Introduction

KSO 790 | Version 3.02 3

1 Introduction

You have made a good choice by purchasing the Edge

milling machine made by HOLZSTAR.

Thoroughly read the operating instructions before

commissioning the machine.

It informs you about the proper commissioning, the in-

tended use as well as the safe and efficient operation

and maintenance of the Edge milling machine.

The operating instructions are part of the Belt & spindle

sanding machine. Always keep it at the place of use of

the Edge milling machine. Furthermore, the local acci-

dent prevention regulations and the general safety notes

are applicable for the field of application of the Edge mil-

ling machine.

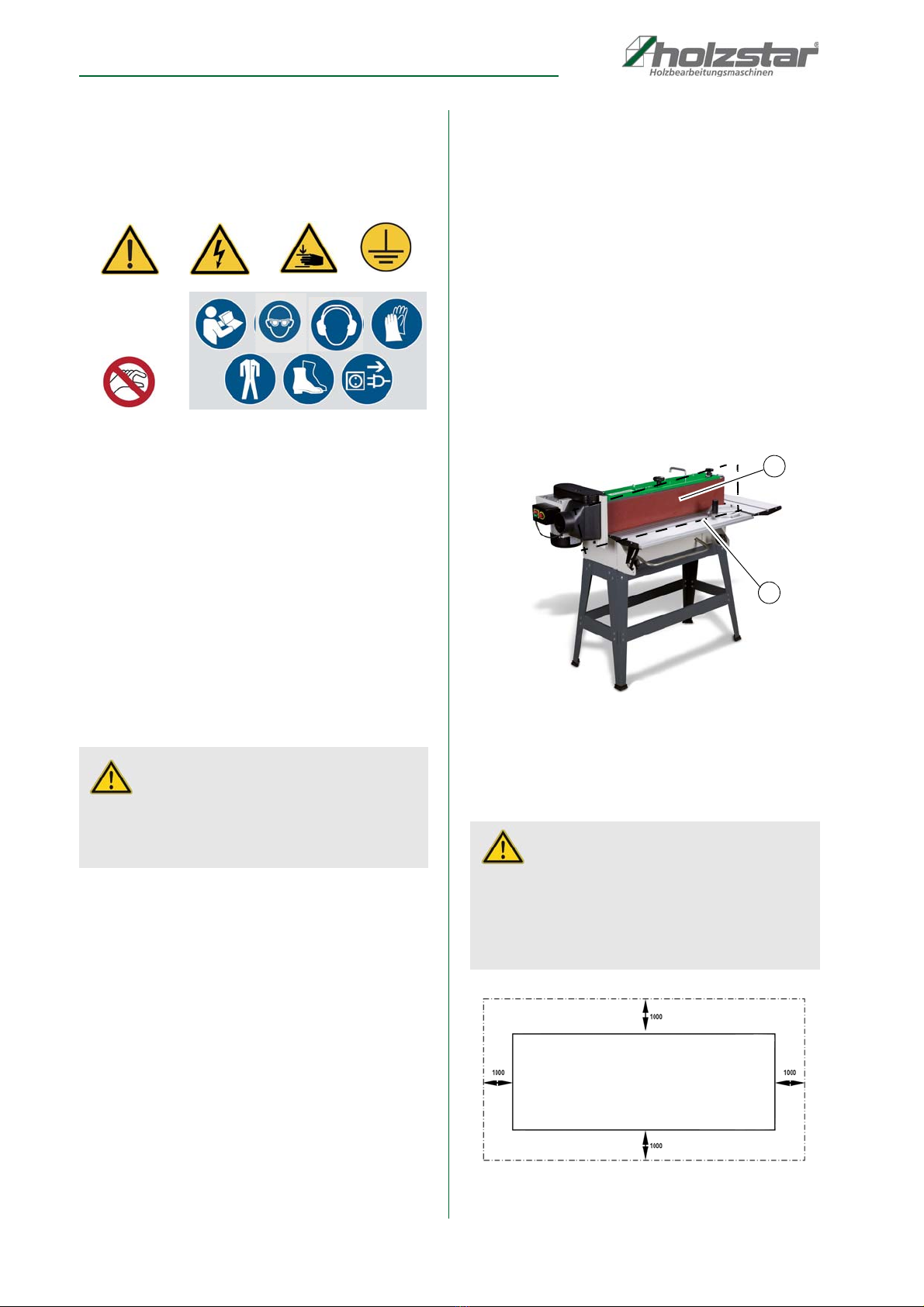

The illustrations in these operating instructions serve the

general comprehension and may deviate from the actual

type.

1.1 Copyright

The contents of these instructions are copyright. Their

application is admissible in the frame of the device. An

application beyond the described application is not allo-

wed without written approval of the manufacturer.For the

protection of our products, we shall register trademark,

patent and design rights, as this is possible in individual

cases. We strongly oppose any infringement of our intel-

lectual property.

1.2 Customer service

Please contact your dealer if you have questions on the

machine or if you need technical advice. They will help

you with specialist information and expert advice.

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair service:

Fax: +49 (0) 951 96 555 - 55

E-Mail: service@stuermer-maschinen.de

Internet: www.holzstar.de

Spare part orders:

Fax: 0951 96555-119

E-Mail: ersatzteile@stuermer-maschinen.de

We are always interested in valuable experience and

knowledge gained from using the application, which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised taking the applicable standards and

rules, the state-of-the-art and our long-term knowledge

and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use

- Use of untrained staff,

- Unauthorised modifications

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the expla-

nations and presentations described here in case of spe-

cial models, when using additional ordering options or

due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery conditi-

ons of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This paragraph will give you an overview of all important

safety packages for the protection of the people using it

well as for a safe and undisturbed operation. Other task-

based safety notes are included in the individual chapters.

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are introduced by

signal words which express the concern of the risk.

DANGER!

This combination of symbol and signal words indi-cates

an imminently dangerous situation which may lead to

death or severe injuries if they are not avoi-ded.

WARNING!

This combination of symbol and signal word indicates

a potentially dangerous situation that can lead to

death or serious injury if not avoided.