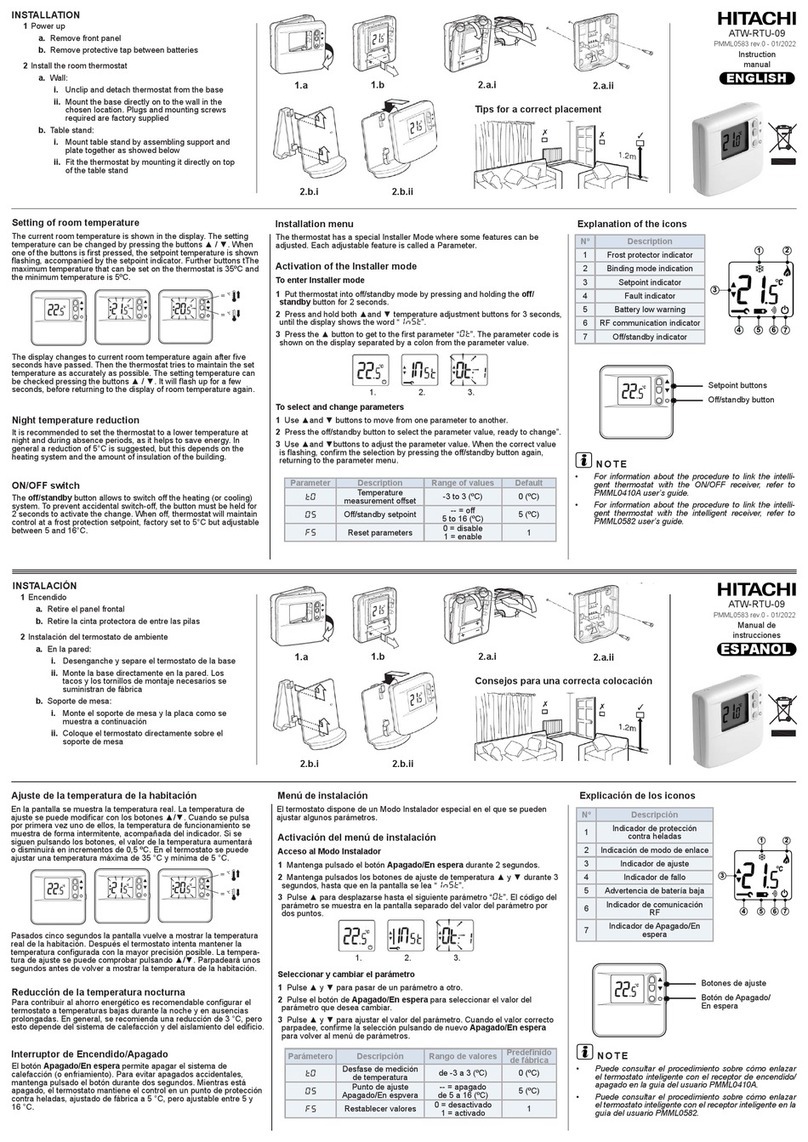

4. CHECKING PROCEDURES

1. Turn ON the power supply for all the indoor units.

2. Set the “TEST RUN” mode by pressing the “MODE” and

“OK” switch simultaneously for more than 3 seconds.

ATTENTION:

In case of the control by using two Remote controllers

(Main & Sub), the test running shall be operated by

the main controller.

NOTE:

-The completion of the automatic address setting requires

3 to 5 minutes after turning ON the power supply.

-The total number of the connected units is indicated on

the liquid crystal display.

-In case that the indicated number is not correct, some

abnormalities exist, incorrect wiring, the electric noise,

etc.

-Turn OFF the power supply and correct the wiring after

checking the following points; (Do not repeat turning ON

and OFF within 10 seconds.)

-Power Supply for Indoor Unit is Not Turned ON or

Incorrect Wiring.

-Incorrect Connection of Connecting Cable between

Indoor Units or Incorrect Connection of Controller Cable

-Incorrect Setting of Rotary Switch (The setting is

overlapped.) on the Indoor Units PCB

-Check to ensure that the “Test Run” mode is not set.

3. Canceling “Test Run” Mode

-When the unit is not operating, press the RESET switch.

-When the unit is operating, press the RUN/STOP switch.

CAUTION:

The setting of the indoor unit number can not be

performed by the controller.

In case of setting the unit number, refer to the item

“Address of Indoor Unit” of Item 2 “Electrical Wiring for

multiple units” and perform the setting.

5. OPTIONAL SETTING AND INPUT/OUTPUT SETTING OF INDOOR UNIT

5.1. OPTIONAL SETTING MODE

Example when

5 indoor Units

are connected.

unit

Normal Mode

When unit is not

Press the “OK” switch and the ”RESET” switch

simultaneousl

more than 3 seconds.

Chan

e to the o

tional settin

mode.

Press the “” or “” switch and set “01” or

“02”. Then press the “OK” switch.

Selection of O

tional Settin

Mode

COOL

SERVIC

°C

SET TEMP

“SERVICE” is indicated and the mode number is flickered.

HIGH

A/C