760-1227—1

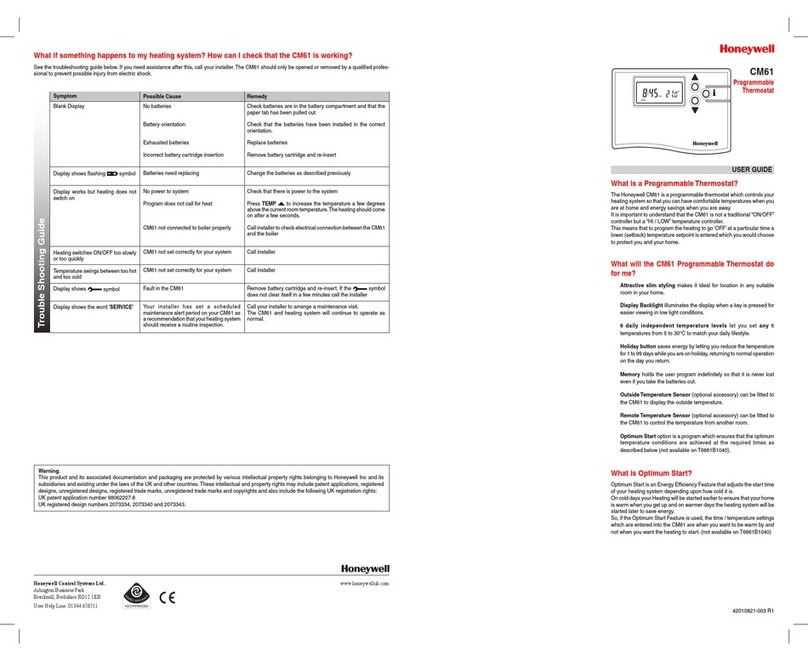

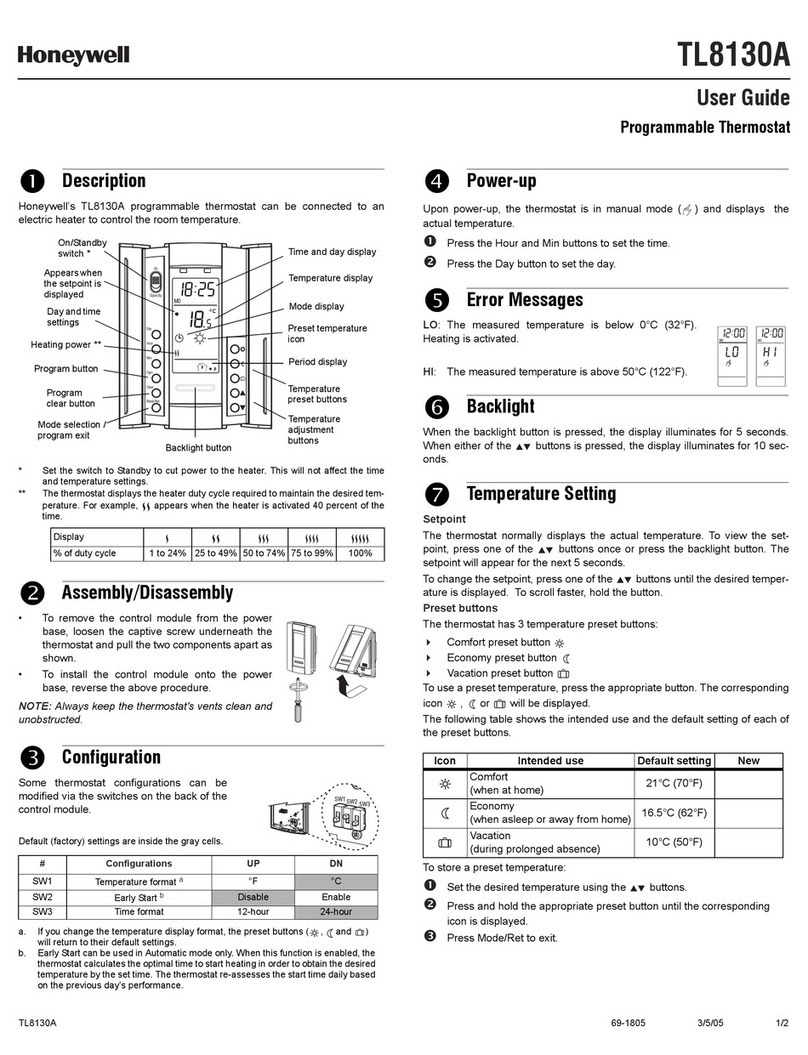

Fig. 12—Restricted set point.

