List of Contents

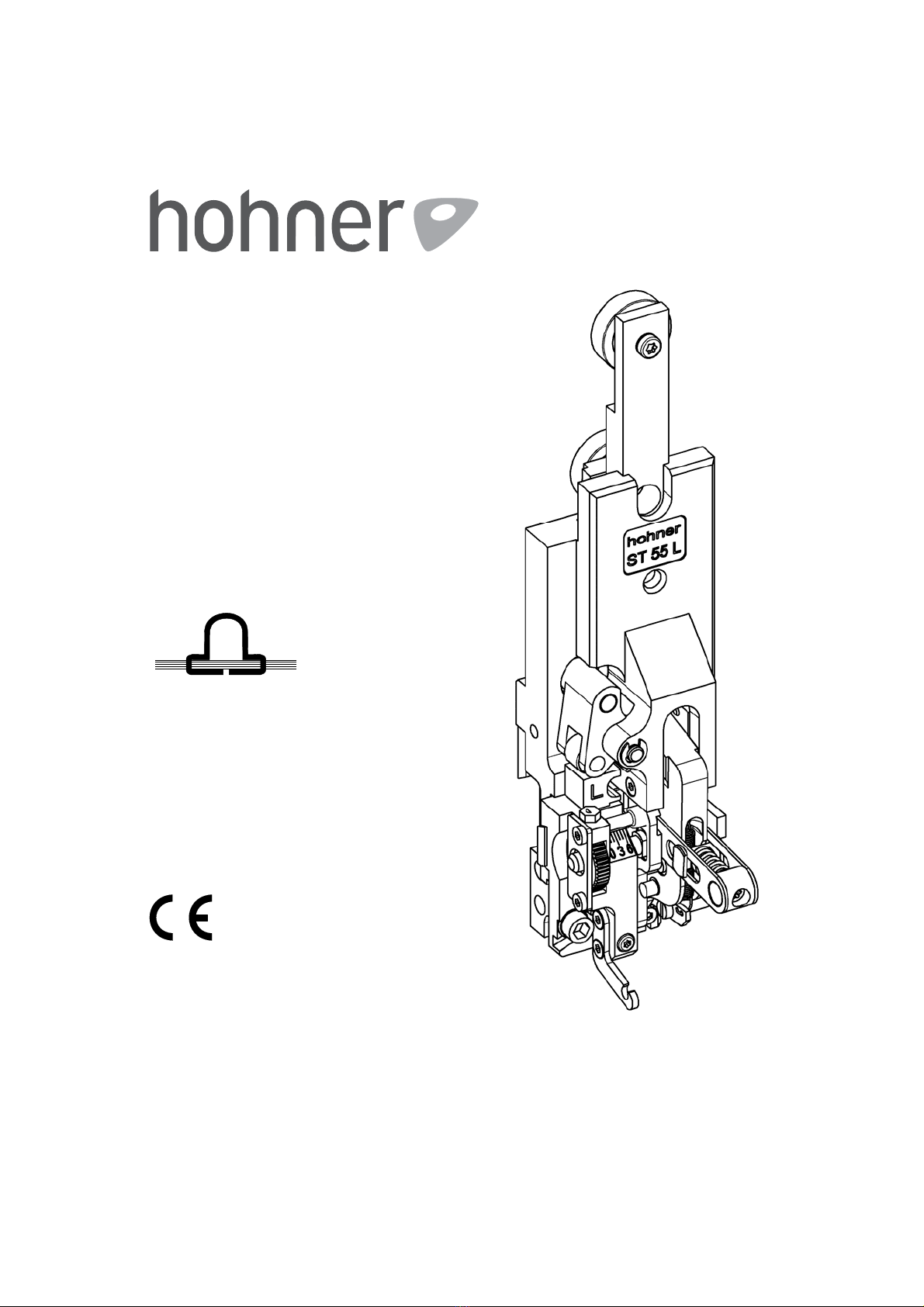

ST 55 L Hohner Maschinenbau GmbH

4

List of Contents

1 SAFETY INFORMATION 6

1.1 Purpose of this document .............................................................................................. 6

1.2 The operator .................................................................................................................. 6

1.3 Safety symbols and the displays that have been used .................................................. 6

1.4 Obligation and liability .................................................................................................... 7

1.5 Correct use .................................................................................................................... 7

1.6 Organisational measures ............................................................................................... 7

1.7 Safety and protective devices ........................................................................................ 7

1.8 Non-formal safety measures.......................................................................................... 7

1.9 Staff training................................................................................................................... 7

