IntelliSense and DUAL TEC are registered trademarks of

Honeywell, Inc.

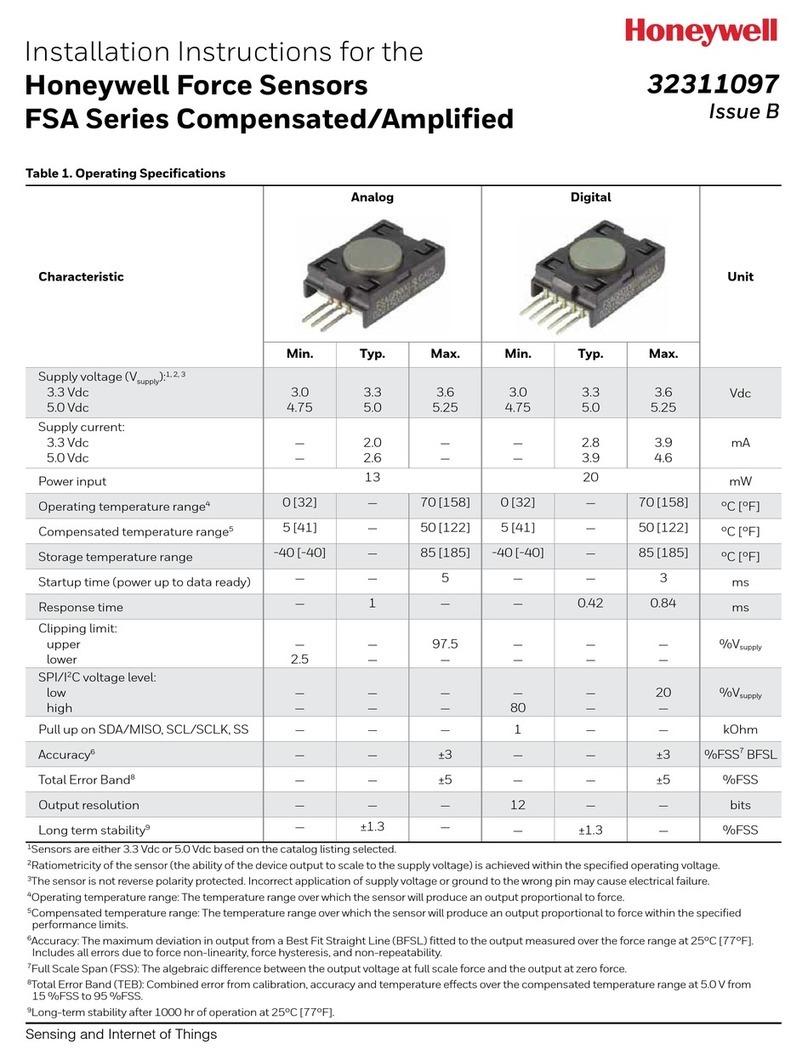

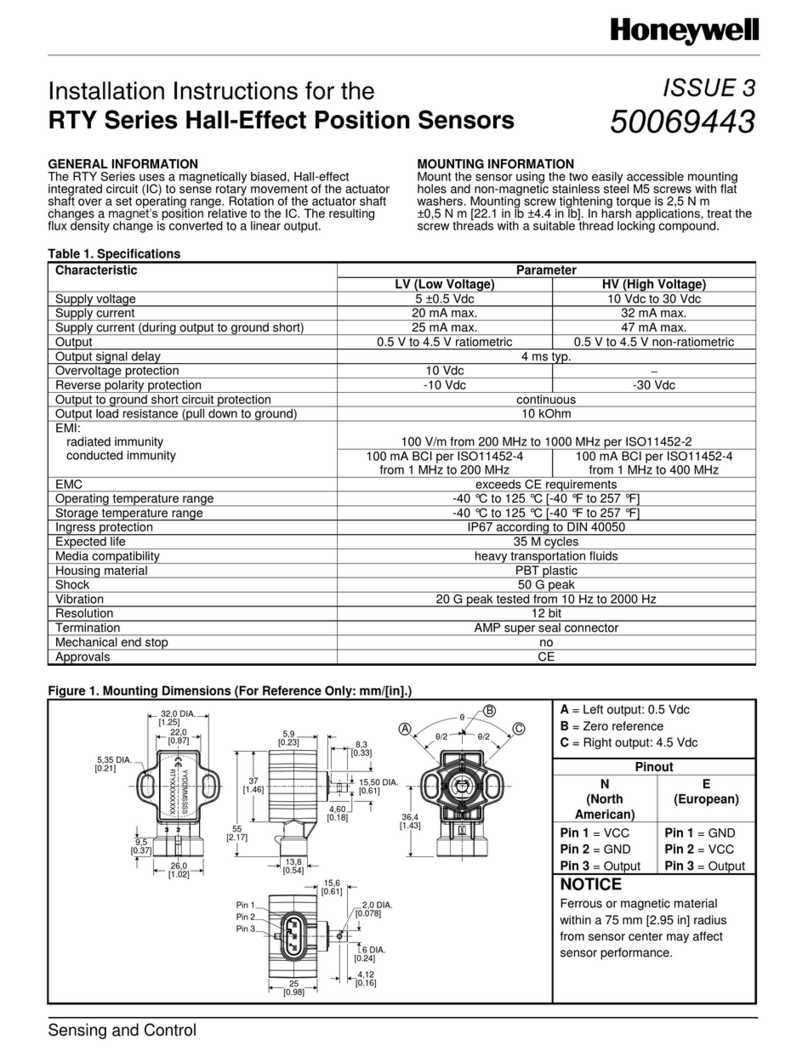

PRODUCT SPECIFICATIONS

Range:

DT-500, DT-500T

11 m x 9 m 35' x 30')

Alarm relay:

Energized Form A NC)

100 mA, 30 VDC

Tamper:

25 mA, 30 VDC

Power requirements:

10 - 14.5 VDC

35 mA, 12 VDC

RFI immunity:

30 V/m

10 MHz - 1000 MHz

PIR white light immunity:

6,500 Lux

Frequen ies:

Center band 2.45 GHz

Sensitivity:

2 - 4 steps within field of

view

SUPERVISION

If the microwave technology stops sending or receiving

signals, or the system electronics are not in normal working

order, the sensor's red LED will latch ON and alarm relay will

open.

The sensor can only recover from this state by cycling power.

If the problem still exists after cycling power, the sensor will

fail the power-up self-test, the red LED will latch ON, and

alarm relay will open. Self-test is performed at power-up and

every two hours after that.

NOTE: The sensor should be tested at least on e ea h year

to ensure proper operation.

