Hobby-Lobby Funster V2 User manual

Other Hobby-Lobby Toy manuals

Hobby-Lobby

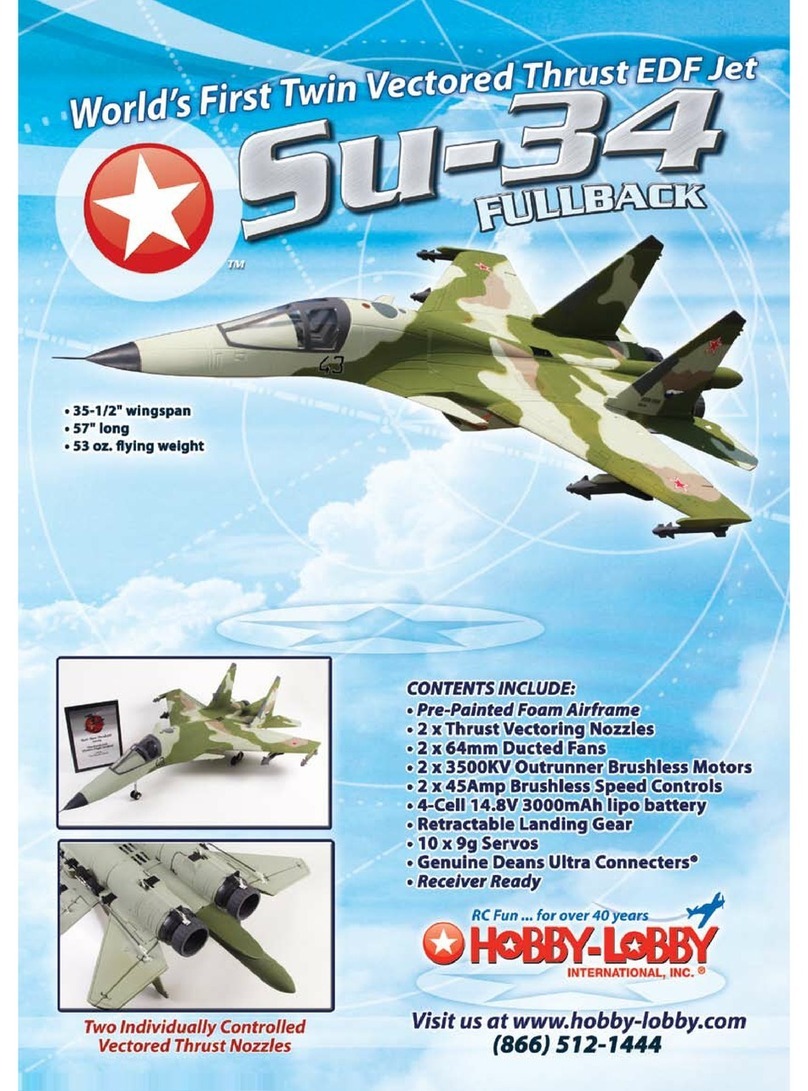

Hobby-Lobby SU-34 Fullback User manual

