Hix R2R User manual

CONTENTS

Receiving & Installation .................................................................................................... 2

Startup .............................................................................................................................. 3

Time & temp. Settings ....................................................................................................... 4

Loading labels ................................................................................................................... 5

Sensor Setting .................................................................................................................. 7

Operation........................................................................................................................... 9

Transfer Application ........................................................................................................ 10

Troubleshooting................................................................................................................11

Warranty .......................................................................................................................... 12

For Customer Service, Call 1-800-835-0606

or Visit www.hixcorp.com

BEFORE warranty repair you MUST get Prior Authorization:

Call 1-800-835-0606

R2R

Reel to Reel Care Label Heat Press

OWNER’S MANUAL

70594 RV G_120820

2

RECEIVING & INSTALLATION

SHIPPING OR RETURNS

NOTE: Save all of your shipping/packing materials.

DO NOT RISK COSTLY SHIPPING DAMAGE!

SHIP ONLY IN ORIGINAL BOX.

1. Place in original crate.

2. Fasten machine to shipping base with bolts provided.

3. Make sure crate top is securely fastened to base

UNPACKING

Remember to save all packing materials - including box, liner and board. You may need

these for shipping your machine or if a repair is necessary in the future.

INSPECTION

Inspect your machine for hidden shipping damage. Contact the delivery company immedi-

ately, should you nd damage.

INSTALLATION

NOTICE: These machines are heavy, utilize team lifting and

lift with your legs when placing the machine.

1. Remove shipping straps and bolts.

2. Supply a clean (void of oils) and dry (void of water) air

source of 70 P.S.I. (6.8-8.5 bar) to the 3/8” NPT air inlet

located on the back of the machine. Requires 4 CFM.

NOTE: Itisstronglyrecommendedthatanexternalairlterandwatertrap

be installed at the machine’s air inlet connection. Compressed

airisdirty.Ithas‘stu’,primarilymoisture,residuesfromoiland

smoke and whatever else is in the air. Compressors or ‘shop air’

mayhavelteredairand/oran“AIRDRYER”afterthecompressor.

IFyourairisnotlteredanddried,YOUMUSTFILTERTHEAIR

andREMOVETHEWATERand‘stu’FROMTHEAIR,before

putting it in most air operated machines, including our press.

There are small valves and ports that can become blocked from

moisture and residue in compressed air, causing your press to

malfunction.Anexternalairlterandwatertrapmustbeinstalled

atthemachine’sairinletconnection,ifyourairisnotltered.

Damage to the machine’s internal air operated components can

occur that will not be covered under warranty. Combination

airlter/watertrapsareavailableatanymajorhardwarestore

or may be purchased directly from HIX (part #71145).

