Transport, Packaging, Storage

KSO 850 | Version 2.08 9

5 Transport, Packaging, Sto-

rage

5.1 Delivery and Transport

Delivery

Check the Edge milling machine for visible transport da-

mage after delivery. If you discover any damage to the

Edge milling machine, immediately report it to the trans-

port company or the dealer.

Transport

Improper transport is accident-prone and can cause da-

mage or malfunctions for which we do not grant any liabi-

lity or guarantee.

Transport the scope of delivery secured against shifting

or tilting with a sufficiently dimensioned industrial truck to

the installation site.

General risks during internal transport

Devices may only be transported by authorized and qua-

lified persons. Act responsibly during transport and al-

ways consider the consequences. Refrain from daring

and risky actions.

Gradients and descents (e.g. driveways, ramps and the

like) are particularly dangerous. If such passages are

unavoidable, special caution is required.

Before starting the transport check the transport route for

possible danger points, unevenness and disturban-ces

as well as for sufficient strength and load capacity.

Danger points, unevenness and disturbance points must

be inspected before transport. The removal of danger

spots, disturbances and unevenness at the time of trans-

port by other employees leads to considerable dangers.

Careful planning of internal transport is therefore essential.

Transport with a forklift / pallet truck:

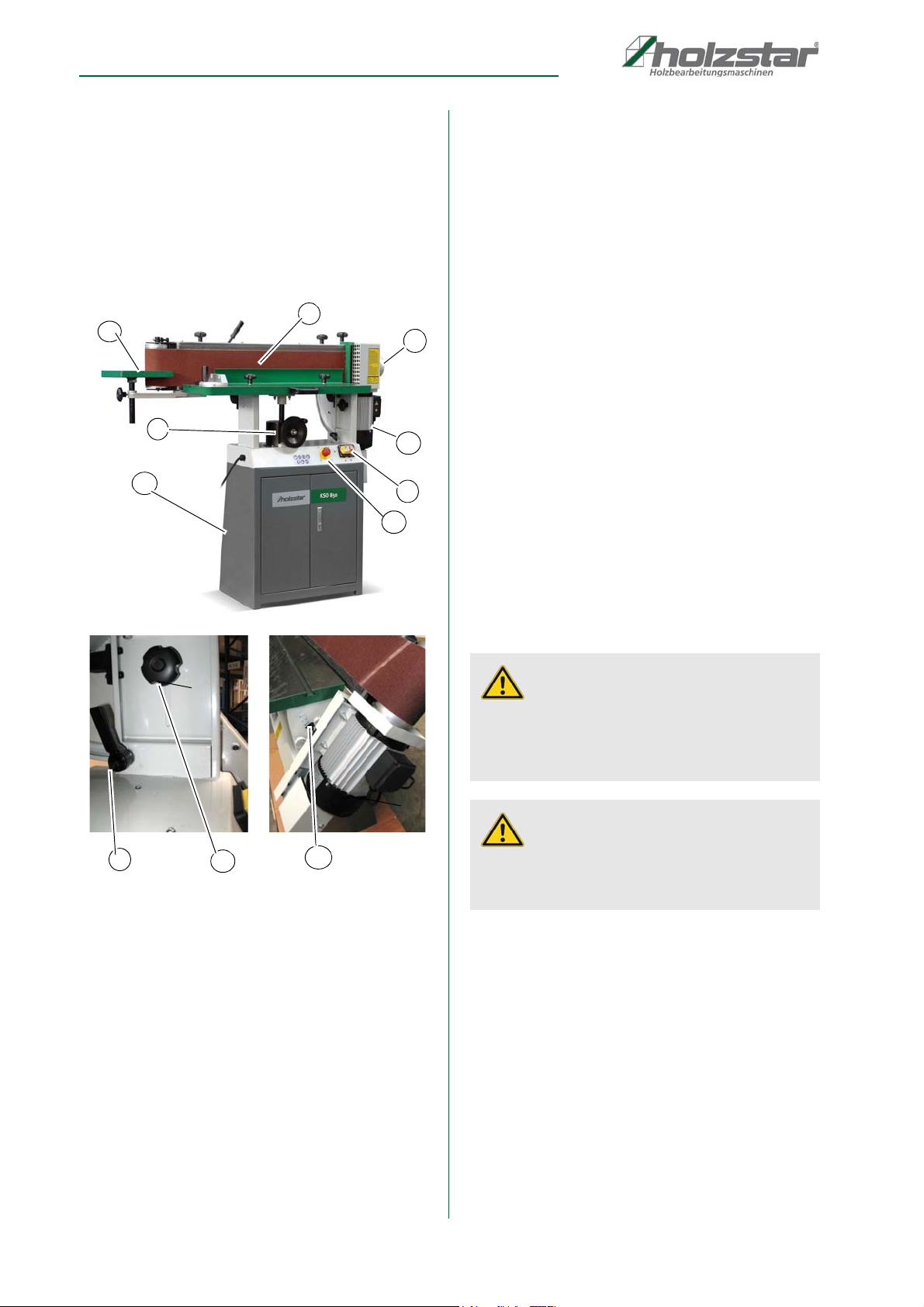

The edge sanding machine can be transported with a

forklift or pallet truck if it is firmly mounted on a pallet.

Transport with a crane:

Step 1: Attach 2 ropes with sufficient carrying capacity to

the crane hook and to the points of the edge

grinding machine suitable for transport.

