OP Series Issue 2 PK 88008

ADJUSTING ROLLER ARMS

The roller lever assembly is adjustable through 360° at

any of 1,980 positive lock positions at intervals of

approximately 0.2°.

To adjust the roller lever to the desired position, hold the

hexagon washer with a wrench and loosen lock nut

sufficiently to disengage the serrations. Hold shaft in

position by means of the hexagon washer so that no

torque will be applied to the internal parts of the unit

when the lock nut is tightened or loosened. Failure to do

so may result in damage to the enclosed switching

mechanism.

Moving lever one serration forward or backward with

respect to serrations on fluted washer changes the

position of the lever approximately 8.2° (see sketch on

page 3).

Moving lever and fluted washer, as a unit, one serration

forward or backward with respect to serrations on the

hexagon washer changes position of the lever 8°.

Moving the lever one serration in one direction, and the

lever and fluted washer, as a unit, one serration in the

other direction, changes position of the arm

approximately 0.2°.

After positioning lever arm, tighten lock nut sufficiently to

prevent slippage of arm, but avoid over tightening.

Excessive tightening will also deform the hexagon

serrated washer and cause lever assembly to bind.

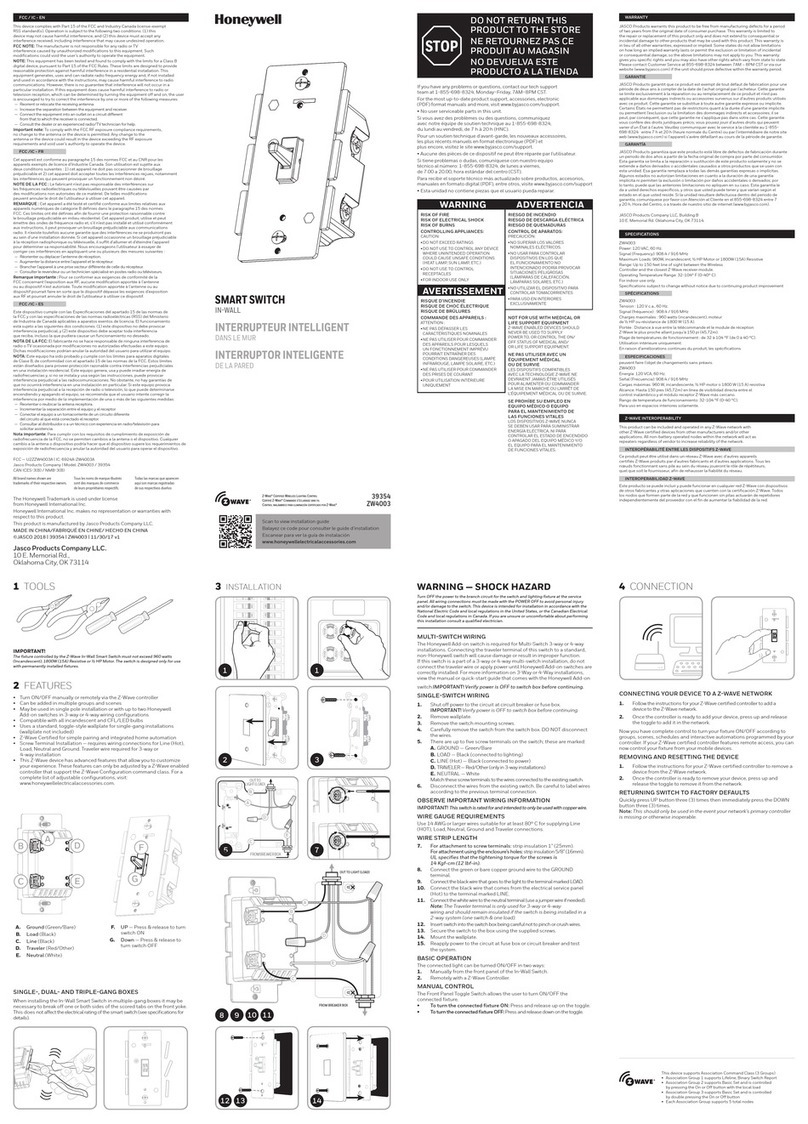

STRAIGHT PLUNGER ACTUATION

Do not actuate by cams or slides or by any other

device which will impart side thrust to the plunger. Use

straight "push" action in the direction of the plunger

motion. Do not oil this plunger mechanism. Sufficient

grease of the proper type is assembled in the plunger

during manufacture to last the lifetime of the switch.

Additional grease, oil, water or fine abrasive may cause

jamming or electrical failure.

