Honeywell XPO Series User manual

Other Honeywell Burner manuals

Honeywell

Honeywell Q349A Series User manual

Honeywell

Honeywell Hauck MEGASTAR MS-25 User manual

Honeywell

Honeywell CS8800 User manual

Honeywell

Honeywell PRO 2000 Series User manual

Honeywell

Honeywell TRADELINE Q314 User manual

Honeywell

Honeywell Eclipse Winnox WX Series User manual

Honeywell

Honeywell Maxon VALUPAK-II User manual

Honeywell

Honeywell Q345U User manual

Honeywell

Honeywell Q179A Operation manual

Honeywell

Honeywell TRADELINE Q314 Operation manual

Honeywell

Honeywell Eclipse ImmersoJet Guide

Honeywell

Honeywell MAXON VALUPAK-II Series User manual

Honeywell

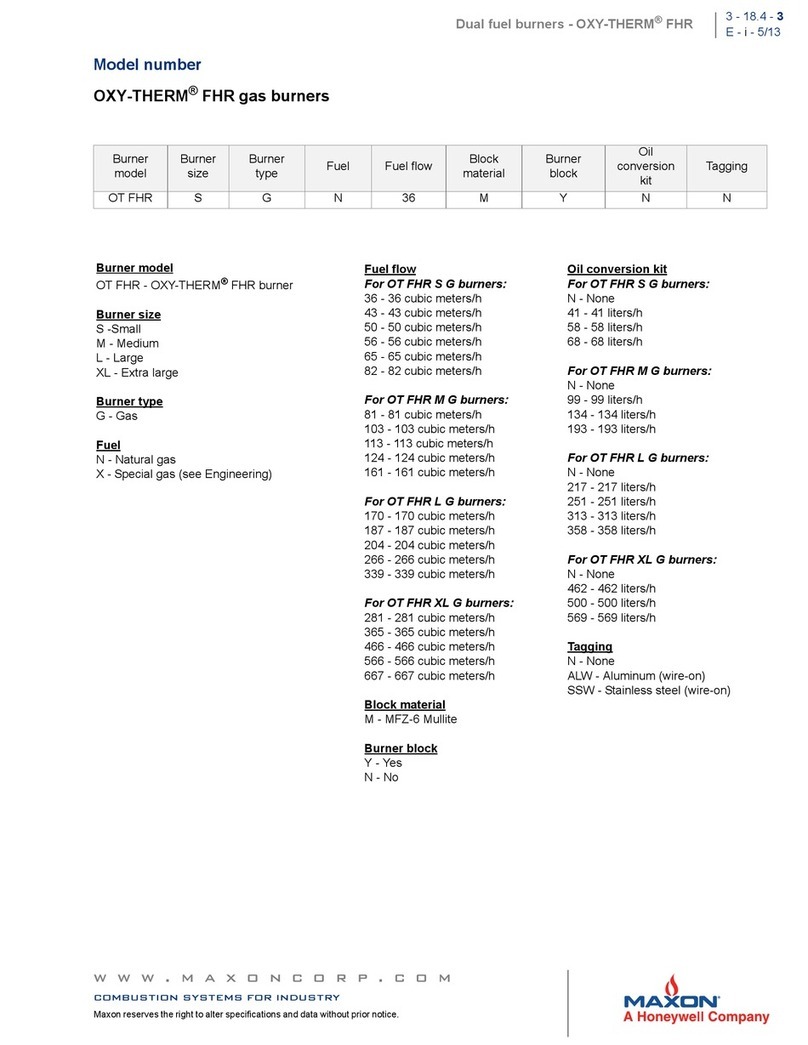

Honeywell Maxon OT FHR User manual

Honeywell

Honeywell Ecomax 3M User manual