DT-500 Series DUAL TEC® Motion Sensor Supplemental Information

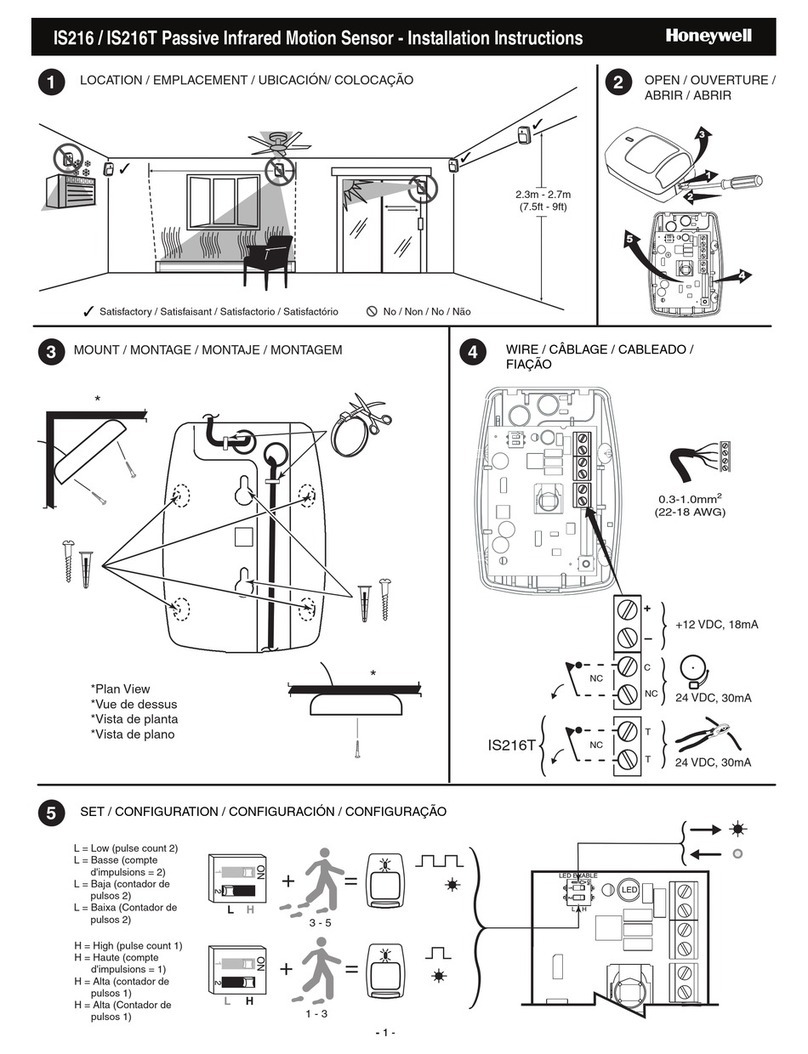

DETECTION PATTERNS

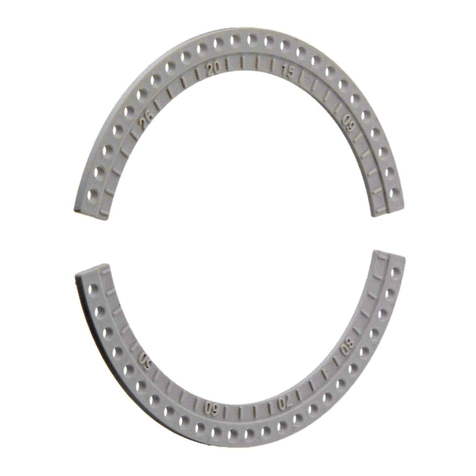

TOP VIEW

Wall Mounted

Wide Angle Lens with Microwave Pattern

SIDE VIEW

Wide Angle Lens

FCC Noti e: This equipment has been tested and found to comply with

the limits for a field disturbance sensor, pursuant to Part 15 of the FCC Rules.

The user is cautioned that changes or modifications not expressly approved

by IntelliSense could void the user's authority to operate this equipment.

This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. How-

ever, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more

of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

IC Noti e: Operation is subject to the following two conditions: 1) this

device may not cause interference, and 2) this device must accept any

interference, including interference that may cause undesired operation of

the device.

This device requires a radio licence, unless it is installed totally inside a

building. User must obtain this licence.)

Une licence est requise pour ces dispositifs, sauf pour ceux installés tout à fait

à l'intérieur d'un bâtiment. Il faut que l'utilisateur obtienne cette licence.)

All Rights Reserved

Copyright 2001 IntelliSense.

5-051-502-00 Rev H

Operating temperature:

-10° to 49° C 14° to 120° F)

UL: 0o to 49o C 32o to 120o F))

PIR fields of view (edges):

Standard lens

22 long range

12 intermediate

6 lower

4 down

Dimensions:

13 cm x 7 cm x 4 cm

5" H x 2-7/8" W x 1-5/8" D

Weight:

200 g 7 oz)

Packaged product:

260 g 9 oz)

Approvals/listings:

FCC certified

IC certified

UL listed

ULC Listed*

C-Tick

IMPORTANT: This sensor does not respond to walk-tests

in a conventional manner. Rather, it tracks motion and

analyzes the signals to confirm a valid alarm condition.

Internally the sensor registers, then confirms an alarm con-

dition. To observe this, take 2 to 4 steps into the pattern then

stop and watch the LED.

