INSTALLATION INSTRUCTIONS

62-0182

® U.S. Registered Trademark

Copyright © 2002 Honeywell • All Rights Reserved

MS4120F, MS4620F, MS8120F

Fast-Acting, Two-Position Actuator

TANDEM MOUNTING

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

NOTES:

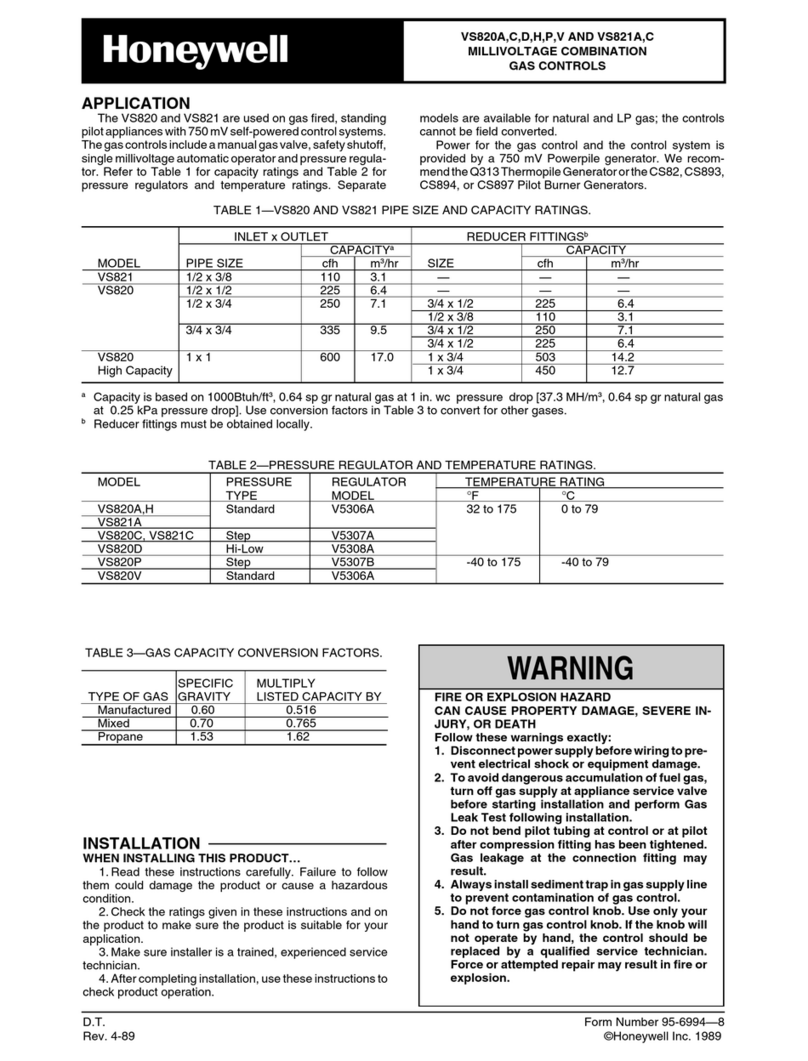

— Individual actuator specifications do not change

when tandem mounted. For specification details

see form 63-2584.

— A tandem mounted pair of actuators provides a

driving/spring return torque of 350 lb-in. and a

maximum stall torque of 850 lb-in. (96 N•m).

Required Accessories (not supplied with actuator):

205649 Mounting Bracket.

1/4 in.-20 bolt, 1 in. long, SAE grade 5 minimum.

1/4 in.-20 nut, SAE grade 5 minimum.

