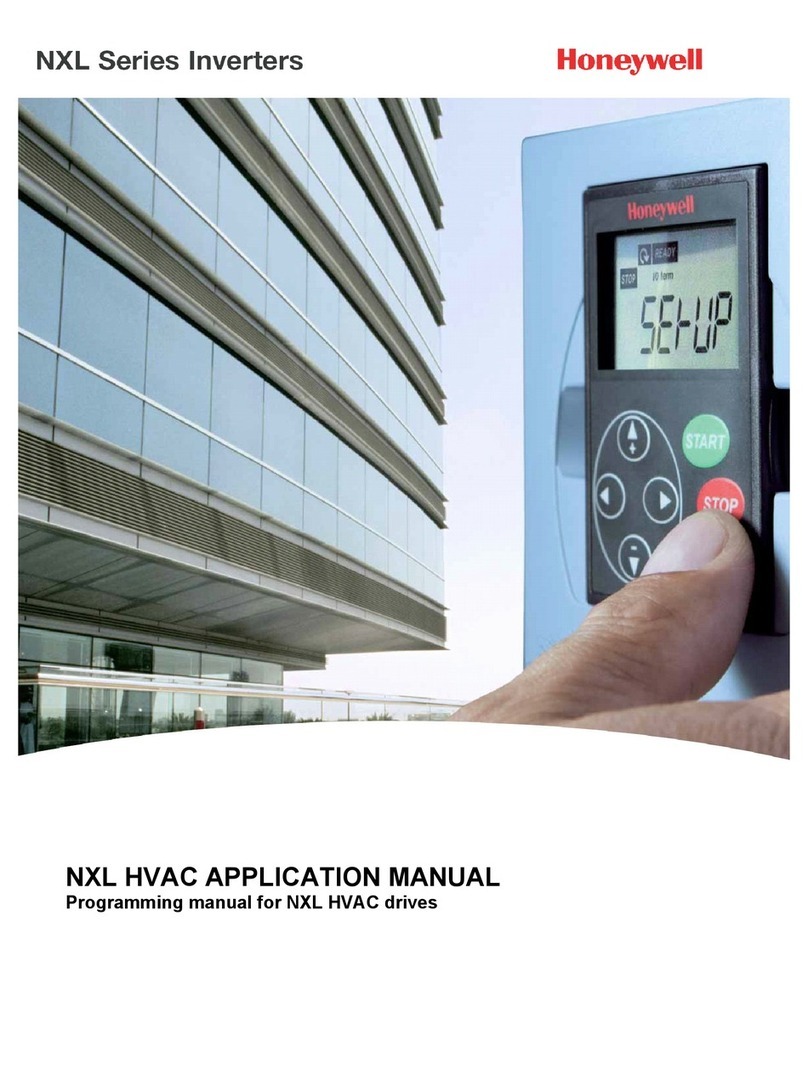

NXL HVAC PID Control

What You Need to Know

Motor nameplate data

−Nominal Current

−Nominal Speed

Signal/sensor specification

−Signal type

(volts, milliamps)

−Range

(0-10, 2-10, 0-20, 4-20)

−Sensor span

Setup

NXL HVAC PID Control

10

3 Run the Start Up Wizard

Note: Running the Start Up Wizard resets all parameters to their default values.

•Hold STOP down for 5 seconds

•Select application type FAN or PUMP and confirm with ENTER

•Select motor nominal speed and confirm with ENTER

•Select motor nominal current and confirm with ENTER

4 Full view of parameters

•P2.1.14 Parameter Conceal Set to 0 (not in use)

5 Control Signal Settings

•For Volt sensor signal use Analogue Input 1 (AI1)

0 – 10 V Default (no settings needed)

2 – 10 V P2.2.6 AI1 signal range Set to 4

•For milliamp sensor signal use Analogue Input 2 (AI2)

4 – 20 mA Default (no settings needed)

0 – 20 mA P2.2.12 AI2 signal range Set to 1

6 PID

•PID settings

P2.9.1 PID activation Set to 1 (activate)

P2.9.2 PID reference

no external reference Set to 2 (value from keypad)

external reference Set to 0 (AI1) or 1 (AI2)

•Where is the sensor connected?

P2.9.3 Actual value input Set to 0 (AI1) or 1 (AI2)

•PID reference (set-point)

Note: Only apply if not using external reference from controller!

P3.5 PID reference value (Set point value in percentage)

% = ((set-point – minimum) / span) x 100

For example: set-point is 3.2 bar, the sensor span is 0 – 5 bar.

3.2 divided by 5 is 0.64; the value to set in P3.5 is thus 64

Note:Only one function per input. If there is a need to change mA input to V input or

vice versa, please see instructions in the NXL HVAC User’s Manual. Available for

download at http://inettrack.europe.honeywell.com/support.