NXS VARIABLE FREQUENCY DRIVES

EN0B-0620GE51 R1107 2

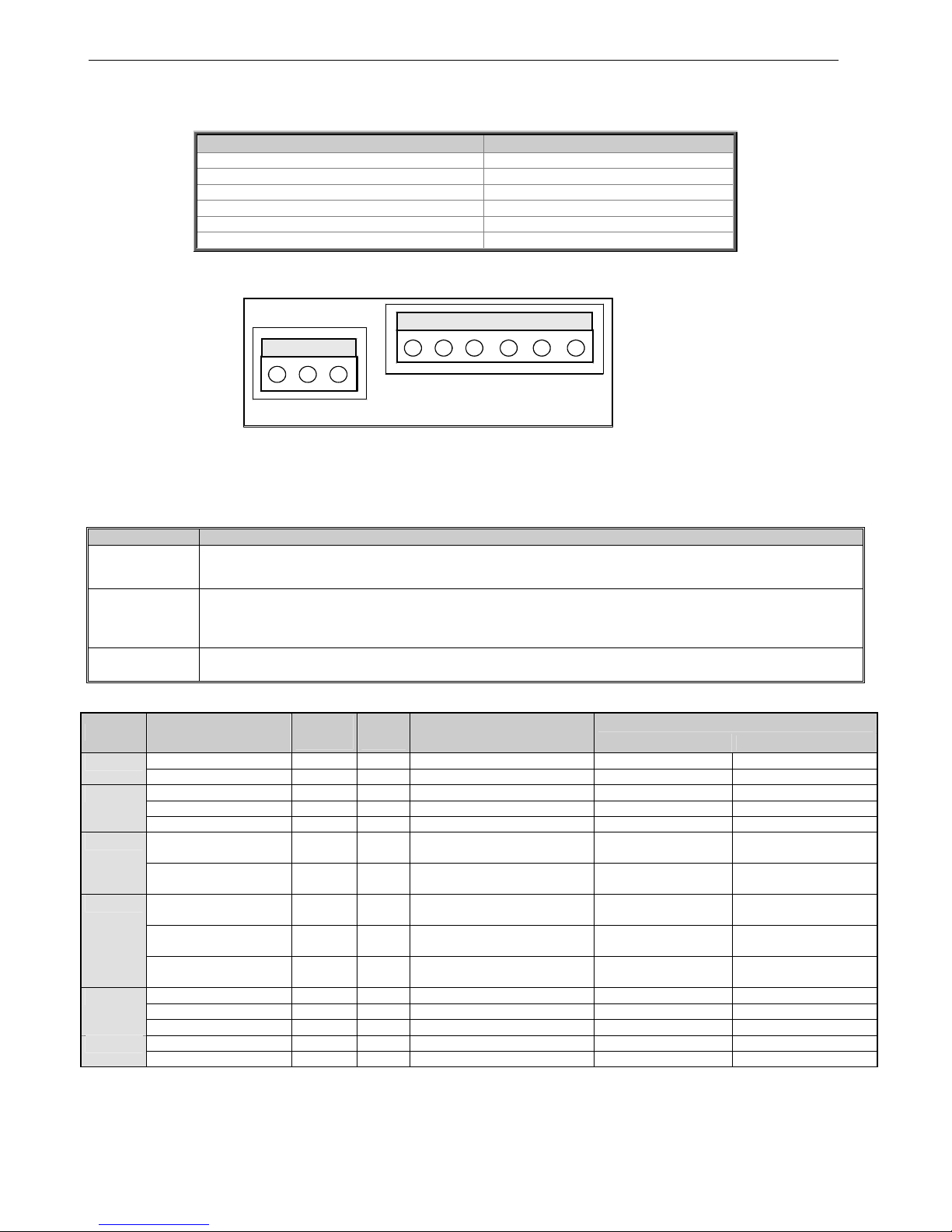

Control Characteristics

Control Method Frequency Control U/f, Open-

Loop Sensorless Vector

Control

Switching Frequency:

FR4 – FR6 (1.1-30kW)

1...16 kHz;

NXS0003…- NXS0061… Default: 10 kHz (no derating)

FR7 – FR9 (37-160 kW)

1…10 kHz

NXS0072…- NXS0310… Default: 3.6 kHz

Frequency reference:

Analogue input Resolution 0.1% (10 bit),

accuracy ±1%

Keypad reference Resolution 0.01 Hz

Field Weakening point 8…320 Hz

Acceleration time 0…3000 sec

Deceleration time 0…3000 sec

Braking torque DC-brake: 30%*TN (without

brake option)

Ambient Conditions

Ambient operating Temperature:

Low overload

-10°C (no frost)…+45°C

(for Fan/Pump)

(with 24 h average +40°C)

Storage temperature -40…+70°C

Relative humidity 0…95% RH, non-condensing,

non-corrosive, no dripping

water

Air quality:

Chemical vapors IEC 721-3-3, unit in operation,

class 3C2

Mechanical particles IEC 721-3-3, unit in operation,

class 3S2

Altitude 100% load capacity (no

derating) up to 1000 m

-1% derating for each 100 m

above 1000 m; max. 3000 m

Relative humidity 0…95% RH, non-condensing,

non-corrosive, no dripping

water

Vibration: 5...150 Hz

EN50178/EN60068-2-6 Displacement amplitude 1 mm

(peak) at 5...15.8 Hz

Max acceleration amplitude

1 G at 15.8...150 Hz

Shock: UPS Drop Test (for applicable

EN50178, IEC 68-2-27 UPS weights)

Storage and shipping: max

15 G, 11 ms (in package)

Enclosure class IP21 : NXS___ V35A2…

IP54 : NXS___ V35A5…

Electro Magnetic Compatibility (EMC)

Immunity Complies with EN50082-1, -2,

EN61800-3

Emissions:

Standard in all EMC-level H: EN 61800-3

(2004) Cat C2, EN 55011

Class A

Integrated option in: EMC level C: EN 61800-3

FR4 – FR6 (1.1-30kW) (2004) Cat C1, EN 55011

NXS0003…- NXS0061… Class B

Safety

EN50178, EN60204-1, CE, GOST R, IEC 61800-5 (see unit

nameplate for more detailed approvals)

Control Connections

Analogue input voltage 0...+10 V, Ri = 200 kΩ,

resolution 10 bit, accuracy ±1%

Analogue input current 0(4)…20 mA, Ri = 250 Ω

differential resolution 0.1%,

accuracy ±1%

Digital inputs 6 positive logic; 18…24 Vdc

Auxiliary voltage +24 V, ±15%, max. 100 mA

Output reference voltage +10 V, +3%, max. load 10 mA

Analogue output 0(4)…20 mA; RL max. 500Ω;

resolution 16 bit; accuracy ±1%

Relay outputs 2 programmable change-over

relay output (1 NO/NC and 1

NO). Switching capacity:

24 Vdc / 8 A, 250 Vac / 8 A,

125 Vdc / 0.4 A. Min. switching

load: 5 V / 10 mA

Digital output Open collector output, 50 mA /

48 V

Motor thermistor Input R

TRIP

= 4.7 kΩ(PTC),

electrically isolated