1.10 Parts of the equipment which are particularly dangerous .............................................. 8

1.11 Maintenance and repair work, elimination of faults ........................................................ 8

1.12 Structural modifications to the stitching head ................................................................ 8

1.13 Cleaning the machine and the disposal of waste products ............................................ 8

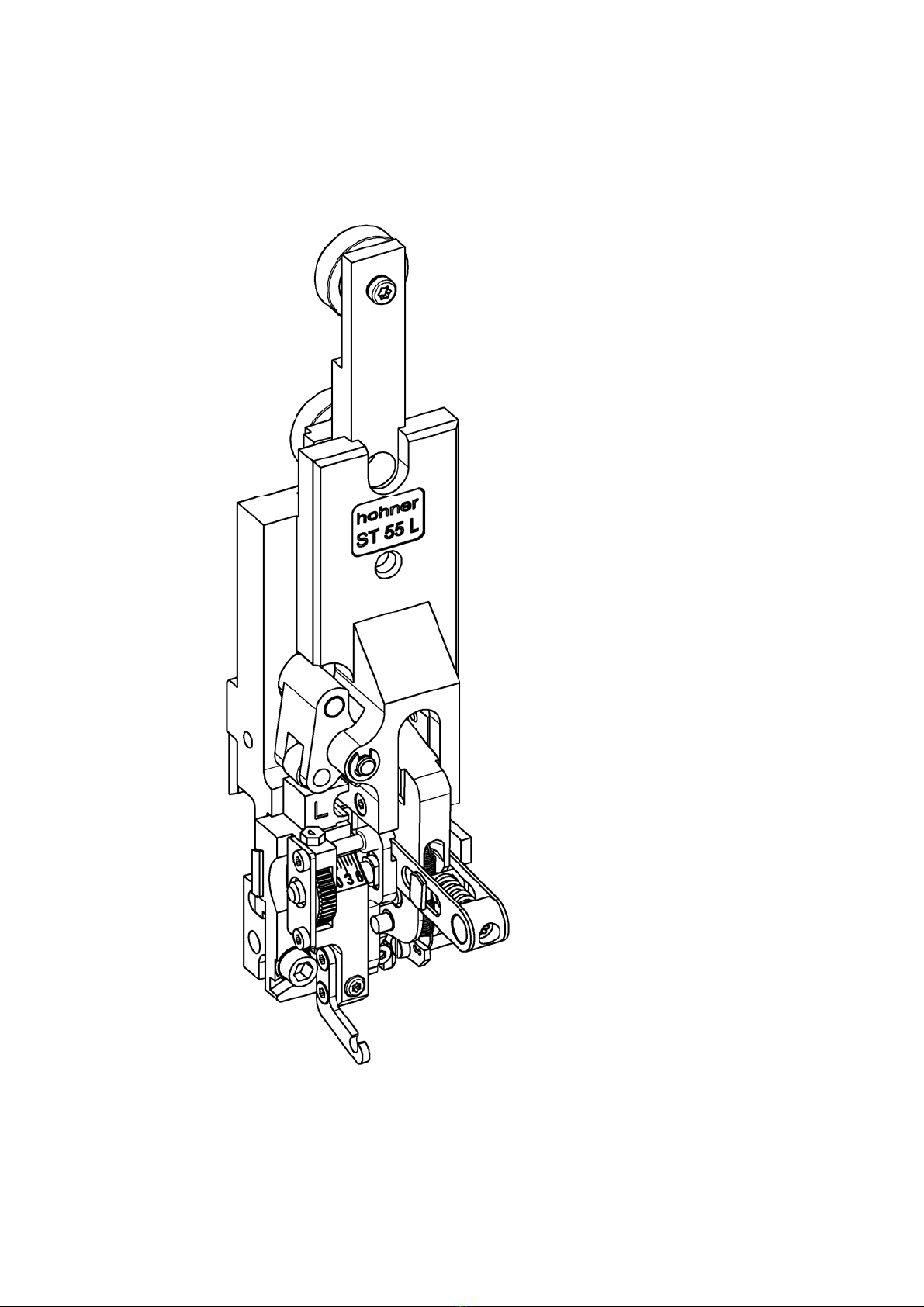

2 DESCRIPTION OF THE STITCHING HEAD 9

2.1 General overview ......................................................................................................... 10

2.2 Conformity ................................................................................................................... 10

2.3 Marking and type plate................................................................................................. 10

2.4 Technical data.............................................................................................................. 10

2.4.1 Normal stitch .............................................................................................................. 11

2.5 Dimensional sheet ....................................................................................................... 13

2.6 Outfitting of the stitching head ..................................................................................... 13

2.6.1 Basic features ............................................................................................................13

2.6.2 Additional equipment.................................................................................................. 13

3 OPERATION 14

3.1 Installation of the stitching head................................................................................... 15

3.1.1 Clamping the stitching head....................................................................................... 15

3.1.1.1 Lateral adjustment of the stitching head........................................................ 15

3.1.2 Fitting the wire guide .................................................................................................. 17

3.1.3 Fitting the clincher box ............................................................................................... 19

3.1.4 Fitting the wire guide hose ......................................................................................... 21

3.1.5 Fitting the hose guide................................................................................................. 21

3.2 Feeding the stitching wire ............................................................................................ 23

3.3 Removing the stitching wire ......................................................................................... 23

3.4 Straighten the stitching wire......................................................................................... 25

3.4.1 Setting the leg length of the stitch .............................................................................. 27

3.5 Setting the former ........................................................................................................ 29

3.6 Spine centering parts ................................................................................................... 31

3.6.1 Installing the holding down device ............................................................................. 31

3.6.2 Adjusting the holding down device............................................................................. 31

4 SERVICING 32

4.1 Lubrication ................................................................................................................... 33

4.1.1 Lubricants .................................................................................................................. 33

4.1.2 Lubrication plan..........................................................................................................33

4.2 Installation and replacement of parts ........................................................................... 34

4.2.1 Replacing the former.................................................................................................. 35

4.2.2 Replacing the driver ................................................................................................... 37

4.2.3 Replacing the bender ................................................................................................. 37

4.2.4 Replacing the knife..................................................................................................... 39

4.2.4.1 Rotating/Changing the flat knife .................................................................... 39

4.2.4.2 Replacing the circular knife ........................................................................... 39

4.2.4.3 Adjusting the circular knife............................................................................. 39

4.2.5 Replacing the clincher................................................................................................ 41