HT(HPC)-100CT Series

HITROL CO., LTD. 11

If there is an atmosphere of explosive gas, do not open the cover of the product.

Make sure that it is not subject to any high impact while moving.

Failure Check

and

Repair/

Maintenance

Precautions

for

Removal

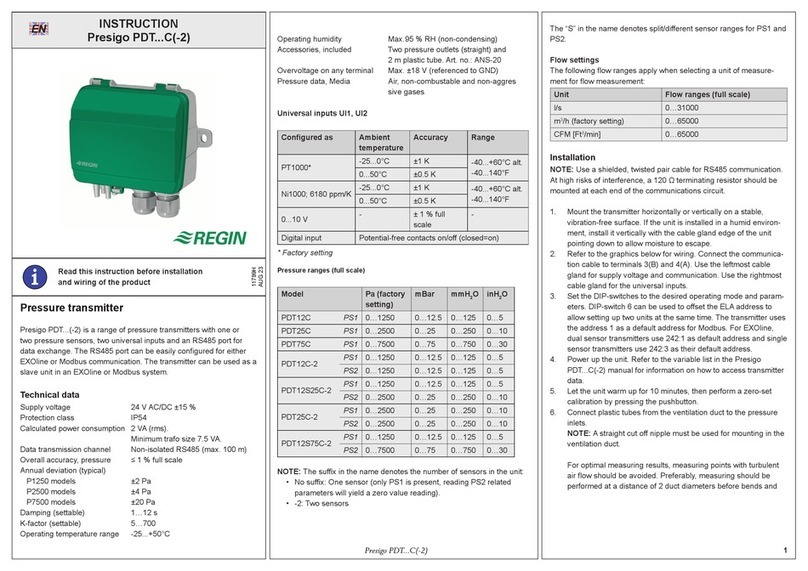

■ Product Test

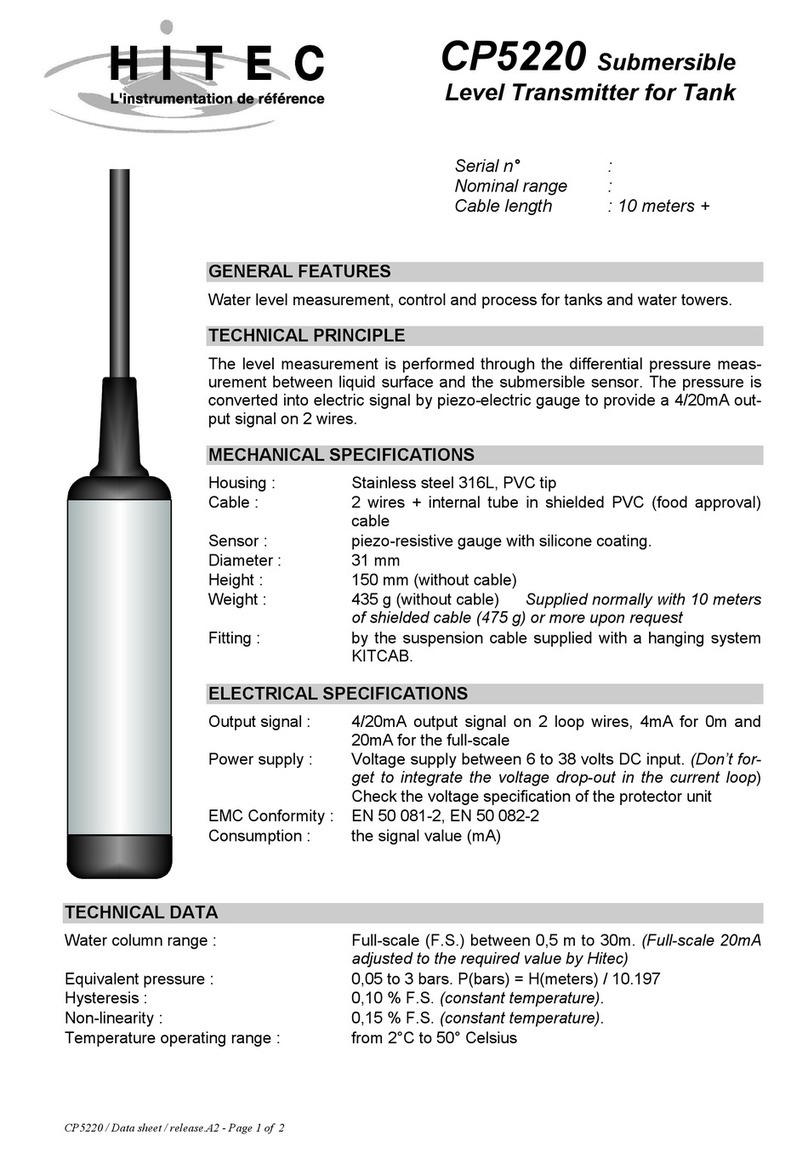

The major checking part for the electrostatic capacity–type level transmitter includes the

sensor part and the transmission part.

The life span of the major parts varies according to user environment, and they can be

used in optimum condition through periodic checking. Therefore, the user should conduct

periodic checking at least once a year for repair and maintenance. Carry out a visual

inspection on the damage, etc., on the product, and periodically remove foreign substances

attached to the probe as these can degrade accuracy. When removing the foreign

substances, be careful not to damage the Teflon part.

■ Failure Check

The level of measured object changes, but the output does not change.

▶ Insufficient power supply

▶ Wrong adjustment of ZERO and SPAN

Only a slight change of output to the change of level of measured object

▶ Wrong adjustment of ZERO and SPAN

▶ Slight change of probe ΔC value

No change of level, but output fluctuation is present

▶ Wrong grounding

▶ Noise on the lines

▶ Extreme fluctuation of measuring device

▶ Bad insulation of probe

Output indicates Full (20 mA) of higher regardless of the change of level of the measured

object.

▶ Wrong adjustment of ZERO and SPAN

Never separate the cover in an environment exposed to explosive gas.

■ Check the level and presence of measure object in the tank before removing it.

■ Wear gloves when removing it, to prevent a burn.

■ Unlock the lock key before removing the cover. (Ex-proof)

■ Disassemble work shall be done with the power off.

■ Make sure that any O-ring or gasket is not damaged while opening or closing the

cover of product.