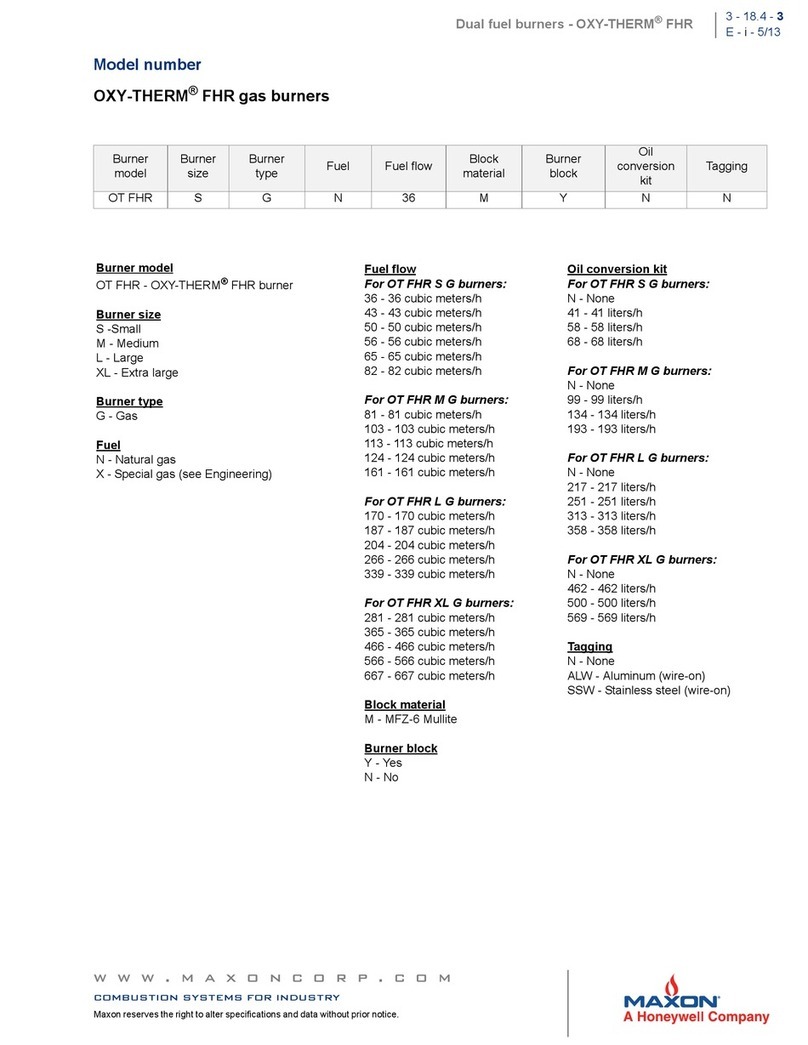

OXYTHERM®FHR DUAL FUEL BURNERS

E - i - 7/99 532M-92012—02

Start-up

Typical ignition sequence

IMPORTANT

OXYTHERM® FHR burners do not include means

for self ignition. Burner ignition procedure is the

responsibility of the end user, according to appli-

cable local, state and national codes. Burner igni-

tion should only be attempted at minimum firing

rates (see capacity charts or contact MAXON) to

prevent pressure surge in the fired chamber.

Checks during and after start-up

During and after start-up, check the integrity of the

system. Check all bolted connections after first firing (first

time on temperature) and retighten if necessary.

Burner adjustment and control

Oxygen-fuel burners require accurate control of both fuel

and oxygen for optimum performance. Piping to individual

burners should include control valves for both oxygen and

fuel. In addition, flow meters for oxygen and fuel capable of

local or remote readout are required for proper burner

adjustment.

Oxygen should only be used with approved

materials, properly cleaned pipe and equipment,

and specially designed systems.

Ordinary materials can be extremely flammable in

the presence of oxygen and air enriched with

oxygen.

Oxy-fuel burners cannot be set up and operated properly

using only pressure requirements for adjustment. Fully

metered oxygen and fuel control systems are required for

safe and optimum performance.

MAINTENANCE INSTRUCTIONS

The OXYTHERM® FHR burner is provided with

quick release clamps to allow for rapid change-

over between gas and oil firing.

ustomer-specific procedures for shut down and

blocking of fuel gas and oxygen supply to the

burner must be developed and adhered to prior to

attempting removal and changing of fuel inserts.

Only trained and qualified service and

maintenance personnel should perform this

operation.

Safety requirements

Regular inspection, testing and recalibration of

combustion equipment according to the installation

manual is an integral part of its safety. Inspection activities

and frequencies shall be carried out as specified in the

installation manual.

Perform the following activities at least annually as part of

a recommended preventative maintenance routine:

• Inspect burner internal parts for wear and oxidation.

• Inspect associated control instruments and devices for

function with particular attention to all safety

permissive switches.

• Perform leak tests on fuel shut-off valves according to

any schedule established by the authority having

jurisdiction.

Visual inspections

Regular visual inspection of all connections (air and fuel

piping to the burner, bolting of the burner to the block) and

burner flame size and aspect are essential.

Recommended spare parts

Keep local stock of operationally critical parts. Contact

MAXON for a complete list of recommended spare parts

for your specific application.