Hitecsa EKWXA User manual

1

04.14 000000 Rev. 000

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Modelos 801.1 │1001.1 │1201.1 │1501.1

Cooling Capacities: 26,0kW a 40,0kW

Pot. Caloríficas: 28,1kW a 43,1kW

11.15 207443 Rev102

EKWXA EKWXBA

AIR COOLED WATER CHILLERS –AXIAL FANS

Cooling only

Sólo frío

With Heat pump

Bomba de calor

2

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

TABLE OF CONTENTS

INTRODUCTION .....................................................................................................................................3

GENERAL DESCRIPTION ............................................................................................................................3

SAFETY PRECAUTIONS ...........................................................................................................................5

GENERAL CHARACTERISTICS ..................................................................................................................6

COMPONENT DESCRIPTIONS ...................................................................................................................6

VERSIONS .................................................................................................................................................9

ACCESSORIES /OPTIONALS ......................................................................................................................9

ELECTRICAL DATA...................................................................................................................................10

APPLICATION LIMITS ..............................................................................................................................11

UNIT RECEPTION..................................................................................................................................12

INSPECTION UPON ARRIVAL...................................................................................................................12

STORAGE ................................................................................................................................................12

RIGGING .................................................................................................................................................12

INSTALLATION LOCATION ......................................................................................................................13

UNIT SETTLEMENT..................................................................................................................................13

SERVICE AREA.........................................................................................................................................13

WEIGHT DISTRIBUTION (KG) ...................................................................................................................14

REFRIGERANT CHARGE ........................................................................................................................15

COMPRESSOR LUBRICANT......................................................................................................................15

START UP .............................................................................................................................................16

LCX CONTROL .........................................................................................................................................16

MCX CONTROL (OPTIONAL UPGRADE)...................................................................................................17

MAINTENANCE ....................................................................................................................................18

APPENDIX: SAFETY CHART R410A ........................................................................................................18

3

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

INTRODUCTION

GENERAL DESCRIPTION

► Manual purpose

This manual and the 88610 and 88611 documents have been created to guide in the correct installation,

start-up and maintenance of the unit. For this reason is essential to read the instructions paying due

attention. The manufacturer waives any liability, for possible damages on persons or stuff, as a

consequence of an improper use of this unit and/or non-compliance with these instructions.

► Manual preservation

This manual and the electric diagram of the unit must be retained and remain available to the operator for

further consultation.

► Local safety standards

Follow the local security standards during installation.

► Electrical network

Check that electrical network features are in accordance to data shown in the data nameplate of the unit.

►Packaging

Packaging material (plastic bags, cellular polystyrene, cloves, etc.) constitutes a dangerous source, for

that it should be kept out of the reach of children and recycled correctly according to local security

standards.

► Maintenance

Before executing any maintenance operation, cut off the unit power supply. Operations have to be carried

out following local security standards.

► Periodic inspections

Carry out periodic inspections to detect possible damaged or broken pieces. If they are not repaired it

could result in damage to people or stuff.

► Incorrect operation

In case of breakdowns or operation faults, turn off unit.

► Repairs

Reparations should be always realized for trained personal authorized by the manufacturer using original

spares. Failure to comply with these warnings could affect the safety features of the unit.

► Modifications

All manufacturer responsibility is declined when the warranty has been expired in case of electrical and/or

mechanical modifications. Alterations in general not expressly allowed and not respecting what is

instructed here, they cause the warranty expiration.

► Use

The unit will only be used for the purpose it has been conceived. Any other use does not imply any kind of

compromise or liability for the manufacturer.

4

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

► Principles of security on installation

The unit is designed and built so that a risk to health and security for people are not supposed. Suitable

project solutions have been adopted to delete possible causes of risk in the system.

► Data actualization

Continuous improvements to the product may determine variations in the data given even without notice

by the manufacturer.

► Standards and certifications

CE QUALIFICATION: Our units have CE brand in accordance with the expected for the relevant

community directive, and its last modifications, as well as for each country's national legislation.

5

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

• Installation and maintenance of air conditioning equipment can be dangerous because the liquid

circulating through the system is pressurized, some elements work at high temperatures and includes

electrical components.

•Only qualified and trained service personnel should install, start up and do maintenance tasks on this air

conditioning equipment.

• During every visit follow recommendations from the Installation Operation Maintenance manual, pay

attention to the indications shown on unit’s stickers and take safety precautions according general

legislation.

• Strictly follow all safety codes.

• Use safety glasses, work gloves and any other work safety accessory.

• For brazing operations use a quenching cloth and have a fire extinguisher at a close distance in case of

emergencies.

• When repairing the unit use only original spare parts and install them properly in the same place and

position where the old parts were located.

• Do not install the unit in explosive atmosphere.