3

STARTUP

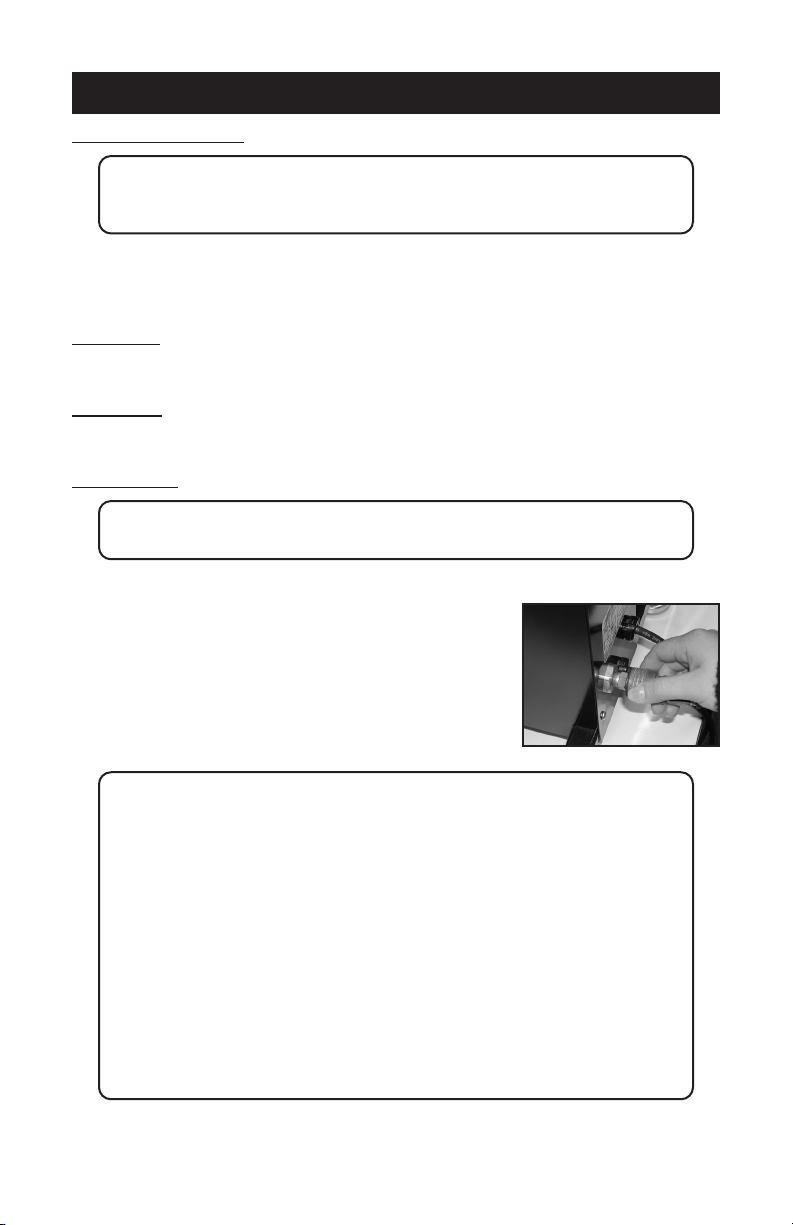

1. Set pressure Turn Knob below air gauge right to increase

pressure. Left to decrease pressure.

NOTE: Air pressure will not decrease until machine

cycles. Set starting pressure to 40-50 PSI.

2. Push Emergency stop button.

3. Make sure Load/Run button is in the “out” (Load) position.

(Press and release to change button position)

4. Plug the machine into the correct grounded electrical outlet.

WARNING: When using an extension cord, use 12 or 14 ga. - 3

conductor. Maximum length, 25’ (7.762 m).

ATTENTION: Utiliser des ralonges d’au moins 12 à 14 ga - 3

phases; longueur maximale de 7.7 mètres.

5. Now rotate Emergency stop button to the right (clockwise)

to release.

6. Push Yellow power button to power on/o the press.

4

TIME & TEMP. SETTINGS

1. To change or set the temperature, press the menu button on the digital control. The light

next to “TEMP” will light. Press the up ▲, or down ▼, button to your desired setting.

2. To change or set the time, press the menu button on the digital control. The light next to

“TIME” will light. Press the up ▲, or down ▼, button to your desired setting.

3. When you have your desired settings press the menu button a third time to lock in your

settings otherwise the previous settings will still be used.

4. Wait for the machine to reach your preset temperature by monitoring the display tem-

perature until it matches the set temperature.

5. Daily cycle is displayed by holding the up key while powering up. It will continue to dis-

play counts (up to 9999) while the up key is pressed. When the key is released it goes

to regular mode.

