GB-2

Installation

CAUTION

Please observe the following to ensure that the

DL..K is not damaged during installation and op-

eration:

– Dropping the device can cause permanent dam-

age. In this event, replace the entire device and

associated modules before use.

– Condensation must not be allowed to get into

the housing (if possible, install pipework with an

ascending gradient). Otherwise, there is a risk of

icing of condensation at subzero temperatures,

the switching point shifting or corrosion in the

device which can lead to malfunctions.

– In the case of an uneven mounting surface,

secure the pressure switch to the mounting plate

or air duct with only two screws on the same

side in order to avoid subjecting the pressure

switch to mechanical stress.

– Protect the connections against dirt or moisture

in the medium to be measured or the surround-

ing air. If necessary, install a filter.

– When using silicone tubes, only use silicone

tubes which have been sufficiently cured. Va-

pours containing silicone can adversely affect

the functioning of electrical contacts.

– In case of highly fluctuating pressures, install a

damping nozzle.

▷

Installation in the vertical or horizontal position, or

upside down, preferably with vertical diaphragm.

If installed in a vertical position, the switching

pointpSwill correspond to the scale valueSK.

If installed in another position, the switching

pointpSwill change and no longer correspond

to the set scale valueSK. Switching pointp

S

must be checked.

ps= SK SK + 13 Pa

[+ 0.052 "WC]

SK - 13 Pa

[- 0.052 "WC]