SAFETY PRECAUTIONS

Before starting installation, service or maintenance turn off system’s main power

switch to avoid electrical shock which may result in personal injury.

WARNING!

6

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

EKWXBA compact units are reversible air cooled water / heat water production and designed for its

installation outdoor. It is provided with R-410A refrigerant charge already for its installation. These units

are manufactured under strict quality control throughout the whole process and when they are finished

they are tested in the factory, checking the correct working of all their components.

1. Remote Control System.

LCX Control System

- Main on-off switch.

- Device control phase sequence.

- Monopolar magnetothermal of control protection.

- Monopolar magntothermal of protection of

compressors crankcase resistors.

- Safety and isolation transformer for 24

Vac power to control itself.

- Contactors for compressors and outdoor fans.

- Controller with LED display of 3 ½ digits and 8 icons

to show all the information on the display itself.

- Display by default: Outdoor water temperature.

- Self-diagnostics with alarm code display.

Main Functions of the Control System

- Regulation Water temperature.

- Counting the hours of operation for maintenance of compressors and pumps if the unit is built with this

optional.

- Visualization of inlet and outlet water temperatures on the unit and Condenser and Evaporation

pressures.

- Timings of starts of compressors.

- Security protection of High Pressure.

- Compressors Electronic protection.

- Outdoor fans protection.

- Water flow protection.

- Intervention for antifreeze security.

- ON/OFF remote.

- Remote changing of operation mode Cool/Heat.

- Condensation and evaporation pressure control with 2 ventilation stages..

- Reversible valve of cycle inversion (Only for het pump models).

- Discharge maneuver. Start and ending of Pressure discharge. Control of run times between defrosts.

COMPONENT DESCRIPTIONS

GENERAL CHARACTERISTICS

7

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

MCX Control System (OPTIONAL UPGRADE)

- Controller is composed of user interface and electronic board.

- Power supply : 20/30 Vdc –24 Vac.

- Panel mounting type.

- Screen with display that allows the inputs and outputs to be

visualized.

- Operating mode : 2 compressors, cooling only and heat pump.

- Defrosting by pressure transducers.

- Management of water circulating pump and hydraulic module.

- Clock programming.

- Programmable controller with 3 access levels: User,

Maintenance and Manufacturer.

Main Functions of the Control System

- Regulates wáter temperature

- Service hour counter for compressors and wáter pumps (optional)

- Intake and outlet water temperature reading displays, as well as, pressure reading displays in evaporator

and condenser stages

- Compressor start timers

- Pressure overload safety protection

- Electronic compressor protection

- External fan protection

- Water flow protection

- Anti-freeze active protection

- Remote ON/OFF

- Remote COOL/HEAT mode toggle

- Condensing and evaporating pressure control by incorporating 2 ventilation stages

- Check valve for cycle reversion (only available for Heat Pump units)

- Anti-frost feature. Anti-frost start and stop settings through pressure readings.

- Anti-frost duration time control.

2. Compressor

Hermetically sealed, alternative compressor with wide operation limits. Equipped with thermal protection, -

any other additional protection is not needed-, it includes its oil charge for the perfect lubrication and

internal shock-absorbing system. The compressor is mounted on the base with antivibration supports and

it is acoustically isolated, guaranteeing a silent and vibration-free operation.

3. Outdoor coils

Coils built with seamless copper tubes and expanded in aluminum fins. They incorporate a distributor with

neck and calibrated orifice (nozzle) to improve gas distribution in Cool mode.

4. Refrigerant-water heat exchanger

Stainless steel plate heat exchanger (AISI 316) welded with a bronze based technique. It’s perfectly

isolated with insulating material to avoid thermal exchange with its surroundings. It incorporates a resistor

to frost protection mode to avoid dangers of breaking by water freezing in case of lack of water flow.

5. Motorfan

Mounted on a square-based embouchure; with a circular opening, which is ideal for optimal aerodynamic

performance of air flow supplied by the fan. Weatherproof completely sealed and permanently lubricated.

They consist of aluminum blades designed for low noise, inserted into the outdoor rotor of a high-efficiency

motor with IP-54 protection and Class F coil insulation. Internal thermal sensors have built-in for their

protection and an external safety grate.

8

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

6. Expansion devices

The unit is equipped with thermostatic expansion valves with MOP on in the inlet of plate heat exchanger

for functioning in refrigeration mode. The expansion in the outdoor coil, when necessary (functioning in

heating mode), is done through orifice (nozzle).

7. High pressure pressostat

Security pressostat connected to the compressor output (maximum pressure point) manual reset. Shut off

is calibrated to a pressure of 42 bars.