5

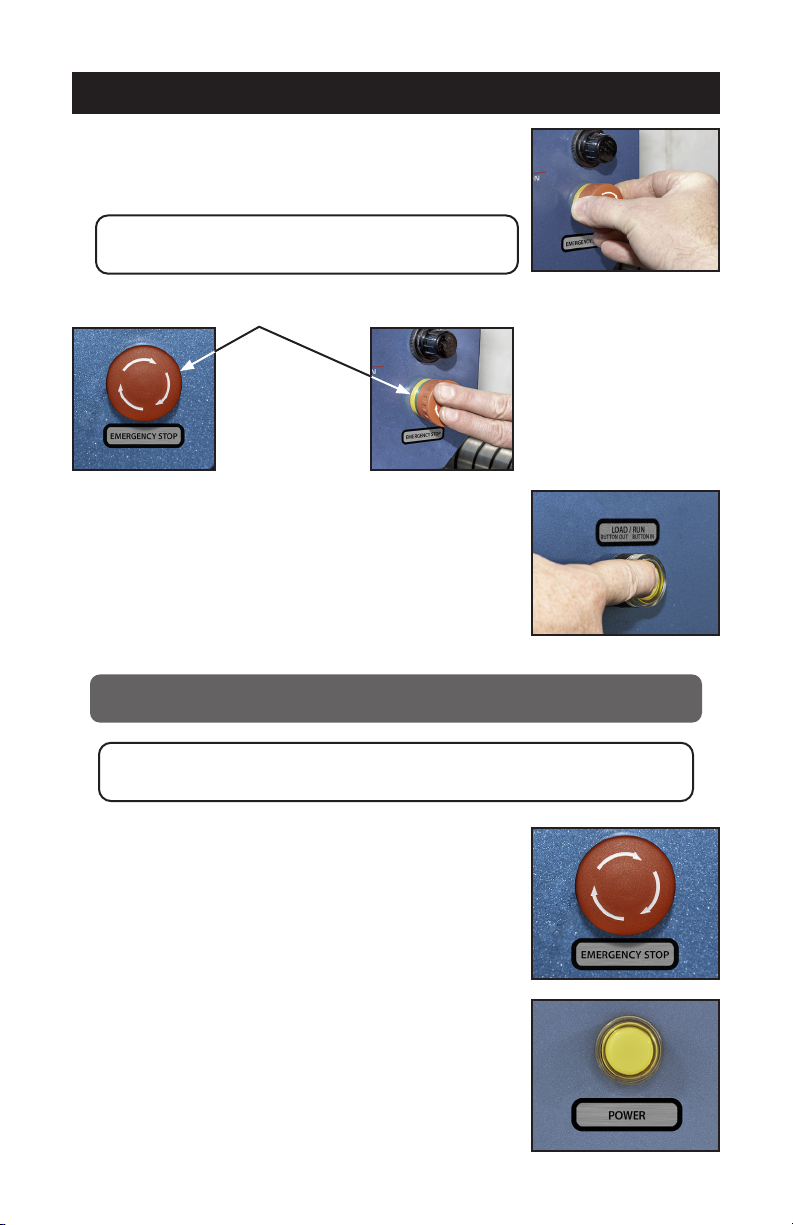

LOADING LABELS

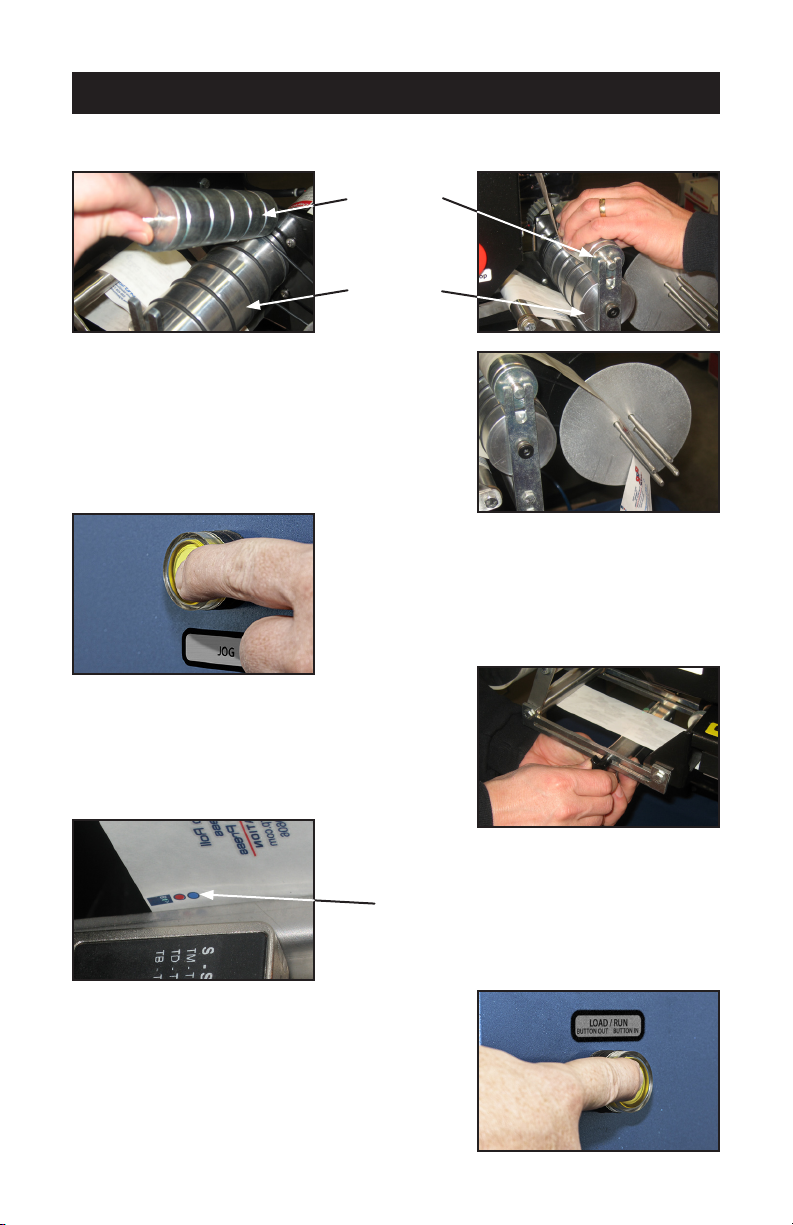

1. Remove Reel Quick Knob and reel face ange (non motor side).

NOTE:QuickKnobscanbeslidoafterrotatingapproximatelyoneturn.

2. Load full reel on supply side (non motor side)

3. Feed Label over top guide rod, under elbow rod and over the sensor.

4. Continue web underneath heat platen and underneath right elbow web guide. Feed

over top guide rod and through slot in drive roller mount.