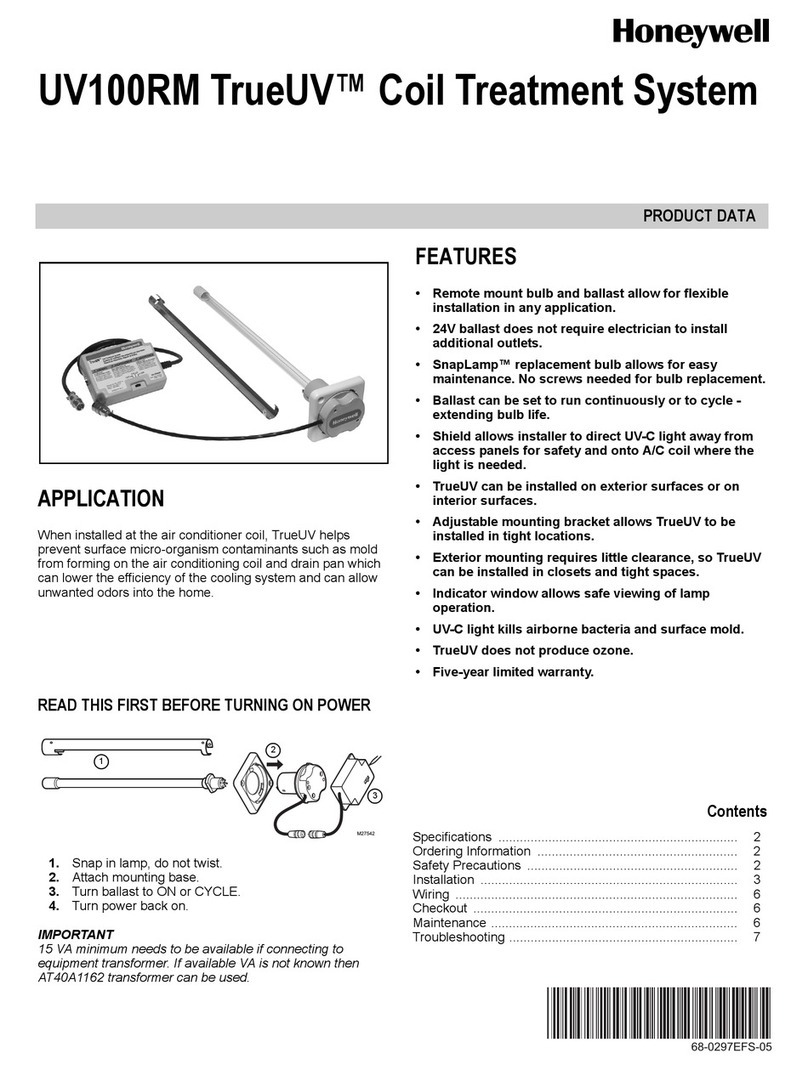

ANIMAL IMMUNITY

To achieve the highest level of attainable animal immunity,

please use the following recommended mounting guide-

lines:

Mount the sensor at the standard height of 2.3 m

7' 6").

Make sure an animal cannot get within 1.9 m 6')

of the sensor, such as by jumping on furniture or

shelving.

Make sure the sensor is level with the wall. Use

a leveling tool and position it vertically across

the face of the sensor. Improper installation can

reduce animal immunity levels.

Make sure the sensor has a clear line-of-sight to all

areas you wish to protect. If the PIR sensor is blocked,

the unit will not alarm.

Aim the sensor toward the interior of the room, point-

ing away from windows, moving machinery, and heat-

ing/cooling sources.

Each installation should be tested to determine the level of

attainable animal immunity, and tested again whenever the

animal configuration changes. The following worksheet

provides additional guidelines for determining the level of

expected immunity:

NOTE: Animal immunity characteristics have not been verified by

Underwriter's Laboratories, Inc.

IMPORTANT: For UL certificated installations, the DT-500 must be con-

nected to a UL listed power supply or UL listed control unit capable of

providing a minimum of four hours of standby power.

*NOTE: The ULC label or listed marking on a product is the only evidence

provided by Underwriters Laboratories of Canada to identify products that

have been produced under the Listing and Follow-up Service.

This Class B digital apparatus meets all requirements of the Canadian

Interferen e-Causing Equipment Regulations.

Cet appareil numérique de la lasse B respe te toutes les exigen es du

Règlement sur le matériel brouilleur du Canada.

SUPERVISION

If the microwave technology stops sending or receiving

signals, or the system electronics are not in normal working

order, the sensor's red LED will latch ON and alarm relay will

open.

The sensor can only recover from this state by cycling power.

If the problem still exists after cycling power, the sensor will

fail the power-up self-test, the red LED will latch ON, and

alarm relay will open. Self-test is performed at power-up and

every two hours after that.

NOTE: The sensor should be tested at least on e ea h year

to ensure proper operation.

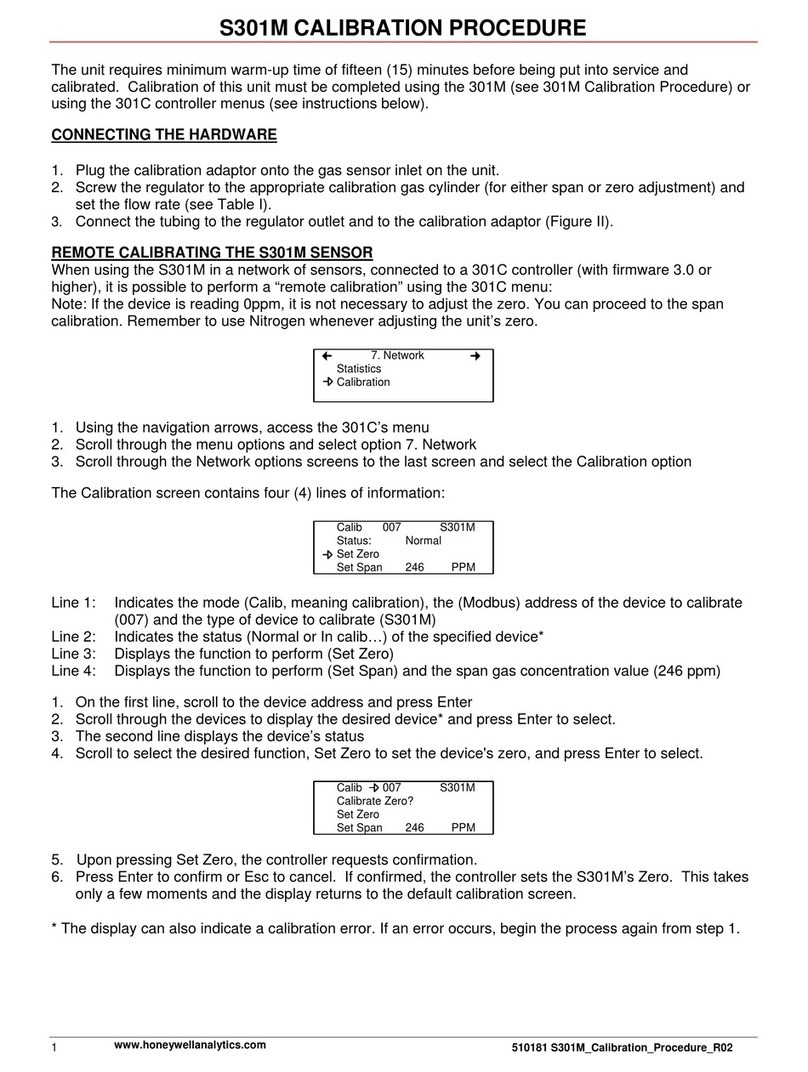

ANIMAL IMMUNITY WORKSHEET

Total combined animal weight s) 45 kg 100 lb.)

Flooring Material: Flooring materials within the sensors field-

of-view will effect the levels of animal immunity. Generally, a

carpeted floor will achieve a higher level of immunity than a

cement floor.

Carpet: deduct 0

Wood: deduct 2.25 kg 5 lb.)

Tile/Cement: deduct 4.5 kg 10 lb.) -

___________

Animal Heat Radiation*: Generally, the longer the hair on

an animal, the less heat or infrared energy they radiate. A

long hair animal tends to achieve a higher level of animal

immunity than a short hair animal.

Long Hair: deduct 0

Medium Hair: deduct 2.25 kg 5 lb.)

Short Hair: deduct 4.5 kg 10 lb.) -

___________

Estimated animal immunity level =

___________

*Use in installations with dogs and cats.