43-TV-33-214 iss.2 GLO May 2015 UK 1

DR Graphic recorder - Installation Instruction

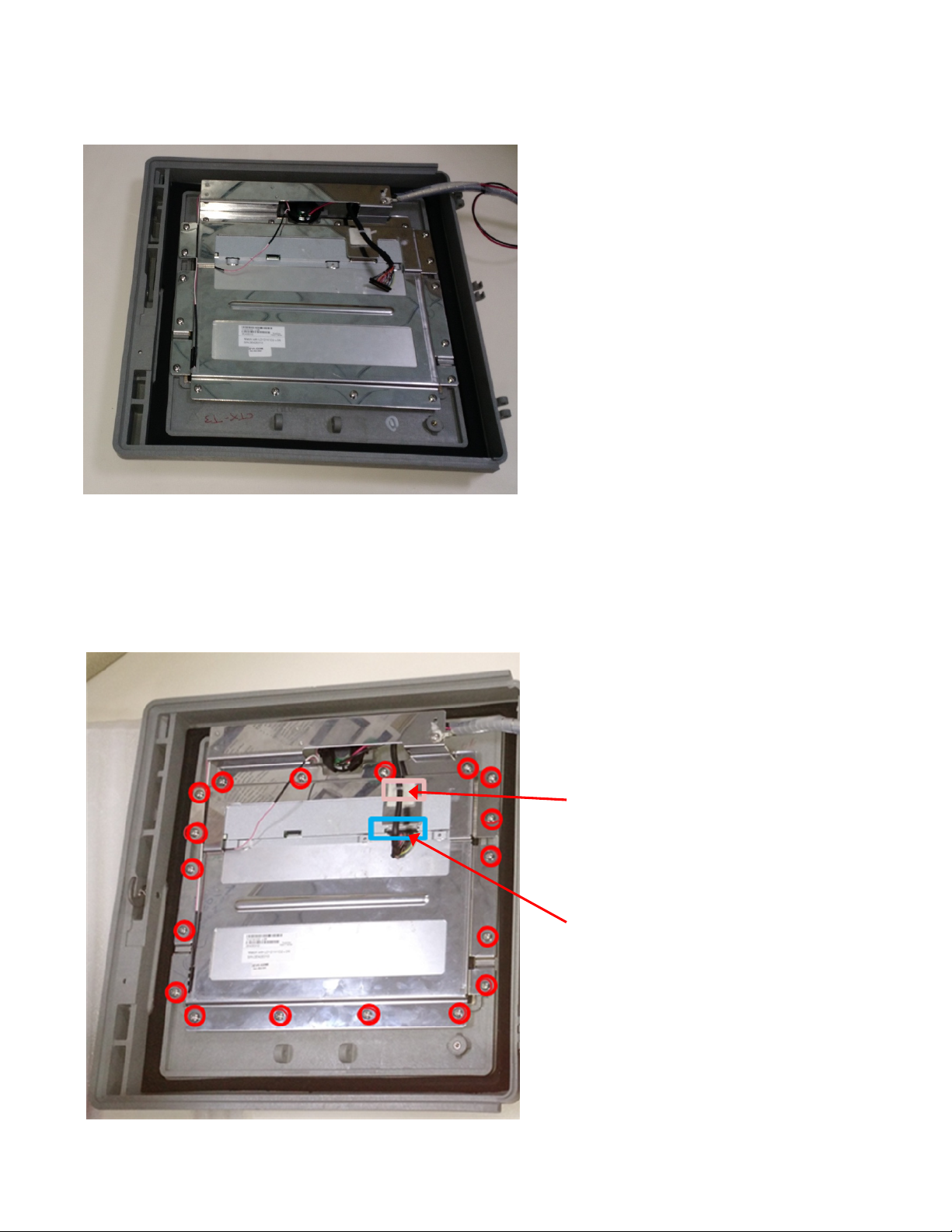

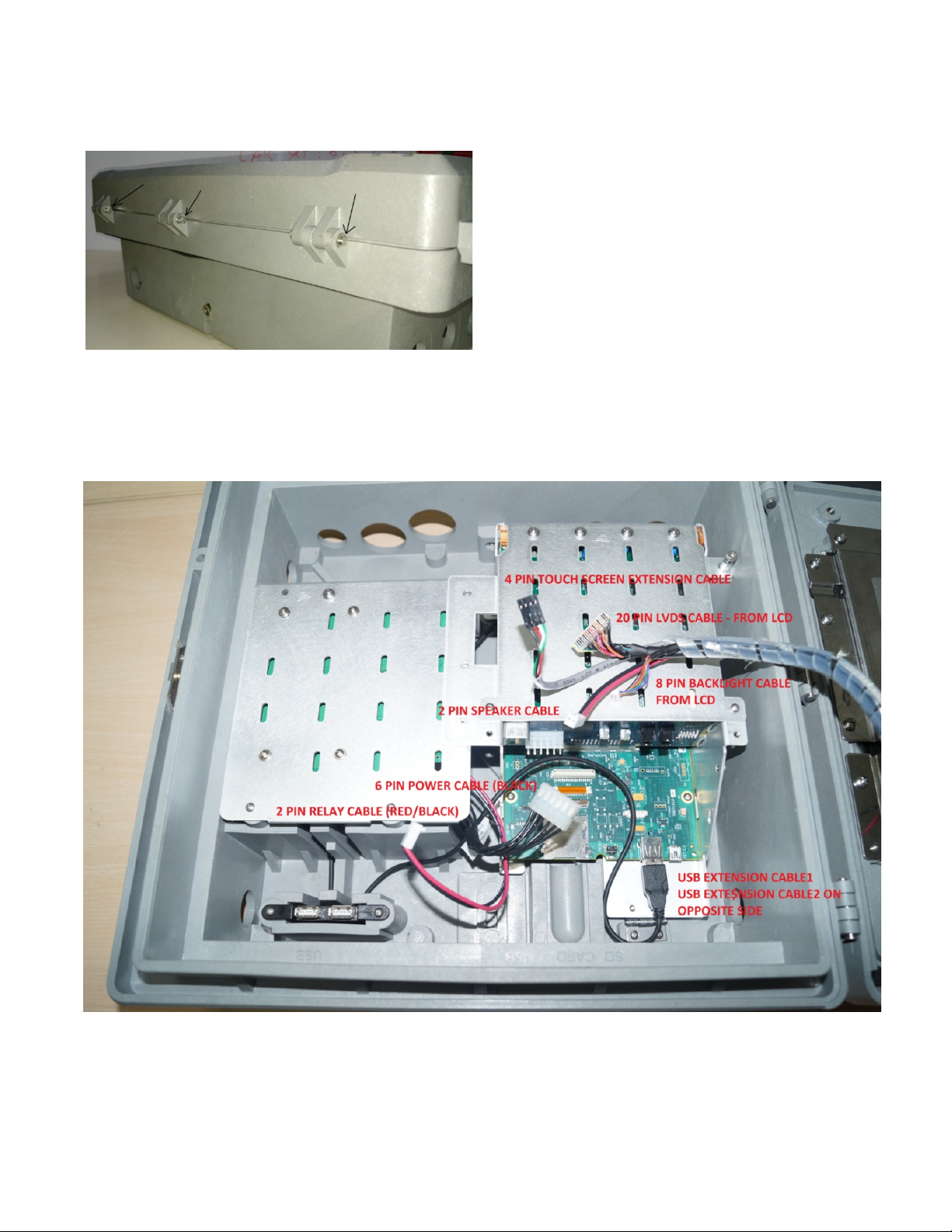

Display Replacement

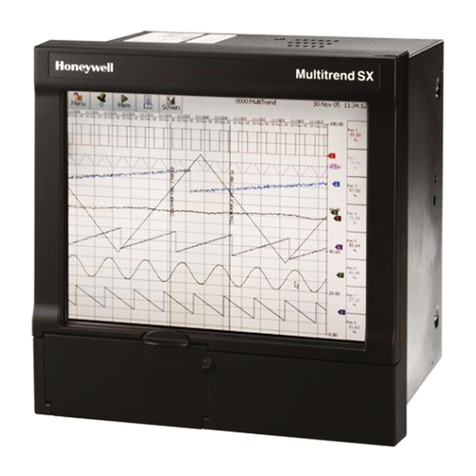

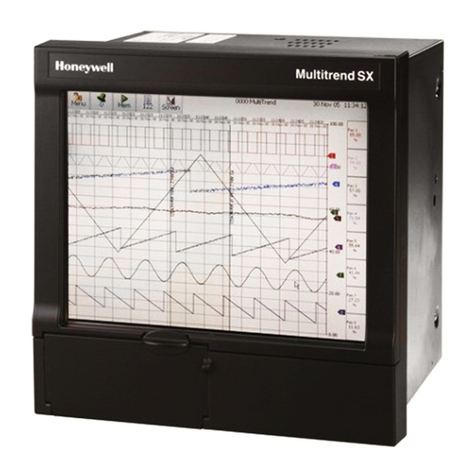

DR Graphic Recorder

This Installation Instruction sheet is intended as a guide for replacing or installing hardware and for setting up

functionality in the recorder. Refer to the User manual for detailed operational requirements.

The DR Graphic recorders are designed for ease of assembly with minimal disturbance to the rest of the unit. If unsure,

please return the unit to your supplier for repair or upgrade.

Opening the recorder and removing the internal chassis of the recorder should only be performed under the following

circumstances:

When an item of hardware requires individual replacement.

When an item of hardware is to be retrospectively fitted.

In all other instances it is recommended that the complete unit be returned to an authorized agent or service centre. For

Agency Approved recorders the product needs to be upgraded or repaired by an Authorized Repair facility

WARNING

HAZARDOUS VOLTAGES

Disconnect all the power, CJCs and IO cabling to the recorder before removing the IO cards chassis or power supply

chassis and attempting any maintenance procedures.

SAFETY TESTS

Upon completion of service procedures detailed in this instruction verify the installation per the installation section of the

product manual.

Failure to comply with these instructions could result in death or serious injury

CAUTION

OBSERVE ANTI-STATIC PRECAUTIONS

Refer to BS EN61340-5-1: 2001. Basic specification. Protection of electrostatic sensitive devices.

Full anti-static precautions MUST be observed when in contact with the electronics of your recorder.

SAVE DATA, SETUPS AND LAYOUTS

Removal of PCBs and battery back-up will result in the loss of all non-volatile data.

Ensure all data and set-ups are saved.

Failure to comply with these instructions may result in product damage.