REEL QUICK KNOB

REEL FACE FLANGE

TOP GUIDE ROD

ELBOW ROD

SENSOR

RIGHT ELBOW WEB GUIDE

TOP GUIDE ROD

DRIVE ROLLER MOUNT

FEED

REEL

HEAT PLATEN

LOWER PLATEN

TAKE-UP

REEL

6

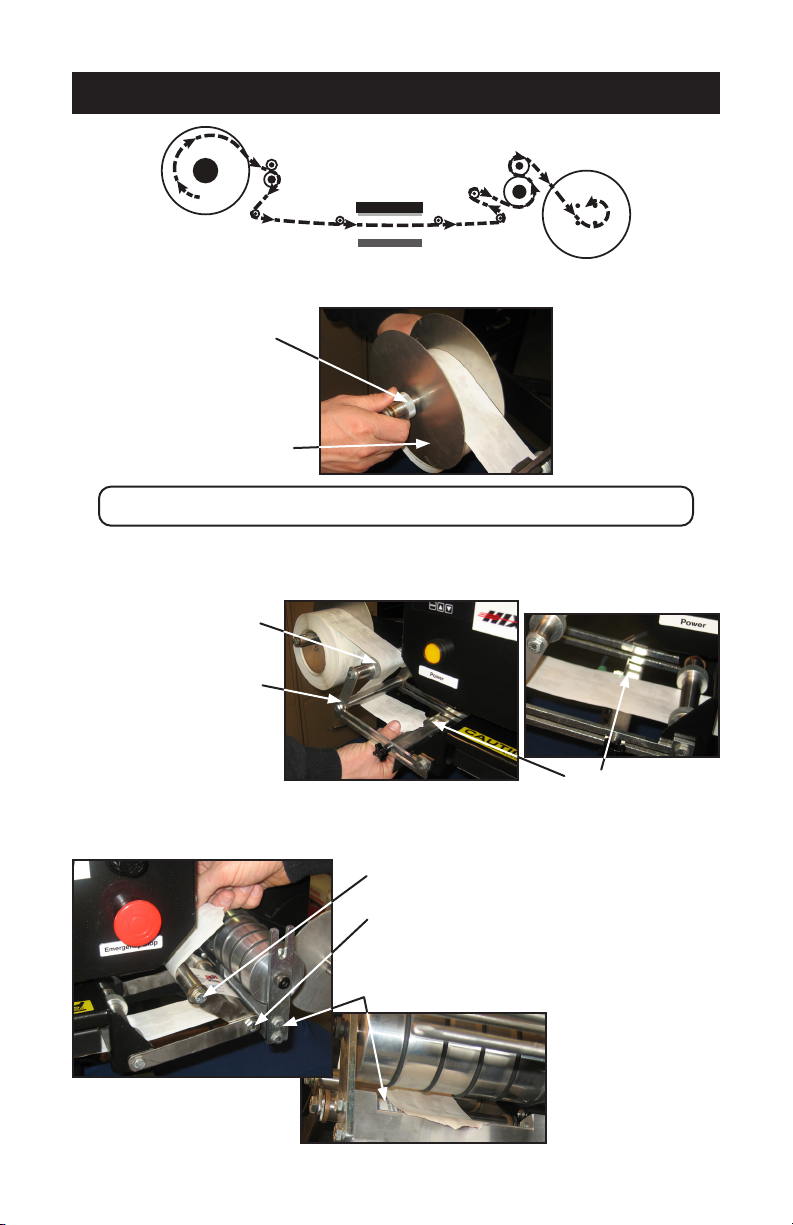

LOADING LABELS

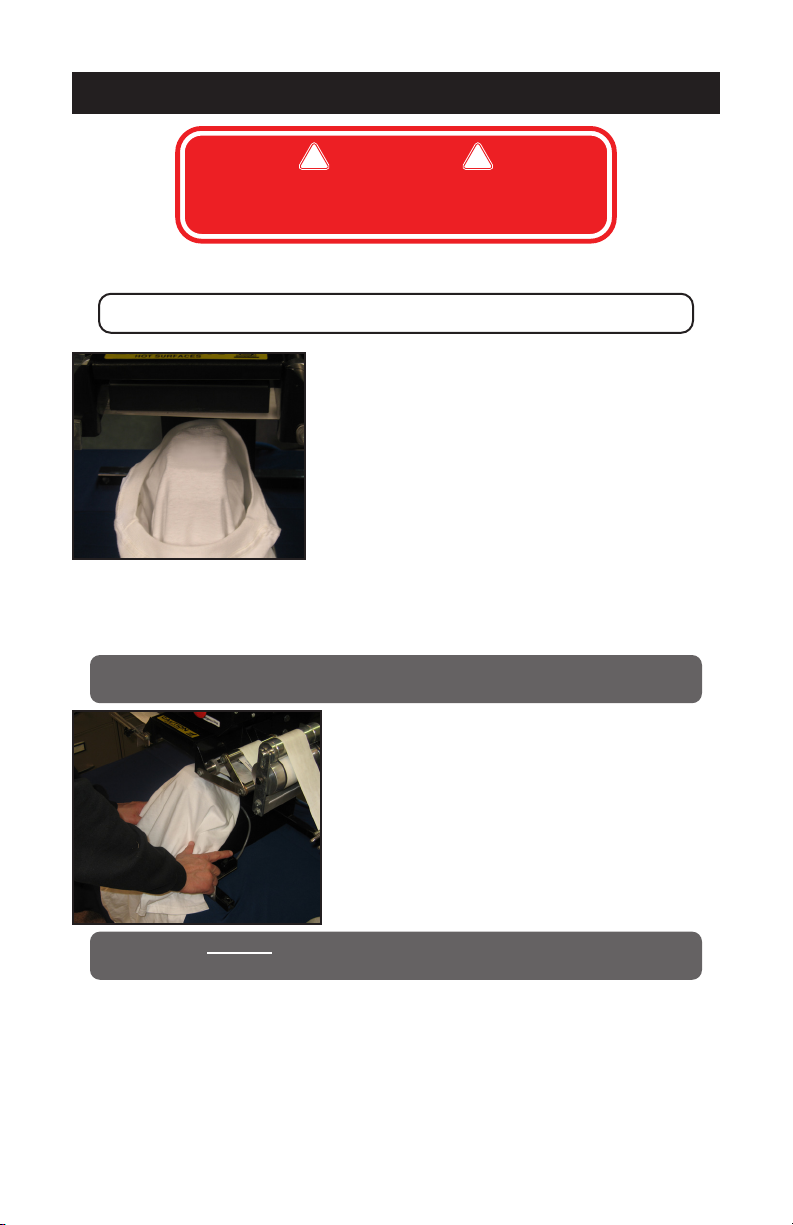

5. For eective web tracking labels should be fed between drive roller and pinch roller

then back over top of pinch roller.

6. Simply place lead edge of label web between four

ngers of take up real and let hang free.

7. Take up slack by pressing and releasing Jog but-

ton on left side of control box.

8. Set sensor position and sensitivity. (see sensor

settings)

9. Position label on platen then move sensor to align

its light beam on the index mark.

