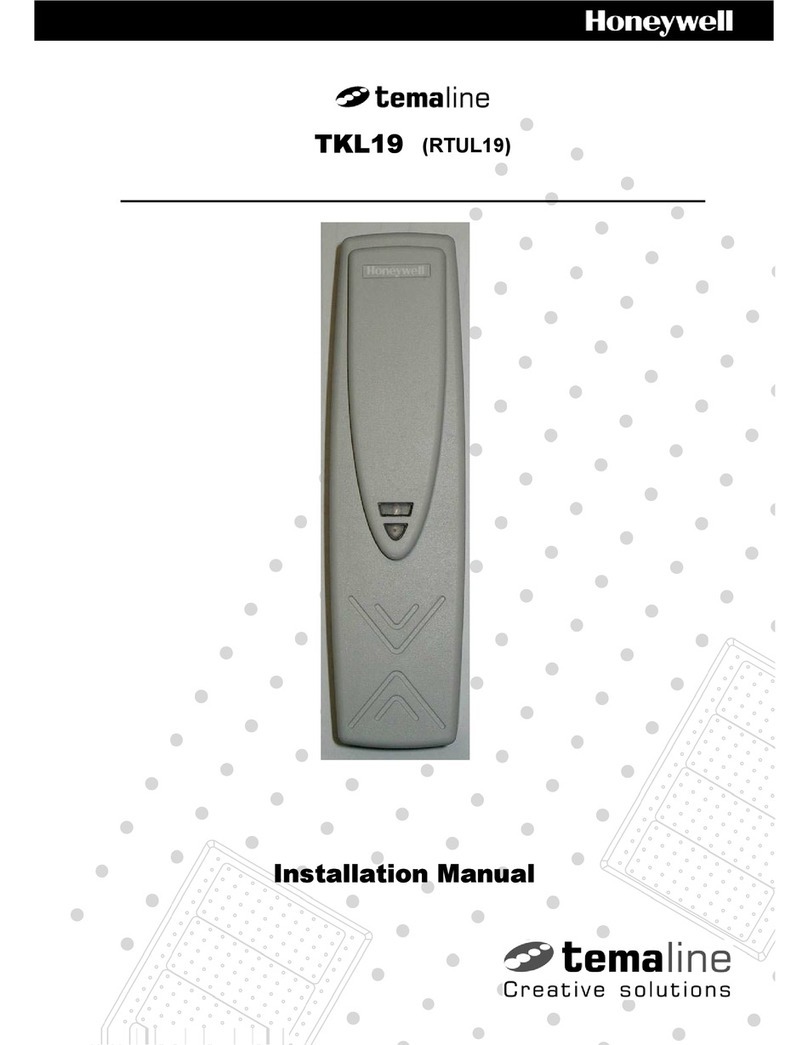

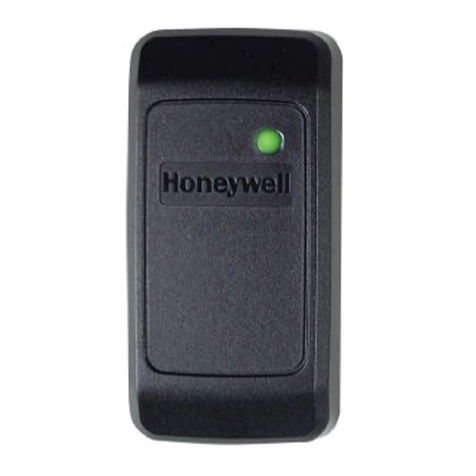

Honeywell IdentIPoint Intelligent Smartcard Readers

ASSEMBLY, MOUNTING AND INSTALLATION

Notes:

The reader and IOM can be mounted either

on a drywall or on a concrete wall using

conduits and a gang-box.

The drywall and gang-boxes shown here

are just representations of the actual

hardware. During installation, use the

hardware as per the required dimensions

and availability.

