HITROL HT-100F Series User manual

HT-100F Series

HITROL CO., LTD. 1

HITROL CO., LTD.

HEAD OFFICE. FACTORY. R&D INSTITUTE

HITROL CO., LTD., 141, Palhakgol-gil, Jori-eup,

Paju-si, Gyeonggi-do, Korea

TEL.: (00)-82-31-950-9700

FAX: (00)-82-31-943-5600

www.hitrol.com

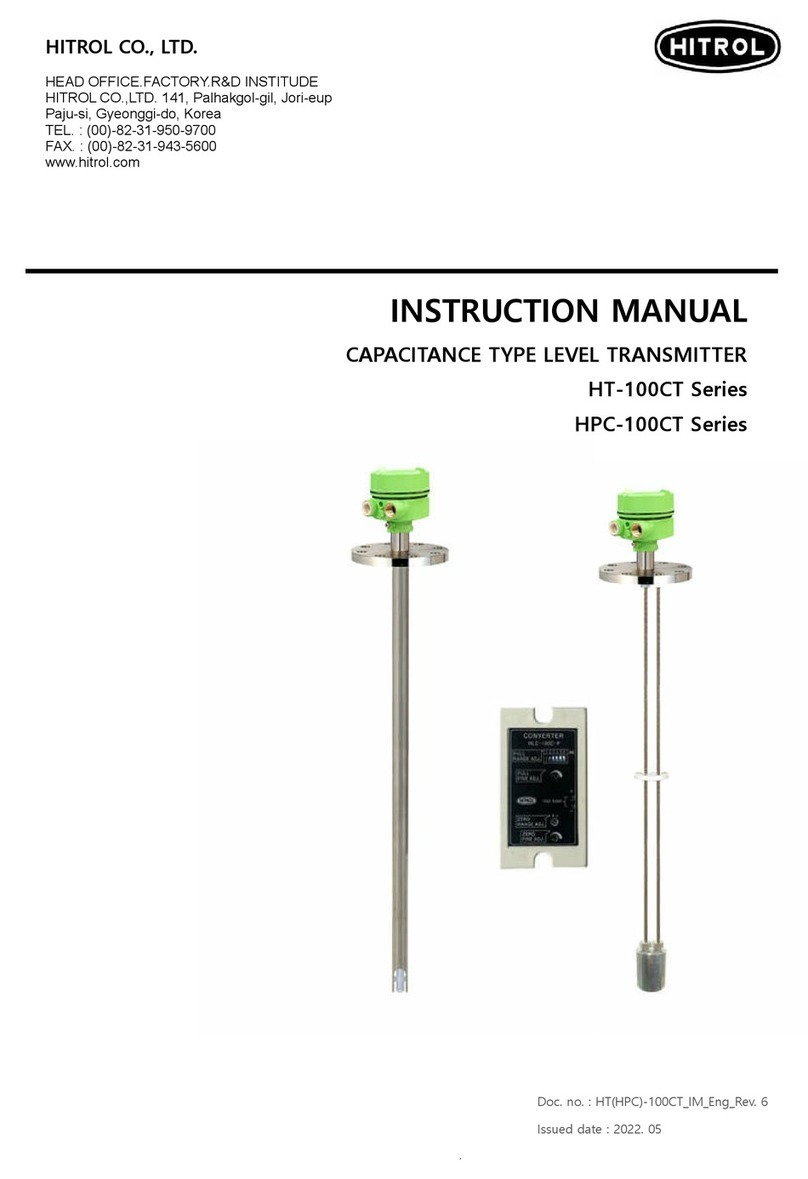

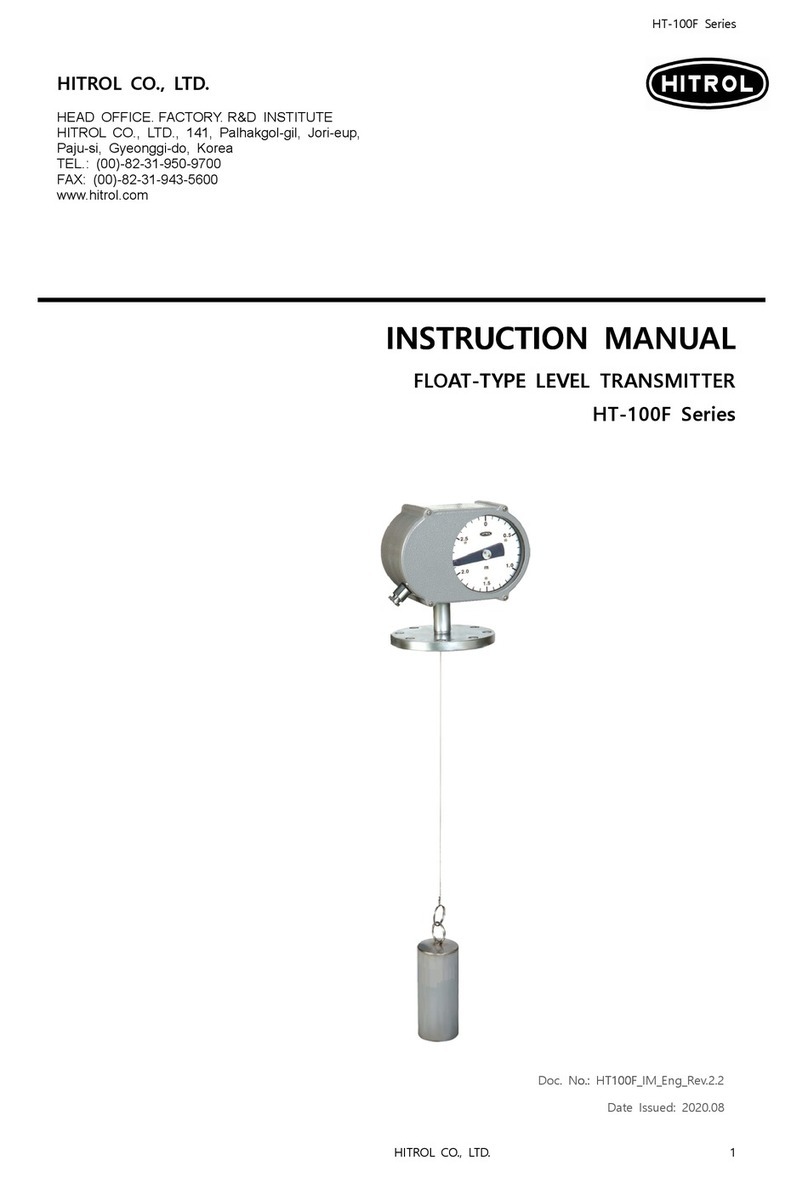

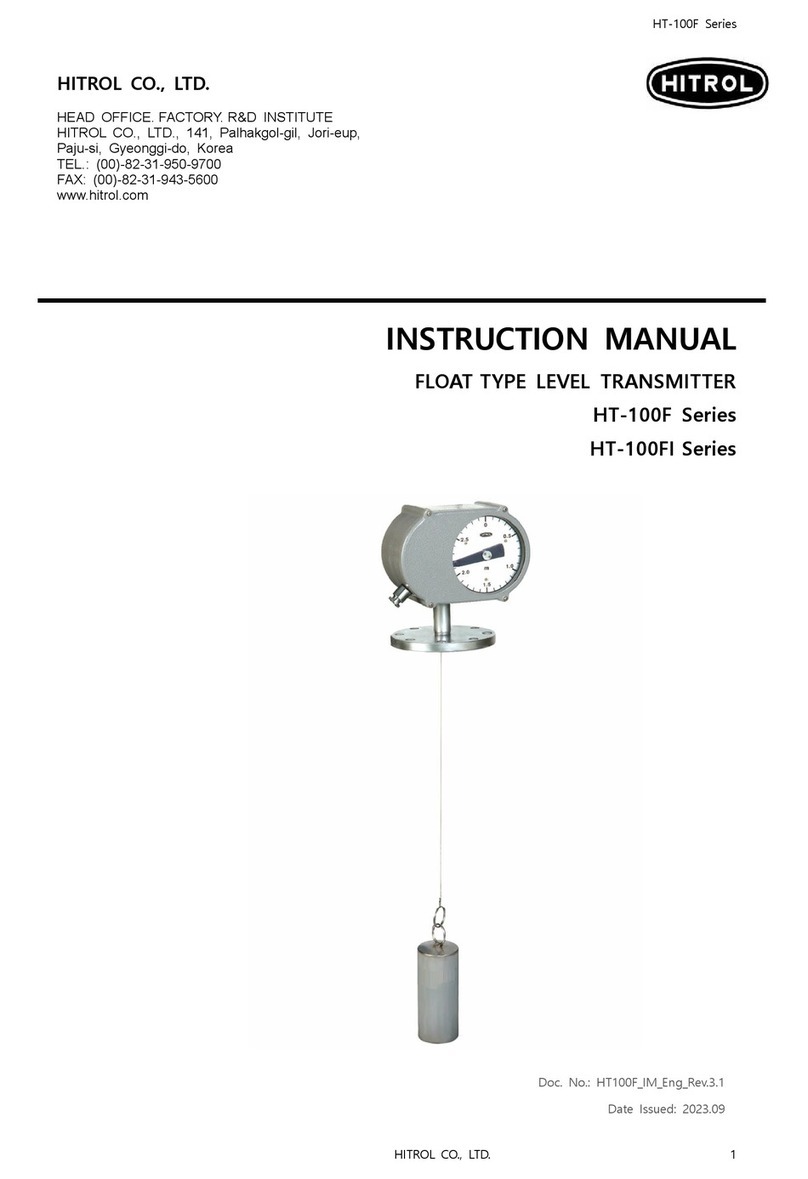

INSTRUCTION MANUAL

FLOAT-TYPE LEVEL TRANSMITTER

HT-100F(I) Series

Doc. No.: HT100F_IM_Eng_Rev.2

Date Issued: 2019.10

HT-100F Series

HITROL CO., LTD. 2

You should be careful where CAUTION is marked to carry

outthework.

You should be well-informed of the contents where

WARNING is marked before carrying out the work.

.

You should be aware of where NOTICE is marked to carry

outthework.

Table of Contents

Overview and Features · · · · · · · · · · · · · · · · · · · 3

Mechanism and Components · · · · · · · · · · · · · · · 3

Specifications · · · · · · · · · · · · · · · · · · · · · · · · · · 4

Specifications of the R/I Converter · · · · · · · · · · · · 4

Float Application Table· · · · · · · · · · · · · · · · · · · ··5

