NO }load

sld,

NC

3voltage side

CaM

~

earth connection

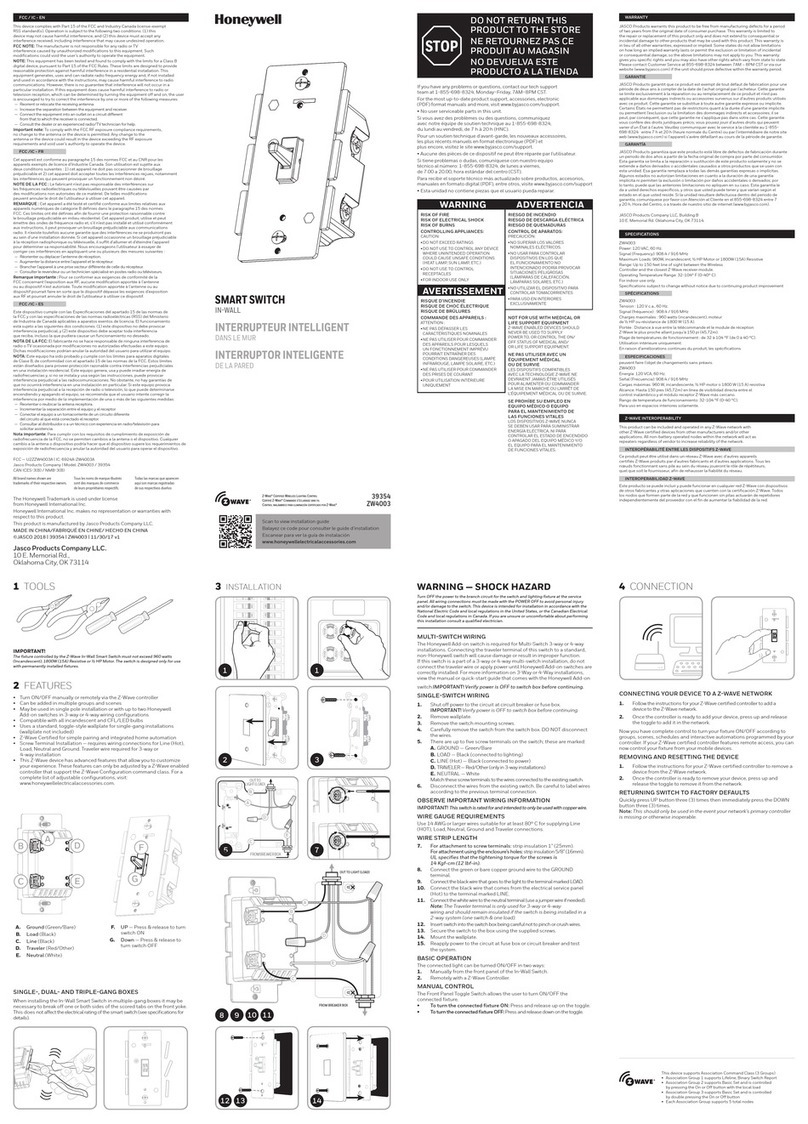

•Disconnect power supply to the pressure switch

before beginning the installation to prevent

electrical shock and damage to the equipment.

•Turn off gas supply before installation.

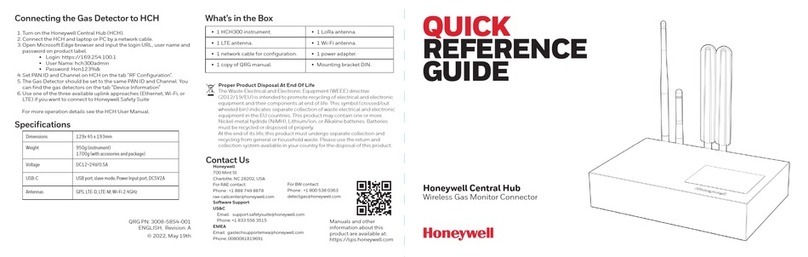

Mounting

and

orientation

In

vertical, or horizontal plane with the setting dial facing

upwards. Make sure that dirt or humidity does not get into the

connection open for ventilation

(G

in

Figure. 1.).

AWARNING

Fig. 2.

C6058

connection

diagram

Fig. 3.