REPLACING BASIC SWITCH

1. Observe this notice:

Disconnect power supply circuit before opening switch.

2. Remove cover of housing, disconnect the lead-in

wires, loosen screws holding the basic switch, then

remove the basic switch.

3. Place replacement switch in the insulator, insert the

screws, and place basic switch in the housing.

4. Tighten the screws and connect the lead-in wires.

5. Be sure small compression spring is returned to its

position between the top of the basic switch and the

internal lever (or above internal lever in the case of

the CCW actuated switches).

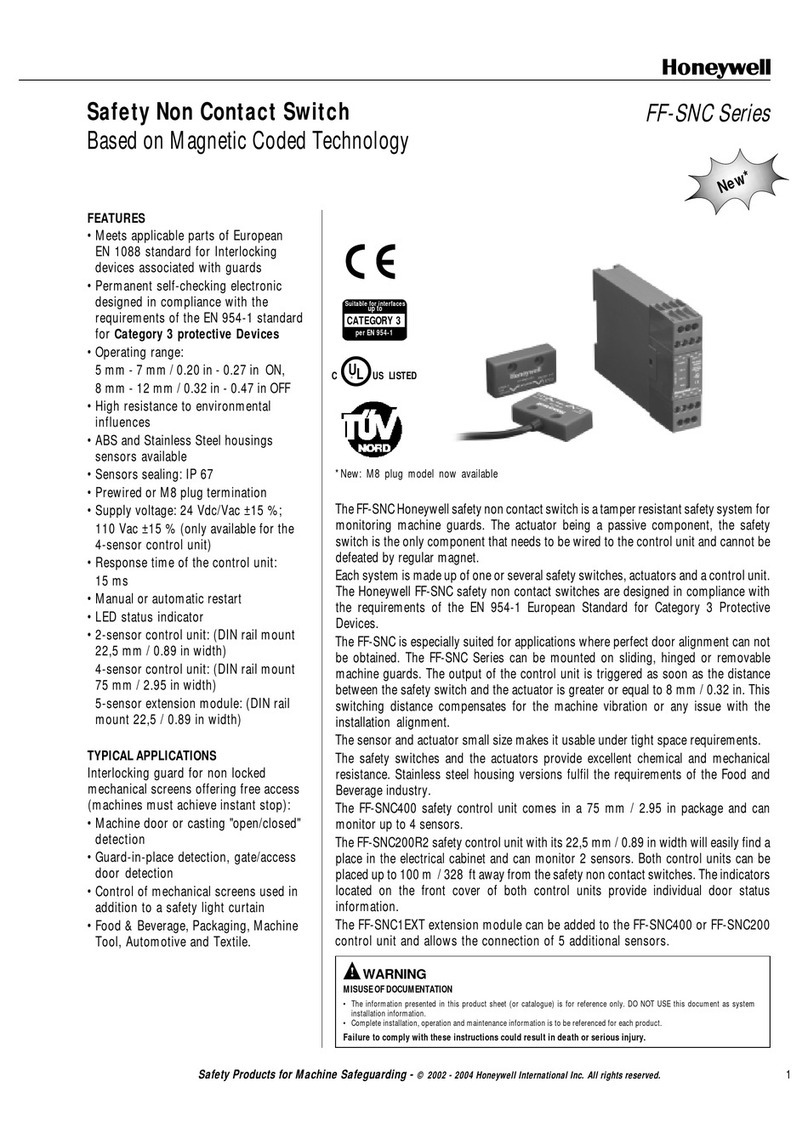

MOUNTING DIMENSIONS

52,3

2.06

Roller Arm

Straight Plunger One-way Roller Arm

Low Force Rod

Straight Plunger

Actuation

ELECTRICAL RATINGS

A UL and CSA listed: L96

15 amps, 125, 250 or 480 VAC;

1/8 Hp, 125 VAC; 1/4 Hp, 250 VAC;

1/2 amp, 125 VDC; 1/4 amp,

250 VDC

B UL and CSA listed: L23

20 amps, 125, 250 or 480 VAC;

10 amps, 125 VAC "L"; 1 Hp,

125 VAC, 2 Hp, 250 VAC; 1/2 amp,

125 VDC; 1/4 amp, 250 VDC

C UL and CSA listed: L59

10 amps, 125 or 250 VAC; 0.3 amp,

125 VDC; 0.15 amp, 250 VDC

D UL and CSA listed: L35

5 amps, 125, 250 or 480 VAC;

1/2 amp, 125 VDC; 1/4 amp,

250 VDC

2 Honeywell •Sensing and Control