Hobby-Lobby

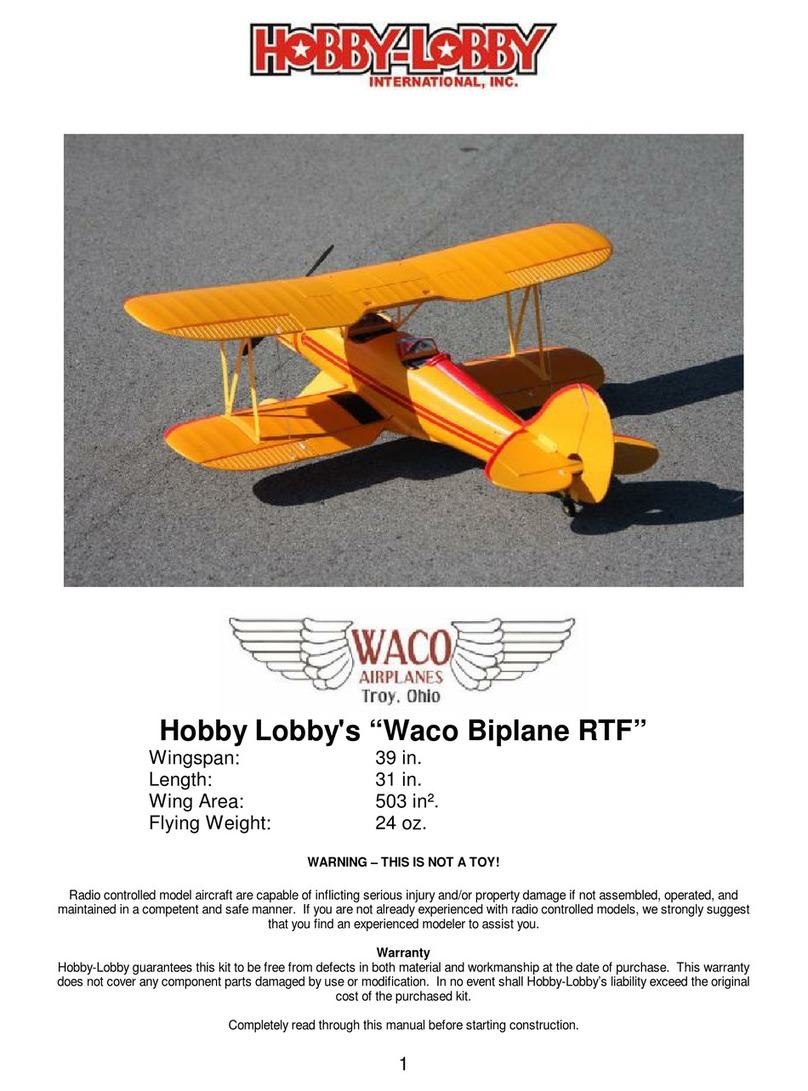

Hobby-Lobby Waco Biplane RTF User manual

Hobby-Lobby

Hobby-Lobby Telemaster Electro V2 ARF User manual