10. Push Load/Run button in to set it to Run mode.

INDEX MARK

PINCH ROLLER

DRIVE ROLLER

7

SENSOR SETTING

1. Jog label by depressing and releasing the Jog button to move the label index mark

such that the light beam is aimed on the Index mark.

2. Reposition guides on guide rod to maintain front to rear centering of label. Do not adjust

left to right position at this time.

3. Depress Load/Run button to the “out” position or Load mode

4. Position the sensor light beam onto the index mark printed on the label web by pressing

the “Jog” button.

5. Press and hold the “Dynamic” push bottom (located on the bottom side of the sensor

- closest to the operator) for about 2 seconds until the light beam changes color to a

Tri-Color beam (Green, Red, Blue). Continue to hold the “Dynamic” push button in.

6. While holding the “Dynamic” push button in, pull the light beam o the index mark, onto

the paper only - hold there for 1 second, then put the beam back onto the index mark -

hold there for 1 second, back o the index mark for 1 second then back onto the index

mark for 1 second - then Release the “Dynamic” push button while the beam is shining

on the index mark.

7. The sensor light will return to a “Green” color and is now trained.

8

SENSOR SETTING

8. Put machine in Load/Run (button in) and activate the two optical control switches, the

label will advance to next index mark and stop. Position label front to rear if necessary

(Step 2 of sensor setting) and right to left on lower platen, using jog button.

9. Now adjust position of sensor head such that the

light beam is just above the Index mark (approx.

3mm) and tighten.

NOTE: When sensing an index

mark on a reflective (shiny)

material, mount the sensor

at approximately 15° off

perpendicular to the material’s

surface to minimize strong

directreectionsandallowthe

sensor to discern the relatively

small optical contrast oered

bydierencesincolors.

When sensing an index mark

on a clear material, position

a reflective surface directly

behind the clear material to

return light to the sensor. Most

clear materials are also shiny;

it is important to include a 15°

skew angle when sensing clear

materials.