8. Dehydrator filter

Bidirectional type filters are mounted in the liquid line. It has a desiccant solid core that minimizes vibration

and friction during operation, as well as absorbing the excess moisture and filter possible impurities.

9. Liquid container

It is, basically, a tank to hold the difference of refrigerant charge required by the unit to operate between

Cooling/Heating.

10. Check valves

Only in heat pump units to carry out the bypass to the expansion system of the secondary exchanger

block. In cooling mode it carries out the bypass to the coil, in heating mode, to the expansion valves.

11. Sheet structure

The unit’s structure is weather resistant and it consists of galvanized steel sheet applying an oven-cured

painting process by polymerizing paint providing excellent coating to whole set and, especially, in edges

and corners. The freestanding base is built with high stiffness steel and the rest of the structure is made of

galvanized steel. The design is intended for easy maintenance. The color of the finished set is RAL 1013.

9

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

STANDARD

Outdoor fans of motors of 6 poles and without compressor isolation

IC

Outdoor fans with 6 poles and with compressor isolation

Type 1: Basic Compressor Isolation [Sound level reduction 2 dB (A)]

Type 2: “Low Noise” Compressor Isolation [Sound level reduction 6 dB (A)]

SIL

Outdoor fans of Bionic Profile of 8 poles and with Compressor Isolation

Type 1: Basic Compressor Isolation [Sound level reduction 3 dB (A)]

Tipo 2: “Low Noise” Compressor Isolation [Sound level reduction 8 dB (A)]

SS

Electronic Fans of Bionic Profile and Compressor Isolation “Low Noise”

CONDENSATION CONTROL

STANDARD, IC and SIL: Outdoor fans AC with variable speed

SS: Speed regulation standard incorporated

EMPOWERED FAN

Incorporation of Electronic Fans EC of bionic profile with more available pressure

This accessory includes Condensation Control of the Unit.

SOFT STARTER

Soft Starters to minimize the intensity peaks at the start of the compressor

ELECTRONIC EXPANSION

Expansion by Electronic Injection valve

HYDRONIC KIT

Option 1: Pumop + Container + Expansion vessel

Option 2: Pump + Expansion vessel

WATER MANOMETER

Manometer incorporation for pressure reading of inlet and outlet water

VICTAULIC

Outdoor Connections of type VICTAULIC Inlet Water

AGRESSIVE

ENVIRONMENTS

Coils coated with Blycol of finned package

Coils with Aluzinc fins

Coils with copper fins

COIL PROTECTIONS

Incorporation of grilles as a protection to avoid bumps in condenser coils

SUPERVISION

External supervision system

MANAGEMENT OF

SEVERAL UNITS

Modular control system via master/slave

*Apart from this options consult our Commercial Department for any other configuration or function not described as available.

ACCESSORIES / OPTIONALS

VERSIONS

10

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

• The electrical power supply to the unit must be within the 10% of the voltage indicated on the nameplate.

Unit start-up at incorrect voltage is not covered by our guarantee.

• When making electrical connections always use unit wiring diagram.

• Be sure that compressor crankcase heater is energized before unit start.

• The installer has to install line protection elements according to local laws.

• The interconnecting wires have to be in protection tube or inside groove channel.

ELECTRICAL DATA

Before starting any type of operation switch off main power switch.