MOUNTING THE THERMOSTAT

1. Remove the thermostat cover by pulling the bottom

edge of the cover upward until it snaps free of the cover clip.

NOTE: The cover is hinged at the top. Remove it by pull-

ing up at the bottom.

2. Carefullyremove and discard thepolystyrenepacking

insert,whichprotectsthemercury switchesduringshipment.

3. Turn the thermostat base over and note the spring

fingers that engage the subbase contacts. Make sure the

spring fingers are not bent flat, preventing proper electrical

contact with the subbase.

4. Set the heat anticipator indicators to the respective

current setting for each stage. See Setting the Heat Antici-

pator section.

5. Notethe tabs along the top insideedgeof the thermo-

stat base. The tabs fit into the subbase notches. Mount the

thermostat base on the subbase and tighten the captive

mounting screws. See Fig. 1.

6. Place the upper edge of thermostat cover on the

thermostatbaseandswingcoverdownward untilit engages

with the cover clip on the base.

Setting

SETTING THE HEAT ANTICIPATOR

Set each heat anticipator to match its primary control

currentdraw. If the primarycontrolnameplate has no rating

or if further adjustment is necessary, use the following

procedure to determine the current draw of each stage. The

current draw of each heating stage must be measured with

the thermostat removed and the power on.

1. Connectanac ammeter of appropriate range between

the heating terminals of the subbase:

Stage 1: between W1 and RH or R.

Stage 2: between W2 and RH or R.

2. Move the system switch to HEAT or AUTO.

3. After one minute, read the ammeter and record the

reading.

4. Aftermounting thethermostat,set theadjustableheat

anticipator(s) to match the respective reading(s) measured

in step 3.

TEMPERATURE SETTING

Move the heating and cooling levers to the desired

positions. The minimum differential between the heating

and cooling set points is 3°F [2°C], which means the

setting levers cannot be set closer together than 3°F [2°C].

The T874 is equipped with a restricted set point feature

for fuel efficiency.

Factory-installed stops are set so the set point levers

cannot be set above 68°F [20°C] or 72°F [22°C] on

heating(depending onthe model)orbelow78°F[26°C] on

cooling (Fig. 12).

Do not attempt to change the location of these stops,

because they are nonadjustable.

SUBBASE SETTING

System switching positions control thermostat opera-

tion as follows:

OFF:Boththeheatingandcoolingsystemsareoff.Ifthe

fanswitchis in the AUTO position, the cooling fan is

also off (Q674B,C,E or G only).

HEAT: Heating system is controlled by the thermostat.

Cooling system is off (Q674A,B or E only).

COOL: Thermostat controls the cooling system. Heat-

ing system is off (Q674A, B or E only).

AUTO:Thethermostatautomaticallyswitchesbetween

heat and cool modes, depending on the indoor tem-

perature (Q674A,C,E or G only).

Fan switching positions control fan operation as fol-

lows (Q674A,B,C or E):

ON: Fan operates continuously.

AUTO: Fan operates with cooling equipment as con-

trolled by the thermostat or with the heating equip-

ment as controlled by the plenum switch.

To switch positions, use thumb and index finger to slide

lever to the desired position. The switch lever must stop

over the desired function indicator mark for proper circuit

operation.

Checkout

HEATING

Move the system switch on the Q674 Subbase to HEAT

or AUTO. Move the heating lever on the T874 about 10°F

[6°C] above room temperature. Both stages of heating

should start and the fan should run after a short delay.

Move the heating lever about 10°F [6°C] below room

temperature. The heating equipment should shut off, and

the fan should run for a short time and then shut off.

COOLING

Move the system switch on the Q674 Subbase to COOL

or AUTO. Move the cooling lever on the T874 Thermostat

about 10°F [6°C] below room temperature. The cooling

equipment and fan should start. Move the cooling lever

about 10°F [6°C] above room temperature. The cooling

equipment and fan should stop.

FAN

Move the subbase system switch to OFF or AUTO, and

the fan switch to ON. The fan should run continuously.

When the fan switch is in the AUTO position, the fan

operation is controlled by the heating or cooling system.