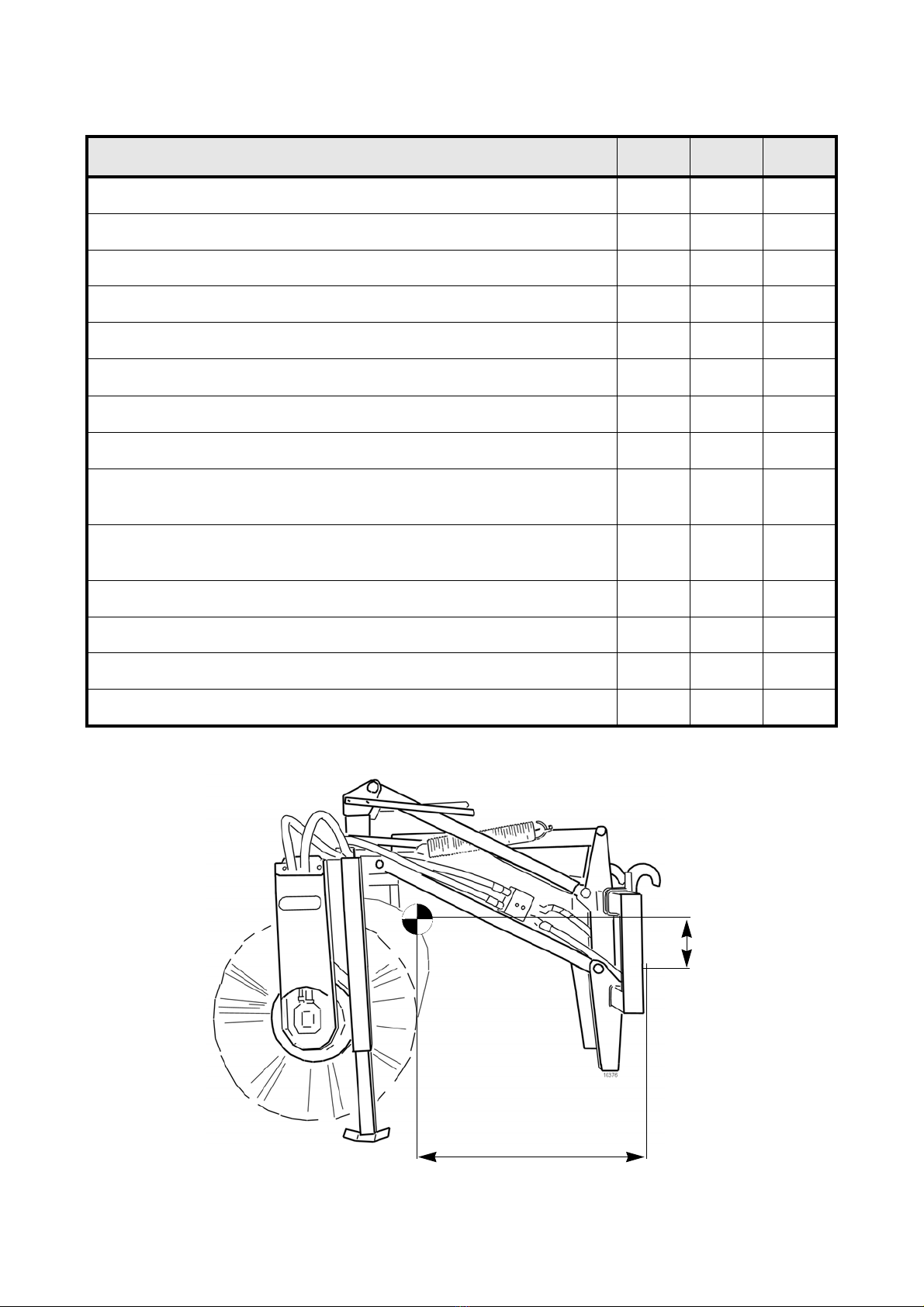

1. Set the sweeper height and tilt.

2. Let the sweeper rotate a short while against the ground.

3. Measure the clean-swept stripe, it shall normally be ca 10

cm.

Warning!

Always lower the attachment so the springs are

relieved before making any adjustments.