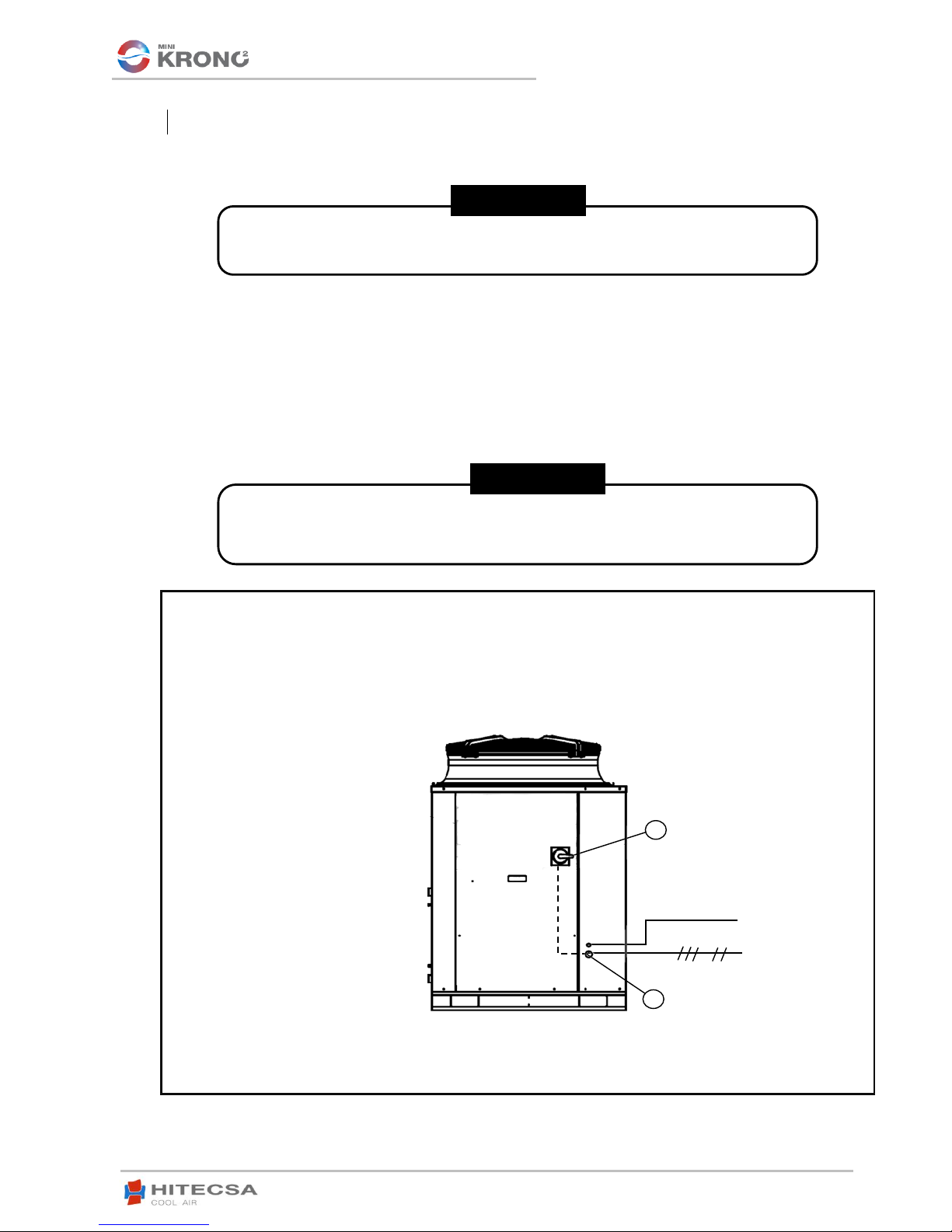

1. Main power supply 400/3/50 + neutral + ground

2. Main power switch

1

2

L1 L2 L3 N T

It is mandatory to install flow switch at the machine water inlet and with previous straight

section of 1,5m without changes in cross section to assure the water or fluid is laminar.

Failure to comply with this causes loss of the equipment warranty.

CONTROL MANEUVER

WARNING!

WARNING!