Approximately 15°

Tr

ansparent or

Opaque Reflective

Web Material

Guide Rollers

Mount the sensor at approximately 15° from perpendicular to

the transparent and opaque reflective materials

Focus Distance

3 mm - 10 mm

FOR FURTHER SENSOR INSTRUCTIONS, SEE

INCLOSED BANNER R58E SERIES EXPERT™

REGISTRATION MARK SENSOR MANUAL

9

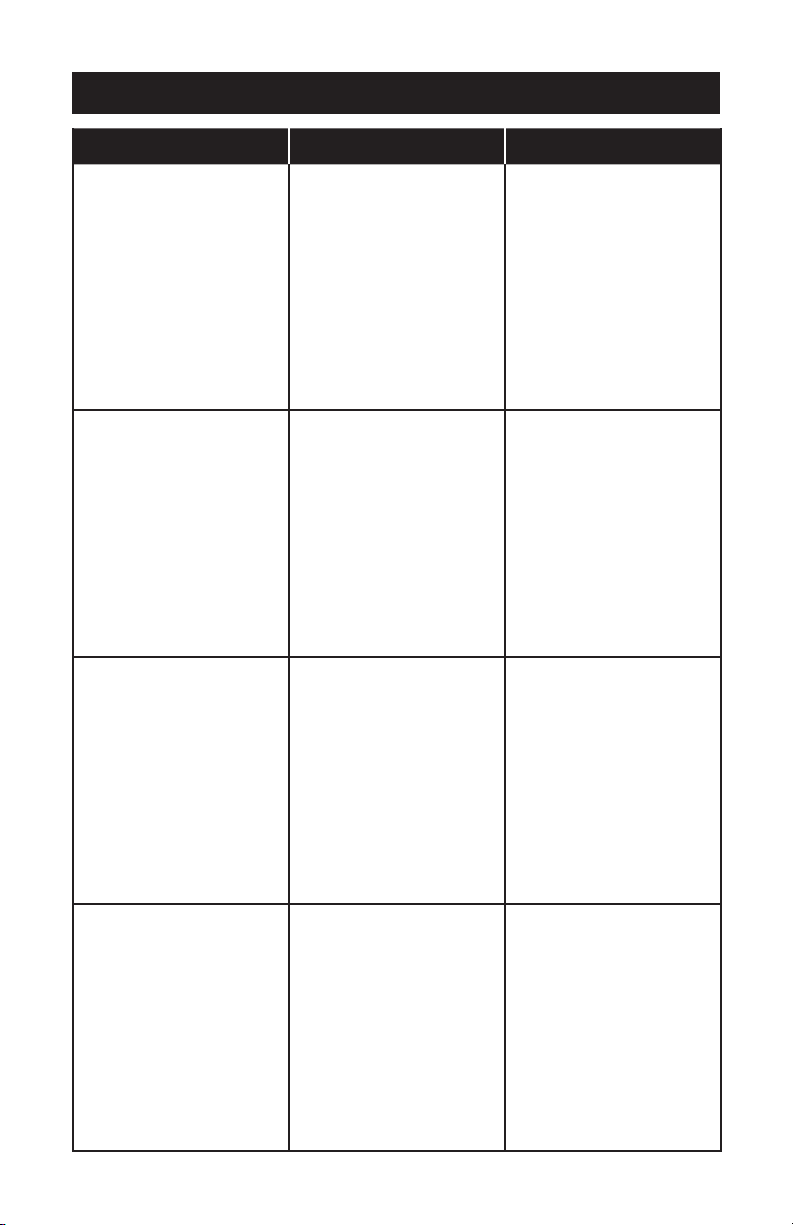

OPERATION

1. Visually check and conrm label is in centered position.

NOTE: If the label is NOT centered, repeat sensor setting

2. Position Garment into desired position

3. Place nger in each optical control switch, heat head will come down and then rise after

set time, take up roll will automatically index to next label.

WARNING:Keephandsandngersclearofthepressingareaatalltimes

topreventaccidentalburnsorcrushingofngersorhand!

WARNING: DO NOT remove any safety guards or operate this

equipment in a manor not intended by the manufacturer.

WARNING:

For use with roll-to-roll transfers only.

DO NOT use with single cut transfers.

! !

10

TRANSFER APPLICATION

Whenyoufailtomakeasuccessfultransferyoucanwonder,“Isitthemachine’s

fault,orthetransfer,wrongsettingsorwhat”?

FIRST, THE BASICS:

1. Be sure to set the heat transfer machine to the transfer manufacturer’s recommended

Temperature, Time and Pressure settings. If you don’t have these specications, con-

tact your transfer supplier for this information and any other special application instruc-

tions as many of the new “High Tech” transfers require signicantly dierent settings

and/or application techniques than those from years past.

2. When you start up your press for the rst time each day, preheat the pad for a minute.

If the press has sat for 3-5 minutes without use, be sure to “preheat” the pad for 10-15

seconds before loading the shirt or making the rst transfer.

3. Be sure the T-shirt fabric is void of any moisture which can reduce the chance of a suc-

cessful transfer.

4. With all of the above recommendations, try making a transfer.

5. If successful, great! You are on your way to making some serious money with your

transfer machine!

6. If you have an area that isn’t transferring completely or as you would like it to, follow

these steps to determine the problem.

• Try increasing the pressure on the machine by 10-20%

• Recheck your temperature required and the press readout. You may want to in-

crease the temperature 10 degrees.

• Try increasing the application time by 2-4 seconds

• If after trying these things there is still a “specic” area (say over in one corner of

the transfer) that isn’t coming out as you would like it to, then try the same type

transfer on a scrap shirt but rotate the transfer 180 degrees (changing the failure

location) If after doing this the problem area is in the same physical location on

the machine, then you probably have a problem with the pad or possibly a warped

platen if the machine has ever overheated severely. On the other hand if the

transfer failed in the same area on the transfer (after changing the location of where

the problem had previously been occurring), then you most likely have a problem

with the transfer or it’s application settings (Temperature, Time or Pressure) and you

should contact your transfer supplier to discuss the problem.

Following these basic guidelines can help you be more successful with each and every

transfer!

11

TROUBLESHOOTING

SYMPTOM CAUSE SOLUTION

1. Machine does not index

properly.

Press set to Load Mode

Sensor not set properly

Press Load/Run button

(pressed in)

First make sure label is

aligned properly. Re-Teach

sensor. See Sensor Setting

Section.

2. Labels do not transfer

properly.

Not enough heat, time or

pressure.

Please refer to transfer

specications while most

transfer target times range

from 1-2 seconds. Pressure

and Temperature settings

may vary depending on

fabric limitations.