Decrease the ground pressure by lowering the adjusting grip.

Increase the ground pressure by raising the grip (picture 7).

Sweeping

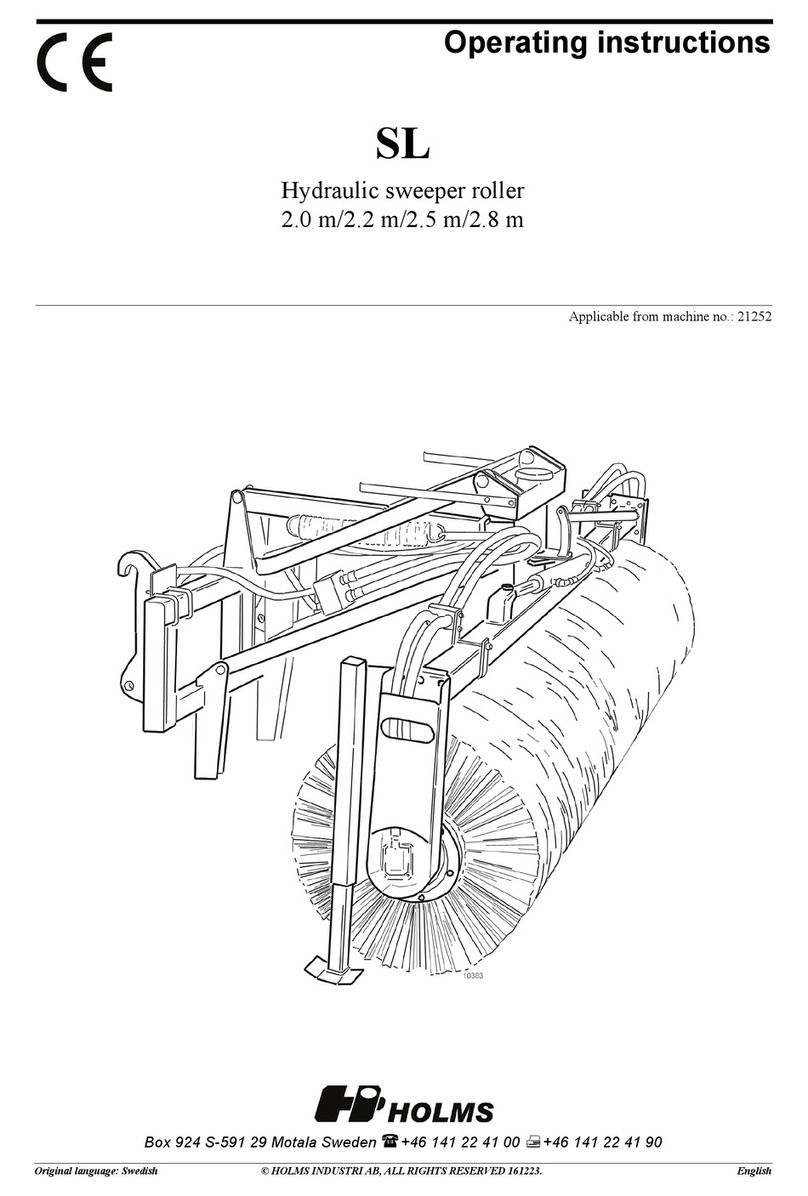

By sweeping the setting normally shall be as described in

“Sweeper setting, height and tilt”. The yellow markers on the

height- and tilting indicators shall be in line. In this position

the loader bracket is vertical to the ground. The sweeper oper-

ates with even pressure over its whole width.

Attention!Do not use the loader heightand tilting function for

ground pressure adjustment.

By requirement of harder ground pressure on any side of the

sweeper or if the sweeper isunevenly worn the adjustment can

be made by changing the tilt setting. By backwards tilting

harder pressure is reached on the side of the sweeper which is

angled towards the loader.

By forwards tilting harder pressure is reached on the side of

the sweeper which is angled from the loader. When lifting the

sweeper from the ground for transport, use tilting backwards

to avoid leaf spring damage.