Reader

Drywall Mounting

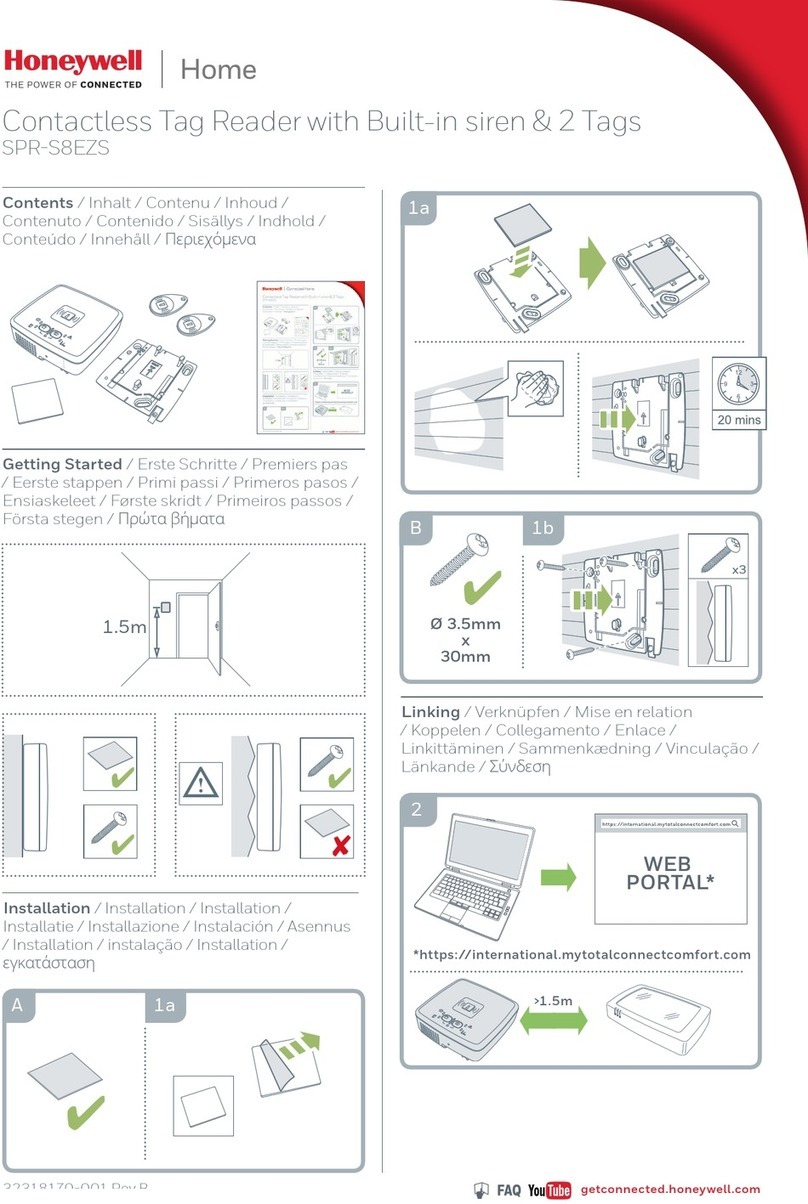

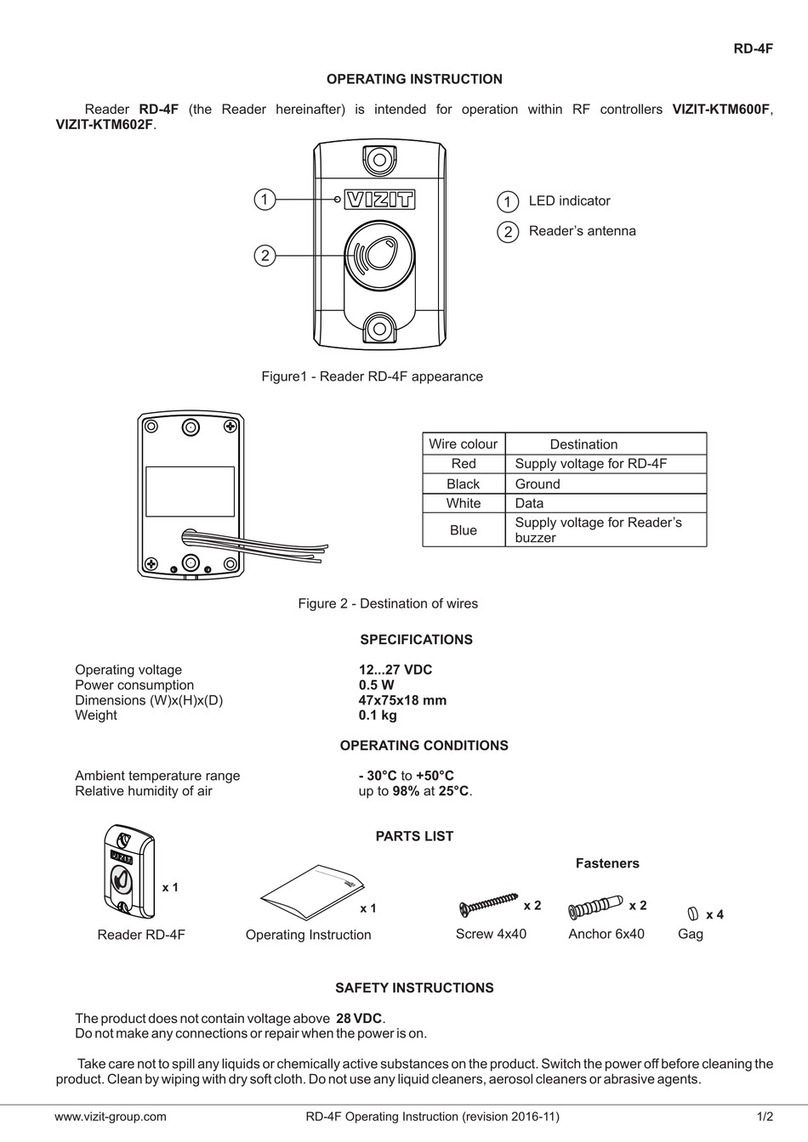

1. Fig.1 and Fig.2 show the parts of the

IdentIPoint reader. Use the back-plate of

the reader to mark out the position of the

reader on the drywall. Mark the positions of

the mounting screws and the opening for

routing the cables.

2. Cut the cable opening on the drywall using

suitable tools and punch an adequate

number of holes for the mounting screws. It

is advisable to use at least four screws for

fixing the reader. Use the wall anchors for

additional holding strength. See Fig.3.

3. Hold the back-plate in position on the

drywall. Align the mounting screws with

their holes and fasten the back-plate

securely on the drywall using the screws.

See Fig.3.

4. Route the field wires including the Ethernet

cable (if required) from behind the drywall

through the cable opening and bring them

to the front of the mounting surface. Clip

the square ferrite clip on the reader’s

Ethernet pigtail. See Fig.6. Connect the

field wiring to the correct Molex pigtails.

See Fig.5. For reader connection details

see Fig.10. Plug the Molex terminal(s) in

ports J9 and J10 at the back of the reader.

See Fig.6. Clip (with two turns wrapped)

the round ferrite clip on the field Ethernet

cable. See Fig.5. Plug the RJ45 connector

of the field Ethernet cable into the Ethernet

port of the reader at the end of the pigtail.

See Fig.6. Drop the excess lengths of

Molex and Ethernet wires behind the

drywall. Set the S1 DIP switch if the reader

is to be connected to an IOM via RS485.

See Fig.10 and appendix for more details.

5. Once all the connections and settings are

done, hold the reader against the back-

plate, aligning the mounting slots at the

back of the reader with their corresponding

catches on the back-plate and push it

downwards until it hooks into place firmly.

See Fig.7 and Fig.8.

6. Use the Allen wrench to tighten the tamper-

resistant screw at the bottom of the reader.

See Fig.9.

Gang-box (concrete wall) Mounting

1. Fig.1 and Fig.2 show the parts of the

IdentIPoint reader. Ensure that the correct

sized gang-box is securely embedded in

the concrete wall. The holes provided in the

gang-box for the screws should align

properly with at least two of the holes

provided in the reader back-plate for the

screws.

2. Hold the back-plate in position over the

gang-box. Align the mounting screws with

their holes and fasten the back-plate

securely on the gang-box using the screws.

See Fig.4.

95-7771

3