1 Introduction

The Honeywell ERX 350 is a microprocessor-based, stand-alone, self-powered data recorder that

measures gas pressure(s), gas temperature, case temperature, and power supply voltages. Sampled

measurements, logged Audit Trail data, Alarms entries, User change events, and operating parameters are

stored in non-volatile memory and may be retrieved directly with a laptop computer, PC, mobile devices,

or remotely via modem. ERX 350 Recorder is capable of recording audit trail data into (up to five)

independent Loggers. Each of the loggers can be configured for; number of items, logging interval and

record size. Recorder configuration (and other activity) is possible via the HMI feature.

The ERX 350 offers large feature set along with a path forward to support new technologies.

The ERX 350 installation consists of mounting and wiring ERX 350 according to the instructions given in

the User’s Manual. Read the installation information provided in the ERX 350 User’s Manual and refer to

the section “Model number interpretation” for more details on ERX 350 model you have selected.

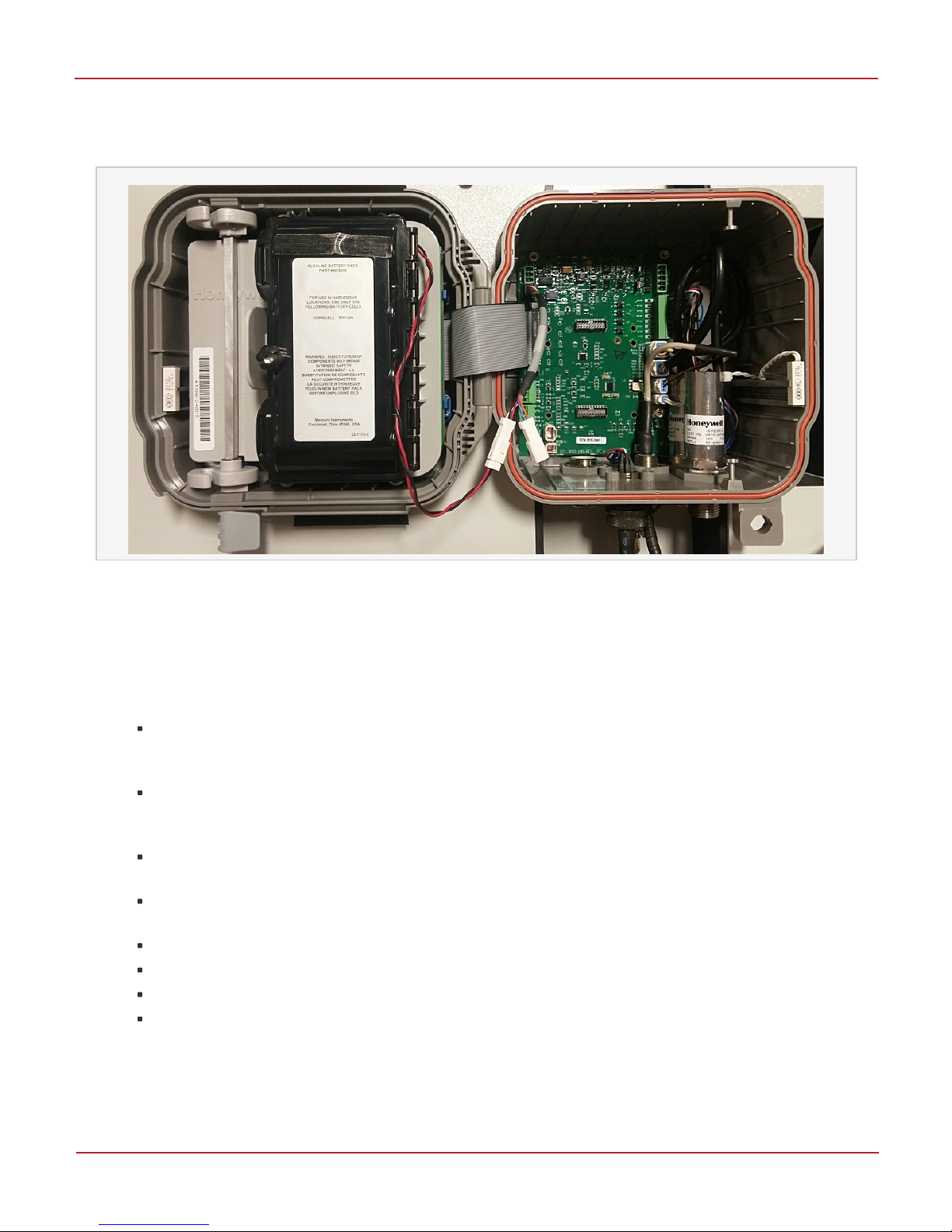

1.1 Components inside the ERX 350

Depending on options ordered, the following components may be installed or provided with the ERX 350

when shipped:

