Hobby King Mig-15 EDF User manual

Other Hobby King Toy manuals

Hobby King

Hobby King Raven 990 MINI DLG 2017 User manual

Hobby King

Hobby King Cessna 195 User manual

Hobby King

Hobby King Micro SU-27 User manual

Hobby King

Hobby King DragonFly EDF User manual

Hobby King

Hobby King ASK-2100 User manual

Hobby King

Hobby King ViperJet G500 User manual

Hobby King

Hobby King Fokker E.111 Fighter Aircraft User manual

Hobby King

Hobby King EPP-P51D User manual

Hobby King

Hobby King Skipper 40228 User manual

Hobby King

Hobby King EXTRA260P User manual

Hobby King

Hobby King Plug-N-Fly Paramotor User manual

Hobby King

Hobby King SBACH 55" User manual

Hobby King

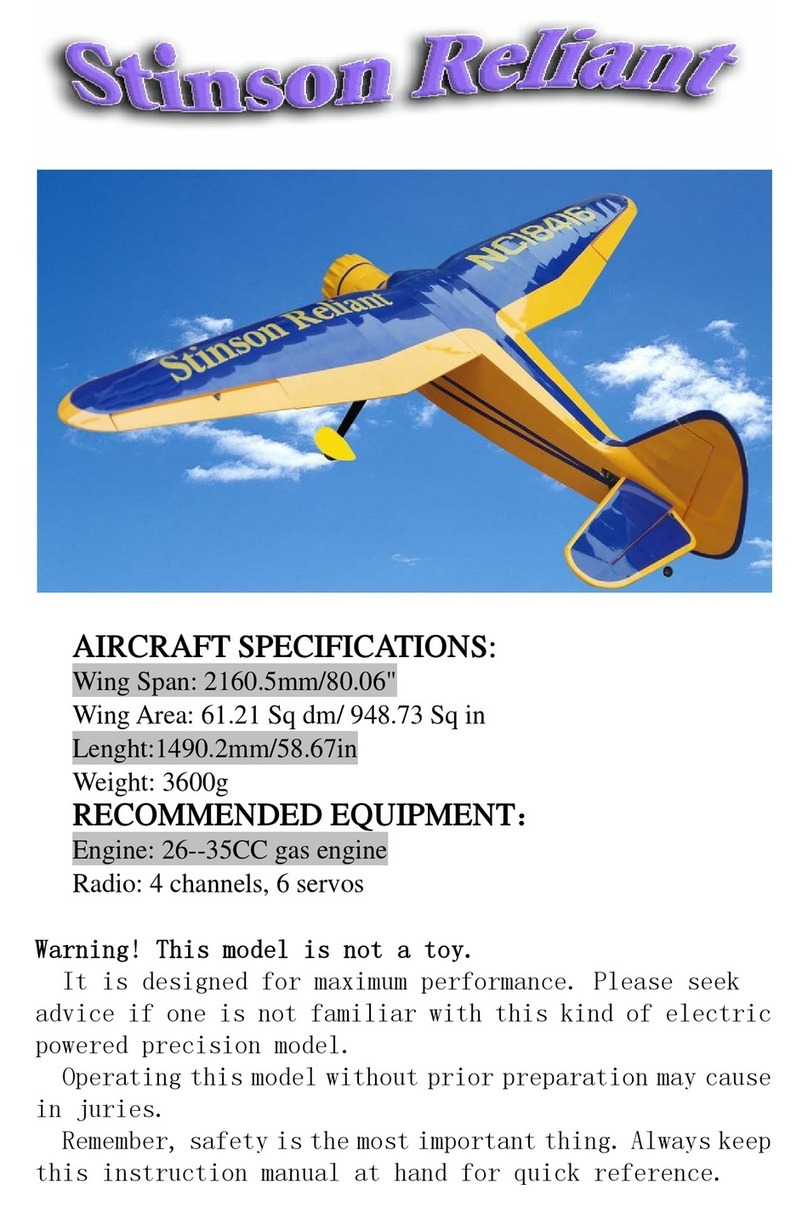

Hobby King Stinson Reliant User manual

Hobby King

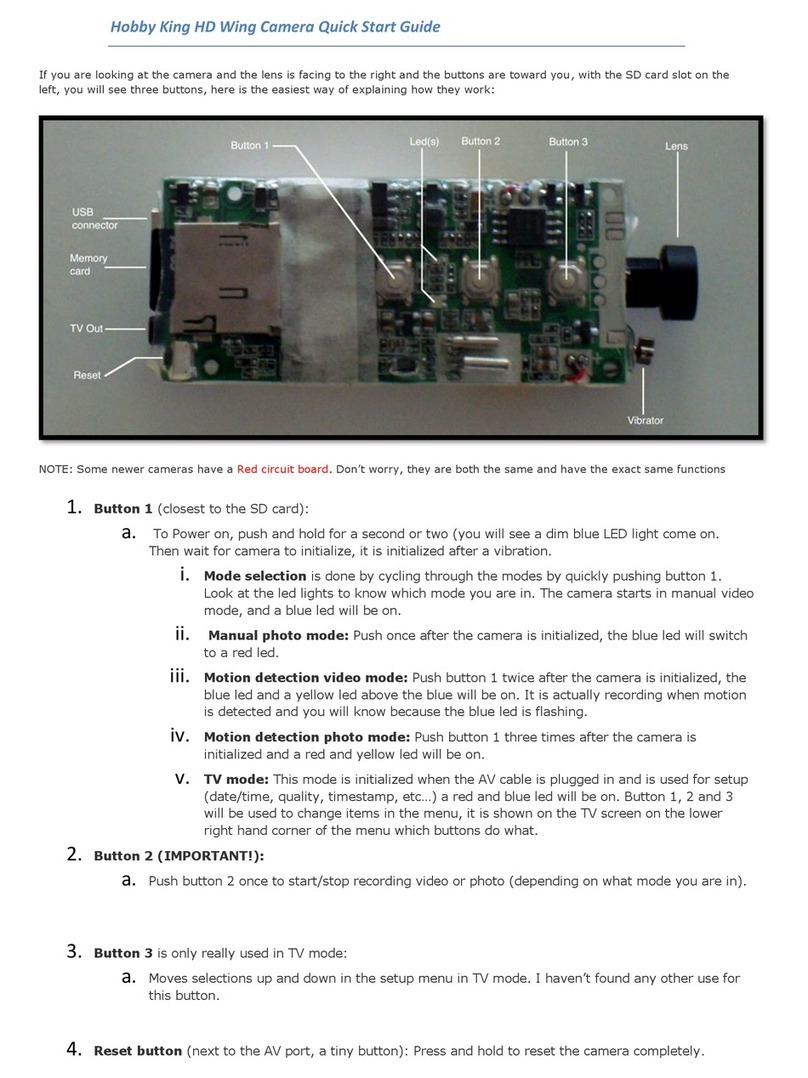

Hobby King HD Wing Camera User manual

Hobby King

Hobby King Angel 920 User manual

Hobby King

Hobby King Libero Quick start guide

Hobby King

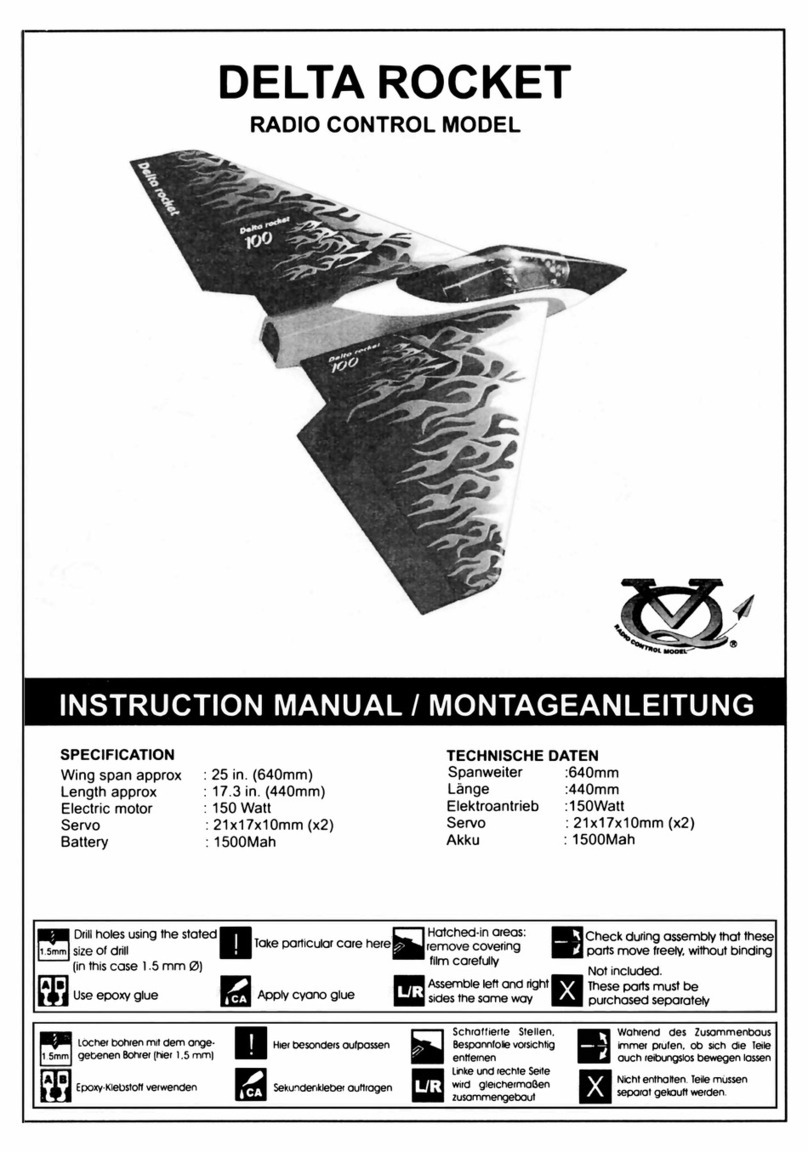

Hobby King Delta Rocket 100 User manual

Hobby King

Hobby King Tanager Glider User manual

Hobby King

Hobby King spitfire User manual

Hobby King

Hobby King Fokker Dr.I User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions