www.maxoncorp.com

combustion systems for industry

Maxon reserves the right to alter specifications and data without prior notice.

© 2013 Copyright Maxon Corporation. All rights reserved.

3 - 18.4 - 8

E-i-5/13 Dual fuel burners - OXY-THERM®FHR

Ratio control requirements

Correct fuel/oxygen ratio control valves should be selected. Trims should be selected to enable use with oxygen. For accurate ratio

control, MAXON SMARTLINK®MRV valves are recommended. Calibrated flowmeters in the fuel and the oxygen lines are

required for establishing accurate volumetric flow rates.

Emission performance

OXY-THERM®FHR burners utilize a patented oxygen staging technology to reduce the formation of NOx in high temperature

furnaces. Through deep staging of the oxidant flow, NOx is controlled to levels typically lower than less advanced oxy-fuel burners.

Best results are achieved in furnaces which are sealed tight from ambient air infiltration or running a slight positive pressure to

prevent the infiltration of nitrogen compounds. Results can vary widely by application. Contact MAXON for estimates and

consultation on best practice.

Exact emissions performance may vary in your application. Contact MAXON for installation-specific estimates and guaranteed

values. No guarantee of emissions is intended or implied without specific, written guarantee from MAXON.

Combustion oxygen and cooling flow

OXY-THERM®FHR burners may be adjusted to operate on ratio, with excess oxygen (oxidizing environment) or with excess fuel

(reducing environment). Typical applications will operate with 1-2% excess oxygen.

If burners are shut down while the furnace remains hot, it is recommended to continue a small flow of oxygen for cooling of the

burner. Alternatively, blower or fan air or can be used for burner cooling during burner shut down. Total elimination of cooling flow in

hot furnaces can result in damage to burner fuel inserts and other parts. For extended shut downs in hot furnaces, it is

recommended that the fuel insert be removed and cooling flow maintained through the burner housing.

Staging ratio control

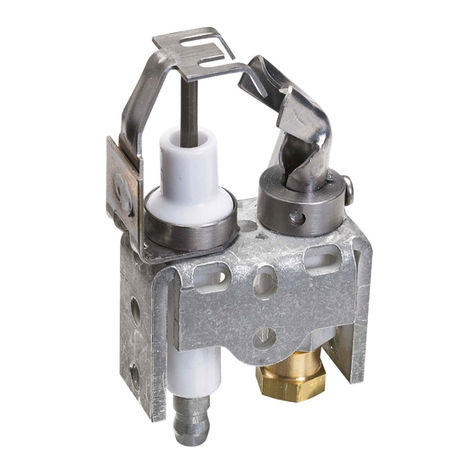

OXY-THERM®FHR burners feature an adjustable staged oxygen design to optimize heat transfer, flame volume and emissions.

Increasing the staged oxygen produces higher radiative heat flux, larger flame volume and lower NOx emissions; decreasing

staged oxygen produces lower radiative heat flux, smaller flame volume and higher NOx emissions. The numbered hole positions

(1-11) shown on the drawing below correspond with the hole positions indicated on the primary/staged oxygen valve adjustment

graphs available from your MAXON sales representative.

Oxy-fuel burners cannot be set up and operated properly using only pressure measurements for

adjustment. Fully metered oxygen and fuel control systems are required for safe and optimum

performance.

1) Increasing staged

oxygen = higher

radiative heat flux

2) Decreasing staged

oxygen = lower

radiative heat flux