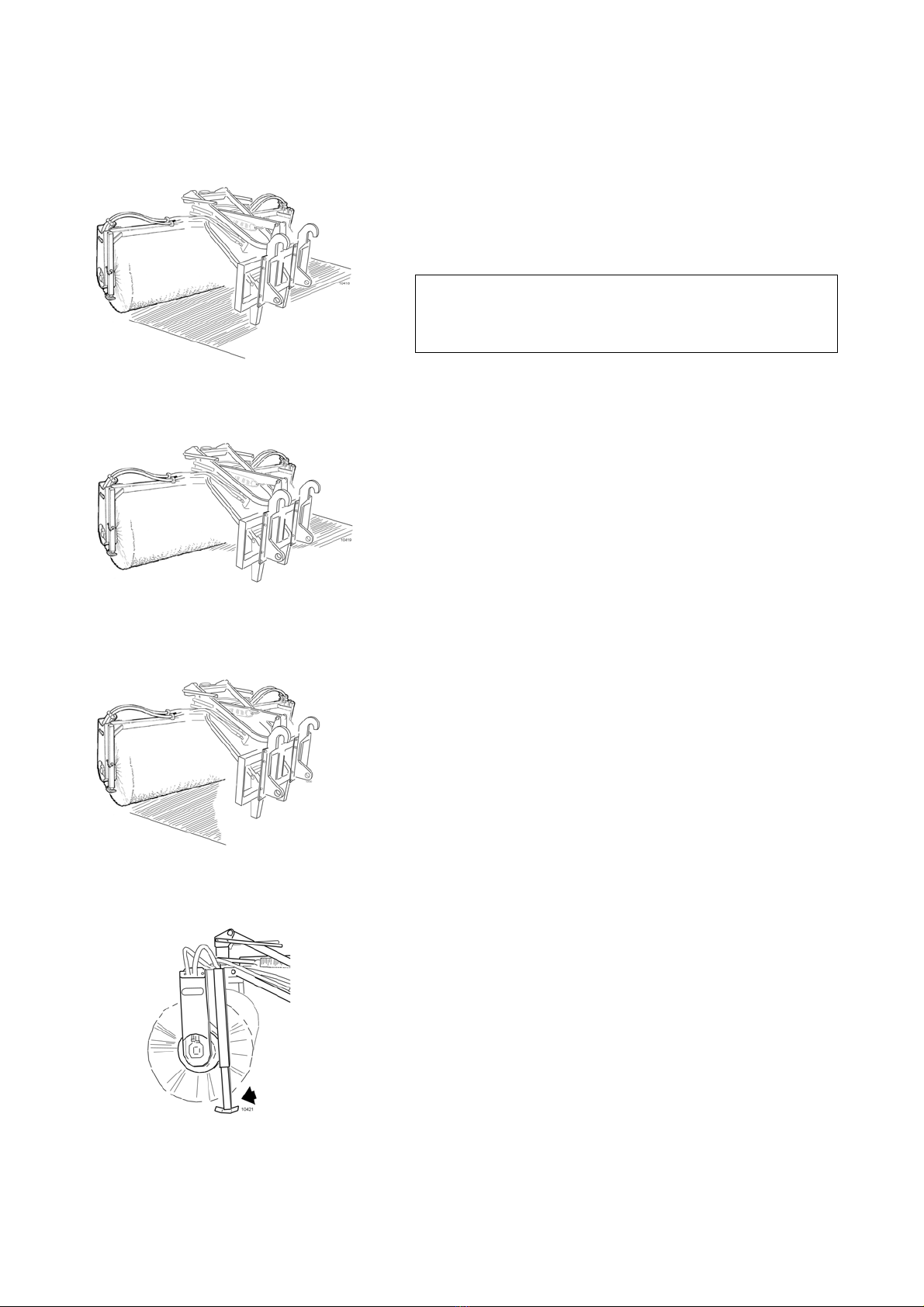

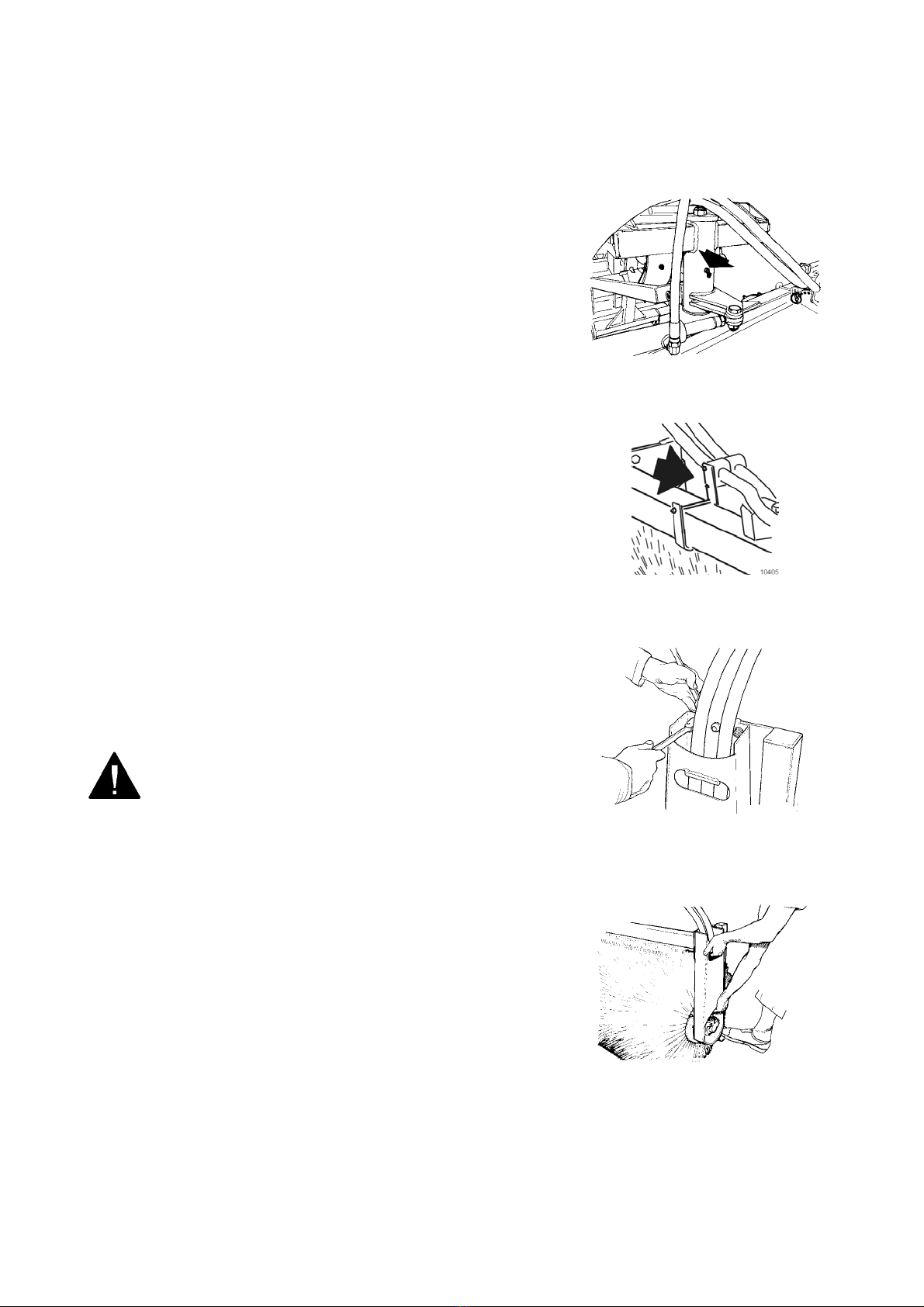

Disconnecting from carrier

1. Loosen the attachment bracket faucets before the sweeper is

placed on the ground to avoid damage on the suspension sys-

tem.

2. Lower and secure the support in parking position.

Attention! The sweeper brushes can be deformed if the sup-

ports are not used when sweeper is parked.

3. Put down the sweeper on the ground.

4. Loosen the quick couplings for the 3:rd and 4:th hydraulic

functions alternatively hydraulic motor circuit and the cable.

8. Sweeper with even ground pressure

10. Sweeper tilted forwards

11. Supports in parking position

9. Sweeper tilted backwards