C6058

connection

diagram

with

DIN

plug

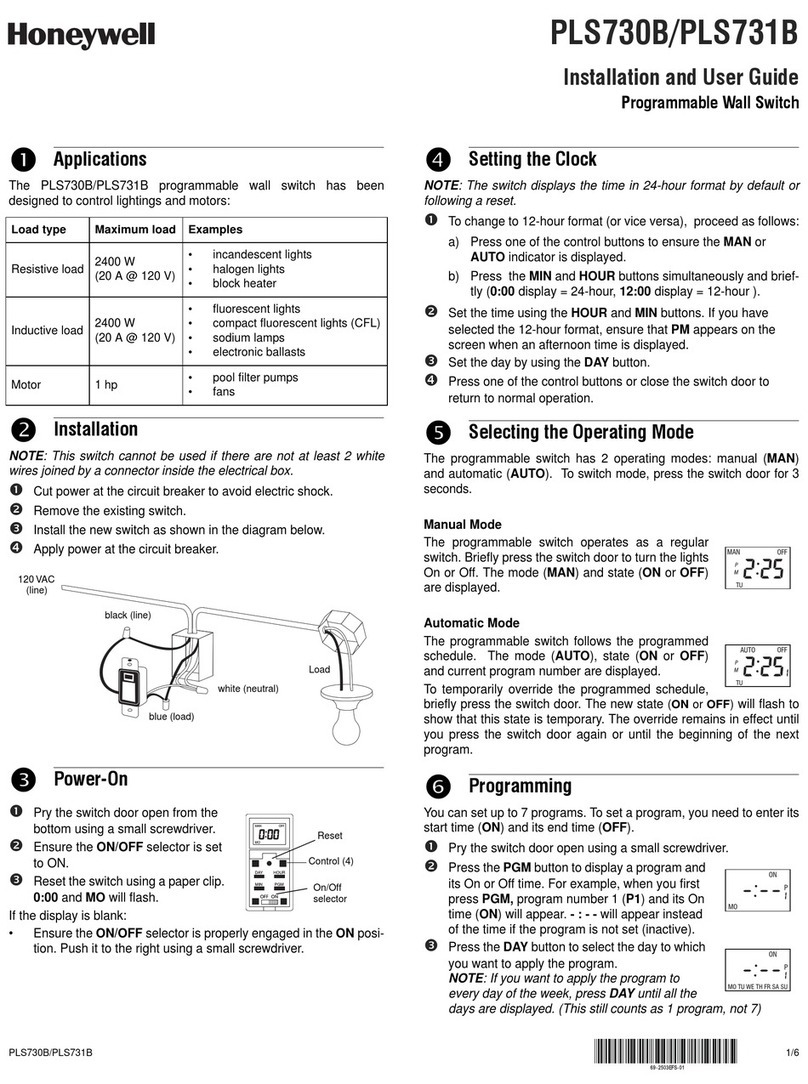

Working

principle

On

pressure

rise,

terminals between

CaM

and

NO

are

closed.

On

pressure fall, terminals between

CaM

and NC are closed.

2

3

blue

brown

NC

CaM

'---------{

3

1--1-----,------'

black

•Do not remove the seal over the pressure inlets,

until ready to connect piping.

Connecting

positive

pressure

inlet

(stand

alone)

1.

Take care that dirt does not enter the pressure switch

during handling.

2.

Remove the dust seal from the positive pressure inlet.

3.

Apply amoderate amount of good quality compound to

the pipe for fitting only, leaving the end thread bare,

PTFE tape tape may

be

used as

an

alternative.

4.

Use asound tapper fitting with thread according to

ISO 7-1 (8S21 ,

DIN

2999) or new, properly reamed

pipe, free from swarf.

5.

Screw the pressure switch onto the pipe, using the

wrench boss incorporated

in

the housing.

6.

Complete the electrical connections as instructed

in

the

Electrical connections section.

Connecting

positive

pressure

inlet

(flange

mounted)

1.

Take care that dirt does not enter the pressure switch

during handling.

2.

Remove the dust seal from the positive pressure inlet.

3.

Place the

a-ring.

If necessary grease

it

slightly to keep

it

in

place.

4.

Mount the pressure switch

on

the valve body and screw

it

tightly with the two M4 mounting screws.

5.

Complete the electrical connections as instructed

in

the

Electrical connections section.

AWARNING

Tightness

test

after

installation

•Spray amoderate amount of of good quality leak

detection spray

on

all pipe connections.

•Start the application and check for bubbles. If a

leak

is

detected

in

apipe connection, remake the

joint.

ADJUSTMENT

AND

CHECKOUT

Electrical

connection

AWARNING

•Switch off power supply before making electrical

connections.

AWARNING

•The adjustment and checkout has to

be

carried out

by

qualified personnel only.

•Terminals are accessible,

no

protection against

electrical shock.

•Take care that the wiring

is

in

accordance with local

regulations.

Use lead wire that can withstand 105

QC

ambient.

The electrical ON/OFF operator

is

provided with aterminal

block for electrical connections.