Step 2: Carefully lift and transport the edge sanding ma-

chine with the crane.

5.2 Packaging

All packaging materials and packaging aids used by the

Edge milling machine are recyclable and must always be

recycled.Packing components made of cardboard are

crushed to waste paper collection.

The foils are made of polyethylene (PE) and the uphol-

stery parts made of polystyrene (PS). You can hand over

these substances to a recycling center or to the disposal

company responsible for you.

The packaging material must not get into the hands of

children, as some plastic packaging may present a suf-

focation hazard when used as a toy.

WARNING!

Severe or fatal injuries may occur if parts of the

machine tumble or fall down from the forklift

truck, pallet truck or from the transport vehicle.

Follow the instructions and information on the trans-

port box.

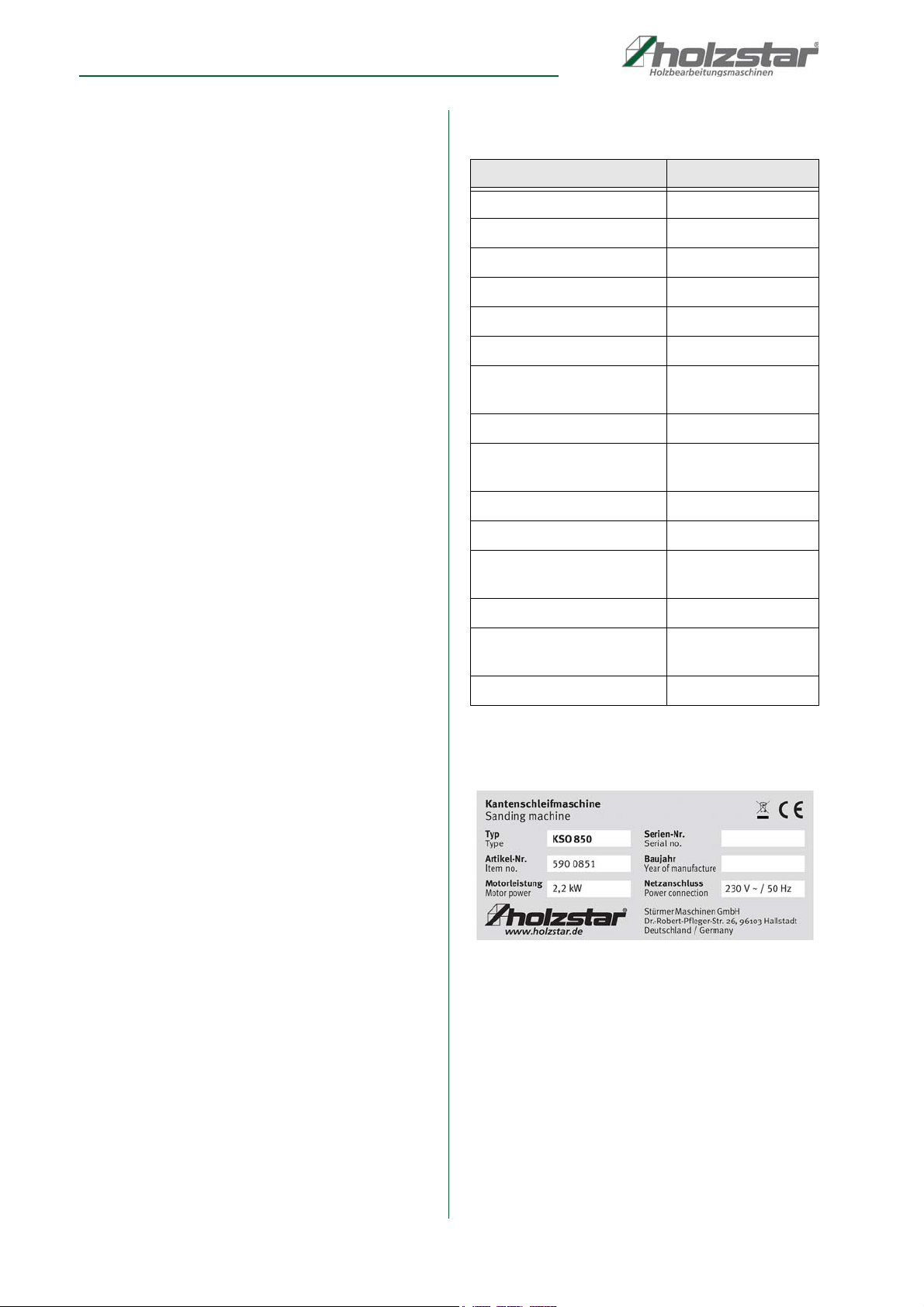

Note the total weight of the machine. The weight of

the machine is indicated in the "Technical data" of the

machine. When the machine is unpacked, the weight

of the machine can also be read on the rating plate.

Only use transport devices and load suspension gear

that can hold the total weight of the machine.

WARNING!

The use of unstable lifting and load suspension

equipment that might break under load can cause

severe injuries or even death. Check that the lifting

and load suspension gear has sufficient load-bea-

ring capacity and that it is in perfect condition.

Observe the accident prevention regulations issued

by your Employers Liability Insurance Association or

other competent supervisory authority, responsible

for your company.

Fasten the loads properly.

WARNING: DANGER OF TIPPING

The device may be lifted unsecured by a maximum

of 2cm.

Employees must be outside the danger zone, the

reach of loads.

Warn employees and, if necessary, advise employ-

ees of the hazard.