Figure 4.1

Figure 4.2

Figure 4.3

Figure 4.4

Figure 4.5

Figure 4.6

Figure 4.7

Figure 4.8

Figure 4.9

Figure 4.10

Figure 4.11

Figure 4.12

Figure 4.13

Figure 4.14

Figure 4.15

Figure 4.16

Figure 4.17

Figure 4.18

Figure 4.19

Figure 4.20

Figure 4.21

Figure 5.1

Figure 5.2

Figure 6.1

Figure 6.2

Figure 6.3

Figure 6.4

Figure 6.5

Figure 7.1

Figure 7.2

Figure 7.3

Figure 7.4

Figure 7.5

Figure 7.6

Figure 9.1

Figure 9.2

Figure 9.3

Figures

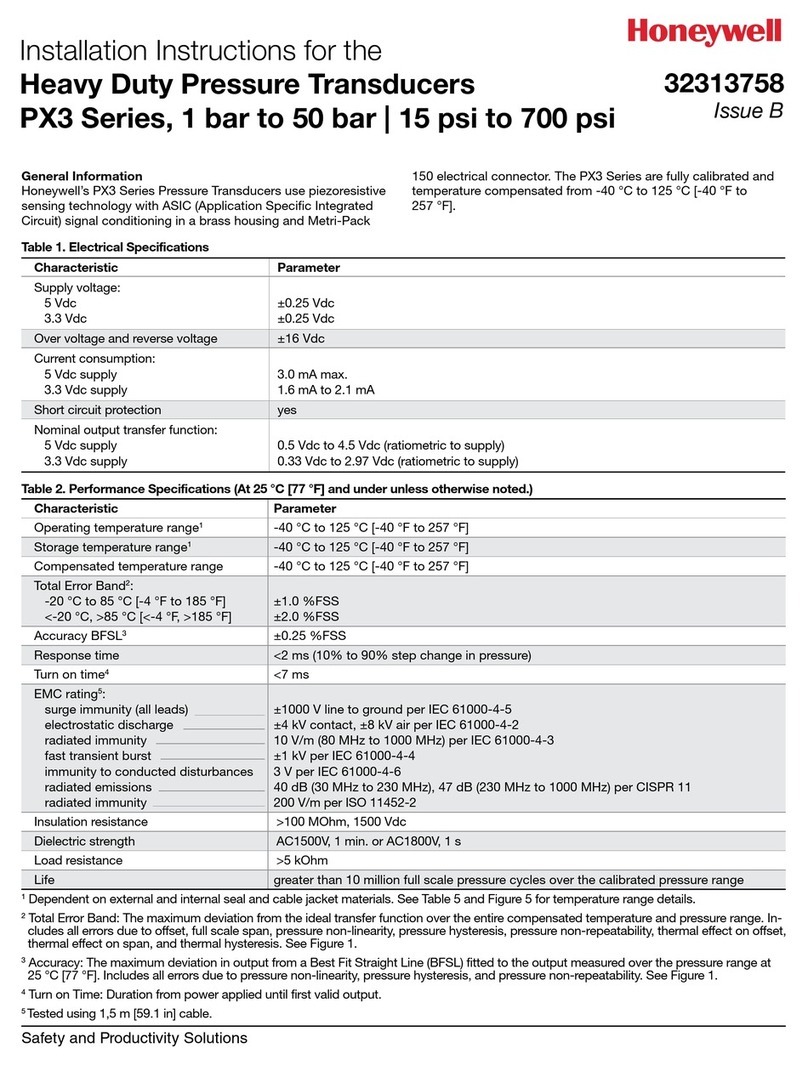

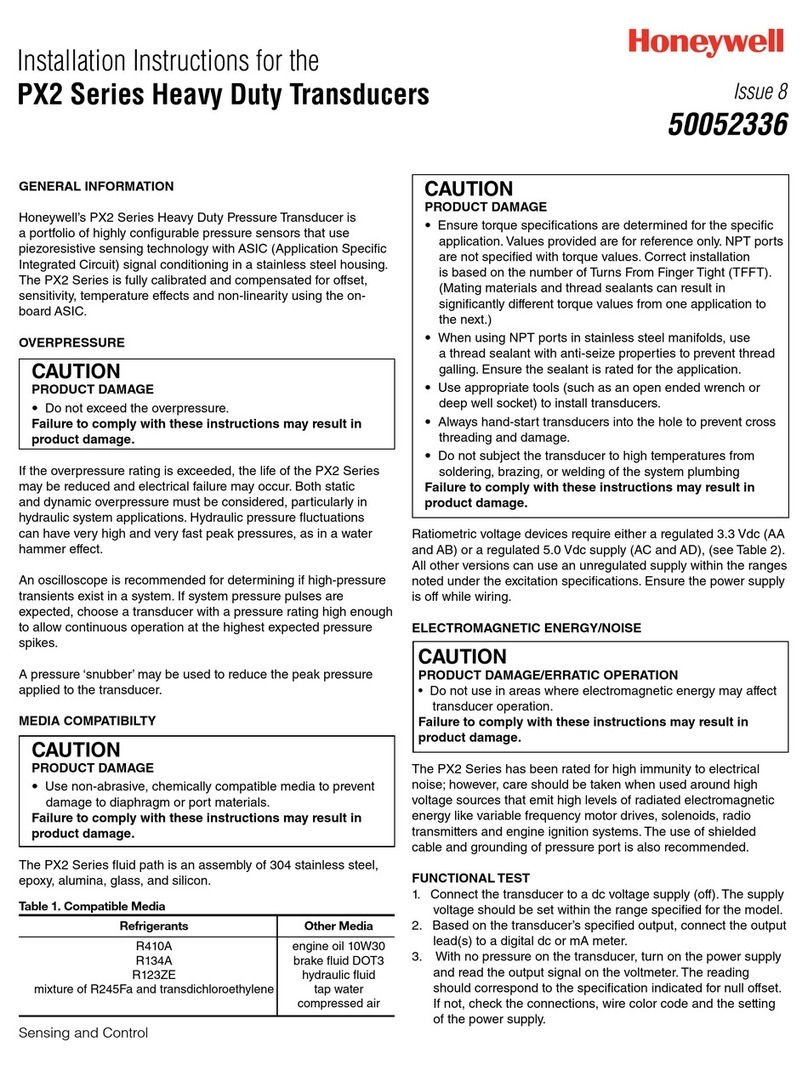