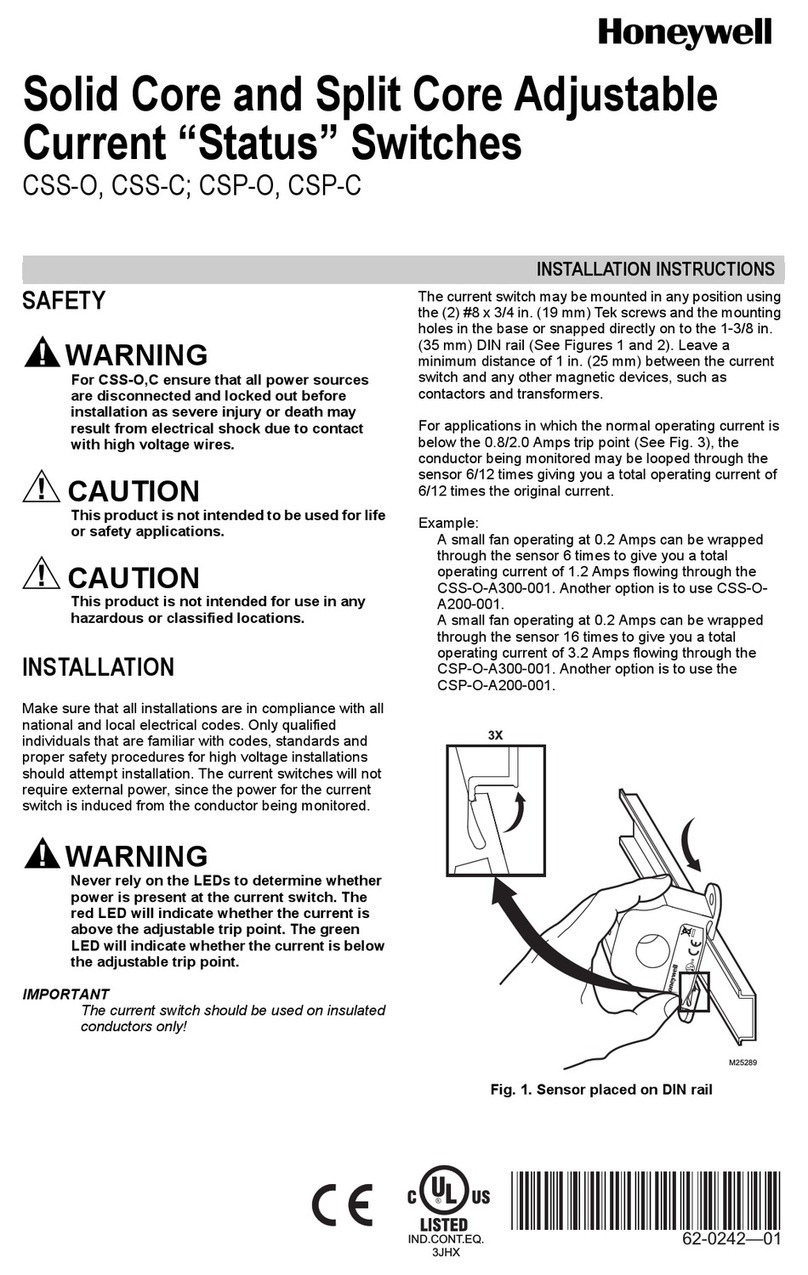

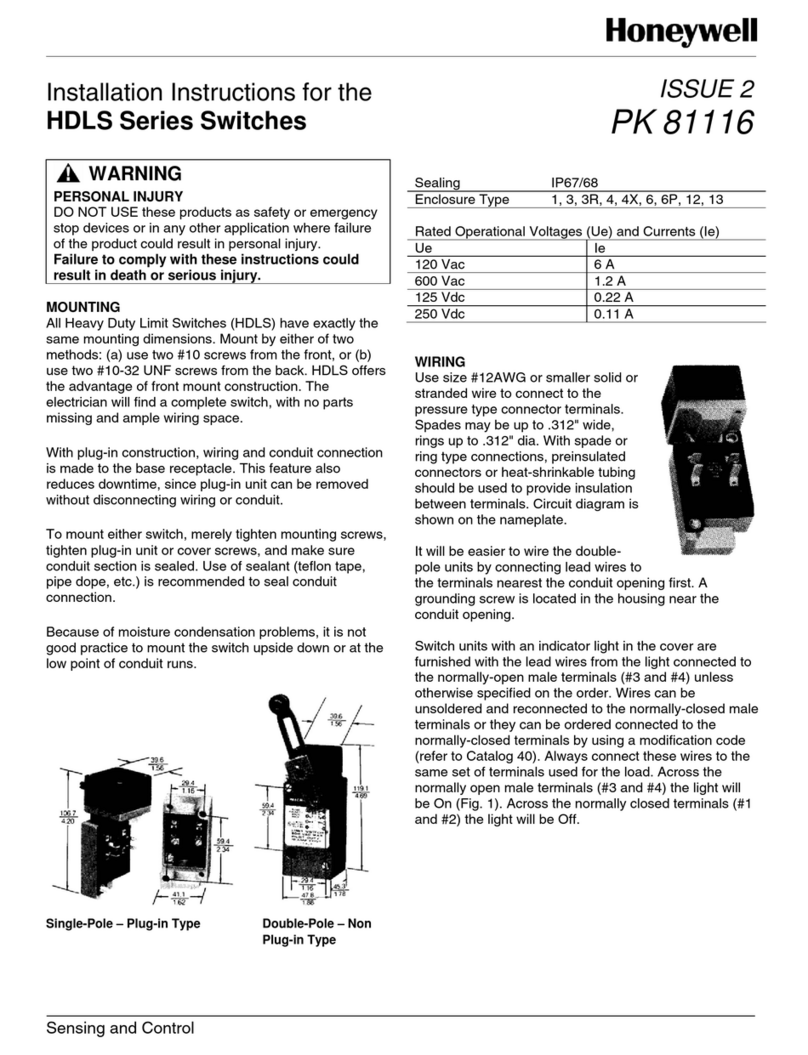

1 Install the DL using screws, a securing clip or an

angle bracket.

66 4,4

(0.14")

ø 6,1

(ø 0.24")

(2.6")

▷Tube connection: Ø 6 mm (0.236").

▷Max. inlet presure pmax = 5000 Pa (20"WC).

Wiring

CAUTION

Please observe the following to ensure that the

DL..K is not damaged during operation:

– If the DL..G (DL..TG) has switched a volt-

age >24V (>30V) and a current >0.1A at

cosφ=1 or >0.05A at cosφ=0.6 once,

the gold plating on the contacts will have been

burnt through. It can then only be operated at

this power rating or higher power rating.

– Note the switching capacity, see page 3

(Technical data).

▷

In the case of high humidity, we recommend

using a pressure switch with gold contact due to

its higher resistance to corrosion. Closed-circuit

current monitoring is recommended under dif-

ficult operating conditions.

▷In the case of low switching capacities, such as

24V, 8mA, for example, we recommend us-

ing an RCmodule (22Ω, 1μF) in air containing

silicone or oil.

1 Disconnect the system from the electrical power

supply.

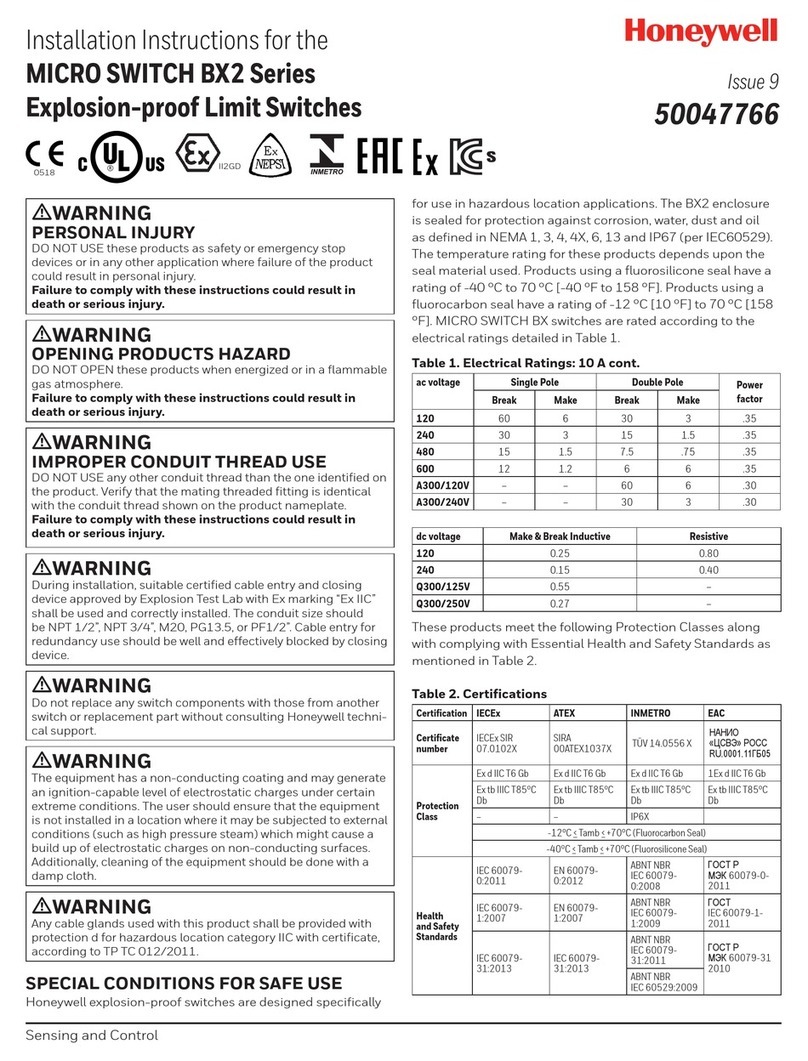

M16 x 1,5:

∅ 4 – 10 mm

COM

3

NC

1

NO

2

NO

2NC

1

COM

3

L1(+) 54