Honeywell

Honeywell Maxon OXYTHERM FHR User manual

Honeywell

Honeywell Eclipse WX0050 User manual

Honeywell

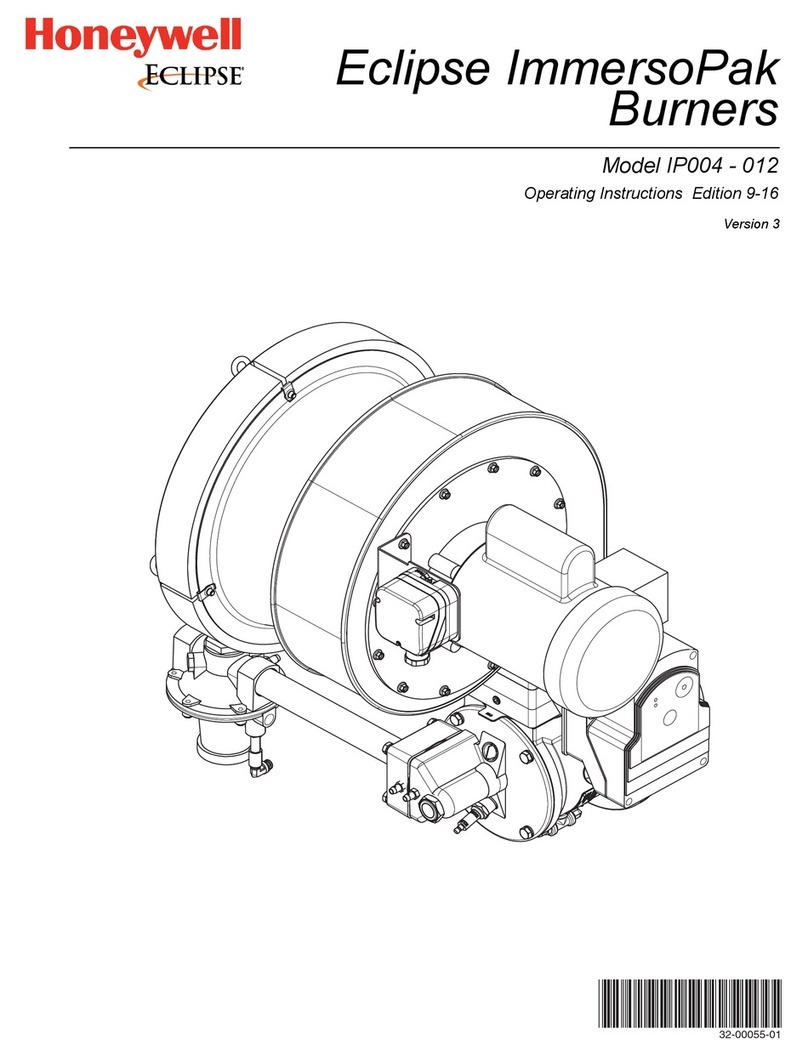

Honeywell Eclipse ImmersoPak IP005 User manual

Honeywell

Honeywell Ecomax Series Manual

Honeywell

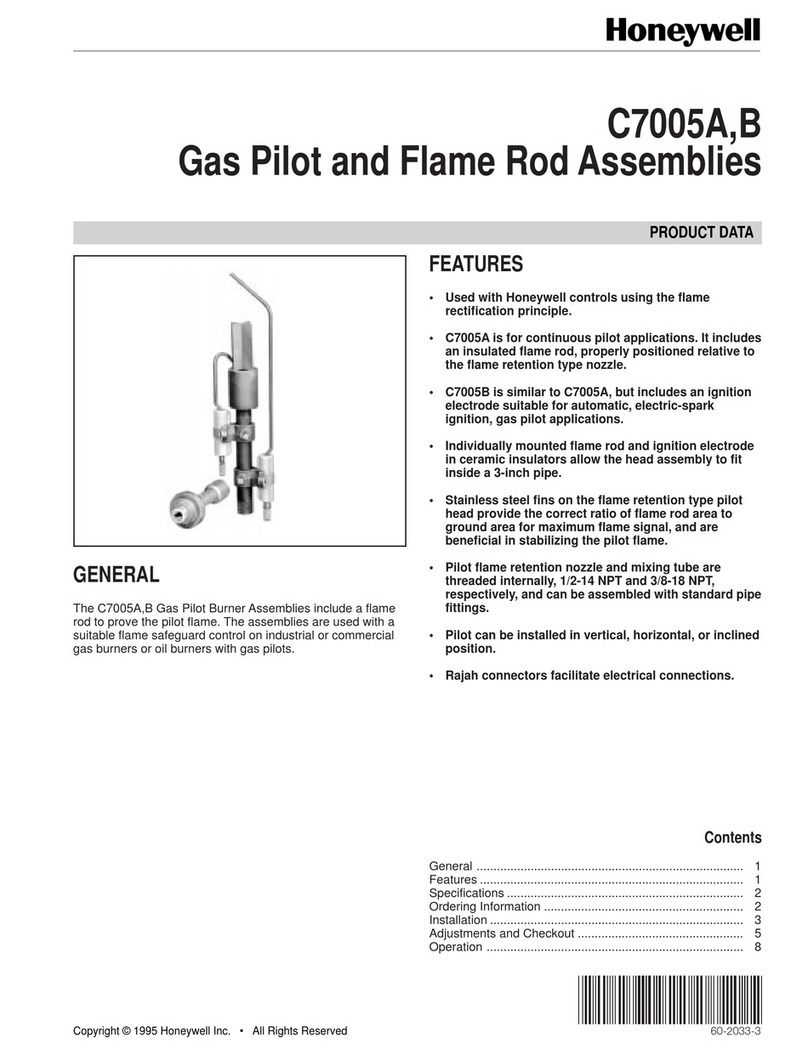

Honeywell C7005A Operation manual

Honeywell

Honeywell SmartValve Q3450A Operation manual

Popular Burner manuals by other brands

baltur

baltur BT 250 DSG 4T manual

muenkel design

muenkel design round burner Operating and installation instructions

baltur

baltur BT 14 DSGW Instruction

artisan

artisan Art-SB1 Care & use manual

AESYS

AESYS TurboFire II Installation, operation and maintenance manual

Riello

Riello RG1RKD Installation, use and maintenance instructions