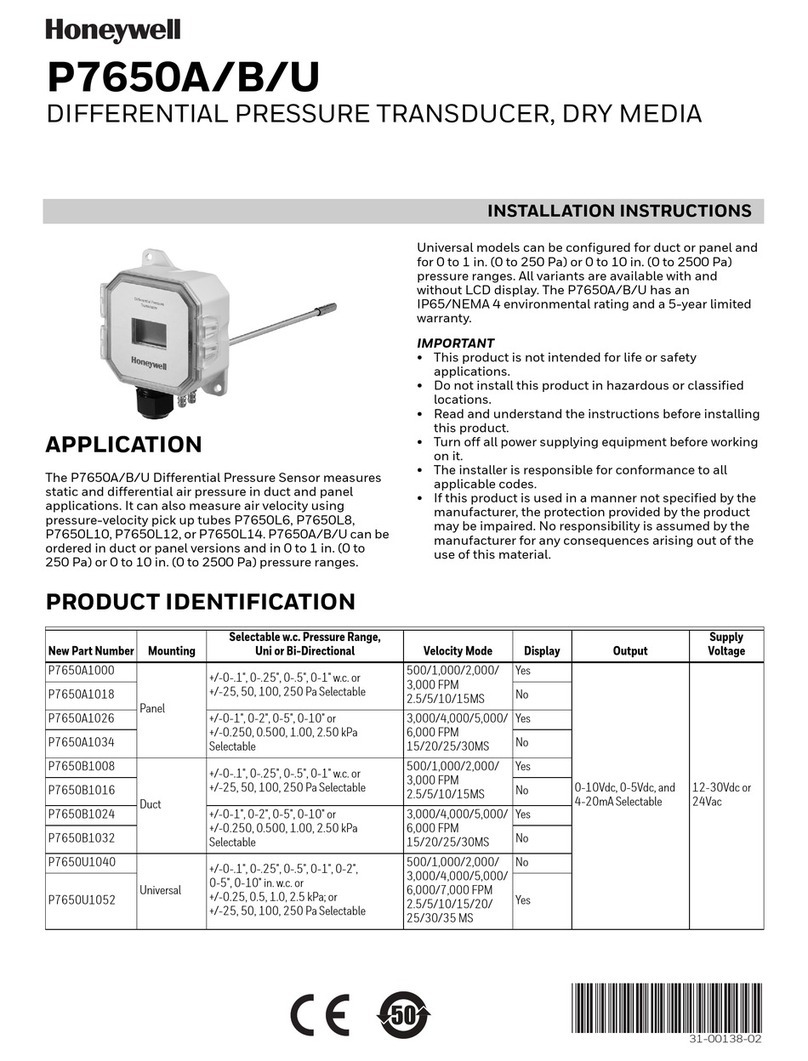

PPT Block Diagram .......................................................................................... 13

Pressure Reading Control ................................................................................ 15

Factory Set Output Levels ............................................................................... 16

User Modified Output Levels ........................................................................... 17

User Modified Pressure Span .......................................................................... 17

