Hix Halux 1200 User manual

16

WARRANTY

1201 E. 27th Terrace • Pittsburg, KS 66762 • U.S.A.

Web site: www.hixcorp.com • Phone: (800) 835-0606 • Fax: 620-231-1598

©2015 HIX Corp.

Design and Manufacturers of Graphic Imaging, Commercial Food, Industrial and Custom Drying Equipment

(Effective October 30, 2015)

HIX will automatically register the equipment on the date it was shipped to you or your distributor. If the

equipment was not purchased directly from HIX, but through a distributor (either domestic or foreign), please

keep a copy of their sales invoice showing the serial number and date it was sold/shipped to you with this war-

ranty. In this case, we will use the distributor’s invoice date as the beginning warranty date. STAPLE A COPY

OF YOUR RECEIPT TO THIS WARRANTY and keep in a safe place to provide verification of your warranty

should a problem occur. Thank you.

Please fill in the following information and attach a copy of your receipt for your records.

Date Purchased: From:

Model #: Serial #:

This warranty applies to equipment manufactured by the HIX Corporation (HIX), Pittsburg, Kansas, U.S.A.

HIX warrants to the original purchaser, its Ovens and Dryers, Heat Transfer Presses, Mug Presses, Mug Glazer,

Retensionable Screen Frames, Textile Printers, Spot Heaters, and Exposure Units against defects in workman-

ship and material, except for wear and tear for a period of “One Year” from the date of purchase. HIX warrants

its Accessories, Reten Splines/Hardware/Tool Kit, and Shuttle for a period of 90 days from the date of purchase.

Thermatrol and doughXpress products are covered under separate warranty.

In the event of a defect, HIX, at its option, will repair, replace or substitute the defective item at no cost during

this period subject to the limitations of insurance and shipping costs stated below.

In the case of heat transfer presses (except the Hobby Lite), HIX warrants the heat casting for the “Life” of the

machine for the original purchaser. If a part becomes obsolete at the time for repair, and/or cannot be reason-

ably substituted for, HIX will credit, at half the then current list price or last recorded price, only that part toward

a new machine or any product HIX offers. This credit offer shall be the sole responsibility of the HIX Corporation

in the event of an obsolete part.

This warranty does not cover belts, rail tape, pads, mug wraps, canvas, rubber blankets, bulbs, glass, rod

ends, turn buckles on printers or damages due to accident, misuse/abuse, alterations or damage due to neglect,

shipping or lack of proper lubrication or maintenance. HIX shall not be responsible for repairs or alterations

made by any person without the prior written authorization by HIX. This warranty is the sole and exclusive war-

ranty of HIX and no person, agent, distributor, or dealer of HIX is authorized to change, amend or modify the

terms set forth herein, in whole or in part.

In the case of a problem with the equipment identified herein, HIX Corporation should be contacted during

regular business hours to discuss the problem and verify an existing warranty. HIX personnel will assist the

customer to correct any problems which can be corrected through operation or maintenance instructions, simple

mechanical adjustments, or replacement of parts. In the event the problem cannot be corrected by phone, and

upon the issuance of a return authorization by HIX, the equipment shall be returned to HIX or an authorized

service representative. All insurance, packaging and shipment/freight costs are solely the responsibility of the

customer, and not that of HIX, and HIX shall not be responsible for improper packaging, handling or damage

in transit. Contact HIX customer service for complete return authorization information. Correct shipping boxes

are available from HIX.

This expressed warranty is given in lieu of any and all other warranties, whether expressed or implied, in-

cluding but not limited to those of merchantability and fitness for a particular purpose, and constitutes the only

warranty made by HIX Corporation.

In no event shall HIX’s liability for breach of warranty extend beyond the obligation to repair or replace the

nonconforming goods. HIX shall not be liable for any other damages, either incidental or consequential, or the

action as brought in contract, negligence or otherwise.

This warranty gives you specific legal rights and you may also have other rights which vary from state to

state.

Installation ........................................................................................................2

Initial Start Up...................................................................................................3

Exposing Screens.............................................................................................4

Determining Exposure Time / Chart ..............................................................5-6

Vacuum Switch Adjustment .............................................................................. 7

Glass Cleaning .................................................................................................8

Fan Filter Servicing...........................................................................................8

Lamp Replacement .....................................................................................8-10

Vacuum Pump Filter Replacement .................................................................10

Lid Realignment......................................................................................... 11-12

Blanket Replacement .....................................................................................12

Troubleshooting Charts .............................................................................13-14

Parts Identification.....................................................................................15-19

Warranty .........................................................................................................20

Halux 1200

Digital Hot Restrike Exposure Unit

OWNER’S MANUAL

CONTENTS

BEFORE warranty repair you MUST get Prior Authorization:

For Customer Service, Call 1-800-835-0606

or Visit www.hixcorp.com

70280 RV H_110115

NOTE:

Due to the unique

hot strike feature, the

Halux-1200D must be

supplied power by a

120V, 20 Amp dedicat-

ed circuit and constnt

voltage between 115-

125V.