Location

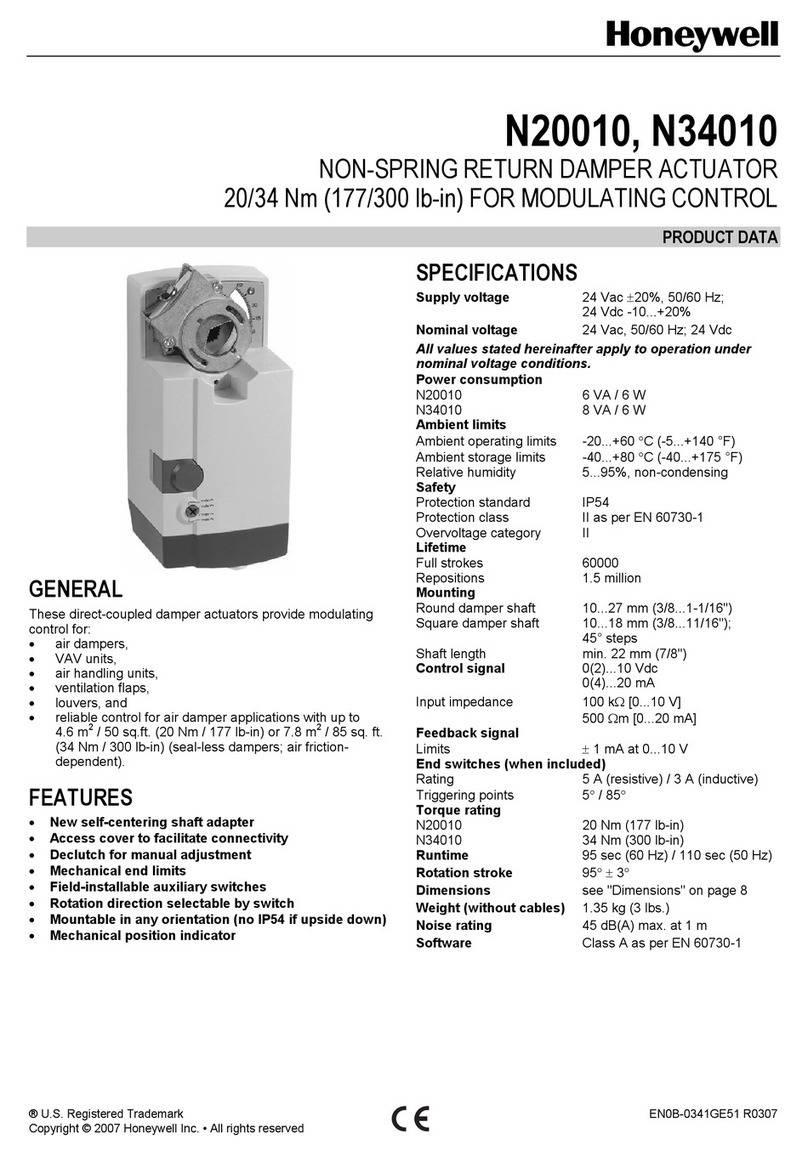

MS4120F, MS4620F, and MS8120F DCA are designed to

operate a damper by driving the shaft in either clockwise

or counterclockwise direction. Each actuator housing

has two slots on the bottom, either of which, with a 205649

Mounting Bracket, secures it flush to a damper box.

NOTE: When mounted correctly, these slots allow actuators

to float without rotating relative to the damper shaft.

Preparation

Before mounting actuators, determine the damper opening

direction for correct spring return rotation. The actuators can

be mounted to provide clockwise or counterclockwise spring

return.

Determine Appropriate Mounting Orientation

See actuator instructions (form 63-2584) for mounting

orientation details.

IMPORTANT

Be sure to mount both actuators to spring return in

the same direction.

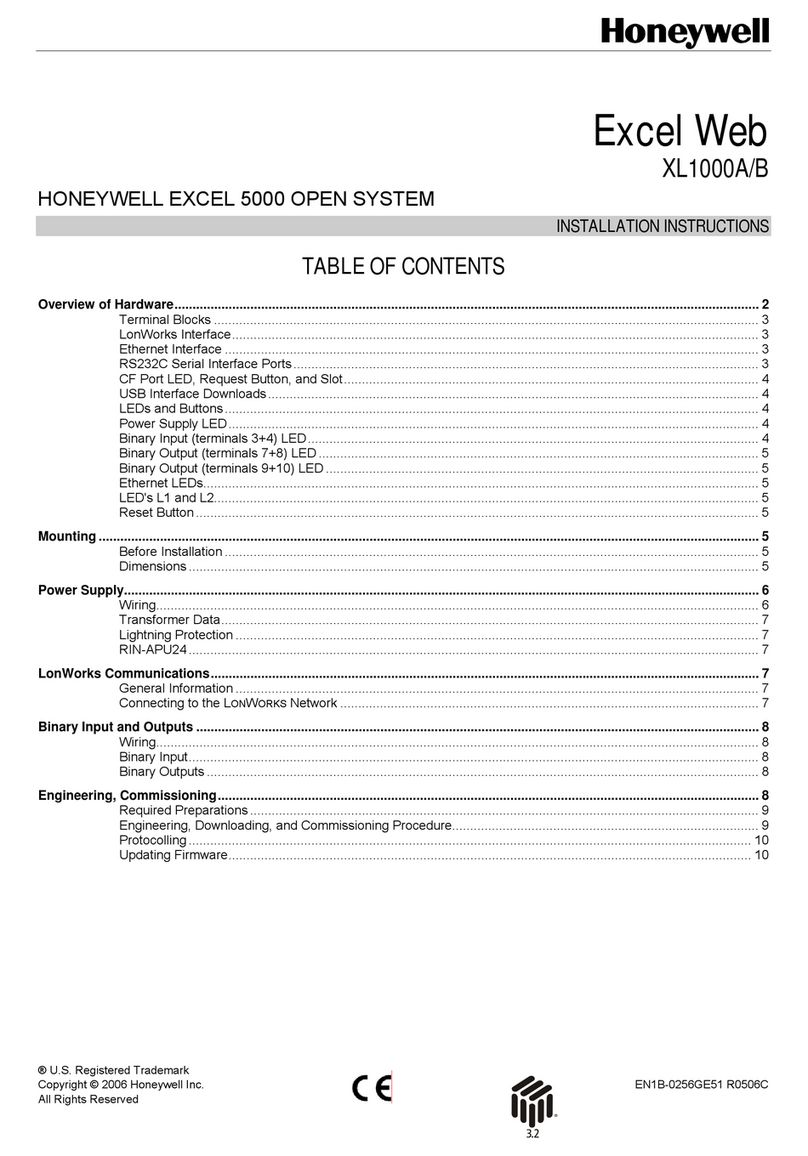

Measure Shaft Length

IMPORTANT

Minimum required shaft length for tandem mounting

is 4 in. Honeywell recommends a shaft length of at

least 6-1/4 in.

If the shaft is less than 6-1/4 in. long, the shaft coupling must

be located between the damper and actuator housing. If the

shaft length is more than 6-1/4 in., the shaft coupling may be

located on either side of the actuator housing.

If the coupling must be moved from one side of the actuator to

the reverse, follow the instructions provided with the actuator

(form 63-2584).

Mounting

CAUTION

Equipment Damage Hazard.

Tightly securing an actuator can damage the

actuator and reduce the output torque.

Mount each actuator to allow it to float independently

along its vertical axis.

CAUTION

Device Malfunction Hazard.

Improper shaft coupling tightening causes device

malfunction.

Tighten shaft coupling with proper torque to prevent

damper shaft slippage.

CAUTION

Actuator Damage Hazard.

Using actuator as shaft bearing causes device

damage.

Use actuator only to supply rotational torque. Avoid

any side loads to actuator output coupling bearings.