Custom Slope (X=) Options .............................................................................. 17

Custom Offset (Z=) Options ............................................................................. 17

Pressure Set Point Set ..................................................................................... 18

Deadband on Set Point ..................................................................................... 18

PPT Pressure to Analog Voltage ...................................................................... 19

PPT Pressure Readings and Analog Voltage Control ..................................... 19

Sensing Remote Analog Pressure .................................................................... 19

Integration (I=) Command, Example 1 ........................................................... 20

Integration (I=) Command, Example 2 ........................................................... 21

S2 Speed Shift Command Example ................................................................. 21

S5 Speed Shift Command Example ................................................................. 22

Deadband and Integration (DI) Command Examples ........................... 22 – 23

Idle Count (IC) Command Example ................................................................ 23

Synchronize Integration Cycles (SI) Command Example .............................. 24

RS-232 PPT Ring Network .............................................................................. 25

RS-485 PPT Multidrop Network ..................................................................... 26

Single PPT Command and Reply .................................................................... 34

Multiple PPT Network Command and Replies ............................................... 35

PPT Electrical Connector Pin Assignments .................................................... 73

Connection for RS-232 Operation and Analog Output ................................... 73

Connection for RS-485 Operation and Analog Output ................................... 74

Connection for Analog Output and Battery Operation ................................... 74

Connection for Computer Operation and

User Controlled Analog Voltage Output ...................................................... 74

Default Single Pressure Reading Timing Diagram ........................................ 75

Default Continuous Pressure Reading Timing Diagram ................................ 75

Continuous Pressure (with IC = 1) Timing Diagram ...................................... 75

Timing Diagram for 20 Readings Per Second ................................................. 76

Timing Diagram for 50 Readings Per Second ................................................. 76

Timing Diagram for 120 Readings Per Second ............................................... 76

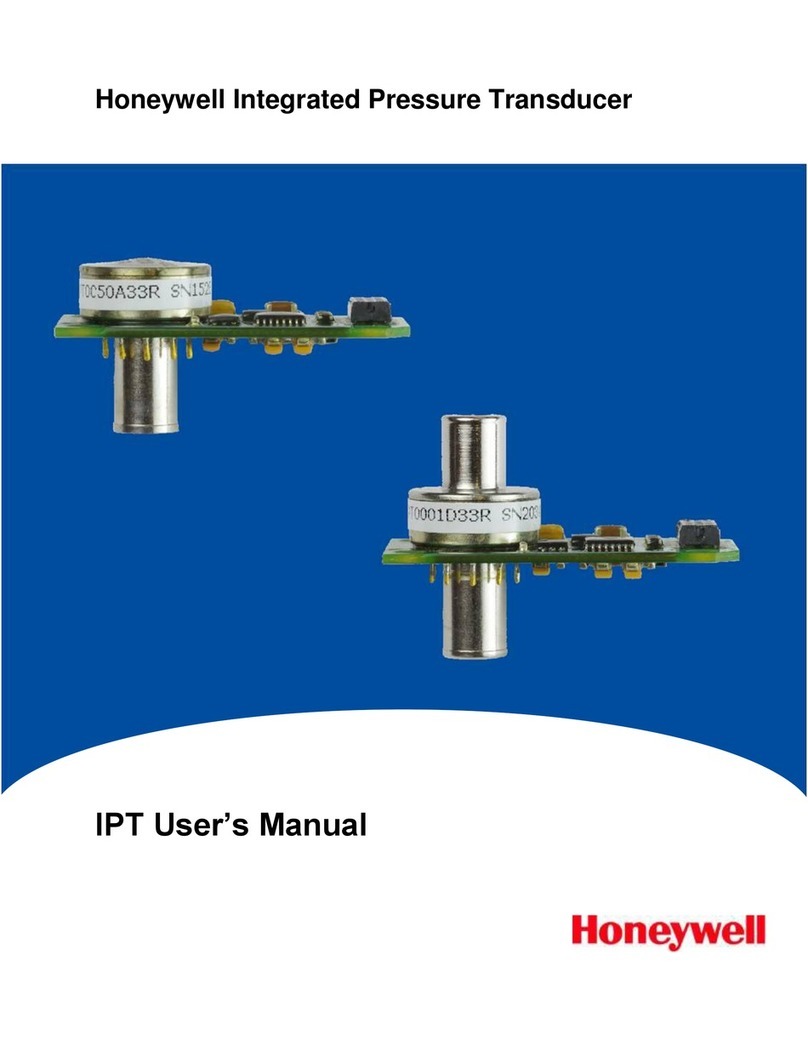

PPT Case Outline ............................................................................................. 80

Electrical Connector ......................................................................................... 80

PPTR Case Outline .......................................................................................... 81

iii