2

RECEIVING & INSTALLATION

NOTE: The HIX Halux 1200D is not compatible with the M&R Trilok

pin registration system.

CAUTION: Before installing or operating this unit be sure to read

these instructions thoroughly. Disconnect all electric

power before performing maintenance on this unit. Never

operate this equipment with the power supply cover re-

moved. If you find that this should be necessary, contact

a licensed electrician. Make sure the circuit for this unit

is well grounded.

WARNING: ULTRA VIOLET LIGHT CAN CAUSE SKIN & EYE IR-

RATION OR BLINDNESS. TO PREVENT DAMAGE TO YOUR

EYES AND SKIN, AVOID DIRECT EXPOSURE TO THE LAMP

WHILE IT IS ON.

INSTALLATION

1. Carefully uncrate exposure unit from its shipping container.

2. Place exposure unit on a level surface close to the wall circuit to

be used. Adjust leveling feet, if necessary, so the unit does not

“rock” on the floor.

WARNING: When using an extension cord, use 12 ga.-3 conductor.

Maximum length, 25’ (7.62m).

3. Check unit over for any transportation damage and make sure all

foreign objects, such as packing material, have been removed.

Clean both sides of glass from any dust. (See page 8)

4. The vacuum hose is connected to the top frame by a small hose

clamp prior to shipping. Make sure the hose connection is still

in place and secure. If the hose seems loose or has come off

during shipping, secure hose and tighten hose clamp screw with

a small flat-head screwdriver.

15

TROUBLESHOOTING

PROBLEM

4. Lamp fails to remain

ignited.

5. Lamp ignites OK

when cold, but

will not HOT

Restrike reliably.

6. Unit fails to turn off

when the power

switch is “OFF”.

7. Blanket won’t “pull”

a vacuum.

POSSIBLE CAUSE

4. a. Lamp housing

cooling fan failure.

b. Obstruction of

air input or output

causing over heat-

ing, thus tripping the

thermostat.

c. Defective high

limit thermostat.

5. Low voltage supply.

Must be 115-120v

on a 120v unit or

230-240v on a 230v

unit. Voltage mea-

sured must be when

unit is on and under

load.

6. Power switch is

shorted.

7. Vacuum leak.

REMEDY

4. a. Replace cooling

fan.

b. Remove obstruc-

tion, allow thermo-

stat to cool, it will

then reset itself.

c.Replace thermo-

stat.

5. Have a electrician

remedy the cause of

low voltage supply

to the unit.

6. Replace power

switch.

7 a. Check hose con-

nections to vacuum

pump and to blanket

frame.

b. Check gasket to

glass seal, replace if

necessary.

c. Realign lid.

d. Check vacuum

pump.

14

TROUBLESHOOTING

PROBLEM

1. Lamp does not ig-

nite and red light on

main power switch

is off.

2. Lamp does not ig-

nite and red light on

main power switch

is on.

3. Unit blows fuses or

trips Main Power

Circuit Breaker.

POSSIBLE CAUSE

1. a. No line power.

b. Supply fuse or

breaker blown.

c. Unit main breaker

is tripped.

d. Main power

switch is defective.

e. Outlet is defec-

tive.

2. a. Vacuum is off.

b. Vacuum blanket

is not pulling down

tightly.

c. Vacuum switch is

out of adjustment.

d. Ignitor is bad.

e. Lamp is burned

out.

3. a. Check amperage

of supply breakers

or fuses.

b. Shorted

capacitor(s). Discol-

ored or inflated.

c. Shorted ballast.

REMEDY

1. a. Check power

source.

b. Reset supply

breaker or replace

fuse.

c. Reset unit’s main

breaker.

d. Replace switch.

e. Replace outlet.

2. a. Turn vacuum on.

b. Determine source

of vacuum leak and

repair.

c. Adjust vacuum

switch.

d. Replace ignitor.

e. Replace lamp.

3. a. Replace supply

breakers or fuses

with minimum rating

of 20 amps.

b. Replace capaci-

tors.

c. Replace ballast.