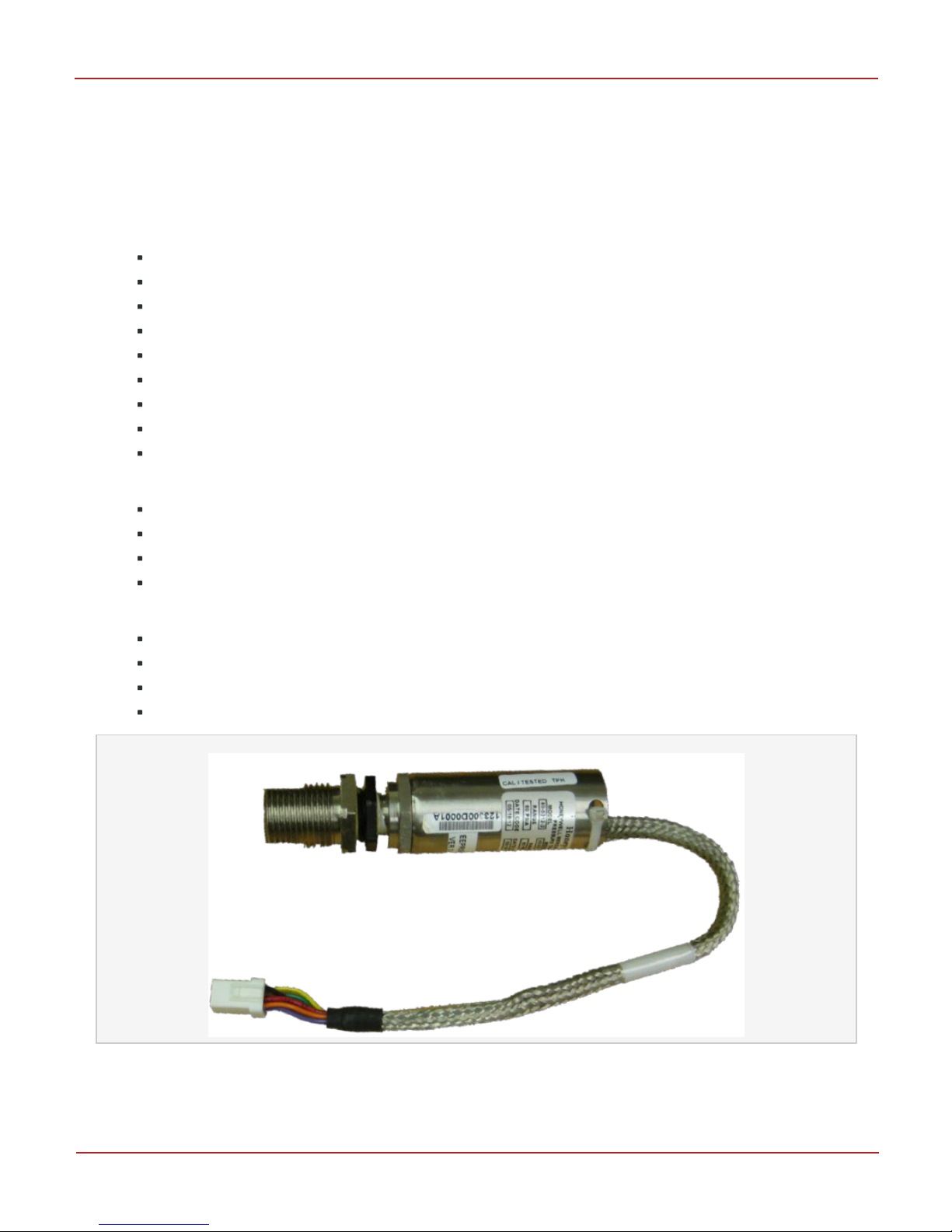

Pressure transducers (up to 2 transducers, already connected)

Temperature probe (already connected)

Landline or Cellular Modem (already connected)

Battery Pack

IrDA Dongle & USB Cable

1.2 Unpacking the ERX 350

1. Remove the contents from the box and check the shipment against the invoice to ensure the

components ordered are provided.

2. Report any shortage or shipping damages to your nearest Honeywell Distributor.

1 Introduction

Honeywell | 1