Components · · · · · · · · · · · · · · · · · · · · · · · ····5

Dimensions · · · · · · · · · · · · · · · · · · · · · · · · ····6

Wiring and Cautions · · · · · · · · · · · · · · · · · · · ··6

Zero/Span Adjustment · · · · · · · · · · · · · · · ······7

Maintenance · · · · · · · · · · · · · · · · · · · · · · ·····8

Attachment and Cautions· · · · · · · · · · · · · · · · ··· 9

Cautions for Removal · · · · · · · · · · · · · · · · ····10

Cautions for Installation · · · · · · · · · · · · · · ·· 10

Cautions for the Inserted External Wire · · · · · · 10

Safety and Environment · · · · · · · · · · · · · · · · 10

Marking · · · · · · · · · · · · · · · · · · · · · · · · · · 10

User Training· · · · · · · · · · · · · · · · · · · · · · · 11

Troubleshooting · · · · · · · · · · · · · · · · · · · · · 11

Output Signal of 4mA or Less · · · · · · · · · · · · · 11

Output Signal of 20mA or More · · · · · · · · · · · · 11

Holding of the Output Current · · · · · · · · · · · · · 11

Hunting of the Output · · · · · · · · · · · · · · · · · · 11

Warranty and Contact · · · · · · · · · · · · · · · · · 12

Warranty and Service · · · · · · · · · · · · · · · · · · · 12

Headquarters / Factory / Research Center · · · · · · 12

HT-100F Series

HITROL CO., LTD. 3

Overview and

and Features

Mechanism and

Components

■Wire type for easy installation

■Local indication (indicator)

■Easy maintenance

The HT-100F Series is a float-type level transmitter for continuously measuring

the liquid level in a container with buoyancy. It is mainly used to measure liquid for

purification, industrial water, sewage treatment plants, wastewater, and fuel tanks.

When the float, which is fabricated according to the specific gravity of the target to

be measured, moves up and down along the liquid surface with buoyancy, the wire

connected to the float is wound around the wire drum by the constant spring.

The rotation of the wire drum is transferred to the gear and, thus, triggers the

indicator pointer.

The magnet in the indicator pointer triggers the reed switch to change the resistance

value.

The changed resistance value is detected by the R/I converter in the housing and

corresponding current value (DC 4-20mA) is continuously output. The HT-100FI has

the local indicator pointer so that it can be checked on site.