3. Upper Platen does not

move.

No air pressure. Check that air connection is

secure.

Check that air supply has

not been interrupted.

4. Unit does not come on E-Stop button is on.

Breaker Tripped

Blown Fuse

Turn E-Stop clockwise and

press Power button.

Locate main breaker panel

and ip tripped breaker to

on position.

Contact HIX Technical

Service 800-835-0606 for

instruction.

12

(Effective 3/1/2020)

HIX will automatically register the equipment on the date it was shipped to you or your distributor. If the

equipment was not purchased directly from HIX, but through a distributor (either domestic or foreign), please

keep a copy of their sales invoice showing the serial number and date it was sold/shipped to you with this war-

ranty. In this case, we will use the distributor’s invoice date as the beginning warranty date. STAPLE A COPY

OF YOUR PROOF OF PURCHASE TO THIS WARRANTY and keep in a safe place to provide verication of

your warranty should a problem occur. Thank you.

Please ll in the following information and attach a copy of your receipt for your records.

Date Purchased: From:

Model #: Serial #:

This warranty applies to equipment manufactured by the HIX Corporation (HIX), Pittsburg, Kansas, U.S.A.

HIX warrants to the original purchaser, its Ovens and Dryers, Heat Transfer Machines, Textile Printers, Spot

Heaters, and Exposure Units against defects in workmanship and material, except for wear and tear for a

period of “One Year” from the date of purchase. HIX warrants Accessories for a period of 90 days from the

date of purchase. doughXpress products are covered under separate warranty.

In the event of a defect, HIX, at its option, will repair, replace or substitute the defective item at no cost

during this warranty period subject to the limitations of insurance and shipping costs stated below (excludes

labor).

In the case of heat transfer presses (except the Hobby Lite and Large Format presses), HIX warrants the

heat casting for the “Life” of the machine for the original purchaser. If a part becomes obsolete at the time

for repair, and/or cannot be reasonably substituted for, HIX will credit, at half the then current list price or last

recorded price, only that part toward a new machine or any product HIX oers. This credit oer shall be the

sole responsibility of the HIX Corporation in the event of an obsolete part.

This warranty does not cover belts, rail tape, pads, mug wraps, canvas, rubber blankets, bulbs, glass.

Warranty does not cover damages due to accident, misuse/abuse, alterations or damage due to neglect, ship-

ping or lack of proper lubrication or maintenance. HIX shall not be responsible for repairs or alterations made

by any person without the prior written authorization by HIX. This warranty is the sole and exclusive warranty

of HIX and no person, agent, distributor, or dealer of HIX is authorized to change, amend or modify the terms

set forth herein, in whole or in part.

In the case of a problem with the equipment identied herein, HIX Corporation should be contacted during

regular business hours to discuss the problem and verify an existing warranty. HIX personnel will assist the

customer to correct any problems which can be corrected through operation or maintenance instructions,

simple mechanical adjustments, or replacement of parts. In the event the problem cannot be corrected by

phone, and upon the issuance of a return authorization by HIX, the equipment shall be returned to HIX or an

authorized service representative. All insurance, packaging and shipment/freight costs are solely the respon-

sibility of the customer, and not that of HIX, and HIX shall not be responsible for improper packaging, handling

or damage in transit. Contact HIX customer service for complete return authorization information. Correct

shipping boxes are available from HIX.

This expressed warranty is given in lieu of any and all other warranties, whether expressed or implied,

including but not limited to those of merchantability and tness for a particular purpose, and constitutes the

only warranty made by HIX Corporation.

In no event shall HIX’s liability for breach of warranty extend beyond the obligation to repair or replace the

nonconforming goods. HIX shall not be liable for any other damages, either incidental or consequential, or the

action as brought in contract, negligence or otherwise.

This warranty gives you specic legal rights and you may also have other rights which vary from state to

state.

WARRANTY

1201 E. 27th Terrace • Pittsburg, KS 66762 • U.S.A.

Web site: www.hixcorp.com • Phone: (800) 835-0606 • Fax: 620-231-1598

©2020 HIX Corp.

Design and Manufacturers of Graphic Imaging, Commercial Food, Industrial and Custom Drying Equipment

Other manuals for R2R

1

Table of contents

Other Hix Industrial Equipment manuals