Hoffmann X-10 Dovetail Routing Machine

- 3 -

Hoffmann Machine Company, Inc. 1386 Drexel Road Valdese, NC 28690

www.Hoffmann-USA.com

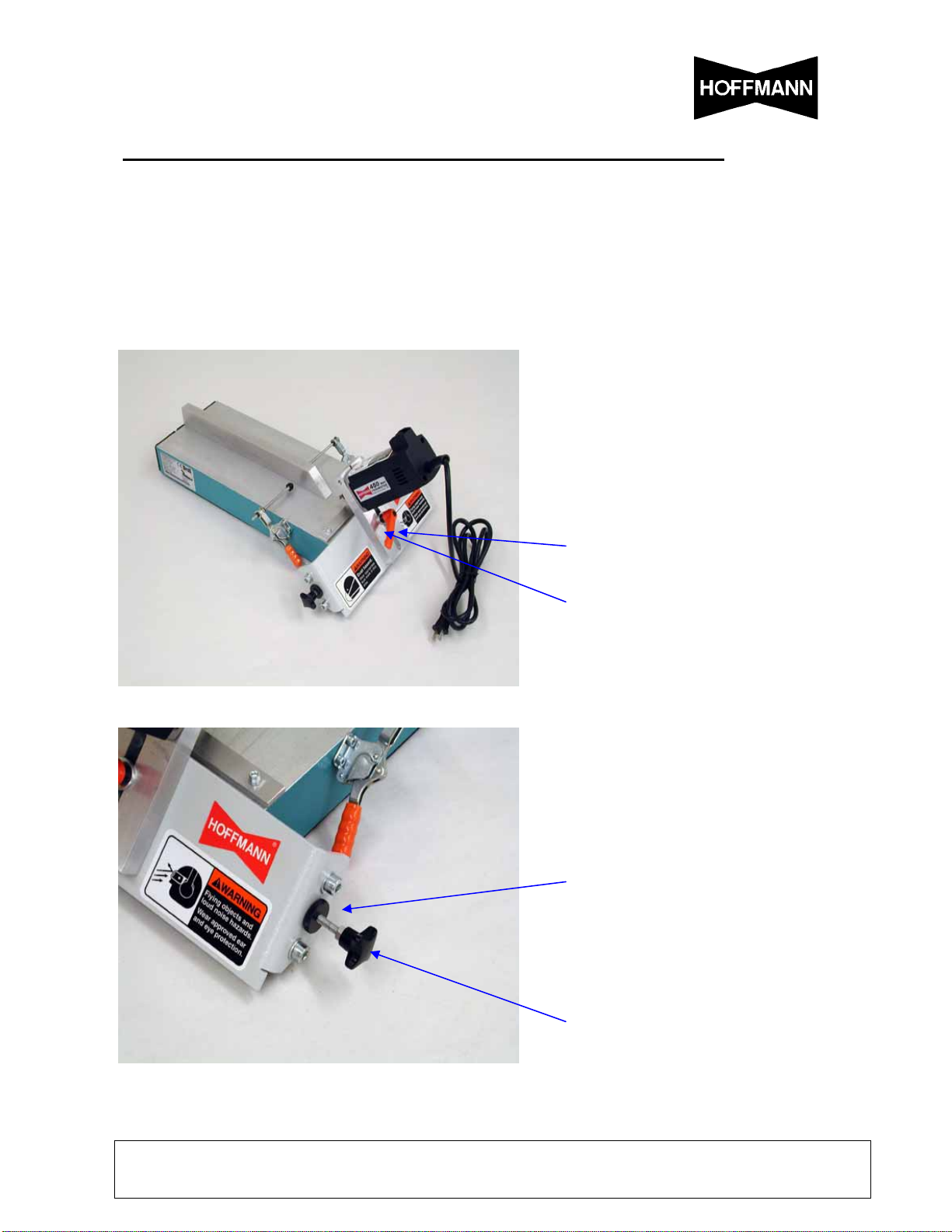

4. General Machine Description

The Hoffmann Dovetail Routing Machine model X-10 is designed solely to process material for the Hoffmann Dovetail

Joining System.

This machine is to be used only to process material for Hoffmann Dovetail Keys, size W-1, W-2 and W-3.

USE OF THIS MACHINE FOR ANY OTHER OPERATION IS DANGEROUS AND WILL VOID THE WARRANTY.

The manufacturer cannot be held liable if the machine is used for any operations other than outlined in this manual.

The Hoffmann Dovetail Routing Machine model X-10 is designed to rout dovetail shaped keyways in hard and

softwoods as well as wood related sheet goods, such as particleboard, MDF, plywood, MDO, etc.

The machine is limited to routing keyways in 45 degree mitered parts only.

Parts with other angles or square or butt-joints cannot be processed.