<Front>

<Back>

HT-100F Series

HITROL CO., LTD. 4

Specifications

Model

HT-100F

HT-100F(I)

Mounting

Top, Flange

Indicator

None

1-point dial

Ambient Temperature

−20°C ~ +60°C

Process Temperature

Max. 80°C

Process Pressure

ATM

Range (m)

Max. 7.5m

Power Source

DC 24V

None (Std.) / DC 24V (Opt.)

Output

DC 4~20mA (2-wire)

Display (Std.) /

DC 4~20mA (2-wire) (Opt.)

Enclosure

Weather-proof (IP54)

Wetted Parts Material

316L SS

Process Connection

100A JIS 10K FF (Std.)

Cable Entry

PF 1/2"(F)

Accuracy

±2% of F.S.

Specifications of the

R/I Converter

Item

Specification

Micom

16bit microprocessor

Supply Voltage

+17 ~ +40V at Typ. +24V

Operating Voltage

+3.3V

Current Consumption

2.5mA or less at sensor 1KΩ

Status Indicator

Bi-color LED (green/red/orange)

Zero/Span Set

Tact switch

Wire Connection

One-touch connector

Ambient Temperature

−20°C ~ +60°C

Dimension

80mm ×65mm ×20mm

Weight

54g

Current Loop Interface

2-wire loop current

Output Current Range (Accuracy)

4~20mA within ±0.2%

Output Current Offset

±0.2mA at 0.01mA / 20 steps

Measurement Sensor Range

30KΩ(15M) at sensor 10Ω

Min.: 200Ω(100mm) / Max.: 50KΩ(25M) at sensor 20Ω

Output Current Definite

TP

HT-100F Series

HITROL CO., LTD. 5

Float Application Table

Float Size

Spring Length

MEAS. Range

S.G

Range

Outer

Diameter

Length

Min

89.1

200

5 m / ~3.5 m

0.7

7.5 m / ~6 m

0.7

10 m / ~7.5 m

0.8

76.3

250

5 m / ~3.5 m

0.7

7.5 m / ~6 m

0.7

10 m / ~7.5 m

0.8

Components

Aluminum Housing

Aluminum Housing

(Indicator Type)

Flange

CS, 304, 316L

Float

304, 316L

Protection Tube

304, 316L

Flange

CS, 304, 316L

Outside

Wetted Parts

Material

Float

304, 316L

<Wire Type>

<Protection Tube Type>

Vent Hole

HT-100F Series

HITROL CO., LTD. 6

Dimensions

<HT-100F>

<HT-100FI>

<HT-100FI Guide Type>

Wiring and

Cautions

R/I Converter

■+ −: DC 24V (DC 4~20mA Loop)

■T: Output Test Point

■H.C.L: Wire to Connect the Sensor and R/I converter

* Cable color: H –Red, C –White, L –Black

■Make sure to connect the power with correct polarity (+, −).

■The power supply must be between +17 and +40V.

■Do not connect the wire with the power connected.

HT-100F Series

HITROL CO., LTD. 7

Zero/Span

Adjustment

Green LED is turned on

when the power is connected

and wiring properly.

S

Step 1

Step 2

Step 4

Step 3

Press and hold the button for 3s

to finish zero/span setting with

the green LED on and then off.

▷Steps 2 and 3 can be interchanged.

▷For the zero (0%) setting, proceed with Step 1 Step 2 Step 4.

▷For the span (100%) setting, proceed with Step 1 Step 3 Step 4.

Caution: Incorrect setting may lead to an incorrect range setting with the orange LED

on and then off.

■Offset

Adjust the error of measuring device or fine tuning of level.

S

M

S

M

S

M

Step 1

Step 2

Step 3

Press the + buttons for 3s

to turn on the red LED.

With the button pressed, press the

/ button for fine tuning.

to adjust it.

or

or

Press the +buttons for 3s

to finish the offset with

the green LED on and then off.

▷Span◁

▷Zero◁

▷Offset adjustment is available regardless of float position.

Press the button

with the float at

0% position.

Press the button

with the float at

100% position.

With the button pressed, press the

/ button for fine tuning.

to adjust it.

HT-100F Series

HITROL CO., LTD. 8

Maintenance

The HT-100F Series level transmitter requires inspection for the sensor, drive, and transmission

sections. The sensor section has REED S/W; the drive section has the wire drum, spring drum,

and spur gear; and the transmission section has the R/I converter.

The service life of parts depends on the operation conditions, and regular inspection is

required to keep the optimum operation conditions. Thus, users are advised to conduct regular

inspection and maintenance at least every year. Exterior damages will be visually checked. The

R/I converter can be checked using a digital multimeter.

<Checking of the Sensor>

Disconnect the sensor wire from the H, C, and L terminals of the R/I converter, and

measure the resistance value of the sensor.

Low and Com

Resistance value of the current level

High and Com

Resistance value of the full level –Resistance value of the current level

High and Low

Resistance value of the full level

<Checking of the Drive>

1. Remove the front cover to see the gear operation.

2. Remove the rear cover to check the wire and measuring tape for any damage.

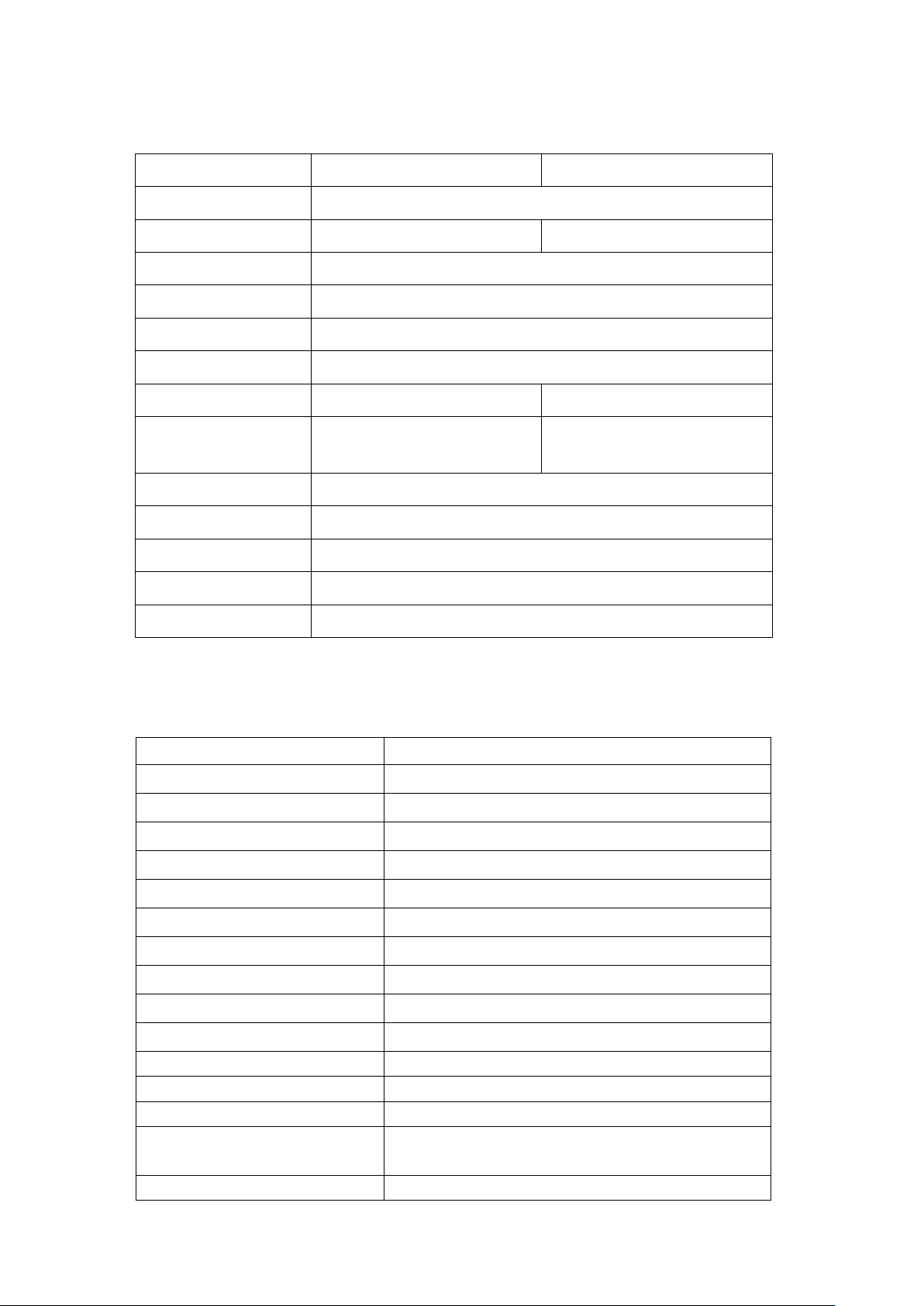

<Checking of the Transmission>

Check the output current of terminals T and –of the R/I converter using the digital multimeter.