Hobby-Lobby

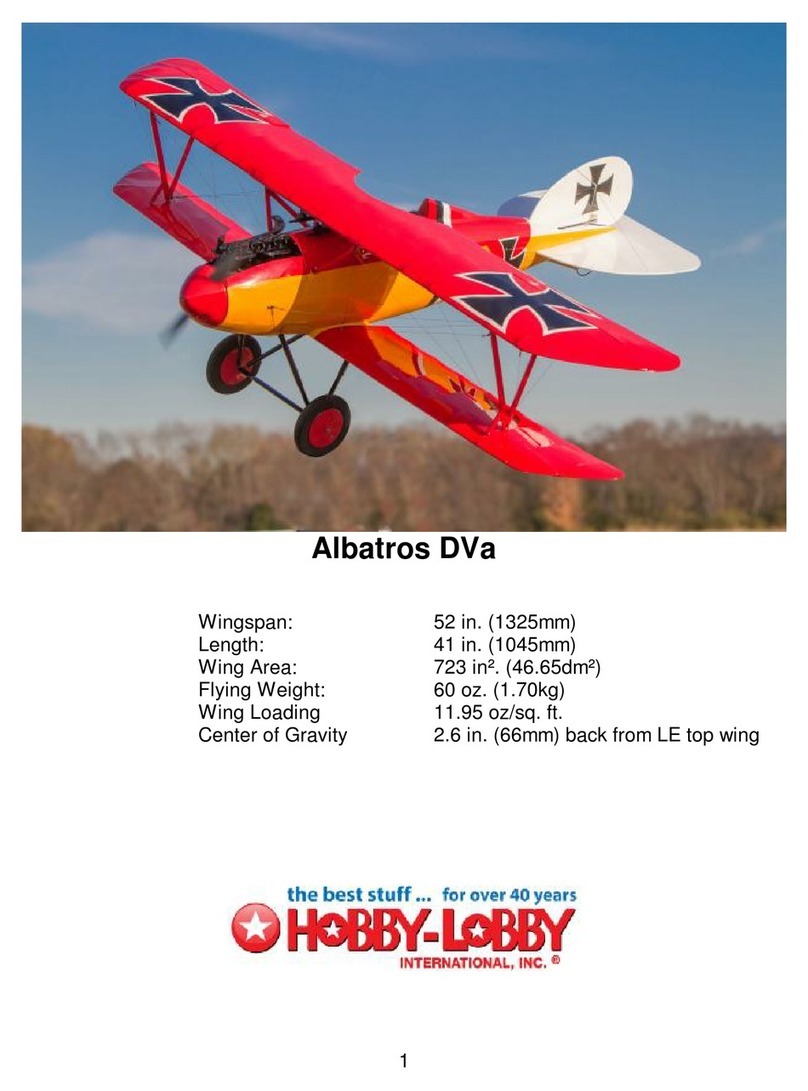

Hobby-Lobby albatros DVA User manual

Hobby-Lobby

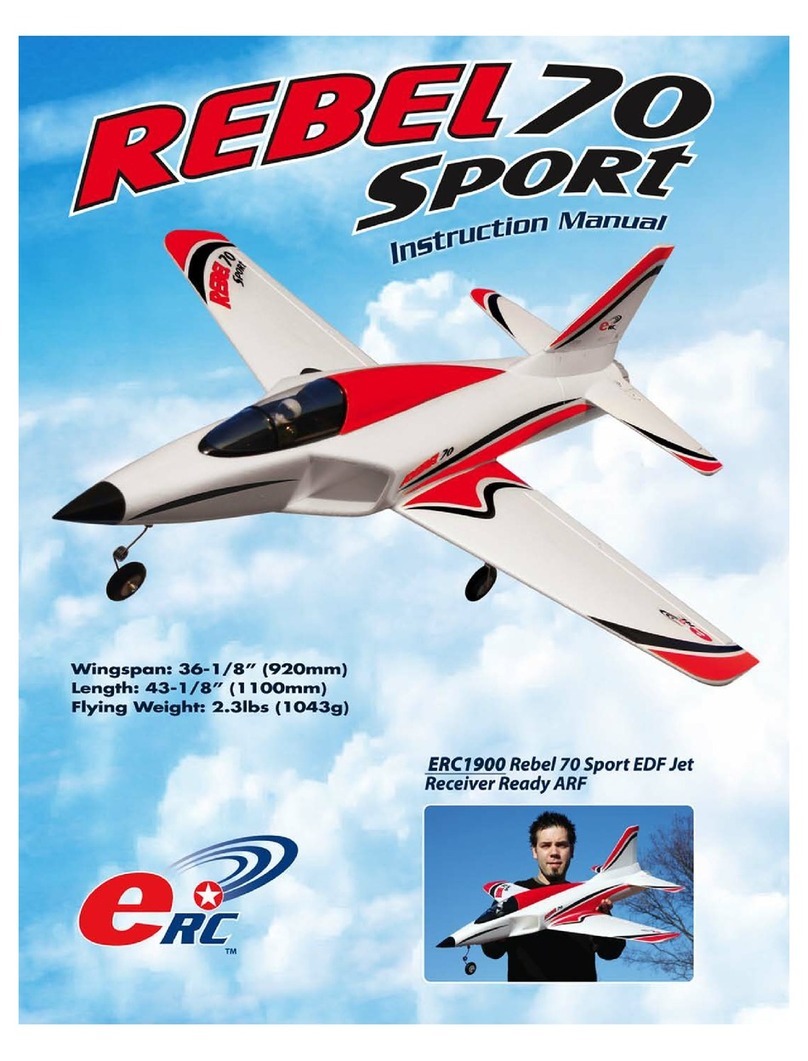