11

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

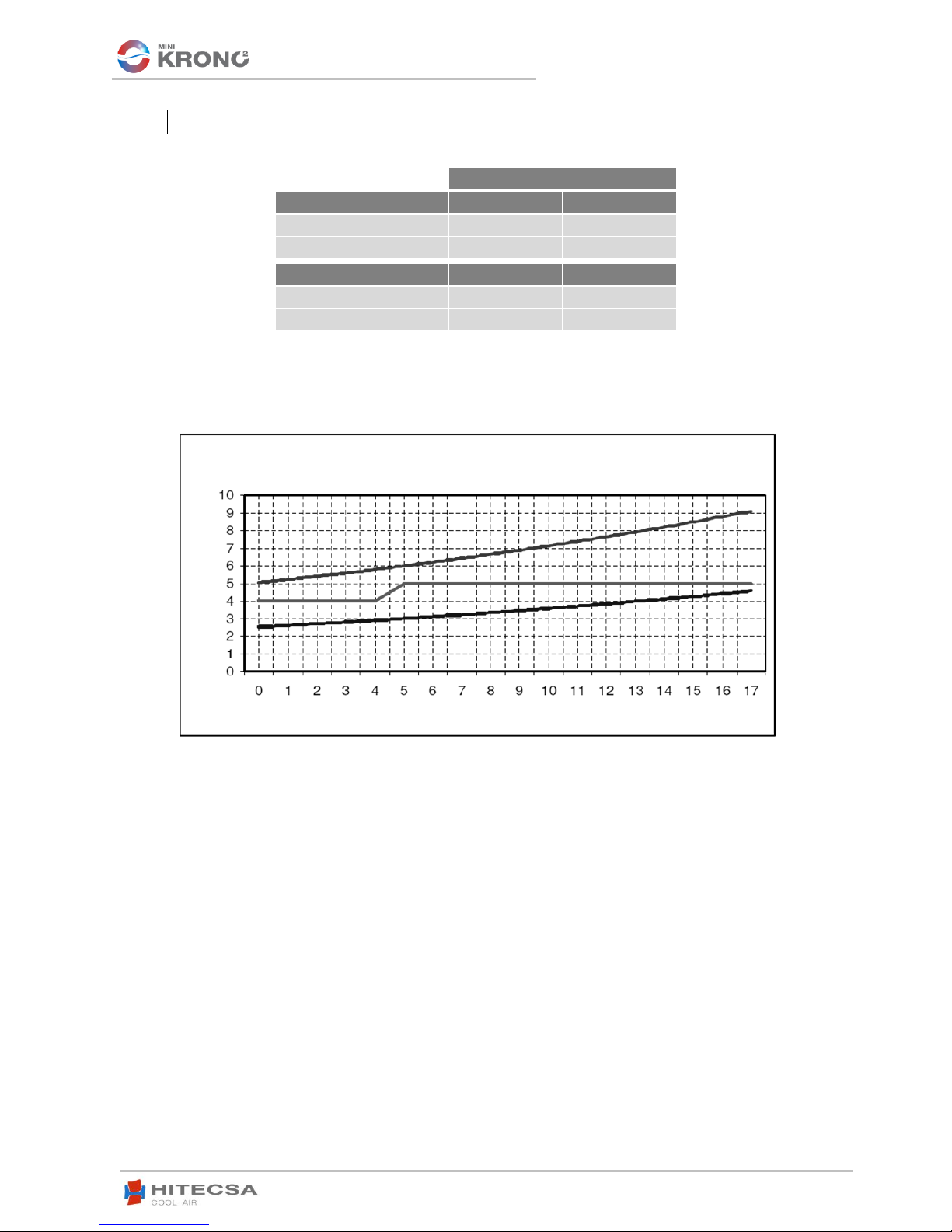

APPLICATION LIMITS

TEMPERATURE

COOLING CYCLE

MÍN.

MÁX.

Outgoing chilled water

5ºC*

16ºC

Outdoor air dry bulb

19ºC**

46ºC

HEATING CYCLE

MÍN.

MÁX.

Outgoing hot water

35ºC

55ºC

Outdoor air water bulb

-10ºC

18ºC***

*For lower temperatures it is necessary to use water glycol mixture.

** For lower temperature use optional low ambient control.

***For lower temperature use optional evaporating pressure.

EVAPORATOR OPERATING LIMITS

Inlet water temperature

Water I/O differential

12

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

• It is advisable to examine carefully the unit upon receipt.

• Inspect equipment received for damage or missing element. If units are damaged or shipment is

incomplete, immediately file the claim with the transport company. (Within the first 48h)

• Check if unit nameplate voltage is correct and agrees with local power supply.

• In case of detecting any damage or anomaly it is recommended to contact our customer support.

If the unit is to be stored before installation, several precautions must be kept to avoid any damages,

corrosion or any other type of deterioration:

• Do not store the unit in locations with temperatures over 50ºC and preferably without exposure to direct

sunlight.

• Minimum storage temperature: -10ºC

• Maximum humidity: 90%

Moreover it is recommended:

- Move it carefully

- Avoid placing other objects on the unit (Unless this is done within the overlay limits indicated in the

packaging)

- Avoid placing the unit with heat shrink protection under the sun, as the pressure of the circuits might

assume values that could lead to activation of the safety valves

• Before moving the unit be sure that all units panels are well fixed.

• Raise and set down the equipment carefully.

• Never tilt the unit more than 15 degrees during transportation (Fig. 2).

• When lifting the unit ensure that it is balanced and steady, keep in mind that the heaviest part is where

the compressor is installed.

• Always transport unit to installation place in original packaging.

RIGGING

STORAGE

INSPECTION UPON ARRIVAL

UNIT RECEPTION

13

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

• Check if construction is able to support unit weight.

• Check that the service area is the one indicated for this unit.

• Choose a place free of dust and waste.

• Consult and respect all regulations concerning installation of air conditioning systems.

• Install shock absorbers in all the installation to avoid noise transmission.

• Check if sound level direction will not disturb any person.

• Make sure the unit is correctly levelled.

• The bed frame should be strong and solid enough to support the weight of the machine.

• Assure the drainages work correctly.