※ The output current can be checked with the test points without opening its wire.

Sensor

Test Point

Indicator

R/I Converter

Power Supply

Digital Multimeter

After checking the sensor parts, the wrong connection of H, C, and L is the cause of the product failure.

HT-100F Series

HITROL CO., LTD. 9

Attachment and

Cautions

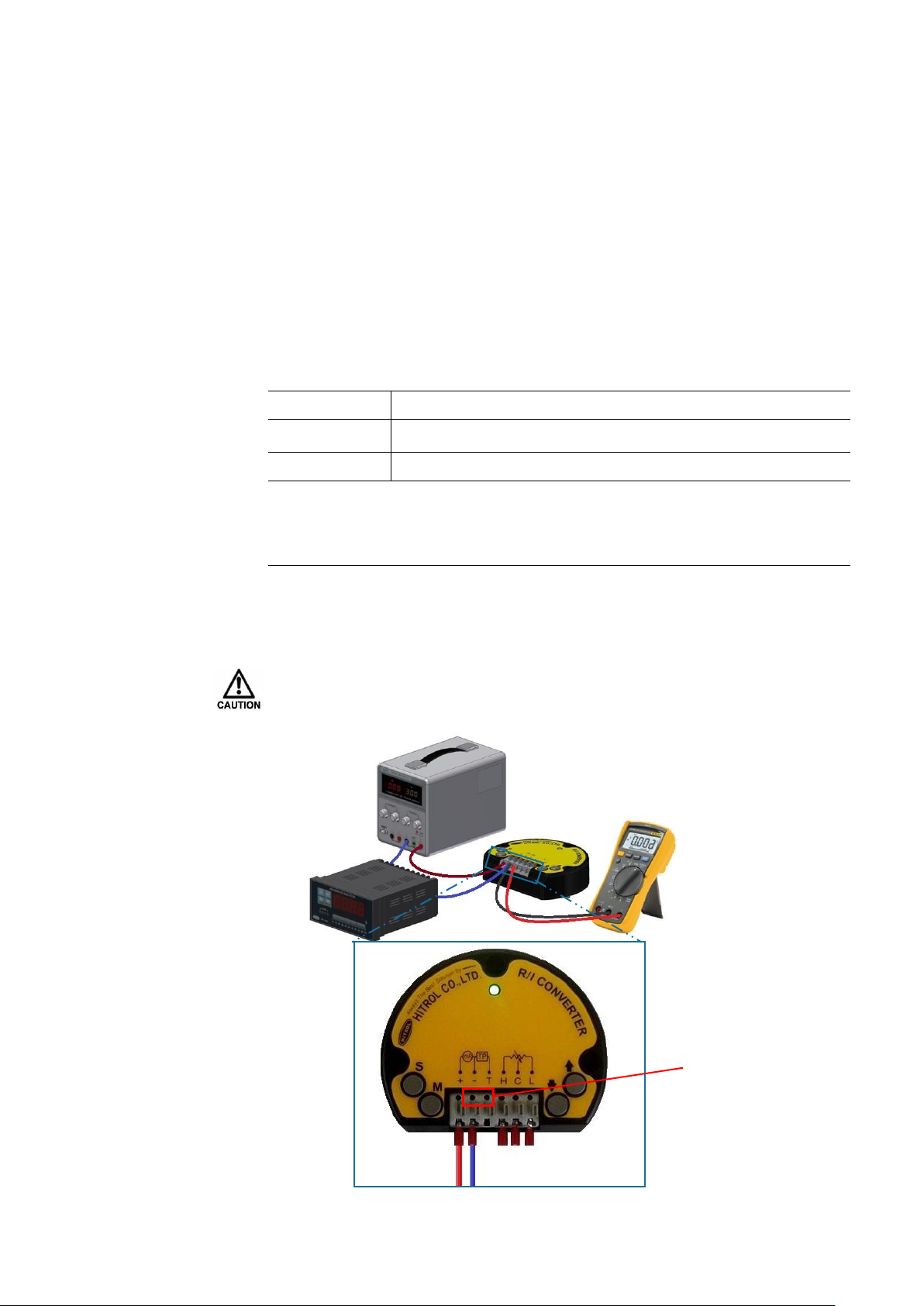

If it is installed on the inlet, install a guide,

or make it distanced from the inlet to

prevent malfunction.