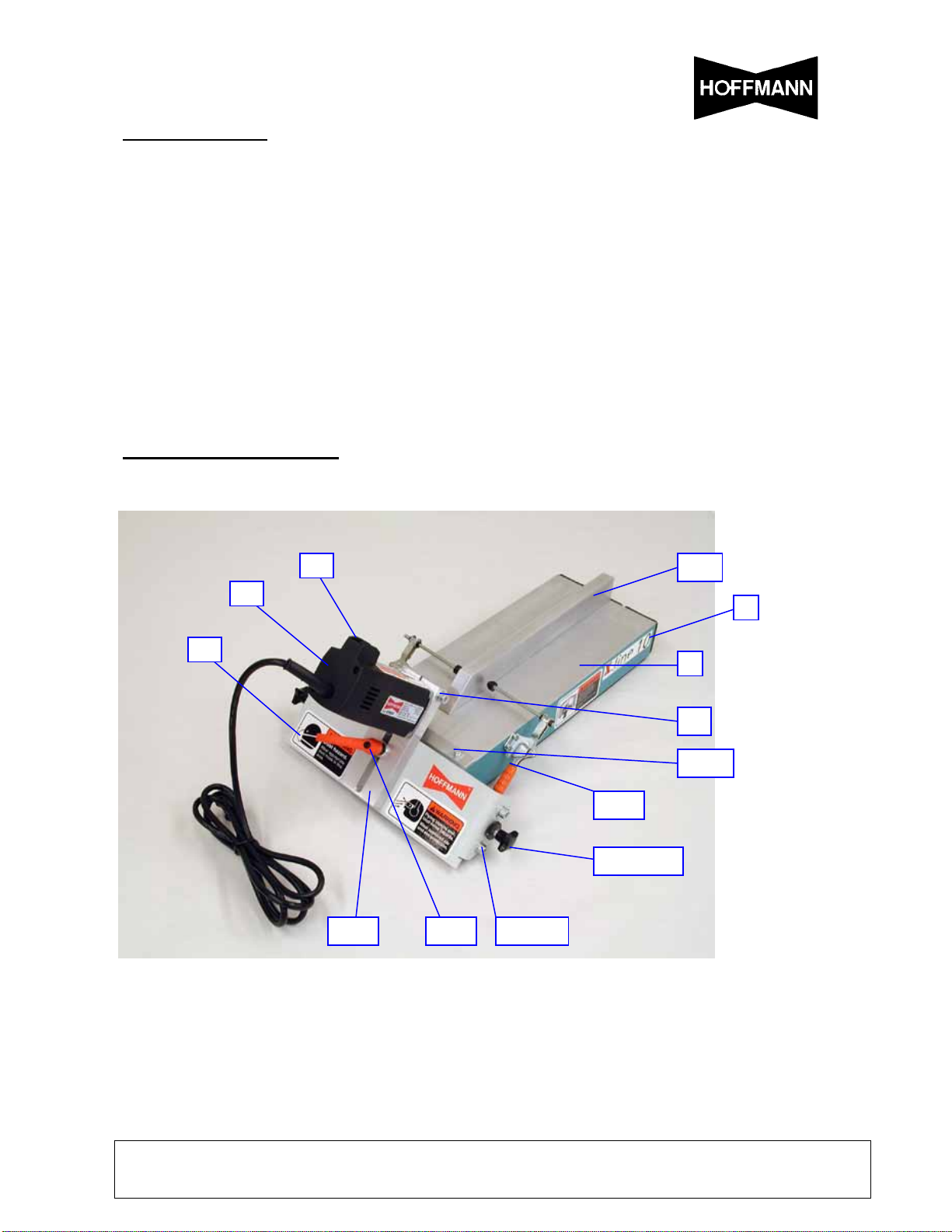

4.1 Operation:

1. The moulding is placed against the left and right hand side of the center guide, with the back side of the

material against the center guide and the miter tip resting against the front edge guide.

2. Adjustable toggle clamps are set and the moulding is clamped against the center guide.

3. The operator turns on the machine and holds the moulding tightly against the center fence with one hand. The

motor is moved laterally with the other hand until the pre-set stops have been reached, it is then returned to

the center position.

4. The motor is switched off, the clamps are released and the moulding removed from the machine.

WARNING:

Keep hands clear of router bit at all times. Bits have sharp edges and will cut even if the motor is turned off.

Touching a spinning router bit can case severe hand injury!!!

Always turn the motor off when removing material and when adjusting the machine.

Never rout into material not clamped securely to the center guide.

5. Potential Risks and Dangers

Even when the machine is used as designed, and when the aforementioned safety rules are adhered to, the potential

risk of injury must always be considered.

It is especially important to be aware of the following:

The risk of pinching between stationary and moveable parts of the machine.

The risk of pinching on the clamping devices of the machine.

The risk of injury from sharp edges when handling, adjusting or changing the tooling.

The risk of injury due to the inhalation of wood dust when operating the machine.

The potential risk of injury on the electrical parts of the machine.

6. Toolkit

The machine is shipped with a Hoffmann toolkit, consisting of:

•Hex key 2.5mm

•Hex key 3.0mm

•Hex key 4.0mm

•Hex key 5.0mm

•Hex key 6.0mm

•Wrench 14mm

•Wrench 17mm

•One Safety Equipment Starter Kit (safety glasses, ear plugs, dust mask)

This starter kit is included as a courtesy to allow the machinery owner to start using this

machine upon receipt. It is the machine owner’s responsibility to supply additional safety

equipment as needed, and the machine operator’s responsibility to use all safety equipment as

instructed.