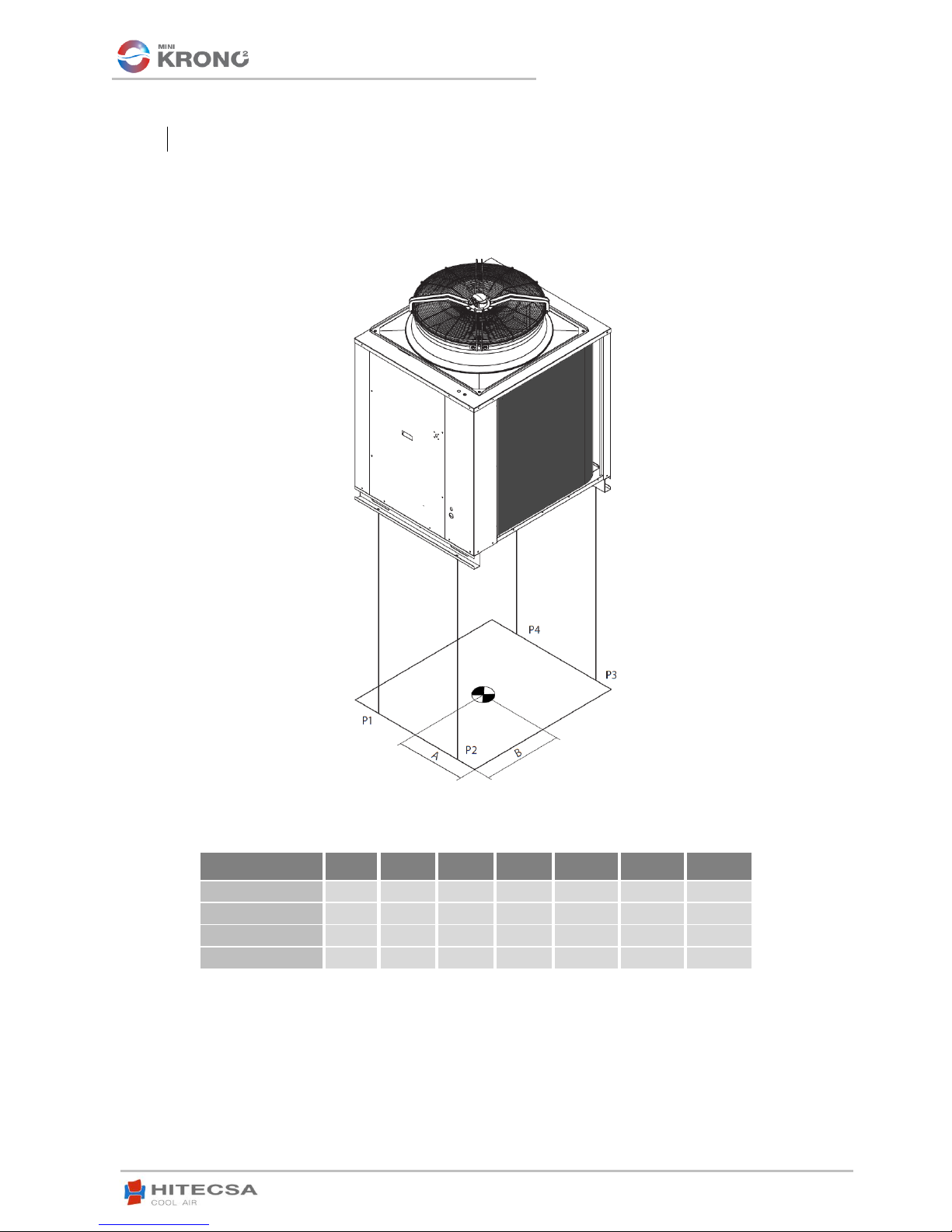

Make sure to respect the following measures for the correct operation of the unit.

1000 mm → Coil sides.

1200 mm → Connections and electrical panel side.

1200 mm → Electrical panel side.

SERVICE AREA

UNIT SETTLEMENT

INSTALLATION LOCATION

14

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

POMPE À

CHALEUR

1

2

3

4

A

B

TOTAL

801.1

62

52

50

60

569

598

224

1001.1

64

61

59

62

546

572

246

1201.1

68

68

62

62

525

567

260

1501.1

69

69

63

63

525

567

264

WEIGHT DISTRIBUTION (kg)

15

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

• If is necessary to add or recuperate refrigerant 410A always do it in LIQUID phase. Supplying refrigerant

in gas or vapor form, by mistake, will result in wrong mixture conditions.

• Due to its high pressure and quick evaporation, refrigerant R410A cannot be kept in liquid phase inside

charge cylinder because bubbles would form, altering the readings.

• The electronic scale is reinforced with a four support-point structure for the weight sensor of the

refrigerant bottle.

• In addition, it can also be used for any type of refrigerant’s charge. The refrigerant’s charge is carried out

opening and closing the valve manually.

• Immediately repair all refrigerant leaks.

• Never overcharge the system.

• Never use compressor as vacuum pump.

• If during operation will appear symptoms of refrigerant loss is necessary to make leak test. Leak

detectors usually employed with CFC and HCFC cannot be used with R410a, due to chlorine in its

composition. A leak detector for R134A may be used but the sensibility will be lower (when sensibility is 1

for R134A, it falls to 0,6 for R410A).