If the liquid flows or slashes,

use the protection pipe type.

Install it on the concrete wall as shown above.

“d” diameter requires a larger diameter than

float and straight piping.

HT-100F Series

HITROL CO., LTD. 10

Removal

Cautions

Cautions for

Installation

Cautions

for the Inserted

External Wire

Safety and

Environment

Marking

■Check the level and presence of liquid in the tank before removing it.

■Disconnect the power first.

■Connect flanges with same dimensions.

■Make sure to insert washers between bolts and nuts to prevent loosening.

■Make sure to insert gaskets between flanges.

■Make sure to install the product and to cover it before supplying power.

■Do not use it for any corrosive gas.

■Use the cable gland connection or metal pipe wiring for the inlet of wires.

Make sure it is not subject to any impact when moving it.

■Cautions

- Make sure to connect the product and container using the required tools.

- Do not apply large impact to the product.

■Disposal

- To dispose a waste product, separate the AMP and body first. It does not contain

any part that is harmful to the environment (e.g., mercury switch).

■Product Identification

The product identification mark is attached onto the housing and shows the model name, serial

number, working temperature, working pressure, and matters regarding output. The serial

number is a unique manufacturing number for the identification of products.

HT-100F Series

HITROL CO., LTD. 11

User

Training

Troubleshooting

Action

Type

Checks

Incorrect zero measurement range setting

Reset

Offset applied

Offset default

Loss of buoyancy or damage to the float

Replace the float

Damaged diode of the R/I converter

Replace the R/I converter

Type

Checks

Incorrect span measurement range setting

Reset

Offset applied

Offset default

Open low cable of sensor

Reconnect the sensor

Damaged diode of the R/I converter

Replace the R/I converter

Type

Checks

When the resistor of the sensor is seriously

damaged, resulting in a short circuit with

the pointer positioned on it

Replace the sensor PCB. (If the float is

out of the position, the output will

sharply rise or drop, leading to

measurement error.)

When the resistor of the sensor is seriously

damaged, resulting in an open circuit with

the pointer positioned on it

Replace the sensor PCB. (If the float is

out of the position, the output will

sharply rise or drop, leading to

measurement error.)

When the wire is not wound

Check if any foreign subsidence is in

the wire drum or if the spring is

damaged.

Type

Checks

Temporary over-measurement (approximately 10%)

and noise output shape due to over-current caused

when a diode of the R/I converter is damaged

Replace the R/I converter.

Output Current of 4mA or Less

Hunting of the Output

Holding of the Output Current

Understand the aforementioned, and never use it to measure any liquid that

exceeds 80°C. In addition, make sure that the ambient temperature of the housing

is maintained at −20°C ~ +60°C.

Output Current of 20mA or More

HT-100F Series

HITROL CO., LTD. 12

Warranty

and

Contact

Warranty and Service

This product is subject to a two-year warranty after shipment, and any unpaid service

will be provided for any damage found under normal operating conditions. If it is not

related to product failure, the service charge will be payable. You can request A/S at

our website or by contacting our headquarters.

Headquarters / Factory / Research Center

Address: HITROL CO., LTD., 141, Palhakgol-gil, Jori-eup, Paju-si, Gyeonggi-do, Korea

TEL.: 031-950-9700 (Headquarters and A/S)

FAX: 031-943-5600 (Headquarters and A/S)

Other manuals for HT-100F Series

2

This manual suits for next models

2

Table of contents

Other HITROL Transmitter manuals

HITROL

HITROL HT-100CT Series User manual

HITROL

HITROL HT-100F Series User manual

HITROL

HITROL HT-100R Series User manual

HITROL

HITROL HT-100F Series User manual

HITROL

HITROL HT-100R Series Configuration guide

HITROL

HITROL HT-100CT-2 Series User manual

HITROL

HITROL HTMF-MF User manual

HITROL

HITROL HT-100CT-2 Series User manual

HITROL

HITROL HT-100R Series User manual

HITROL

HITROL HT-100PT User manual