3

INITIAL SETUP

The “hot Restrike” feature, eliminates warming times between ex-

posure, saving electricity and extending bulb life. Due to this unique

Hot Strike feature, the Halux-1200D must be supplied electrical

power by a 120 volt, 20 amp dedicated circuit and constant voltage

between 115-125 volts.

The Hot Restrike System provides the advantage of a simple ex-

tremely reliable system with no moving parts, however some con-

sideration must be made to ensure consistent screen exposures.

From a “Cold” start (e.g. first screen to be exposed for the day) the

lamp requires a 1 minute warm up cycle to bring the lamp to full

intensity. Also if more than 90 seconds elapses between screen

exposures, then the lamp should be cycled on for a minute to ensure

full intensity of the lamp for consistent screen exposures.

To warm up the lamp before starting your first exposure, follow this

procedure.

1. Plug in your unit to the proper voltage power source (120V or

230V) as indicated on the serial number I.D. tag. NOTE: Ade-

quate voltage is required for proper operation. A minimum of

115V on a 120V circuit is required. The 230V version requires

a full 230 volts to operate properly. If voltage drops below

required level unit will not re-light. Simply wait 2 minutes to

cool and restart.

2. Close the blanket lid and latch the lid shut with the rubber latch-

hooks.

3. Turn the Main Power switch “ON”.

4. Turn the Vacuum switch “ON” and allow the blanket to pull down

tight to the glass.

5. Set the timer on at least 1 minute and press the “Start” button. To

change the time setting - see detailed instructions below.

6. The lamp will illuminate and quickly increase in intensity. When

the time set on the timer reaches “0” the lamp will extinguish.

Turn the vacuum switch off and release the blanket lid.

7. Within 90 seconds place the first emulsion coated screen frame

into the unit, as detailed on the next page, and start an exposure.

4

OPERATION

DIGITAL TIMER

1. Turn Main Power “On”. Timer will illuminate.

2. To change time setting, press the button on the front of the

timer face. Timer will display “Minutes” and “Seconds”.

3. To program the desired time (minutes and seconds), press the

button; once for each digit. The counter will loop from 0-9.

To change to the next digit, press the button and again

press the button until the desired number is reached.

4. Once the new time is entered, press the “MD” button on the

face of the timer to lock in this new setting. Failure to press

the “MD” button will not “lock” in the new setting.

5. Press the “Start” button on the control panel. This will start the

timer and turn the exposure lamp on.

6. Timer will count down and when time reaches zero, the expo-

sure lamp will extinguish.

7. If at any time you want to extinguish the exposure lamp before

time expires, you may do so by pressing the “RST” button on

the face of the timer.

13

REPAIRS

7. Retighten the 1/4” allen screws on the hinge bracket at the back

of the unit.

8. Turn off the vacuum and allow it to stabilize.

9. Carefully lift the lid to the open position and push the end of the

gas spring back onto the ball connector.

10. Check operation, repeat alignment procedure if necessary.

11. Replace the plastic gas spring end covers and recheck for proper

operation.

BLANKET REPLACEMENT

NOTE: If the blanket fails to pull a vacuum, check the Troubleshooting

Chart for possible causes. If you determine that your blanket

has begun to leak, it needs to be replaced. New blanket re-

placement kit can be ordered from HIX Corporation by call-

ing Customer Service at 800-835-0606. Refer to Customer

Service sheet CS-170.

12

MAINTENANCE

LID REALIGNMENT

NOTE: The light and vacuum are sealed under the lid by means of

rubber gasket on the underside the lid frame. This rubber

gasket may compress over time. If light is seen from the

sides of the unit, or if the vacuum does not occur, the rubber

gasket may be compressed or the lid is out of alignment.

These problems can be alleviated by realigning the hinges.

1. Begin with the lid in the open position. Remove the plastic cap

from the lid end of one of the gas springs. While holding the lid,

pull end of gas spring straight out and off of the ball connector

as you continue to manually hold the lid up.

CAUTION:It is important to do this operation with the lid up, failing

to do so could cause injury due to the sudden release of

pressure on the gas spring!

2. Gently lay lid back down onto the glass and turn on the vacuum

switch.

3. Loosen 1/4” Allen-head capscrews on the side of the exposure

unit (2 on each side). (See figure above)

4. Loosen 1/4” Allen-head capscrews from the back of exposure

unit. (2 on each side).

5. The vacuum pull will self align the hinges.

6. With the vacuum still applied, retighten the 1/4” allen screws at

the sides of the unit.