• To find small leaks, you will need a detector for HCF. Sensibility for R410A is approximately 23 grams

per year.

• If gas leak is detected is necessary to remove and recuperate complete refrigerant charge. Pressurize

system with dry nitrogen. If leakage has been not detected break a vacuum, dehydrate and charge with

refrigerant.

Compressors with R410A refrigerant use polyester synthetic oil. Each compressor’s manufacturer

recommends a specific type of oil for its products. The compressor or the system should not be left opened

to atmosphere more than 15 minutes. Synthetic lubricants are used as ester (POE, Polyol Ester) that have

a high solubility with R410A. Since these types of oils are very hygroscopic, more care should be taken

rather than with the conventional ones. Furthermore, when these synthetic oils are mixed with minerals or

alkylbenzene, they deteriorate producing capillary obstruction or failures in the compressor. Do not mix

them under any circumstance.

COMPRESSOR LUBRICANT

REFRIGERANT CHARGE

Never use oxygen to pressurize system or purge lines for leak test. Oxygen reacts

violently with oil, which can cause an explosion resulting in damage, personal injury

or death.

If it is necessary to make brazing operation, first fill the circuit with dry nitrogen.

Burning refrigerant 410A results in toxic gas emissions.

ATTENTION!

ATTENTION!

16

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

START UP

• Start up to be performed by qualified technical people.

• Make start-up check list and use similar check up for service and maintenance. Record chilled water inlet

and outlet temperatures and pressures, outdoor air temperature, volts and amps of each compressor and

fan motor, suction and discharge pressure of each compressor.

• Should remind that after four hours of system operation is necessary to clean air filters.

• Observe at least 3 cooling cycle operations.

• Due to the fact that the unit has frequency converters for compressors and fans, it’s essential that the

supply be at a minimum of 300 mA to prevent supply cuts caused by the differential switch.

LCX CONTROL

► START UP:

► SHUTDOWN:

•Check if all wires are well tightened.

•Check if all panels are firmly secured with screws.

•Verify if there is no refrigerant or oil leakage.

•Verify if unit is installed on level.

•Verify if there is enough space for service and maintenance.

• Check if drain holes in unit base are not blocked.

• Check if the cranckcase heater of each compressor has been energized at least 24 hours before unit start up.

• Check if air filters are clean and correctly mounted.

• Check all grills, air diffusers, air ducts and flexible connections.

• Be sure that electrical power source agrees with unit nameplate rating.

•Fans rotate in the right direction.

BEFORE START –UP

17

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

MCX CONTROL (OPTIONAL UPGRADE)

► START MENU

Keypad utility

(UP) By pressing and holding this key for, at least, 3 seconds the unit will start up if it

was shutdown or it shuts down if it is running.

(DOWN) By pressing and holding this key, at least, 3 seconds the unit will toggle

between cooling and heating mode. If the unit is running, it needs to stop prior to

switching modes and then it must be started up once again.

(ESC) Pressing this key leads to a shortcut to the ALARMS menu.

(RETURN) This key takes the user to the MAIN MENU screen if it is pressed in the

START MENU screen. It is also used to enter menus for other selected options.

►MAIN MENU

Keypad utility

(UP) Used to scroll UP between highlighted

options.

(DOWN) Used to scroll DOWN between

highlighted options.

(ESC) Returns to the previous screen of a

highlighted option.

(RETURN) Advances to the next screen or sublevel of a highlighted option.

ON. Starts up the unit using the last settings.

OFF. Shuts off the unit according to the established time parameters.

Heat/Cool.

Toggles between operating modes.

18

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

►PASSWORD LEVEL

There are 3 clearance levels for different parameters or system setting options.

Level L0: User Access, no password required.

Level L1: User-Maintenance Access.

Level L2: Manufacturer authorized Access ONLY.

DISPLAY “A” DISPLAY “B” ALARMAS/NOTIFICATIONS

COMPRESSOR

WATER PUMP

EXTERNAL FAN

ANTI-FREEZE HEATER

COOL / HEAT / ANTI-FROST MODE

19

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

►INPUTS / OUTPUTS

**The MCX controller automatically alternates

water pumps for the next start up cycle, after

24 service hours have been logged, in order

to prolong the life of the components. (Only

available for units with more than 1 water

pump)

POSITION

ANALOG INPUTS

DIGITAL INPUTS

ANALOG OUTPUTS

DIGITAL OUTPUTS

1

Intake water

temperature.

Differential pressostat / Flow

switch.

NO OUTPUTS. ONLY

when Condensation

Control OPTIONAL Kit

is installed, there is a

reading in ANALOG

OUTPUT slot #3.

Compressor 1

2

Outlet water

temperature.

Thermal protection

Compressor 1.