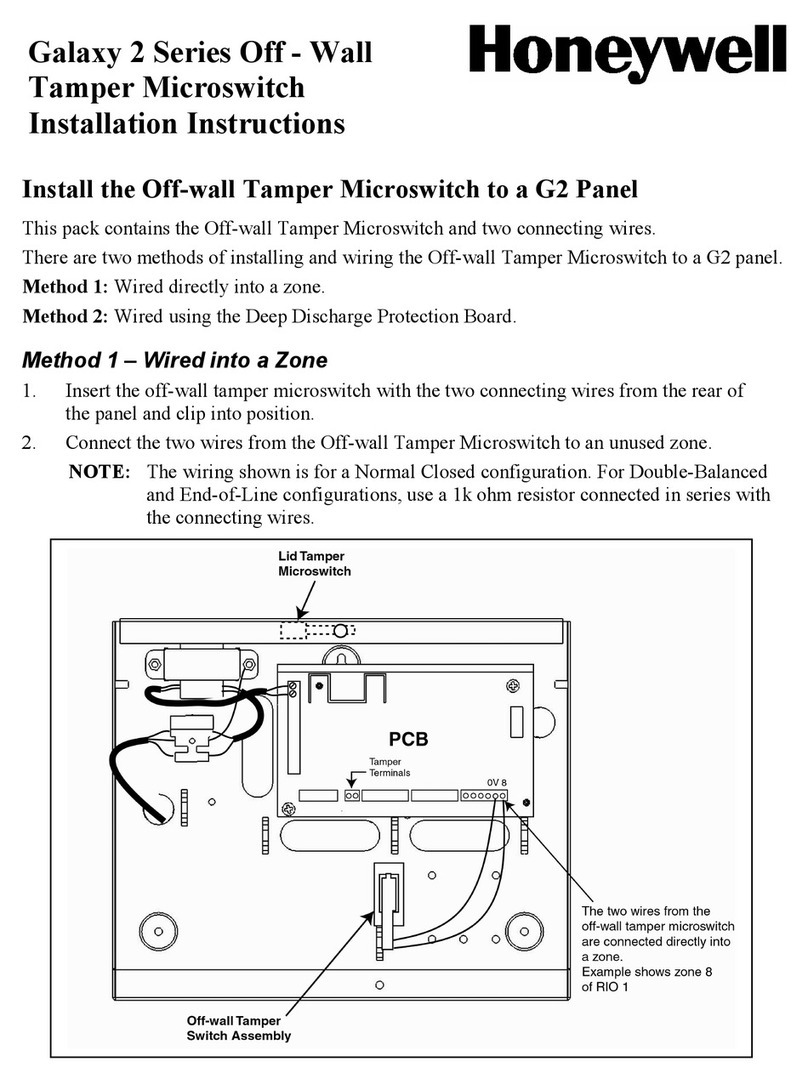

Wiring

Follow the instructions supplied

by

the appliance

manufacturer. Refer to Figure

2.

and

3.

Connection diagram

C6097A.

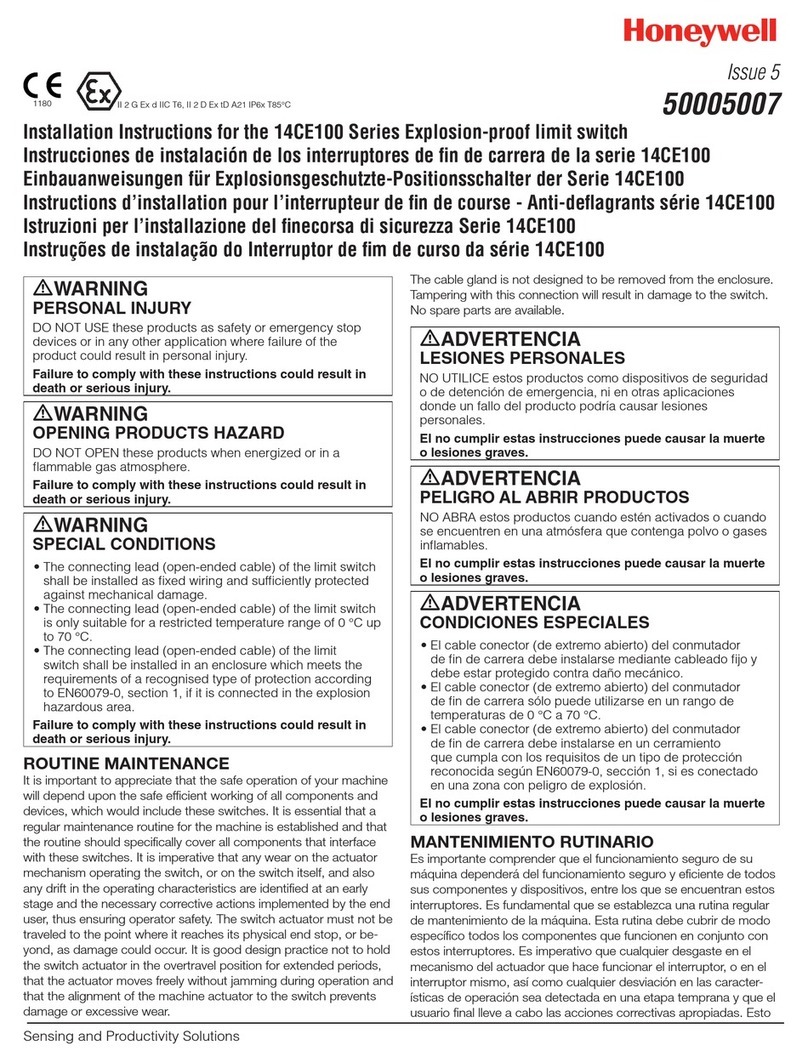

Pressure

set

point

adjustment

(tolerance

±

15

%

over

total

scale)

NOTE: The knob readings are approximations of the actual

settings.

1.

Remove the cover of the pressure switch.

2.

Turn the dial clockwise to increase or

counter-clockwise to decrease the pressure set point.

3.

Replace the cover.

3

EN1R-91729907R1-NE