Page 4 of 24

1

1.

.2

2

E

El

le

ec

ct

tr

ri

ic

ca

al

l

C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

The RTU is powered at low voltage (12VDC 160mA), preferably using a

power supply module with battery backup (RTU-Qxx), or using an ordinary

power supply having the same characteristics. The power cables must be

dimensioned as indicated in the table below. The maximum allowable voltage

drop on the power cable is 1V.

• Cable length(m) = 1V / (I[A] load x 2 x (res [Ohm/km] /1000))

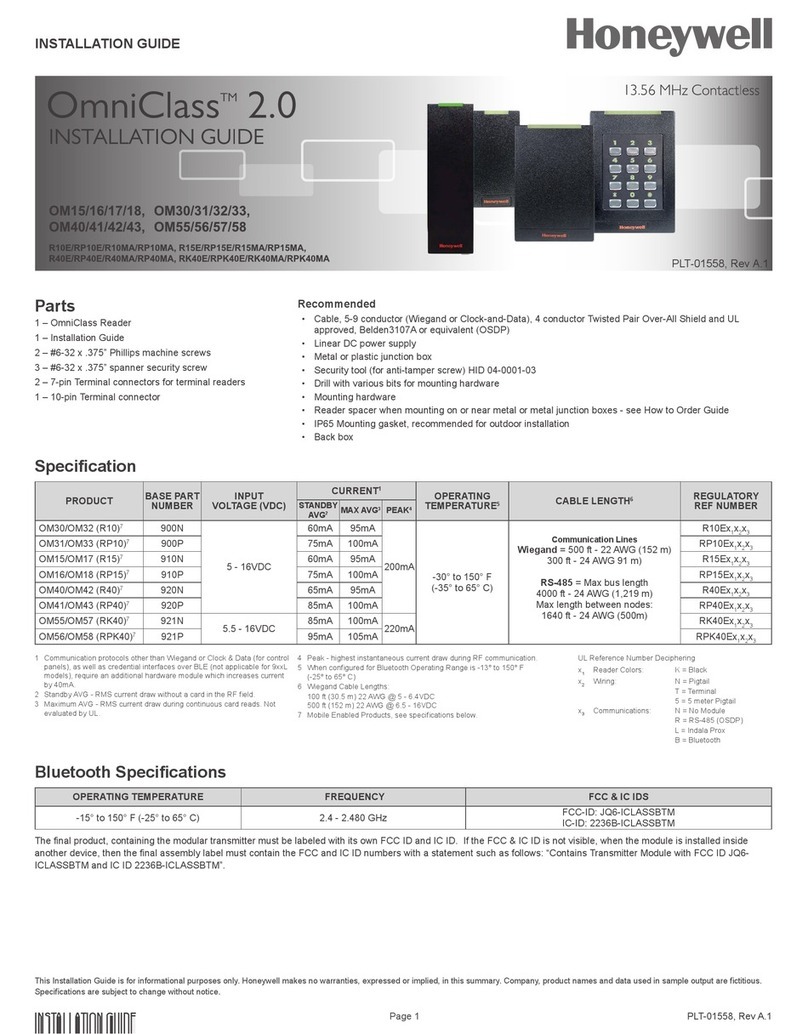

Cabl e Type Ext ensi on [ m] based on l oad

AWG mm2 ohm/ Km 160 [ mA] 320 [ mA]

12 3. 3 5. 7 548 274

14 2 8. 8 355 178

16 1. 3 14 223 112

18 0. 9 21 149 74

20 0. 6 34 92 46

22 0. 35 52 60 30

24 0. 2 85 37 18

The device is equipped with 2 non-removable cables of 2m length:

• Two-pole, twisted, unpolarized cable dedicated to the LON line

connection

- LON a 0,325 mm2white

- LON b 0,325 mm2orange

• Ten-pole cable, providing the following signals:

- +12VDC 0,34 mm2red

- GND 0,34 mm2black

- INPUT 1 + 0,22 mm2green / white

- INPUT 2 + 0,22 mm2gray / green

- RELAY 2 contact C 0,22 mm2brown

- RELAY 2 contact NC 0,22 mm2white

- RELAY 2 contact NO 0,22 mm2blue

- RELAY 1 contact C 0,56 mm2green

- RELAY 1 contact NC 0,56 mm2yellow

- RELAY 1 contact NO 0,56 mm2gray

The signals must be connected using a shunt box with IP protection level

in conformance with the type of environment in which it is to be used:

- IP55 for moist environments

- Recessed box or IP31 at least for inside installations

The shunt box must be positioned within the perimeter controlled by the

access control system.