Hobby-Lobby Rebel 70 Sport Jet User manual

Hobby-Lobby

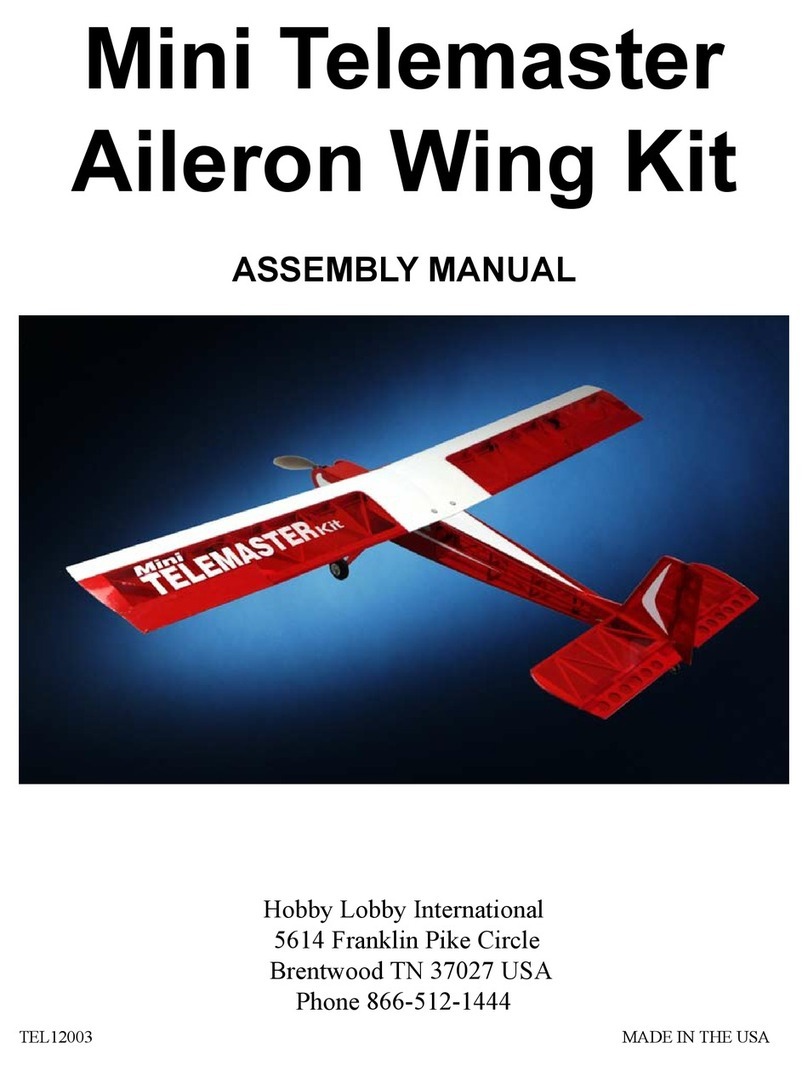

Hobby-Lobby Mini Telemaster Aileron Wing Kit User manual