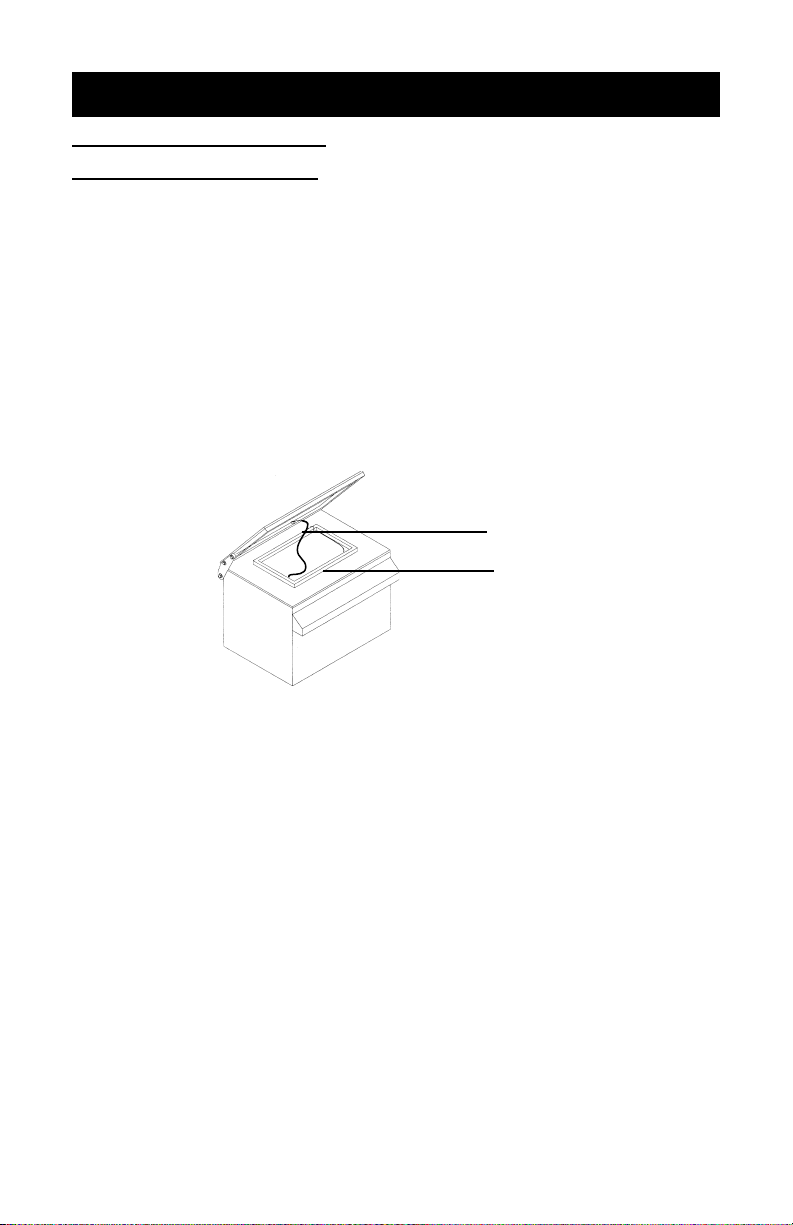

Gas Spring and

Plastic Cap

1/4” Allen-head

Capscrews

1/4” Allen-head

Capscrews

5

EXPOSING

EXPOSING A SCREEN

Maximum screen sizes:

One 24” x 42” or Two 21” x 24”

NOTE: Put the screen in the center of the glass. Keep at least 2”

from any edge of the glass to prevent damage to the vacuum

blanket rubber.

1. Place your screen frame in the center of the glass, screen side

down with your output image in place.

2. Place bleeder cord on top of and inside the frame and across the

image. (See illustration below) NOTE: This cord facilitates quick

blanket draw down and releasing of the vacuum after exposure

and the vacuum has been turned off.

3. Close the blanket lid and latch the lid shut.

4. Turn the Main Power switch “ON”.

5. Turn the Vacuum switch “ON” and allow the blanket to pull down

tight to the screen and the glass.

6. Set the timer on the desired exposure time for the type of emul-

sion and screen you are going to expose. See “Determining

Your Optimum Exposure Time” on page 6 or your filled in chart

on page 7 if you have already determined your exposure time.

7. Press the “Start” button located to the right of the timer dial to

begin the exposure.

8. At the end of the selected time, the lamp will extinguish.

9. Turn the vacuum switch off, release and open the lid and remove

the screen frame. If another screen is to be exposed, do this within

90 seconds or a brief warm up of the lamp will be necessary as

described in the “Initial Startup” instructions on page 3.

Bleeder Cord

Screen

Table of contents

Other Hix Industrial Equipment manuals