Compressor 2. (for

units with 2

compressors)

3

Cond / Evap

pressure Cool /

Heat.

Thermal protection

Compressor 2. (for units with

2 Compressors)

4 way valve (ONLY

available with Heat

Pump units)

4

Evap / Cond

pressure Cool /

Heat.

External fan termal sensors.

Anti-freeze heater

5

---

Safety pressostat. High

Pressure readings.

Water pump for 1-

pump KIT. (No Kit,

shows no output. If 2-

pump Kit is installed,

outputs are shown in

#9 and #10 slots.)

6

---

Remote Start-Stop.

External fans ALL set

to lowest speed

setting.

7

---

Remote Cool/Heat selection.

ONE fan in high

speed, the rest in the

lowest.

8

---

Second SETPOINT.

ALL fans in the high

speed setting

9

---

Thermal protection for Water

pump 1 (for 2-pump Kit).

---

10

---

Thermal protection for Water

pump 2 (for 2-pump Kit).

---

ANALOG INPUTS

DIGITAL INPUTS

0= Not Active

1= Active

ANALOG

OUTPUTS

DIGITAL OUTPUTS

0= OFF

1=ON

20

AIR COOLED WATER CHILLERS –AXIAL FANS

EKWXA/EKWXBA

11.15 207443 Rev104

►SYSTEM PARAMETERS

Display screen

Display screen “A”.

Select the Reading to be shown in Display

screen A when the unit is running. By default,

the reading shown on Display screen A when

the unit is shut down is “OFF”.

Display screen “B”.

Select the Reading to be shown in Display

screen B when the unit is running.

. Password

Displays Installer-Maintenance password.

Setup

System ON/OFF.

Indicates wether the unit is running (ON) or if it is

shutdown (OFF), it also allows starting up or

shutting down the unit by selecting ON/OFF.

Restart After Disconnection Mode.

Following a sudden power outage, this indicates

the operational mode for restart.

System HEAT/COOL

Indicates current operating mode HEAT/COOL

and, it also allows switching between modes.

If the unit is running, it stops before switching

operating modes and then it is started up in the

new mode.

Scheduler Enable.

Enables/Disables Programming Mode.

►REGULATION PARAMETERS

Configuration

Temperature Regulation Entry

This is used to tell the system whether regulation

will be applied to IN or OUT water temperature.

Calibration of the Regulation Probes.

Adjusts probe regulation values in the range

between -99,9 and 99,9.

Setpoint.

Cooling Setpoint Temperature.

Sets the value of the operating Cooling Setpoint

temperature in ºC, by default this value is set to

7ºC. Values can range between 6,0 and up to

17,0ºC.

Lower Limit Setpoint Temperature.

This is used to set the lowest limit of the Setpoint

temperature in Cooling more.

By default this value is 6,0ºC.

High Limit Setpoint Temperature.

This is used to set the highest limit of the

Setpoint temperature in Cooling more.

By default this value is 17,0ºC.

Heating Setpoint Temperature.

Sets the value of the operating Cooling Setpoint

temperature in ºC, by default this value is set to

45ºC. Values can range between 35,0 and up to

55,0ºC.

Lower Limit Setpoint Temperature.

This is used to set the lowest limit of the Setpoint

temperature in Heating more.

By default this value is 35,0ºC.

High Limit Setpoint Temperature.

This is used to set the highest limit of the

Setpoint temperature in Heating more.

By default this value is 55,0ºC.

►COMPRESSORS

Activation

Activation of Compressor 1.

Activates or disables compressor 1.

AI1: Regulation of INTAKE water.

AI2: Regulation of OUTLET water.

OFF: No reading shown.

IdOF: ON/OFF state.

Set: Setpoint value for current operating mode.

reg: (Varies according to the model of the unit)

AI1: Intake water temperature. (Default setting)

AI2: Outlet water temperature.

OFF: No reading shown.

IdOF: ON/OFF state.

Set: Setpoint value for current operating mode. (Default

setting)

reg: (Varies according to the model of the unit)

AI1: Intake water temperature.

AI2: Outlet water temperature

OFF: The unit is set to Standby or OFF mode.

ON: The unit starts up.

EQUA: The unit resumes operation under the same settings

as the last time it was running before loss of power.

This manual suits for next models

1

Table of contents

Other Hitecsa Chiller manuals

Popular Chiller manuals by other brands

Daikin

Daikin EWAQ005AAV3P Operation manual

Carrier

Carrier PERFORMANCE 50VT-A24 installation instructions

Telemark

Telemark Cryogenics instruction manual

KoolMore

KoolMore OF-700 Instructions for use

Lennox

Lennox ECOLOGIC Series Installation, operation & maintenance manual

Skope

Skope Pegasus PG100HC-2 user manual