Hobby-Lobby

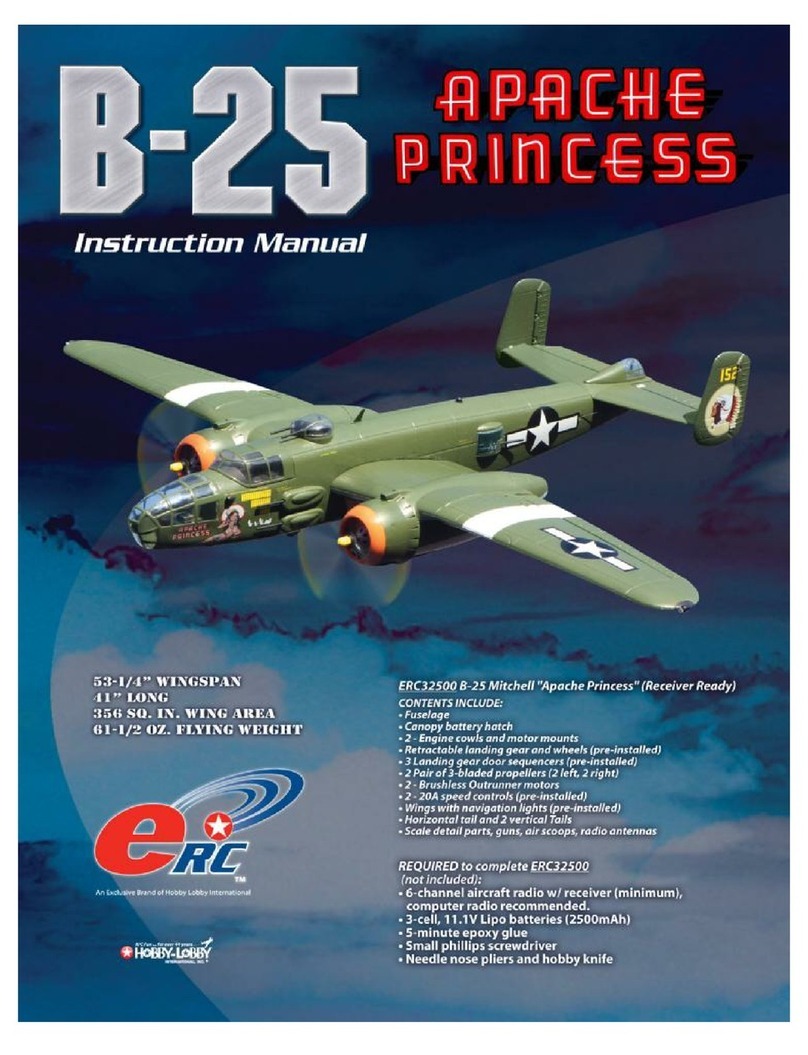

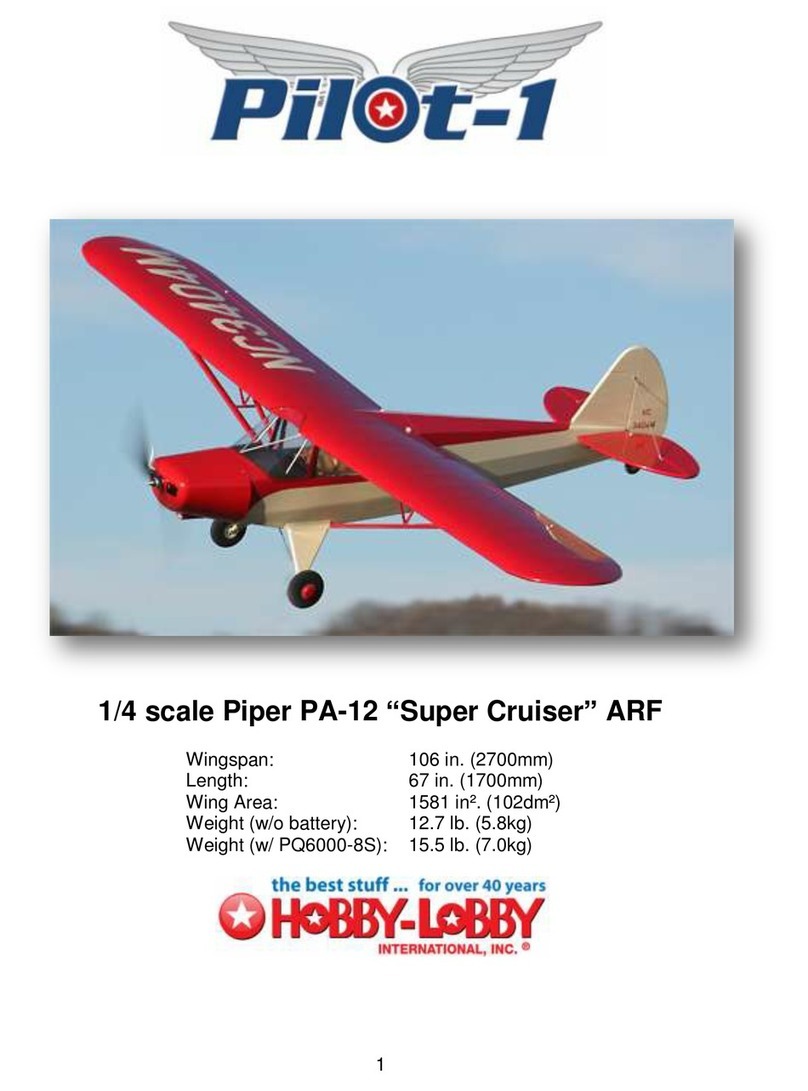

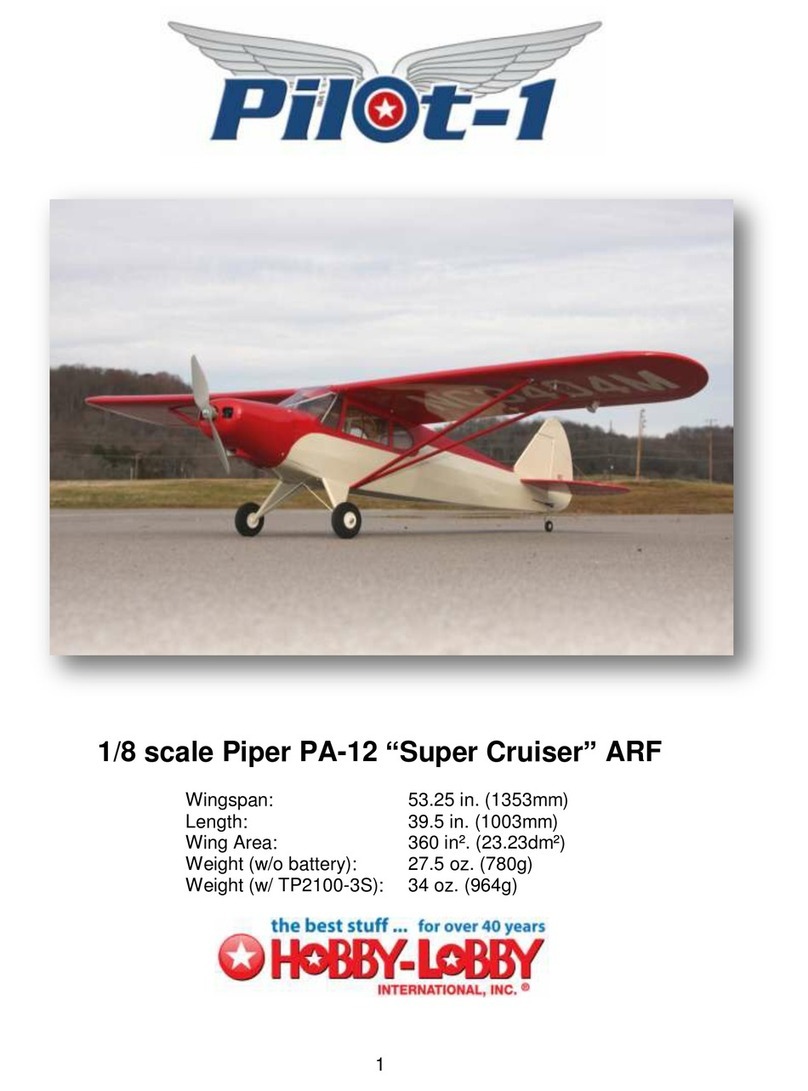

Hobby-Lobby Piper PA-12 Super Cruiser User manual

Hobby-Lobby

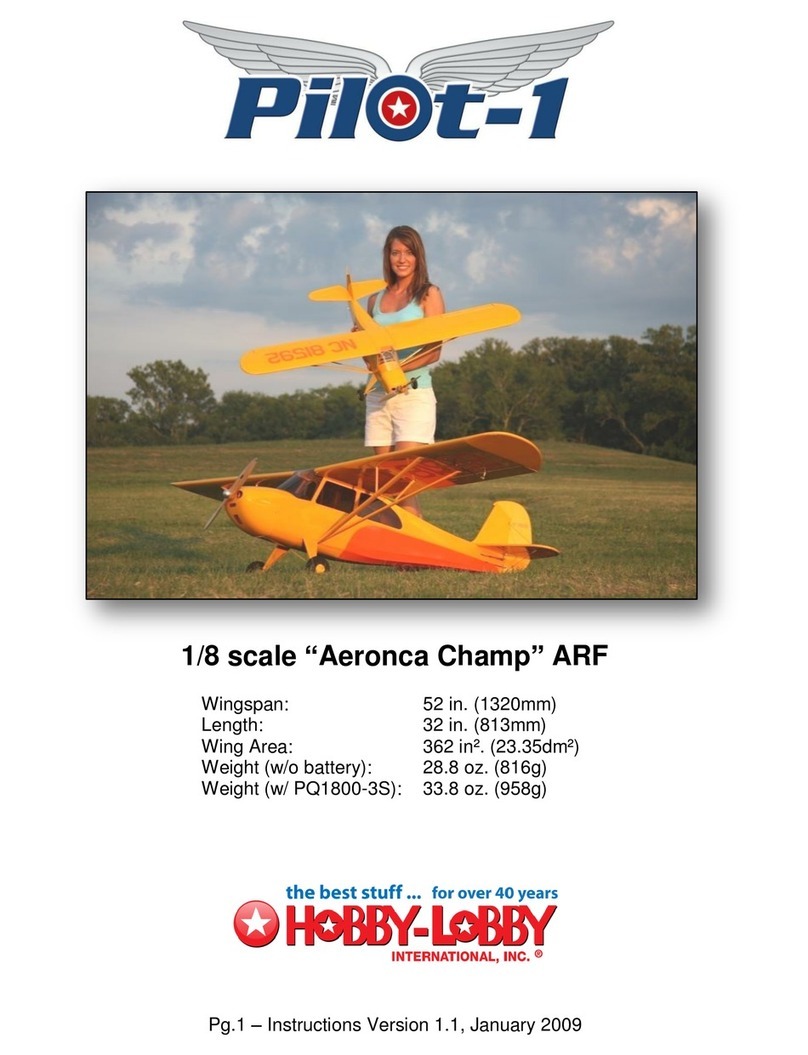

Hobby-Lobby Pilot-1 User manual

Hobby-Lobby

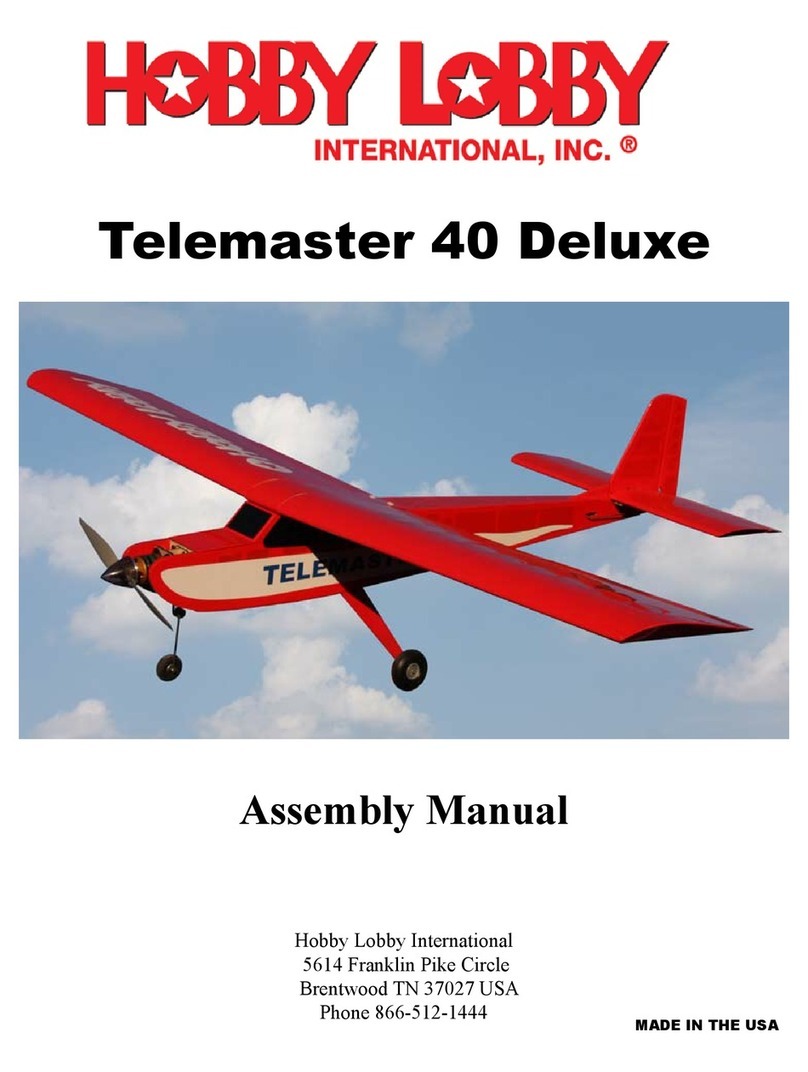

Hobby-Lobby Telemaster 40 Deluxe User manual

Hobby-Lobby

Hobby-Lobby ESM1100 User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions